Having heard from several reliable sources that development work for a next generation cloud-based BIM tool is underway Martyn Day looks to Autodesk’s manufacturing division for some clues as to how it might work.

Autodesk has a vision. In the future it believes that applications will be available on any device, anywhere, irrespective of operating system. People will be able to collaborate with many others in real time through a managed environment and utilise the power of large servers to optimise, enhance, compute and suggest design solutions that we could never envisage. Our tools, capable of deriving complex geometry, will be able to directly drive fabrication ‘machines’, which will recreate these forms quickly with high precision. It is a big and compelling vision for anyone with an imagination.

But what we have now is quite far from that. The rapid proliferation of Autodesk point solutions and services is going through a messy patch, with the mitosis of desktop products with cloud equivalents. For instance AutoCAD has a cloud-based version called AutoCAD 360. The cloud version of AutoCAD is a ground-up redevelopment and does not really compare in feature set to the desktop version, which is what Autodesk eventually intends for all its products.

There is also a Mac version of AutoCAD that has a slightly different feature set again, mainly due to the OS differences. Convergence of even one product line is not so simple and will take many more years of development.

Revit in the cloud?

Before we dive into the latest news and scuttlebutt on Revit and the cloud, I need to first highlight what is happening in the manufacturing division of Autodesk — as developments there will likely eventually impact the word of Revit and Building Information Modelling (BIM).

While AEC magazine concentrates on covering technologies impacting Architecture, Engineering and Construction, we also have a sister publication DEVELOP3D, which monitors the manufacturing world. The cloud is having a more immediate impact on the next generation tools in manufacturing, with a number of brand new cloud-based applications looking to unseat the status quo of popular desktop modelling tools.

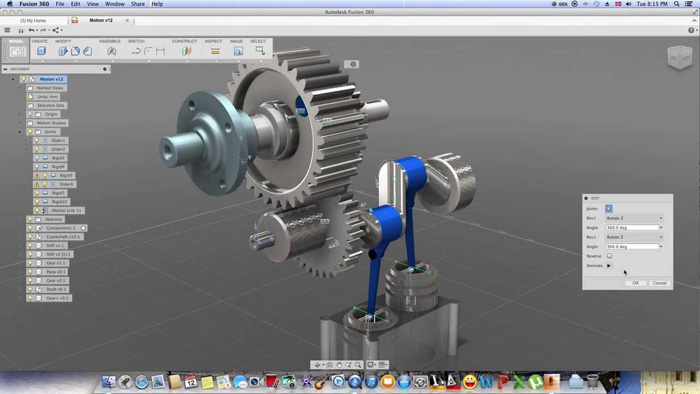

As the AEC industry moves at a much slower pace, developers of manufacturing CAD software are testing out their new modelling tools that are delivered via cloud technology. Here Autodesk has Fusion360, which is its next generation 3D modelling tool for engineers. Ultimately Fusion360 will replace Autodesk’s previous generation manufacturing application, Inventor, at some point in the future.

Inventor is a Windows-only 3D modelling application that only works on a desktop PC. Fusion360 is a cloud-based application that resides on a server and is accessed from a 200MB desktop thin-client on Mac OS or Windows. It will also be available via a web browser from any machine or operating system soon.

A Fusion360 subscription is just $25 a month. As Inventor is a mature product (released 1999) and Fusion360 is new (released 2013), written from the ground up, Inventor still does a whole lot more than Fusion does. But what Fusion does, it does better and faster.

Given Revit’s age (launched 2000), huge models and well known performance ‘issues’ and Autodesk’s future cloud vision, we have been eagerly waiting for something similar to happen in Autodesk’s AEC development.

Watching Fusion360 make leaps and bounds these last two years has seemed like an eternity. AEC Magazine has now heard from several trusted sources that development work for a next generation cloud-based BIM tool is underway and will be with us ‘sooner, rather than later’.

There are very few, if any details, available at present but Fusion could be a template to look at should you be interested.

When it came to creating a new 3D cloud-based modelling tool for manufacturing Autodesk chose to start from scratch and Fusion360 had a thin-client / server architecture, and now has an in-browser option (see Project Leopard). But with Revit, I would be very surprised if Autodesk did a complete ground up re-write to make it cloud-deliverable — even though that is what I believe Revit needs.

Autodesk realises that the AEC market moves at quite a slow pace and people are quite conservative. To come out with a radical new product that could confuse all their customers would be risky.

For the first few years, Fusion did not really offer an alternative to what was available on the desktop, just a few key capabilities. With Revit, Autodesk may look at a way to get what is available today but host it online, offloading some of the hardware problems by splitting off the Revit Database (as seen in Project Skyscraper) and having a thin-client style interface as Fusion has.

Saying that, it may surprise us completely and create a new Revit style product. A cloud-based BIM tool would also liberate Revit from Windows and finally bring it to the Mac. The benefits of having a BIM tool hosted in the cloud would be huge for collaboration, with datasets being available to all project participants via the BIM360 service, as well as hosted management, rendering, analysis and benefits on-site. And instead of a beast of a machine with 32GB of RAM, you might be able to get away with an iPad Pro! It is at this point I must seem like a child feeling his Christmas presents a little bit too hard.

Conclusion

For now, most of my thoughts are on what the Revit team will deliver given the strong rumour of a Fusion360 cloud-delivery template. We have already seen cloud-delivered Revit sessions in the way Autodesk demonstrates forthcoming versions of Revit such as ‘Sunrise’, which became the R2 release.

While I am sure many customers would prefer to have the current system completely replicated and delivered, I would be more impressed if it was a ground up rethinking of what a modern BIM tool should be.

The more advanced BIM practitioners are crying out for better tools and are fed up of work-arounds. The whole concept of breaking down models in projects is because of the limitations of Revit to handle large files. The need for expensive networking and compressors to shunt huge models data around is also because of the software architecture. A move to the cloud should eradicate all this. Instead of hardware bottlenecks, large firms will need robust and thick internet connectivity.

To just take the existing code and host it online would be a travesty, not to take the opportunity to re-architect and modernise the code to perfrom better and make use of the cloud infrastructure.

It’s an important port as it’s the most important BIM platform out there and could impact hundred of thousands of users.

This week Autodesk is hosting its annual Autodesk University in Las Vegas, where more details of these developments may be announced. AEC magazine will be there to bring you all the latest news.

If you enjoyed this article, subscribe to AEC Magazine for FREE

What else is going on at Autodesk?

Computation design

Autodesk is keen to rapidly develop and link its products to the Dynamo computational design engine. Integrating FormIt with Dynamo is the first stage of enhancing conceptual design with computational-driven forms. Again this echoes Autodesk’s manufacturing division’s vision of providing optimisation and generative solutions for structural designs in products.

In the time it takes a designer to model one solution to a problem, with generative and evolutionary design tools, the computer could suggest 50 or 100 geometrical variants, which would solve the design criteria. We are not that far off from when the computer actually aids the design process, as opposed to just helps document it. Expect a deeper integration of Dynamo in all products as well as more cloud-based computational tools.

Fabrication

With modular construction becoming increasingly popular, Autodesk is aware that its AEC products need to be able to link to and drive fabrication machines. These could be laser cutters, robots, CNC milling machines, or concrete 3D printers.

Autodesk has a team dedicated to developing solutions and interfaces for core products such as Revit to ‘play friendly’ with this emerging, connected, modular, fabrication market. It seems convergence is not just for software development but also for industries, as ‘digital manufacturing’ becomes the end goal for all professions.

BIM360

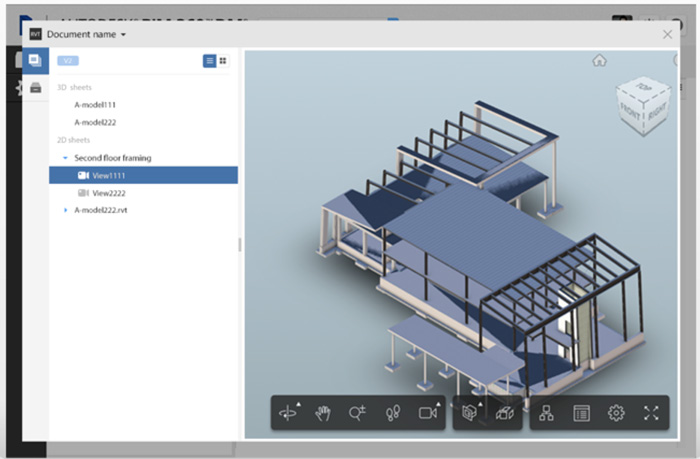

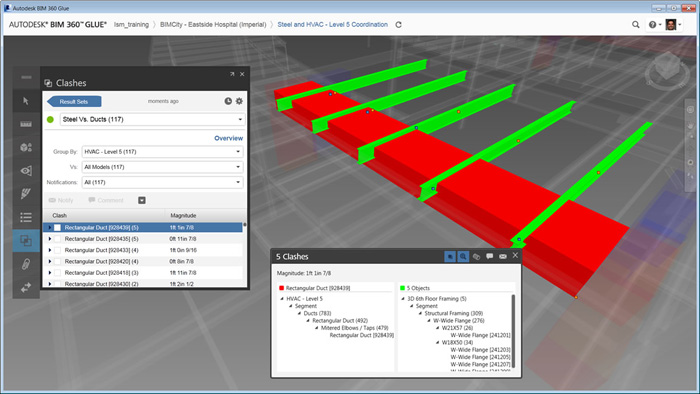

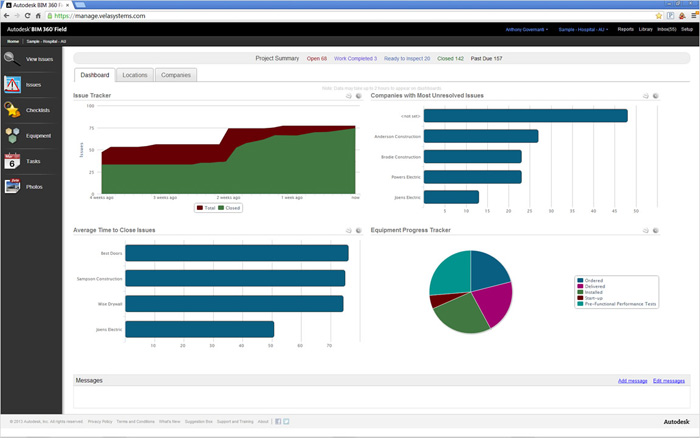

Autodesk BIM360 is the cloud backbone to connect Autodesk’s AEC products and customers. It currently consists of four products, Glue, Field, Plan and Building Ops. Glue is like an online Navisworks for model viewing, analysis and markup. It works in the browser and on an iPad and drives the BIM360 Layout App, which links BIM to a robotic total station for on-site layout.

Field links on-site workers to the latest design information for collaboration and reporting. Plan is a web service for creating and tracking project work plans, while Building Ops is a mobile facilities management asset management service.

Coming soon to this mix is Project Alexandria, Autodesk’s latest attempt at delivering a document management system.

Autodesk has not had much success at developing a enterprise-wide document management systems, with a few historic failures under its belt. Recently it has fared better with the likes of Buzzsaw and Vault but still does not compete with the likes of Bentley ProjectWise.

Project Alexandria looks to be the company’s most serious attempt to date to provide a project-based management layer. It will be based within BIM360 as a paid-for service. Project Alexandria will manage both 2D and 3D data, from multiple applications. Document viewing, markup, approval and sign-off workflows can be created together with some degree of automation. As it is in the cloud access can be from anywhere — on-site, on a laptop or phone — and it appears to have a very clean user interface design.

While the codename Alexandria is more than a hint at the historic library in Egypt and one of the seven wonders of the world, one hopes that the product does not share a similar fate.

Memento and Recap

Through acquisition and development Autodesk has created a number of laser scanning and photogrammetry applications and capabilities for all vertical markets, product design, architecture, surveying, manufacture, construction, films, and games. The two main products it is championing are Recap and Memento.

Recap supports photogrammetry and laser scans but is probably more targeted at the surveying and wide area data capture field, which is dominated by very expensive, difficult-to-use applications, mainly from laser scanning vendors.

Recap is a relatively low cost solution that can work on a tablet and show in real time the results of collective scans. Unfortunately, despite a soft release, the product suffered some negative feedback with a number of early technical issues but with subsequent releases, the team is really starting to get the product in shape.

Memento is a generic application that again works with point clouds or photogrammetry data, offers a very minimal interface but can pull off magical results interpreting gigabytes of data.

Autodesk has used Memento on a number of prestigious projects for data capture for international museums, archeology, environmental, gaming and reverse engineering. It is a ‘Swiss Army knife’ for creating rich project models from masses of dumb data. This video will blow your mind on the possibilities of photogrammetry.

Forthcoming capabilities will enhance the resolution of taking these huge ‘life-size’ models to 3D printers enabling prints with details down to 10 micron. As Autodesk has its own 3D printer, the Ember, the company has been refining its scan-to-print, to preserve the detail captured at high resolution. The market of reality computing is still embryonic but all it takes is for designers to realise the potential of this new capability.

Skycatch

Autodesk has just announced a strategic investment in US Unmanned Aerial Vehicle (UAV) company Skycatch, which it hopes to support with Autodesk Recap.

Skycatch is an autonomous drone that can fly around building sites at regular intervals on set flight paths, capturing structures and landscapes with video. The drone can return to base, drop the battery and stored video, reload with a new battery and memory and refly the route. Autodesk can take this image data and create accurate 3D survey models of building sites. It could also be used to find materials, check building progress and create 4D timeline models.

Skycatch transforms the way sites can be surveyed and monitored. Autodesk ReCap can be used to process the collected data.

AutoCAD

As a general rule we tend not to write much about 2D and AutoCAD, however it is still a significant contributor to Autodesk’s income and makes up for a considerable percentage of usage within Autodesk Suites.

Autodesk wants to improve the way its software upgrades on customer’s desktops. As opposed to having to delete the previous installation and reinstall, or perform a partial update to the code, which can damage customisations and tool layouts, Autodesk is investigating ways to stream updates to the software without negatively impacting the system. Here, AutoCAD is the guinea pig and advances made will be shared throughout Autodesk’s other deskbound applications.

If you enjoyed this article, subscribe to AEC Magazine for FREE