The new revolution will bring convenience, not disruption, writes Greg Demchak, senior director, Digital Innovation Lab, Bentley Systems

For many, the concept of artificial intelligence (AI) inspires dread rather than intrigue. AI gone awry is a staple of science fiction, with countless examples of creations turning on their masters. For a quick refresher, the film Ex Machina and the series Westworld provide a high-gloss view.

In the AEC industry, many designers, engineers, and builders have a more practical concern – will AI technologies negatively disrupt how we build infrastructure? Will they have to completely abandon trusted workflows and switch to technologies that might not even work correctly?

In our team’s work at Bentley Systems’ Digital Innovation Lab (iLAB), we explore emerging new technologies and how they can be applied to real-world use cases in the design, construction, and operation of infrastructure.

We also hear about initial reactions to AI in infrastructure from AEC companies. Though digitisation in general has swept the industry, AI technologies have been slower to take off. Any mention of AI in construction site offices will draw blank stares, as they do not realise what AI can do for them.

Though potential clients will be hardpressed to explain how AI will help them deliver a project, the technology is most likely already in active use – they just do not realise it. Even though innovative AI solutions will help revolutionise how AEC companies design, build, and maintain infrastructure, I do not think their arrival will cause a major disruption. Rather, AI technologies have the potential to slot into existing workflows and technologies, enhancing how people already work.

Most of us already use AI technologies on a basic level. For example, Microsoft Viva now analyses how people work and suggests ways to improve productivity, such as by sending emails when the recipients are more likely to immediately receive them. Autofill functions on smartphones and email platforms are increasingly adept at predicting what word or phrase you are about to type next. And YouTube can instantly sift through millions of videos to unearth something that fits your taste.

All of these innovations are using AI, yet we don’t regularly think of them as AI. They are just one more feature that makes life more convenient. AI has been seamlessly blending into our lives, to the point where we do not even notice that it is there.

I think the same will happen to AI solutions for the AEC industry. Though the technology is just starting to be applied in real-world cases, an array of organisations, both long-established and brand new, are developing AI applications that promise to dramatically improve design, construction, and operations.

Learning by example

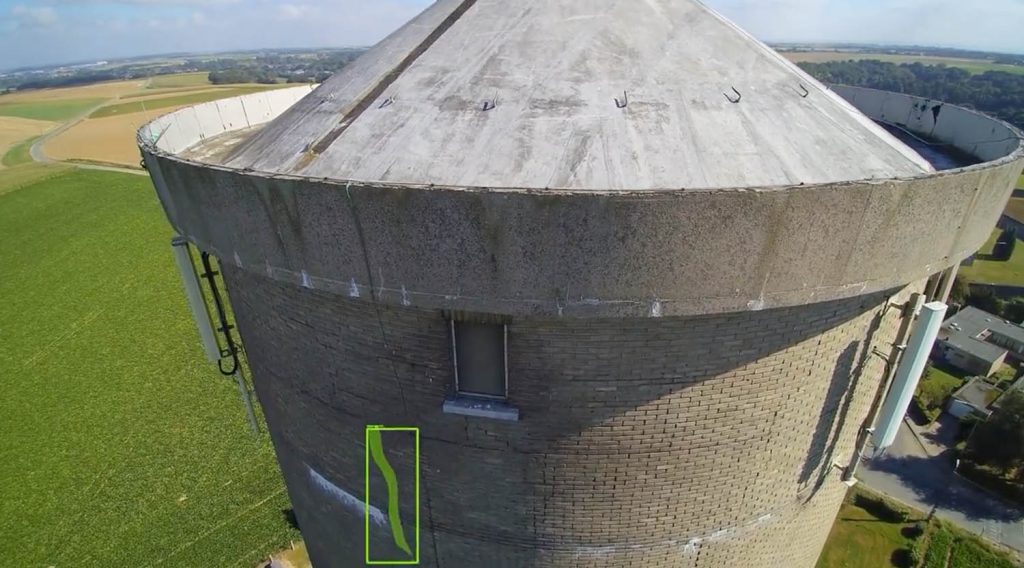

La Société Wallonne des Eaux (SWDE), a regional water corporation, owns and maintains a series of water towers throughout Belgium. One tower in Juprelle had seriously degraded over time, with burst joints, separation of edifice bricks, and multiple cracks. The organisation needed to quickly repair the damage to keep the water tower in service, but they needed to find a way to make all the repairs in one session.

SWDE had already relied on drones to capture more detailed inspections than the human eye can capture, but even drone images require interpretation. They discovered that Bentley Systems was in the process of designing AI capabilities to detect cracks, corrosion, and other faults for its ContextCapture application, which generates digital twins from captured images and resulting machine-learning models. The two organisations worked together to refine the capabilities and tested them out on a reality mesh of the tower. As a result, SWDE automatically detected 1,704 cracks in the tower, with 520 of them having a crack length of less than 2 millimeters – easily overlooked by the human eye.

Bentley is now rolling out the technology to improve other types of infrastructure inspections, such as their work with Collins Engineers to test and validate automated crack detection for bridges.

Another way that AI can improve operations and construction is by augmenting digital twins with neural radiance fields (NeRFs). Usually, organisations update digital twins with an array of cameras and sensors. While this method does provide valuable information on the current state of the project area, creating an immersive, detailed, 3D replica of significant physical changes, such as the completion of a building, usually requires creating an entire new reality mesh rendering.

Though digitisation in general has swept the industry, AI technologies have been slower to take off. Any mention of AI in construction site offices will draw blank stares, as they do not realise what AI can do for them

NeRFs can insert changes and new elements into a digital twin with a fraction of the effort required for manually creating them. Neural networks can take a partial set of 2D images and quickly transform them into complete scenes. In a demonstration of Nvidia’s NGP Instant NeRF (see below), the organisations instantly took four pictures of a model holding a Polaroid camera, with each picture capturing a different angle. Within seconds, the application generated a full 3D representation of the model and her surroundings, as artificial intelligence filled in the gaps. Operators can then freely rotate around the representation of the model with a smooth refresh rate.

NeRFs have the potential to render physical changes to assets, placement of construction vehicles, or even visitors to the site in near real-time. Your digital twin does not just bring in static video feeds, but could produce a three-dimensional captured reality that you can fly through.

NGP Instant NeRF became available just a few months ago, but organisations such as Bentley are already examining the technology to determine how to incorporate it into the digital twin creation process.

For design, organisations are starting to turn to inspiration from AI image generators, such as OpenAI’s DALL-E and Midjourney. These services can quickly generate a variety of 2D images based on prompts, such as “modern industrial style open office” or “elephant eating pancakes in the style of Pablo Picasso.”

In the iLab, we recently used AI-generated images to create concept art for a virtual reality office space experience for an upcoming conference. With just a few keywords, we were able to generate three-dimensional-looking visuals we used to test ideas. These quick sketches allowed us to quickly cycle through ideas and led to a design decision for the virtual space.

And various new organisations are working to bring even more types of AI assistance to the AEC field. Both TestFit and Hypar are working on applications that can automatically generate concept designs that auto-compute area, cost, and constructability. Put in definitions, such as size, number of floors, building function, and parking requirements, and their applications can create models that follow best practices and can give estimates of what dimensions and features are needed, which can help with feasibility studies and cost estimates.

Then, Obayashi went one step further, working with SRI International and Hypar to develop an AI function that can analyse a photograph of a building’s exterior and create an analogous building facade in Hypar. It is as easy as selecting a favourite photo or a generated image and dragging it onto the model. In less than a minute, Hypar generates a 3D facade design from the example image.

Scaled Robotics is working on a way to transform workers into image capture vehicles by having them wear hard hats with embedded cameras. As they walk through the job site, they can use reality capture to automatically compute compliance and progress in the field. Their specialised AI model can classify point clouds and compare those points against a BIM model to produce a compliance report.

What most of these breakthroughs in AEC AI have in common is that they aren’t aiming to completely disrupt the way we design, build, and maintain infrastructure. Rather, they are individual tools that can add value to existing processes. These innovations seem exotic now, but once they prove their worth and become part of the regular toolbox, they will seem as commonplace as BIM and digital design. Once you start using it and you get used to it, AI is no longer scary.

Main image caption: In Belgium, SWDE is using AI to automatically detect cracks in water towers.

Image courtesy of Bentley Systems