We tend to take the perpetuity of iconic buildings for granted. From generation-to-generation, they have dominated skylines, and their silhouettes embody the very character of a city. In 2019 the world learned of the horrific news that the famous Notre-Dame de Paris was engulfed in flames

When disaster strikes and a building which means so much to everyone is destroyed, it’s hard to look away from rolling 24/7 news coverage and one is filled with disbelief and sadness. On 12 April 2019, as Notre-Dame still burnt, the French president, Emmanuel Macron vowed to put all of France’s resources into rebuilding the iconic cathedral.

The CAD industry is not one to miss a silver lining marketing opportunity in a dark grey cloud. Shortly after the horrific news, CAD software firms were in full swing offering to provide their AEC tools to the project for free. Some even contributed cash to the rebuilding effort. There was also a scramble to try and locate laser scan surveys of the cathedral which had been carried out in the past, so they could rapidly model the asbuilt in their BIM and CAD solutions. Thankfully, this frenzy didn’t last too long. It wasn’t until spring this year, two years after the fire, that Autodesk has made any mention of its involvement in the rebuilding of NotreDame, in which Revit is playing a role.

Five days after the fire, Macron announced he wanted to see the cathedral rebuilt “more beautiful than before” in just five years. To do this, the design team, specialist renovators and construction firms, will have to overcome some substantial hurdles. The main problems include the sourcing of original like-forlike materials and the painstaking work required to preserve original elements and repair fire the damaged stonework.

The cathedral roof was made from oak beams cut from centuries-old trees, which were even difficult to source in the 13th century. With our habit of cutting down trees, Europe doesn’t have many that are tall enough. Many experts think the project is more likely to take decades.

Emmanuel Di Giacomo, EMEA BIM ecosystem development manager at Autodesk, France explained, “We were shocked, all the world was shocked, especially at Autodesk. Our CEO, Andrew Anagnost was shocked and very sad about this.

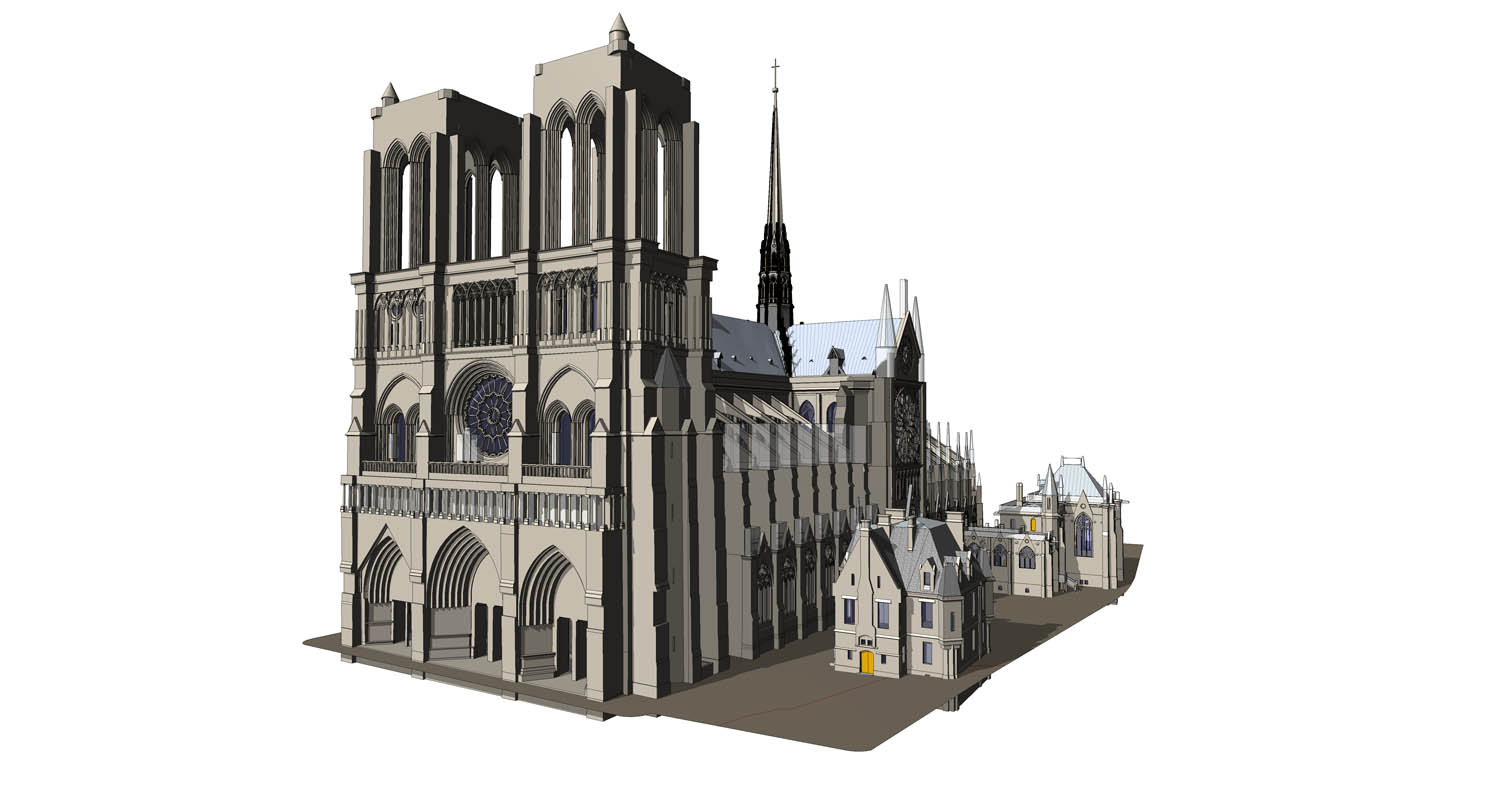

“We immediately resolved to help in the reconstruction of Notre-Dame and we made a cash donation to the reconstruction fund. We thought that it would be important to help with BIM and we started to work with a company to create a BIM model of the cathedral pre-fire based on laser scans created by art and architectural historian Andrew Tallon.”

Belgian-born Tallon had carried out a laser scan of Notre-Dame in 2010. With the backing of a European arts documentary he set out to capture the cathedral from top to bottom using a Leica Geosystems laser scanner, starting at the west-side entrance.

At the time, Tallon wanted a laser scan of the building to understand the nature of Gothic structure and to identify any structural anomalies. Up till that point all the standard surveys used to create drawings had tidied up errors of alignment, somewhat over-egging the precision and capabilities of 13th century builders. Tallon’s laser scans were the only really accurate as-built measurements of the cathedral. Sadly, Tallon died a few years before the fire at Notre-Dame and could not realise just how much his work would mean to the rebuilding of this fantastic Gothic masterpiece.

While Autodesk had this underway, there was no organisation at a French Government level in charge of the reconstruction. It was under the auspices of the Ministry of Culture but there was a specific subsidiary called DRAC (direction régionale des affaires culturelles) involved. To speed up the process on 28 November 2019, Macron created a new public organisation called the EPA (établissement public à caractère administrative), which basically translates as the public administration. He named a former army general Jean-Louis Georgelin to head it up and create the conditions to enable reconstruction and opening within five years, with the spire being completed by 2026.

Autodesk engaged with the EPA and had a number of good conversations about using BIM, with the added bonus that the company was already creating a pre-fire BIM model from the most accurate survey.

The team has been carrying out a lot of post-fire drone surveys to identify where the stones have fallen down, so they could be reused, repaired and put back in position

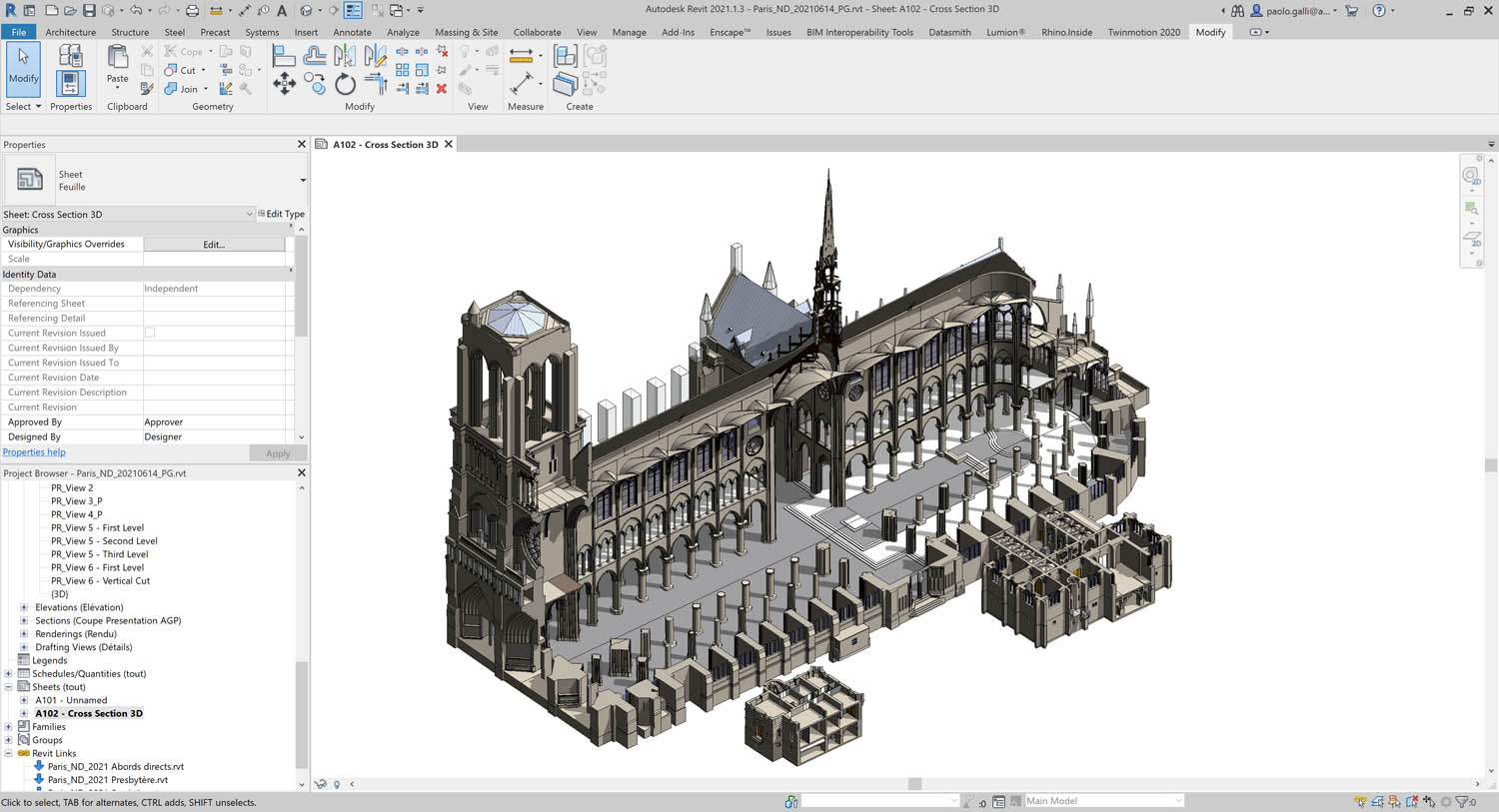

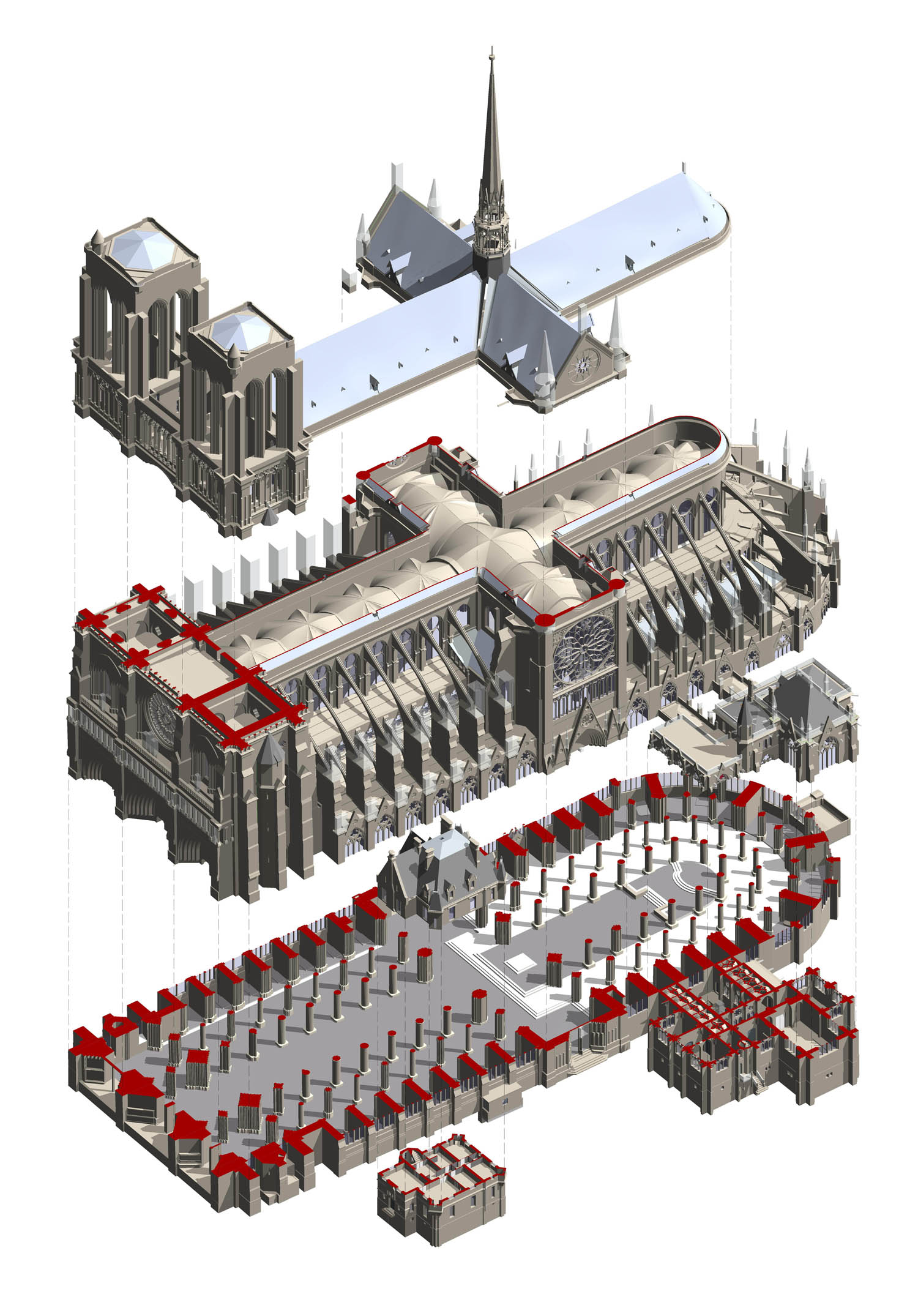

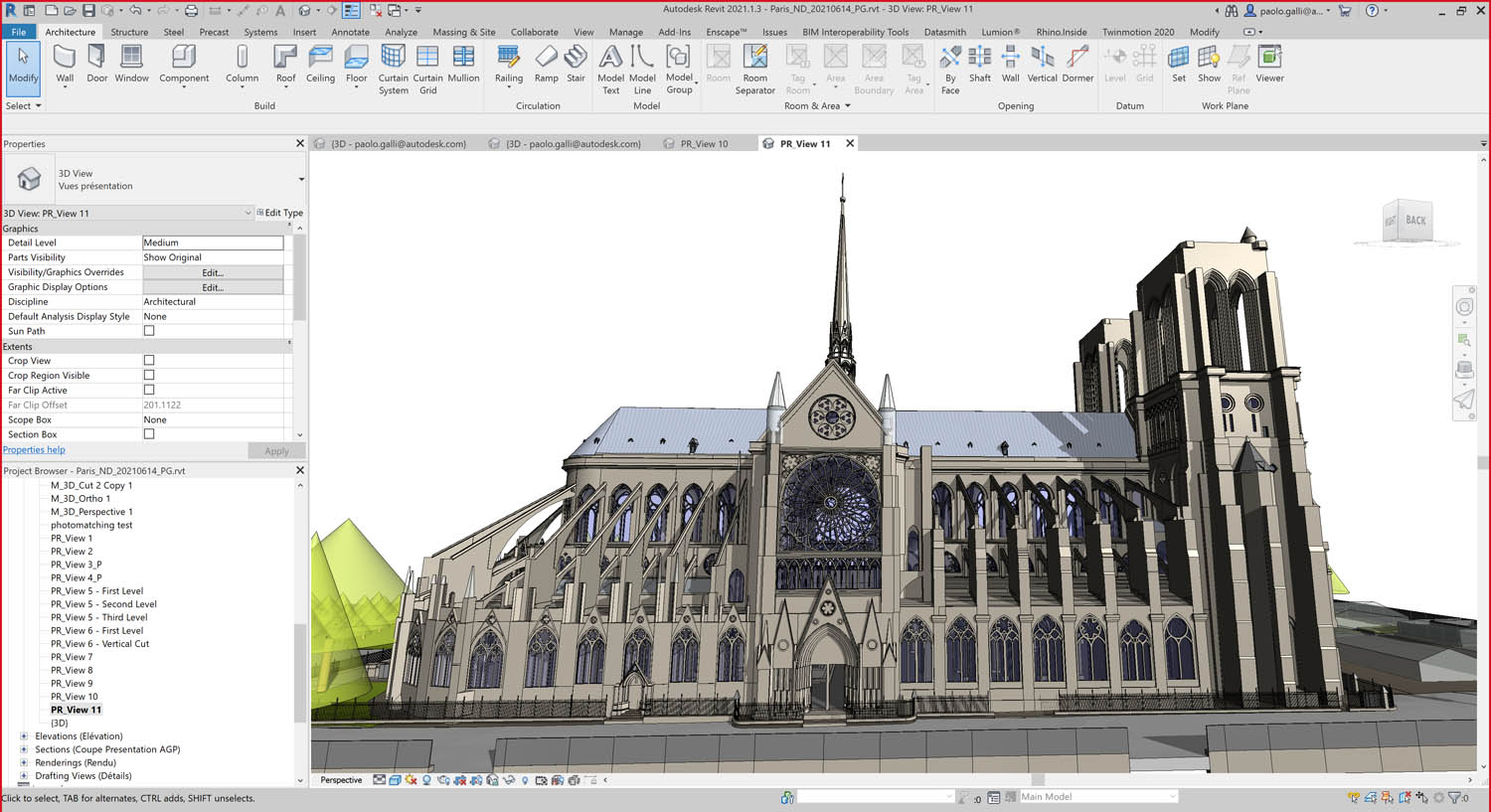

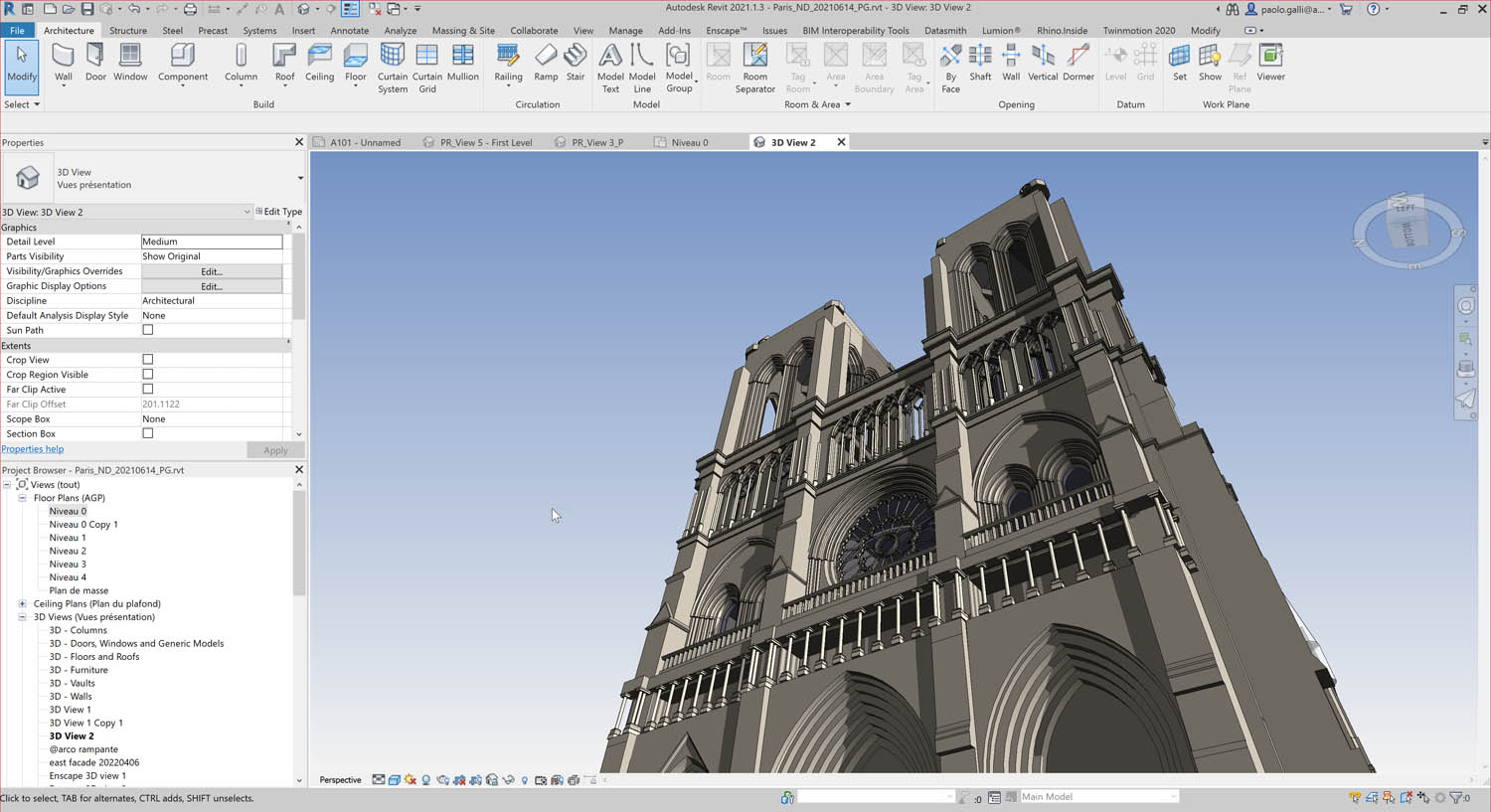

The EPA and Autodesk collaborated on the development of the creation of a Revit BIM model, focussing on the structural elements of the building, the stonework. They modelled the crypt, the sacristy, the spire, Notre-Dame itself and the gardens behind the cathedral. There is no carpentry model because there were no detailed drawings of the roof structure and there were no laser scan in the voids. The EPA had a number of specific uses for the BIM model, including planning for site logistics, crane positions, material delivery and organising site security. Because of the extensive lead pollution, access to the site needed to be controlled and extensive safety measures had to be taken by those working on the site.

Autodesk provided some licences of its AEC suites, with access to AutoCAD, Recap (laser scanning) and Revit and gave the EPA access to Autodesk’s online collaborative platform, Autodesk BIM 360, for model sharing and project meetings. Unfortunately, Covid-19 has thrown a spanner in the timeline and the project has already lost a year, if it will truly be completed by 2024. The removal of the original scaffolding put up at the time of the fire, was also proving to be time consuming.

The team has been carrying out a lot of post-fire drone surveys to identify where the stones have fallen down, so they could be reused, repaired and put back in position. The post fire BIM model was built in Revit from a survey carried out using 12 laser scanners which collected 46,000 scans.

New stones are being made by hand. The idea is that even the carpentry will be remade by hand too. One of the other concerns is that so much water was pumped into the Cathedral that key structural elements might have moved or that it may have impacted the foundations.

New stones are being made by hand. The idea is that even the carpentry will be remade by hand too. One of the other concerns is that so much water was pumped into the Cathedral that key structural elements might have moved or that it may have impacted the foundations.

There are about 250 craftsmen of various trades onsite, and while material preservation and new stonework and woodwork will rely on traditional crafts, there will be a mix between these skills and digital skills, using laser scanning, drone, BIM etc.

Autodesk is currently discussing with the EPA, the potential to use the BIM model for the operation and maintenance phase, connected with IoT sensors to avoid any future fire

Autodesk hopes the EPA will leverage BIM 360 and BIM to speed up the process and avoid any onsite issues. Di Giacomo sees a big advantage in using BIM to examine the cabling of fire prevention systems within the building. It goes without saying that the EPA wants to make sure the future fire prevention system will be perfect. As they are building back in exactly the same way with lots of wood (sourced from around the forests of Le Mans) fire prevention is one of the more critical parts of the rebuild.

Many of the subcontractors working on Notre-Dame are in the French regions, not in the capital. Access to BIM 360 coordination is less of an issue than onsite with very tight security and extensive protection required to work in the toxic lead environment. It’s taken two years to clean up the site, so now they can go back in and collect the remaining bits of burnt roof structure. The EPA is using the BIM model to decide where the new scaffolding should go. As the project progresses, Navisworks and other Autodesk solutions could be used to plan 4D and 5D timelines.

Autodesk is currently discussing with the EPA, the potential to use the BIM model for the operation and maintenance phase, connected with Internet of Things (IoT) sensors to avoid any future fire. This would be with the newly launched Autodesk Tandem Digital Twin Platform.

Conclusion

Macron is still dedicated to pushing forward to deliver on a breakneck timeline. Even with all the digital tools we have at our command, this seems an incredibly unrealistic deadline.

If traditional manufacturing skills are to be used exclusively, that is a bottleneck within itself. Then there is sourcing the material and having to deal with Covid -19 and a whole year just to clean the site up. This all needs to move in parallel at breakneck speed.

With both an accurate pre-fire BIM model and a post-fire BIM model, there are a lot of benefits to be squeezed out of the digital twins. I can’t help but feel it would be prudent to use modern manufacturing techniques to replace stone and woodwork.

While in Barcelona the Sagrada Família has been a work in progress since 1882, the designers continuing on that task have utilised modern CAD and computer numerical control (CNC) techniques to fabricate new stonework and improve productivity. I can see the argument as to why you’d want to rebuild as it was, traditionally handmade, as you wouldn’t digitally print out a portion of a damaged Vincent Van Gogh.

By the sounds of it, most of the digital benefits for Notre-Dame will come as material is shipped to site, and coordination becomes essential to speed up reconstruction. I am sure it will also be an important environment for designing the new Cathedral roof structure, together with assembly sequencing.

My final thought is we need to laser scan every building that is precious to us as soon as possible and it reminds me of the work being done by CyArk which is a non-profit organisation which aims to scan, digitally record, archive and share the world’s cultural heritage. In every country, there should be a mandate to capture what we fear losing the most. A digital copy isn’t perfect, but certainly better than nothing should something terrible happen.

A brief history of Paris’s beloved cathedral

Notre-Dame has played a key role in French history for 850 years and is the official ‘point zero from which all distances to Paris, France are measured.

Construction started during the reign of King Louis VII (1163 AD), taking 183 years to build, it was France’s first Gothic stone building. In 1431, England’s Henry VI was crowned King of France and in 1804 Napoleon Bonaparte held his Emperor’s coronation at the site. The cathedral has survived the French Revolution, two World Wars, Nazi occupation and acid rain.

The church measures 130m by 48m, with a 35m roof height. It was built mainly from limestone (from the same quarry that was used to build Versailles), wood from oak forests in Normandy, iron and lead. The design heavily utilised the then ‘new’ flying buttress external load supports for the masonry, an idea brought back from the crusades. It’s claimed that 1,300 oak trees were cut down for its roof between 1160 and 1170, and many could have been 300 to 400 years old at the time.

The 96m spire which burned down in 2019 was an 18th century replacement and in the 19th Century an additional spire was added. The support structure for the spire had so much wood in it, it was affectionally known as ‘the forest’. France is currently felling the 1,000 oaks needed to replace the roof and spire structure.

The Notre-Dame fire

In the early evening of April 15, 2019, a fire broke out beneath the roof of Notre-Dame Cathedral. As a UNESCO world Heritage site, the 12th Century building was offered the highest protection status possible.

The French Fire Brigade regularly practised emergency exercises at the site, as everybody knew the timber roof was a potential fire hazard. Fire wardens regularly checked beneath the roof three times a day. This required ascending the 387 steps each time to get to the roof voids. The Cathedral was fitted with smoke and fire alarms.

Constructed from stone and wood, the fabric of the building had suffered years of erosion and wear from weather and pollution. The wooden roof was covered in lead sheeting but as we all know, if left for too long, fissures grow and water can get in. This led to extensive rotting in the spire and roof timbers. They were spongy and had become powdery with age. French Ministry of Culture and the archdioceses of Paris had raised €100 million in the previous ten years to carry out extensive restoration of the cathedral. At the time of the fire, the building was enveloped in scaffolding and the repair work was underway. At 6:20 in the evening the fire alarms went off and the guards evacuated the cathedral. The first inspection failed to find any fire and it was only on a second visit after seeing smoke, that the fire was finally located and it was well advanced.

Unfortunately, the fire alarms were not automatically routed to the Fire Brigade and they were not called until half an hour after the fire was found. By the time firefighters arrived, the fire in the roof had been going for at least an hour. The white smoke that was rising from the roof turned black and flames could be seen from the spire.

Firefighters mainly worked from inside the structure, braving falling debris and what would become a much worse problem – 400 tons of molten lead. Intensity of the fire was so strong it cracked stones and melted lead joints in the stained glass. Within an hour of the firefighters arriving, the Spire of the cathedral collapsed sending a fireball through the rest of the attic. Nothing could be done about saving the wooden roof, so firefighters concentrated on saving the bell towers, which was successful after 15 hours fighting the flames.

In the aftermath, only one third of the Cathedral roof survived; the rest of the roof fell into the interior of the church, bringing down some of the vaulted stone ceilings. However many of the rib vaults held.

While much of the story is about the physical damage to the iconic building, the fire combination with lead created a health hazard both on-site and around Paris. Lead levels on Parisian streets were five times the indoor legal limit.

The cause of the fire remains a mystery, a post-fire inquiry identified the only possible culprits as being possible faulty electrical wiring or discarded cigarette butts from restoration workers. The cost of repairing the building is estimated to be anywhere between $1.13 to $2 bn.

The Revit model in numbers

The concept of using a modern day BIM modelling tool to create a digital twin of an 800 year old stone church certainly had us raising our eyebrows. BIM is great at modern buildings because they are mostly perfectly rectilinear. Take a 13 Century building and add some wear and tear, a little bit of warping and some subsidence, and it can be difficult to model accurately.

The Revit BIM model contains 12,450 objects, most of which are adaptive components with a mix of traditional Revit families. From the model they found out that Notre-Dame has 30,028m of stone walls and 3,925m2 of lead roof. The model includes 186 vaults, and every vault was different, which proved the most time consuming to model from the laser scan.