Space Group is not only an architecture firm, but also a hotbed of AEC-related software development. The company’s technology portfolio includes Twinview, one of the most advanced BIM digital twin offerings available, as Martyn Day reports

It’s been a few years since we last looked at Twinview, the digital twin software from Space Group, based in Newcastle upon Tyne, UK. Over the intervening period, the term ‘digital twin’ has become increasingly prevalent in the industry, with big software firms like Autodesk dedicating considerable resources to creating new applications for what is expected to be a big market.

Space Group, headed by Rob Charlton and group CTO Adam Ward, is actually a collection of companies. Its activities include a functioning architectural practice, but it is also a hotbed of software development. The technology developed at Space Group was initially created to service the firm’s own needs, but it has since expanded its activities to provide bespoke BIM solutions for key industry players, as well as commercial software for the general market.

Space Group caught the BIM bug early on in Revit’s development. The company then ran with the idea, creating along the way the Bimstore for software components, BIM.Technologies for consultancy services, and an annual conference (BIM Show Live). Thanks to its efforts, the UK’s North East has become a centre for advanced BIM skills.

The twin conundrum

Before launching into the subject of Space Group’s Twinview software, I must first address the elephant in the room. That elephant, of course, is the term ‘digital twin’, which has become somewhat divisive.

The whole concept of digital twins has been overhyped, leading to the emergence of two distinct camps. The first camp is populated by those who live, sleep, eat and breathe digital twins, seeing the technology as a natural expansion of BIM. For that reason, they are convinced it will be huge.

The second camp is populated by those who roll their eyes at the term, seeing it as yet another case of ‘the Emperor’s New Clothes’, in an industry particularly prone to that affliction.

In my view, the digital twin is a great concept in theory — but there are commercial practicalities to consider. In short, the utopians have to come to terms with the reality of its niche appeal, which means limited market demand.

All that said, Twinview is one of the digital twin products that has been in the market the longest. That’s given Charlton the experience to admit that the concept has not necessarily found a home in the plethora of use cases predicted.

For instance, digital twins are not an easy replacement for, or update to, traditional computer aided facilities management (CAFM) software and associated workflows. Instead, the concept has seen more traction in London, where firms with extensive buildings portfolios need to ensure efficient running of these properties, in order for them to qualify as green investments when used as assets in investment property funds.

Find many more articles like this in AEC Magazine

👉 Subscribe FREE here 👈

So while there are certainly digital twin customers out there, they have to be hunted down. In most cases, there is a very specific problem that needs solving. Securing sales is not, as many in the industry would like to believe, like shooting fish in a barrel.

As Charlton puts it, “People don’t buy things because they are clever bits of technology. You’ve got to have a value proposition.” A lot of BIM people may suddenly be styling themselves as digital twin experts, he continues, but the truth is that there are not many real digital twins in the world.

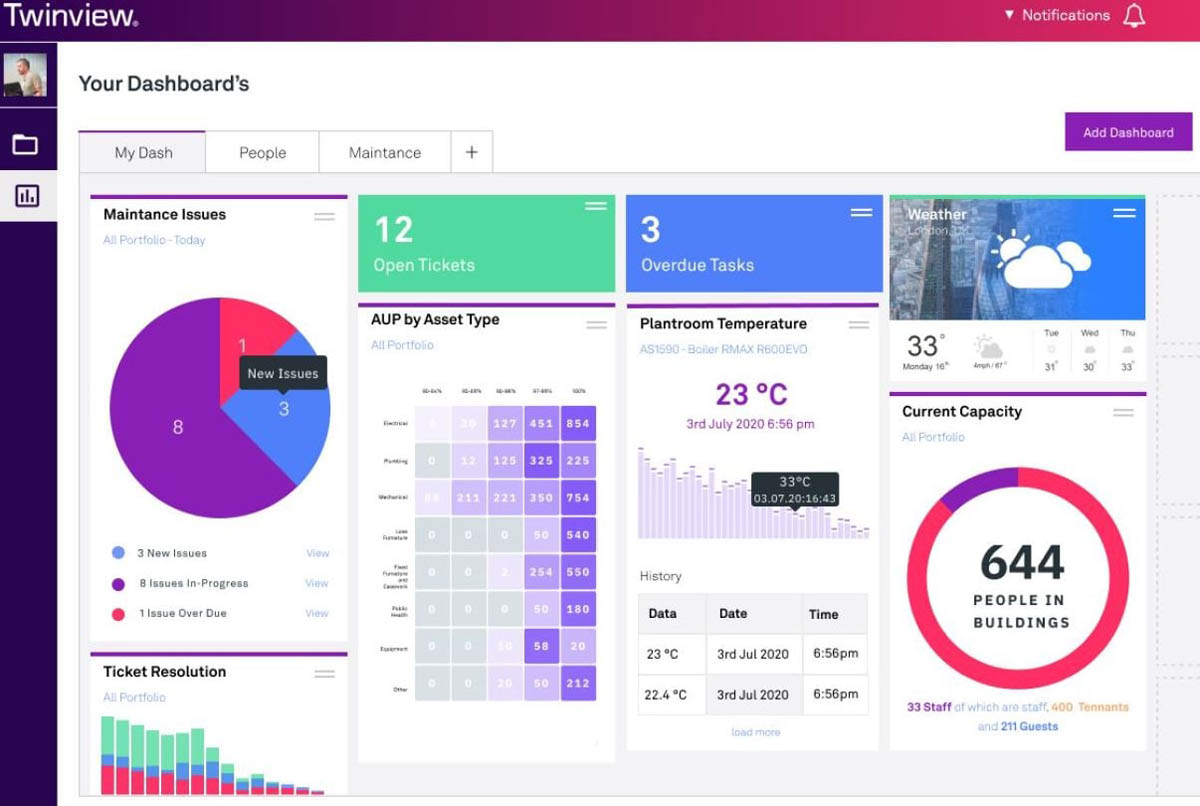

That said, Twinview has customers located in many different nations, he continues. “We’ve got live projects all over the world: South Africa, Abu Dhabi. And basically, they’re using Twinview for lots of things. It’s a place to bring everything together. It could be your single digital model. It could be to improve your tenant experience. And it’s fantastic for golden thread. It does all of that. One of the big things is understanding the building — IoT sensors telling you how much energy you are using, where it is being used, how it is being used. Clients are using it that way to optimise their buildings.”

With four years experience and feedback from users giving Space Group a better understanding of the multiple value cases that firms use to cost-justify ‘twin’ technology, Twinview has expanded, become more flexible and now has a highly modular approach

It’s a five-year project, he says, and Space Group is still very much an early adopter. “We’re still testing the use cases. We’re still trying to find examples. We’ve got over 300 buildings, over 2.5 million tracked assets, from a school in the UK, to an 85-floor tower in the Middle East, to the National Archive in New Zealand.”

The company is also doing some work with the NHS around compliance, as well as other firms concerned about asset management. Other customers need metrics for their annual environmental, social and governance (ESG) reports. The best adopters, he says, own their own estates and operate their own buildings.

Spotlight on Twinview

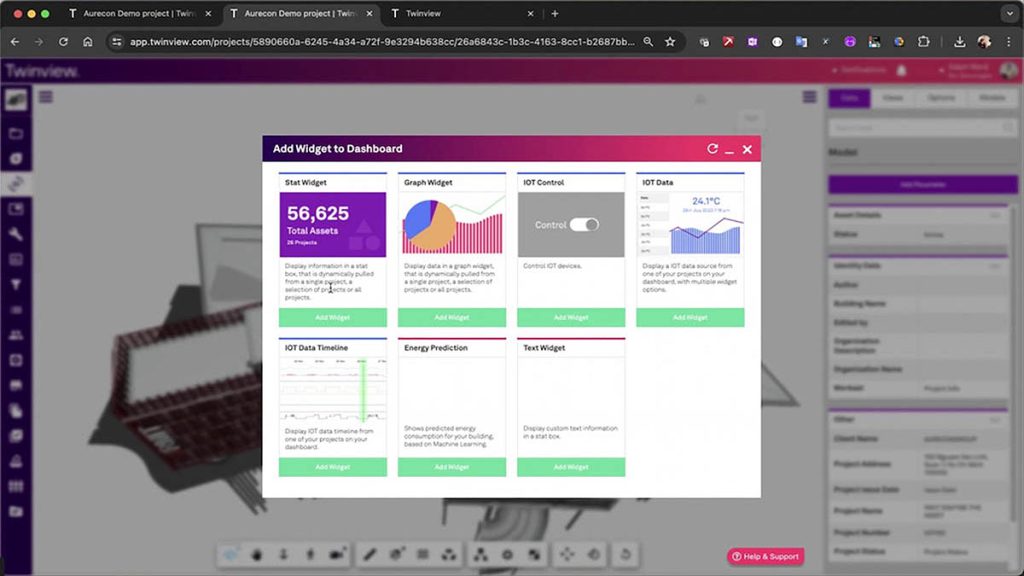

Through the various phases of design, build and operate, Twinview is an application that aims to create a ‘digital thread’ to manage data throughout the lifecycle of a building. It collates data from multiple inputs, supports content collaboration and assists in creating documentation during construction for operations. It also connects to IoT sensors, runs predictive maintenance analysis, replaces CAFM and delivers personal tenant experiences via custom mobile apps.

With four years experience and feedback from users giving Space Group a better understanding of the multiple value cases that firms use to cost-justify ‘twin’ technology, Twinview has expanded, become more flexible and now has a highly modular approach.

It’s no longer an all-or-nothing solution, nor solely reliant on a BIM model as its starting point. It’s just as happy providing a 2D experience, or operating without any graphical elements and acting as a conduit to IoT sensor data. This enables the product to better align with customer needs and budgets and to also address buildings that do not have a BIM twin and may only ‘exist’ in design terms as scanned documents.

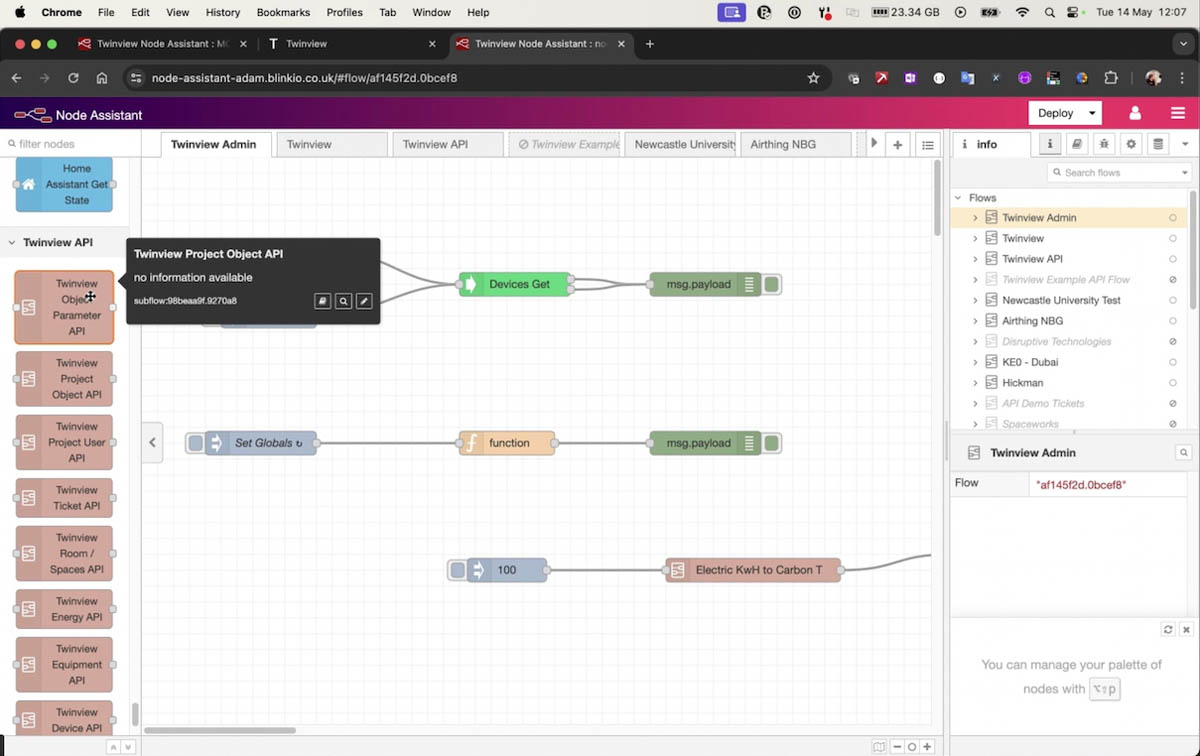

The IoT connection in Twinview has had a refresh. As Ward explains, a more interchangeable way to integrate real-time data into Twinview was needed. In response, the company has introduced Node Assistant, which is based on the IBM Node-RED flow-based, low-code development tool for visual programming. In this way, says Ward, “we decouple the data ingestion layer from the application.”

This enables Twinview to integrate with BACnet and Modbus building management communications protocols, as well as other third-party systems. Using this highly configurable plug-and-play interface, users can set up all manner of real-time data streaming connections and rules.

One of the known limitations of many web-based twin applications is that linking groups of IoT sensors through web based protocols can generate so much web traffic that legitimate traffic flows may be misdiagnosed by service providers as denial of service attacks. To get round this problem, some commercial digital twin applications limit the frequency with which sensor data can be reported, resulting in measurements taken at intervals of minutes, rather than seconds. Twinview, by contrast, can pull data at very high frequency rates and run real-time monitoring. Using the Node Assistant, data can be transformed, viewed and used to set off other actions via logic, generating notifications or automated building functions, based on real data.

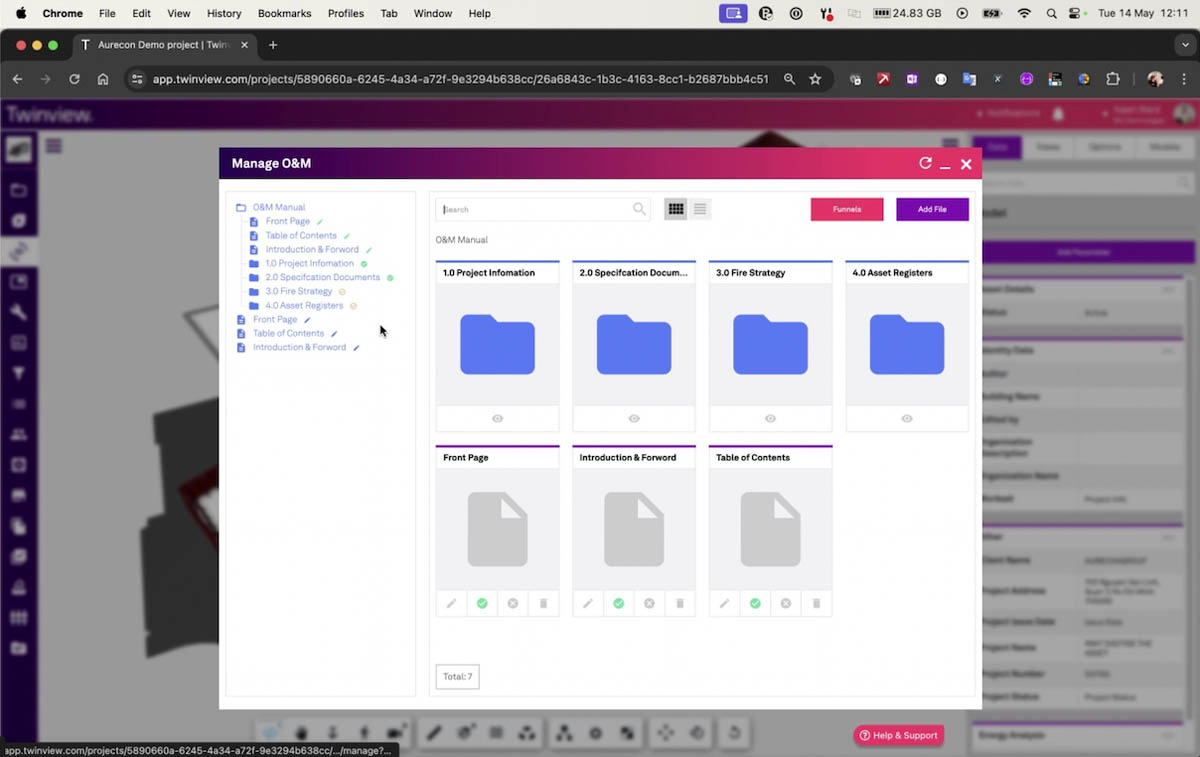

Twinview now has a bunch of tools intended for use in the construction phase. Ward highlights that traditional digital twin workflows have been viewed as something to put in place at the end of construction, prior to hand off. Twinview’s O&M (Operation and Maintenance) Builder enables the user to define the O&M template to create manuals. They define their requirements in Twinview and then basically allow the design team to upload during construction.

In this module, ‘funnels’ can be set up for project participants to populate relevant folders with files for assets found in the building. This is a smart way to collate all the relevant documents required for record-keeping and downstream use. By assigning the upload of documents to individuals, the system automatically sends out alerts and monitors progress on the number of documents expected to be handed over at delivery.

There are whole document submittal workflows built into the system and everything is centrally and securely stored. O&M Builder can auto-generate O&M manuals from these files. If files change, O&M Builder saves copies with each amendment, keeping a history of revision. This process can be carried out in parallel with construction and saves the ingestion of huge amounts of documents all in one go at the end of a project.

Working in 2D mode

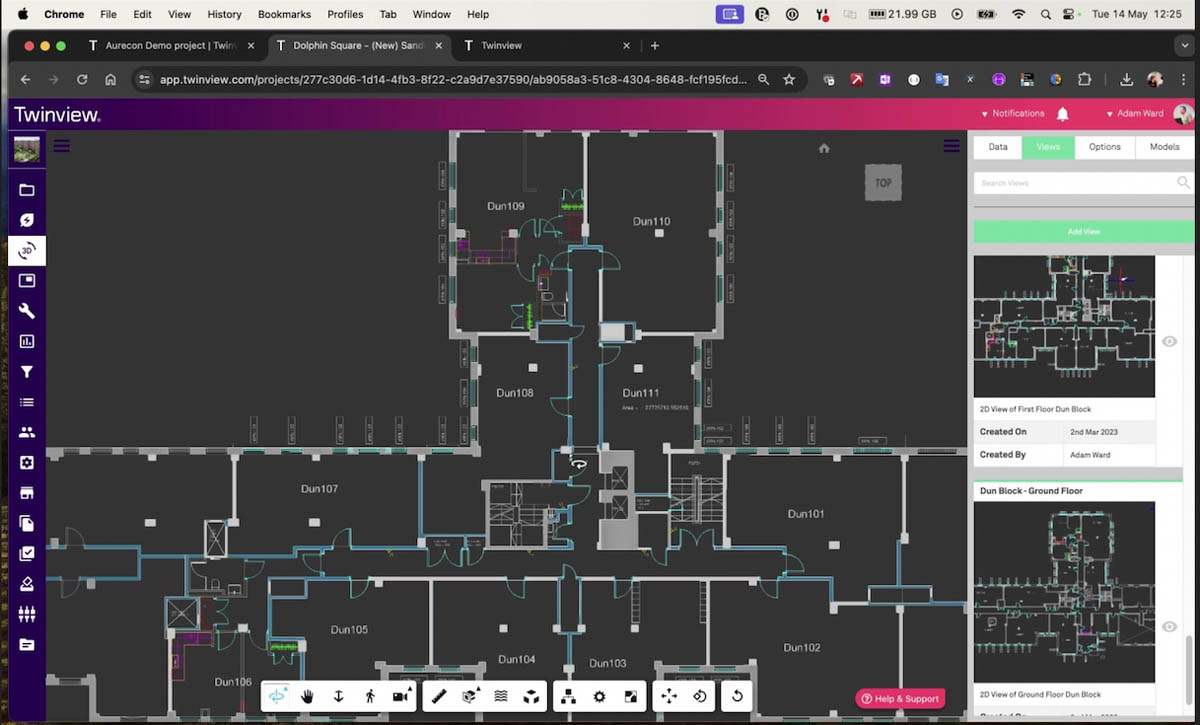

One of the more surprising additions to Twinview is support for 2D, which uses CAD drawings and even supports scans. All asset information can be associated with 2D elements, with associated dashboard reports, and all the 3D features are available in 2D use.

This aligns Twinview with more traditional CAFM workflows, where assets can be searched for and automatically displayed. Ward suggests that, in onboarding with a 2D approach, building a digital twin is harder, because CAD data is “more dumb” when compared to BIM data with all its rich metadata. However, many buildings simply don’t have a BIM model.

“In Twinview, we can bulk upload 2D,” Ward explains. “Every project has an asset register, dictating which assets belong in which rooms. Data inherently has a hierarchy and structure. Assets are usually blocks, which we can identify. Every room typically has a polyline around, which defines the extents of the room and the architect would use this to work out the floor area. We just hook into what already exists.”

“The beauty of Twinview,” Charlton adds, “is that, if you mature down the line, you can still use Twinview and add BIM, IoT, create dashboards and build O&M manuals.”

Value points

The journey of Twinview, and the capabilities that have been developed, tell the story of what happens to digital twin technology when it meets reality.

Customers have many value points which start them on a twinning journey. There is no one holistic ‘digital twin’ religion driving customers. It’s all about need.

The 3D nature of BIM-driven CAFM does not really add that much value. It’s still all about assets, dataspaces and performance.

The idea that a digital twin can start with a scanned drawing, a DWG or a DGN is just as relevant — and probably more common — than the software industry would like to admit. This experience, along with customer feedback, has shaped the Twinview experience as it stands today. And that’s why this product is so incredibly adaptable.