At Autodesk University in December, the company had the opportunity to show off a range of rapidly evolving cloud services and expand on its vision for the future, as Martyn Day describes in the second part of his report from the event

In part #1 if our report on Autodesk University 2017 we focused on new CEO Andrew Anagnost’s vision for the company, as well as the emerging Forge development platform, which is intended to transform the way that developers create add-ons for Autodesk products and that customers access services and data.

We also looked at some of the work done to flesh out Autodesk’s cloud architecture and online services. While this multi-year process has sometimes seemed protracted, confusing and even incoherent, at this year’s Autodesk University, it finally felt as though all the pieces were coming together, with the Autodesk BIM 360 platform looking impressive in demonstration.

For the AEC keynote at the event, Nicolas Mangon, vice president of AEC strategy and marketing, was first up on stage. He began by highlighting some of the technologies – among them geolocation, infinite computing, big data and remote sensors – that are allowing us to live our lives differently, always connected and more in control.

As he pointed out, these technologies have huge implications for the AEC market. They will increase automation, assist design and planning and enable digital fabrication and construction.

But while we may be in the midst of a technological revolution, automation is not a silver bullet. Today’s federated AEC process is still fragmented and complex and software that deals with one issue at a time can’t adequately solve all the multiple problems it is bound to encounter, due to the fragmented way that the industry works.

A more holistic solution must be found and this is where BIM comes in. At the centre of the BIM process is data and, if you combine BIM data with the capabilities of cloud, everything gets pulled together. Mangon’s mantra, then, is ‘connected BIM’ – and not just for digital aspects of projects, but also for the physical ones, too.

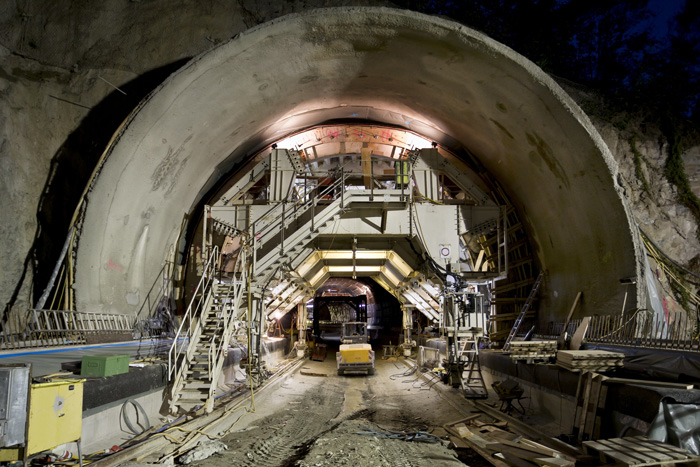

Moving on to customer examples, Mangon highlighted the Grand Paris Express, encompassing 200Km of new railway and 68 train stations, with 90% of it underground, due to be completed by 2030. Mangon commented that this £20 billion project is the first of its kind to use BIM from start to finish and has involved 36 architectural and civil firms developing horizontal and vertical models in Civil3D and Revit. The team has used the models to optimise designs, taking into account escape routes, the results of fire/smoke analysis and the best locations for safety equipment.

Meanwhile, Dubai’s stunning Museum of the Future by BuroHappold Engineering, constructed by BAM, has been developed using end-to-end digital workflows. In particular, using Autodesk BIM 360 Field has helped to achieve a 65% reduction in rework. The building explores the future of science, technology and innovation and is intended to serve as a platform where the latest inventions and prototypes from up-and-coming start-ups and the world’s technology giants can be demonstrated and tested.

Modern-day designs

While the AEC process may be complex in itself, modern-day designs are increasing in complexity, too. Risk can be better managed through digital tools. Autodesk has been developing some powerful generative design tools, which combine machine learning (a branch of Artificial Intelligence or AI) with the power of the cloud, to optimise complex designs based on real-world design criteria.

Augmenting human capabilities, computers can explore tens of thousands of design options and come up with a wide range solutions. As Mangon puts it, these kinds of capabilities mean that, “We can do more and get better results with less.” A case in point is Dutch design build firm, Van Wijen, which has not only embraced modular, factory-based design and construction, but is also using generative design for land development work in urban neighbourhoods.

By defining backyard size, sunlight, views and optimum use of land parcels, the company has been able to increase the quality of its work and reduce time to market. All this is based on software running iterations to find the best designs for customers, while maximising the amount of housing on each plot.

And in a case of ‘eating its own dogfood’, Autodesk used generative design to optimise the layout of its new offices in Toronto. First, the company got feedback from office workers as to how they wanted to work. Then, it fed a range of competing criteria into the system – variables such as daylight, buzz, productivity, views, workstyle, acoustics and proximity to bathrooms/kitchens. The system then generated a range of floorplan layouts that met the criteria.

Generative design is also finding uses in civil engineering. Complex grading can be rapidly assessed by applying geometric constraints, giving immediate feedback regarding volume of material to be moved and cost, for example. This enables ‘optioneering’ and potentially means that projects have a less negative impact on the environment, while offering the best return on investment. And all this can be achieved before construction even starts

On-site safety, too, is becoming increasingly important and with Internet of Things (IOT) advances, construction sites generate more useful data than ever before. One of Autodesk’s hot developers, Smartvid.io, uses AI to scan video and images of construction sites in order to locate workers, materials and equipment. It’s now possible to connect Smartvid.io’s intelligent solution to BIM 360 Field and BIM 360 Docs, where photographs and videos taken on site can be analysed to locate materials, flag missing safety equipment, identify people and point out potential hazards in less than 90 seconds. Autodesk has made a strategic investment in this developer and so we can expect to see more AI capabilities online soon.

IoT solutions for construction are growing, in fact – especially in wearable sensors for workforce safety. These sensors provide real-time information on workers involved in slips, trips or falls, alerting site managers as to the ‘who, when and where’ of a specific incident. If a site needs to be evacuated, all workers can be alerted simultaneously and tracked in real time. Autodesk believes that the Revit model in the cloud can act as a model connected to IoT sensors. Mangon also suggested that Navisworks might be used for visualising IoT data in real time or for looking at historical reports.

For Mangon, all these capabilities naturally feed off Autodesk’s cloud solution and common data platform, BIM 360, which provides connected ways of working, upstream and downstream in AEC, from design to fabrication and construction and on to operations and maintenance.

BIM 360 developments

Sarah Hodges, Autodesk director for BIM 360 presented on the developments around this product, clearly the subject of a big product push at this year’s University. Using an example of the KPF-designed China Zun Tower in Beijing, Hodges recounted how designers and construction teams used BIM 360 to create the 524-metre monster skyscraper in China’s capital. The building has one of the largest concrete- filled cores ever, which required 256 trucks and 96 hours to pour. The building was so complex, in fact, that many parts were fabricated and assembled offsite. Using BIM 360 to coordinate the construction, the firms involved racked up 80% fewer changes on the project, identified 5,000 issues prior to construction, and avoided 6,000 issues on site.

One of the key inhibitors to collaboration is that, due to the way teams work and software has been developed, teams stay disconnected and data lives in silos. Software developers are now trying to break down these barriers by producing common data environments (CDEs), which are basically databases for 2D and 3D models and documents that provide a single source of truth. Strategy firm Boston Consulting Group has identified that, if the AEC industry were to adopt full-scale digitisation in non-residential construction, it could reduce annual global costs of engineering and construction by between 13% to 21%, amounting to a $1.2 trillion saving in a $10 trillion industry.

Last year, Autodesk introduced BIM 360 Docs to add to the other BIM 360 services Glue, Field and Ops. All these applications, while using the cloud, were not initially connected and in many ways didn’t really deliver on the vision of a holistic solution. This year, Autodesk has made a considerable number of improvements to the individual components, but more importantly, has connected everything up to create a seamless experience, a true ‘one-stop shop’.

Hodges described the advances made as so significant that they represent “second- generation BIM 360”. Data no longer needs to be uploaded into different applications and BIM 360 shares information across the whole project.

The new platform of BIM 360 builds on the base of project data, with Forge and Analytic layers, and then offers tools for Design, Pre-construction, Execution, Handover and Operation. Recognising that there are many types of applications used in a project, Autodesk has launched a new Connect and Construct Exchange, a one-stop shop where customers can find integrations with apps that work with hosted data within BIM 360 from partners and authorised Autodesk developers.

Assemble Systems was highlighted as one of these developers: its tools now work with data hosted within the BIM 360 environment. These enable construction professionals to condition, query and connect their data to key workflows. including bid management, estimating, project management, scheduling, site management and finance.

In the next few months, Autodesk plans to bring out a beta version of a cost management system from BIM 360 and is prepping its machine learning development, Project IQ, to move into the mainstream. Project IQ has analysed 225 projects and over 30 million issues that have gone wrong in real building projects. This analysis has helped it to learn from mistakes made and better able to predict outcomes. Construction managers get alerted when Project IQ identifies potential problems, enabling workflow changes to be made that mitigate risks and preempt issues before they arise.

Collaboration for Revit is extremely popular, being used in 144 countries housing 100,000 models and sharing 1.6 million Revit updates a month. Hodges highlighted how this is set to get a refresh with an ability to handle all project data with no upload or download and no more PDFs. It will enable isolated views in real time, Mechanical, Electrical, Architectural and in a centralised model in the cloud. There will be developments in package transmittals from individuals and teams, all to the common data environment.

To make this happen, Civil3D, Infraworks, Plant 3D and AutoCAD will all get collaboration plug-ins to be included in the project data. Hodges described this as true multi-discipline BIM.

Autodesk’s initial development of BIM 360 felt very ‘bitty’, but every project has to start somewhere. And today, BIM 360 looks and feels much more like the backbone for collaboration originally promised. Autodesk finally recognises that Revit isn’t the only data generator in town. Civil engineering has been welcomed to the party. It’s now possible to view all model data geolocated with intelligence in one environment which, since it’s on the cloud, means it’s everywhere. The ability to connect to third-party cloud-based services will become increasingly significant.

Conclusion

It has been a long time coming, but Autodesk’s promise of what the cloud could do is being delivered in BIM 360. The AEC industry faces extreme challenges, not only from its federated composition and complex processes, but also from delivering high-risk, complicated assets in a world of low margins.

We don’t have to look too far right now to see what can happen when things go wrong onsite, and how quickly project overruns can kill huge beasts. Last year’s average profit on construction projects in the UK was -0.5%. If that were not bad enough, issues on site can lead to penalties in their millions.

When cloud first became a topic, we were all more focused on desktop applications going online. The real benefits, it turns out, lie in connecting everyone, maintaining one version of the truth, reducing duplication and errors and delivering on-demand experiences. The next phase will come as third-party cloud-based applications and machine learning tools integrate, analyse and drive through the benefits of being able to process big data.

In the next article we will look at Autodesk’s predictions for the industry of the future, as BIM drives digital fabrication, mass customisation and modular design.

If you enjoyed this article, subscribe to AEC Magazine for FREE