Starting out life as a modelling tool for structural engineers, Advance Steel has evolved into a highly capable steel detailing solution. Greg Corke reports on the AutoCAD-based software, which offers advanced modelling, connection design and a managed environment for the production of drawings, bills of materials and Numeric Control code.

With over 30,000 users worldwide, Graitec is one of the largest structural software developers in the world, but the company remains relatively unknown in the UK. This is starting to change though. Building on its acquisition of Autodesk reseller, Adris Computing Concepts, in 2009 the French company formed Graitec UK, and now a year later it is beginning to gain traction with its Advance range of structural engineering and detailing tools.

There are three products in the Advance family. Advance Design for the finite element analysis (FEA) and design of reinforced concrete and steel structures, Advance Concrete for reinforced concrete detailing inside AutoCAD, and Advance Steel for steel fabrication detailing and general arrangement drawing production inside AutoCAD.

Advance Steel, the subject of this review, has actually been in the UK for a number of years. Originally called HyperSteel, the product was sold by specialist structural software developer and reseller, CADS. The Poole-based company not only sold Advance Steel, but also adapted the product for the UK market, developing local content and libraries as a value add. In 2009, however, the relationship between CADS and Graitec ended and Graitec integrated all of CADS’ localisation work directly into the core product.

Like most modern steel fabrication and detailing software, Advance Steel is a 3D product. It provides a range of tools to model steel structures in 3D, from beams, columns, and connections, right down to the individual nuts and bolts. From this master model, the software can automatically create general arrangement and detail drawings, cutting lists/bills of materials (BOMs) and NC (Numeric Control) files for automated workshop machinery. Then, should the model change in any way, all of this can be automatically updated.

One of the most important selling points of Advance Steel is that it works directly inside AutoCAD. Its file format is DWG, so it offers good compatibility with other systems and it offers all the benefits of Autodesk’s seasoned CAD system, such as rendering, DWF export for design/review and sharing data over the web and a fully customisable user interface. It also means that, for those already up to speed with AutoCAD, the learning curve is not as steep.

Modelling and connections

Modelling inside Advance Steel can be as easy as drawing an AutoCAD line, then using standard AutoCAD commands to copy and array elements to build up a frame. Additionally lines can be automatically changed into intelligent structural members, with the user having full control over orientation, section size, centre of gravity and numbering/classification.

The product comes with a comprehensive library of hot and cold rolled sections. Standard UK, European, and International hot rolled sections profiles are all included and compound and custom sections can be created as required. Advance Steel also has close links with a number of UK manufacturers and libraries of cold rolled building products are also included from the likes of Ayrshire, Metsec, HiSpan, Tegral and Structural Sections.

Structural elements can be intelligently cut, notched, drilled or welded and any number of openings created for doors windows or ducting. Should the position of any of these change the structural element will automatically heal.

Advance Steel supports linear and curved grids, and also includes a number of import/export options to help make the most of upstream and downstream data.

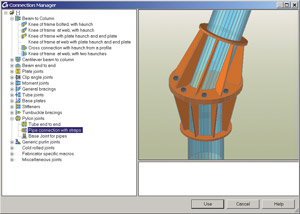

The product comes with a vast library of parametric connections and these can be used to automatically connect structural members to each other, creating endplates, bolts, welds and shortening or extending members. Full control is provided via dialog boxes, which include dynamic graphical illustrations that change depending on the context and the parameter selection. Custom connections can also be defined.

Connections can be validated against the new EC3 codes with the system providing a full report if a connection fails. To enable this forces and loads need to be applied to the model and this can be done manually using an engineer’s report as reference or imported directly from a structural design application.

Traditionally, Advance Steel’s connections have been accessible via a collection of icons found in a dedicated toolbar, but the 2010 release introduces the Connection Vault. Designed to make things easier for less experienced users this groups together all of the connection types in a single browseable visual environment to make it easier to choose.

For detailing connections are compliant with the British Constructional Steelwork Association’s (BCSA) green book and the system offers similar support for other regions.

To verify the model the system can carry out clash detection between all structural elements; right down to individual bolts. Potential clashes are presented in a list, but resolving them is still a manual process. It would be useful to have a direct link between the list and the position of the clash in the model, as well as the ability to manage the process — in a similar way to how Word manages its spell checking with options to change or ignore.

Complex modelling

Advance Steel features specialist macros for the design and detailing of complex steelwork including straight and spiral stairs, handrails, ladders and balustrades. The macros are British Standard compliant and not only help model all the required structural elements but also typical connection types and footings. Macros are presented through clear dialogue boxes and everything is fully customisable. For bespoke stairs that are not covered by macros, the full range of components is available to build them up manually.

Advance Steel also includes broad functionality for modelling sheet and plate metal. This ranges from simple circular and rectangular plates to more complex folded, twisted or conical forms. According to Graitec, with AutoCAD handling the geometry for such forms it helps ensure that these complex plates can be fabricated and machined properly. This makes it of particular interest for bridgework, where lots of multiple angle shapes, box girders and plate girders with big cambers and curves are often used.

Interoperability

With AutoCAD as its foundation product, Advance Steel already has good interoperability with other AEC products through DWG, DXF, DGN and other formats. For more intelligent exchange of data it offers import and export for the object orientated file format, IFC 2×3 (Industry Foundation Classes), plus a direct two-way link to Revit Structure.

For links to other structural engineering software it supports CIS/2, the CIMsteel Integration Standard, and is able to import and export fabrication and analysis model types. This means it can accept data from CIS/2 compliant analysis applications and use this data as the foundation for its fabrication model. It also supports SDNF (Steel Detailing Neutral File) version 2.0 and version 3.0, which includes definitions for straight and curved beams, plates and cuts on elements.

Interoperability with other Graitec software is managed through the GTC (Graitec Transfer Centre), which offers ‘intelligent’ model transfer between all Graitec products. Finally, for those involved in plant design it has a bi-directional link between Advance Steel and PDMS from Aveva.

Collaborative working

A key feature of Advance Steel is its model share technology, which enables multiple users to work on one model at the same time. Starting with a single master file, users check out parts of the model, from a single beam to a complete section, to work on their local machine. Any connecting geometry is greyed out and can be referenced but not edited. Then, when data is checked back in everyone is made aware of it.

Drawings, BOMs and CNC

While the 3D structural model forms the backbone to Advance Steel it is the final output that drives steel fabrication. This includes drawings, bill of materials (BOMs), and output code for workshop CNC machines.

General arrangements and workshop details can be automatically created from the master model and the style of these drawings customised with full control over scale, dimensions and labels. Users can modify anything within a drawing and the full AutoCAD toolkit is also available to add any additional details.

BOMs are also directly linked to the master model and these can be placed on drawings or exported to a number of common formats including Excel and PDF. A number of templates are provided including beam list, bolt list, part list and material summary, and these are also fully customisable.

For NC code generation, Advance Steel outputs to NC-DSTV and NC-DXF files which can be used to communicate with beam lines, drill lines, notching machines, angle lines and also plate burn cuts and plate folding machines.

The full power of Advance Steel comes into play if any changes are made to the master model and intelligent links are maintained to all drawings, BOMs and NC output. This is all controlled within the Document Manager and the system will flag up any documents that need updating and a simple click of the mouse will action these updates. For GAs and details the system only updates the drawings themselves and any additional annotations that were previously added will be retained.

Conclusion

With its roots stemming back to the 1990s, Advance Steel has matured into a highly capable 3D steel detailing solution. It boasts a powerful modelling engine, intuitive connection design and is efficient in its production of drawings, BOMs and NC code. It also offers support for a wide range of import/export formats and its multi-user capabilities is very useful for busy detailing offices.

The fact that Advance Steel is based on AutoCAD also offers many benefits. It boasts a shallow learning curve for existing AutoCAD users, its native file DWG file format and import/export options means good interoperability, it has built-in rendering tools, good 3D navigation tools, and DWF is readily available for design/review and sharing data over the web. For those with existing AutoCAD seats it also compares favourably on price to competitive products.

While Graitec will have its work cut out to displace the likes of Tekla Structures and StruCad, which have a strong footing among the larger UK steel fabricators, there is a big opportunity for Advance Steel with the smaller, specialist fabricators and engineering practices that are still using vanilla AutoCAD and LT in a largely manual workflow. This, plus its ability to make light work of complex detailing tasks such as stairs and railings, means there is much potential for Advance Steel. With Graitec now placing a big emphasis on the UK market, 2010 is going to be a critical year for the AutoCAD-based product.