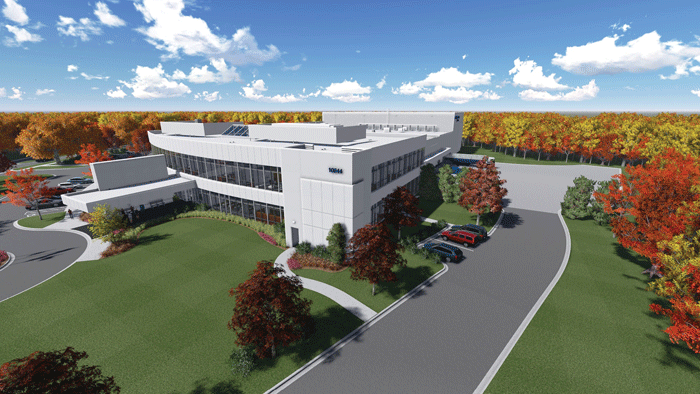

By sharing structural model data with the detailer early and often in the design phase Fitzpatrick Engineering was able to compress the construction schedule on Octapharma’s new blood plasma facility by eight weeks

When Octapharma determined that centralising its storage and lab processing would save the company $1 million per month, accelerating the construction schedule of its new North Carolina blood plasma facility was paramount. Fitzpatrick Engineering Group was able to compress the construction schedule by eight weeks, by sharing accurate structural model data early and often with the detailer in the design phase. With the help of tightly integrated design and analysis software Fitzpatrick Engineering implemented a better, more efficient way to deliver structural steel, reduce RFIs and change orders, and help Octapharma save $2 million.

Shortening the schedule

With $1 million per month on the line, meeting the tight schedule was crucial on this project. Technology and BIM have helped facilitate faster projects, but faster doesn’t always mean more efficient. Doug Fitzpatrick, president of Fitzpatrick Engineering Group explains, “Even though we work in BIM now, in 3D, most of our projects require delivery of 2D construction documents. The construction team, and ultimately the fabricator’s detailer, must then recreate its own 3D data from our 2D documents and do so in a fraction of the time that we had to create the 3D models in the first place. It is an outdated linear process still overly reliant on 2D drawings and a costly waste of effort on every project.”

New construction delivery processes (such as design-build, integrated project delivery, and fast tracking) seek to speed the process, but haven’t necessarily addressed the efficiency problem. “The traditional detailing process has simply been pushed earlier into the structural design phase,” explains Fitzpatrick.

“Sometimes there is a one-time electronic hand-off of structural information; a noticeable improvement, however, any information after that has to be recreated manually from 2D drawings.” This meant that the earlier the detailing started the less design information there was to transfer electronically, and the more data the detailer had to recreate by hand.

Sharing 3D data

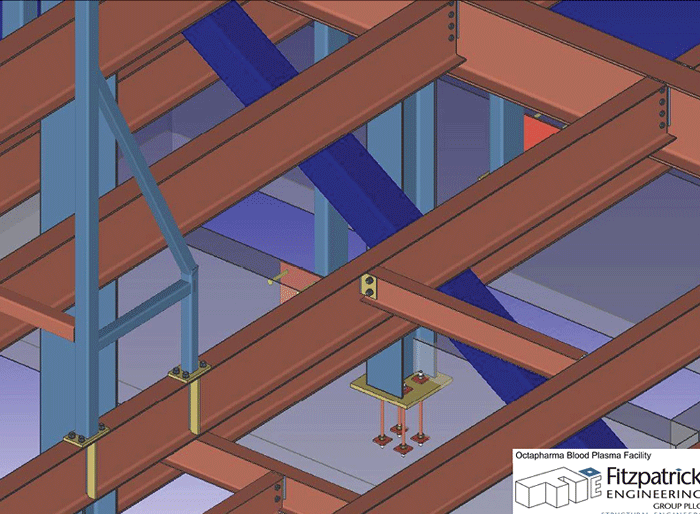

Fitzpatrick Engineering Group used RAM Structural System for structural analysis and design, AECOsim Building Designer for modelling, and MicroStation PowerDraft for drafting.

Bentley software’s interoperability made it easy for Fitzpatrick Engineering Group to collaborate. For this particular project the architect, mechanical, electrical, and plumbing firms all worked in Revit; the contractor worked in Navisworks; and the freezer specialist worked in AutoCAD.

“We shared our AECOsim model as a Revit model for the design and construction teams via the Integrated Structural Modeler (ISM),” explains Fitzpatrick.

“The ISM allowed us to easily update models for the team members on a weekly basis yet still leverage all the AECOsim features and functionalities that make our new process more efficient.”

Fitzpatrick Engineering Group realised that keeping the steel detailer’s data in 3D as long as possible was essential. With AECOsim Building Designer’s enhanced CIS/2 export. Fitzpatrick Engineering Group could share accurate model data repeatedly with the detailer during the design phase. This ensured the detailer had the most accurate and up-to-date information and virtually eliminated the need for the detailer to recreate data from 2D documents. Fitzpatrick Engineering Group and the detailer also worked to ensure the steel fabricator’s preferences were incorporated into the model.

A faster, more efficient process

“The ability to share model data multiple times during the design phases of the project was the key component to meeting the demanding schedule,” noted Fitzpatrick. “The process allowed us to reduce the traditional 12- to 14-week delivery time of the fabrication package down to just six weeks. Best of all, this new process enabled by AECOsim is sustainable. It can be applied to all of our projects going forward allowing us to provide real value to our clients.”

With accurate data in an accessible format, the detailer eliminated errors re-entering and recreating data. As a result, Fitzpatrick Engineering Group needed about one-third less time to review the fabrication package. “Because we can now reliably send accurate data, the menial task of checking lengths, section sizes, cambers, steel grades, and so on has virtually been eliminated. We can now focus our attention on the more unique aspects of our design,” explained Fitzpatrick.

“The ISM and IFC export have been key enablers in sharing our model data,” noted Fitzpatrick. “They allow us to work in a robust Bentley analysis and design environment yet still provide useful information for other members of the design and construction team.” The link between RAM Structural System and AECOsim Building Designer also helped shorten the time needed to prepare construction documents. “With AECOsim we are able to produce accurate drawings quickly at any phase of the project. This speed and accuracy would not have been possible without AECOsim,” said Fitzpatrick.

If you enjoyed this article, subscribe to AEC Magazine for FREE