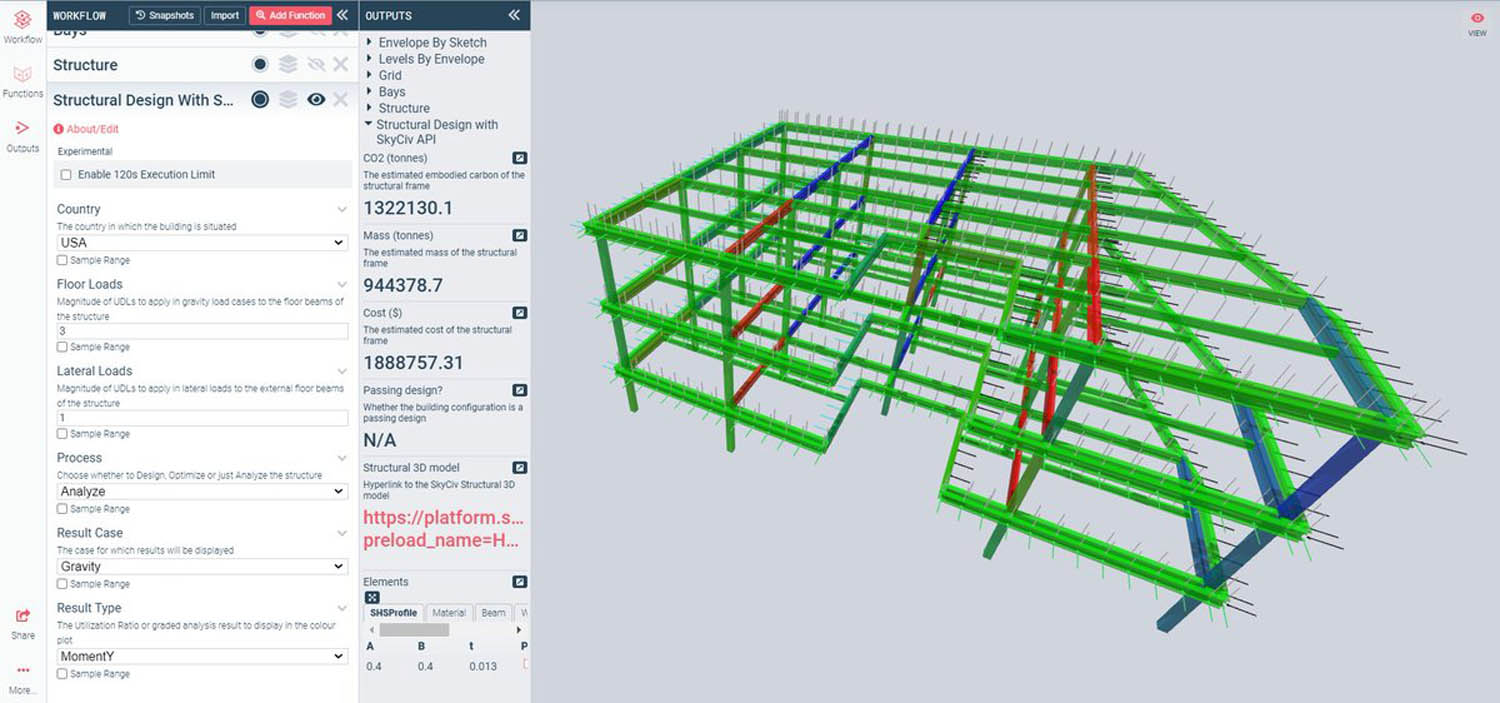

Could a small software firm help users to sidestep much of the detail modelling and drawing production associated with BIM 1.0? Martyn Day reports on Hypar, a company looking to do exactly that

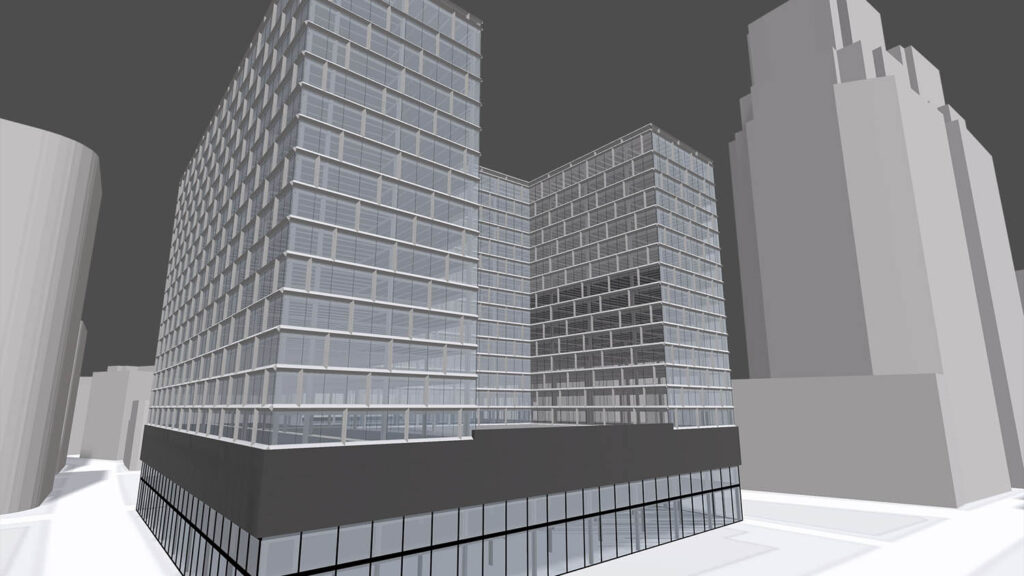

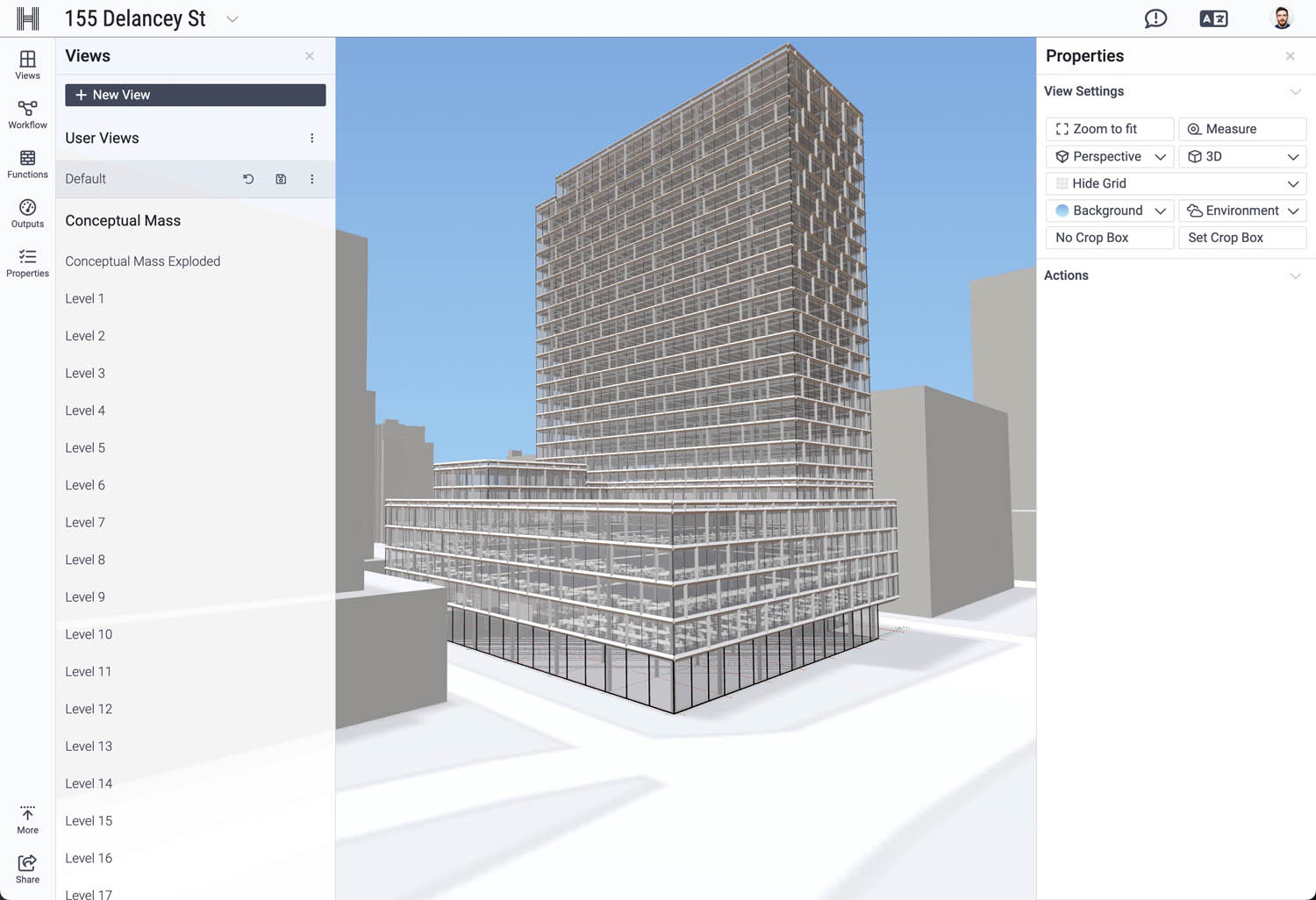

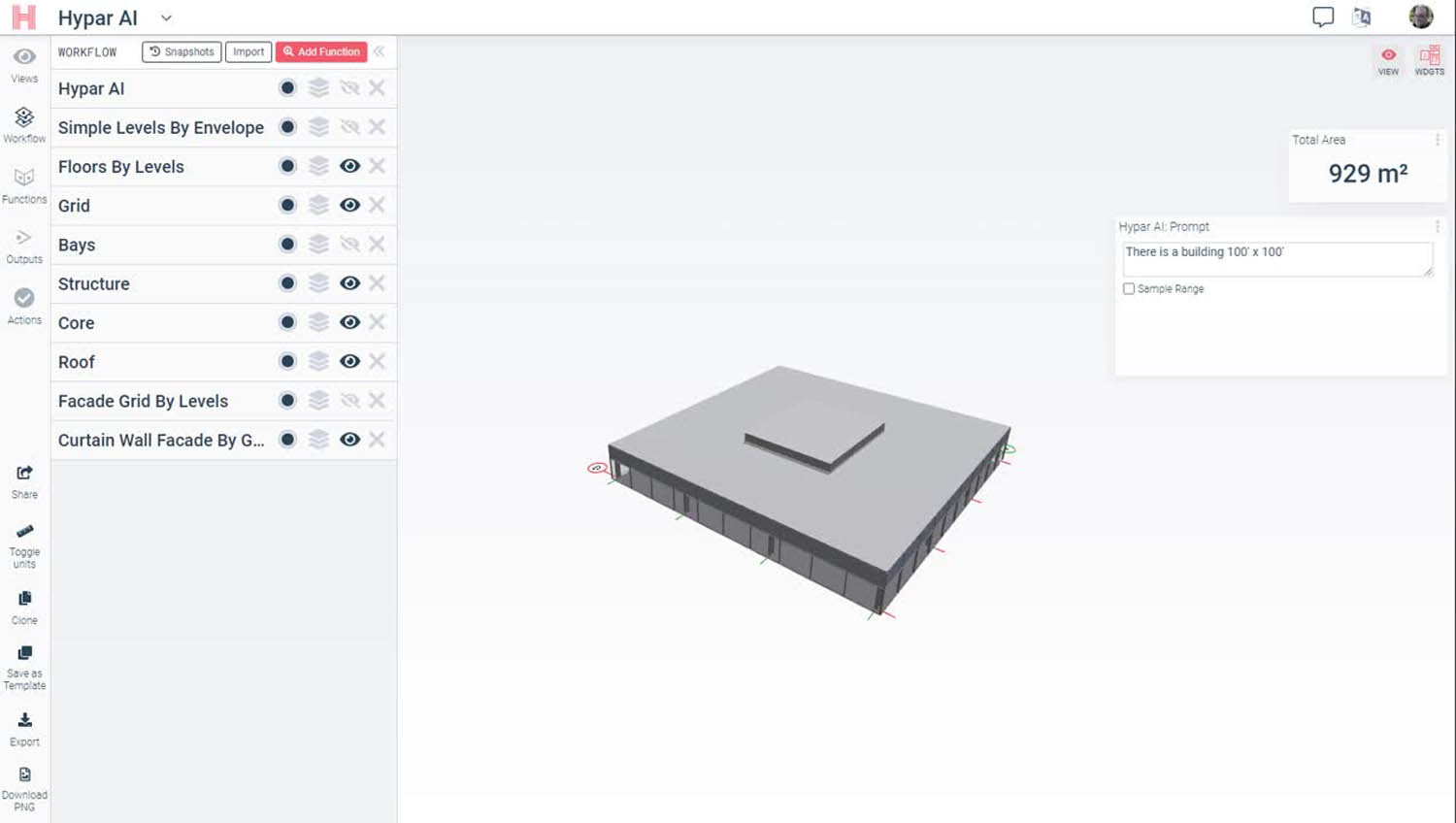

Imagine a computer aided design system that can model a building from a written definition. The user simply types their request into a chat box: ‘A two-storey retail building, and 14 storeys of residential, arranged in an L shape.’ In seconds, a model appears, conforming to the user’s exact requirements, complete with surrounding site conditions and including structural elements, facades and condominium layouts.

To refine the results, the user just adds to the descriptive text. Different floors, for example, might be defined by different text commands.

This is where BIM 2.0 is headed. In many ways, it’s already there.

Founded in 2018, Hypar.io is the brainchild of two seasoned industry veterans: Anthony Hauck and Ian Keough. Hauck was the head of Revit product development and spearheaded Autodesk’s generative design development. Keough is fondly known as the ‘father of Dynamo’, a visual programming interface for Revit.

The pair are widely respected in the industry for their work on developing some of the most popular programmatic design tools used by architects today. When it comes to design tool development, they have been there, done that and bought the T-shirt.

At Autodesk, Hauck and Keough took part in the development of Project Fractal, a tool compatible with Dynamo for generating multiple design solutions according to a customer’s own design logic. It was used in space and building layout design, optimising room placement and structure and generating options that meet core specifications.

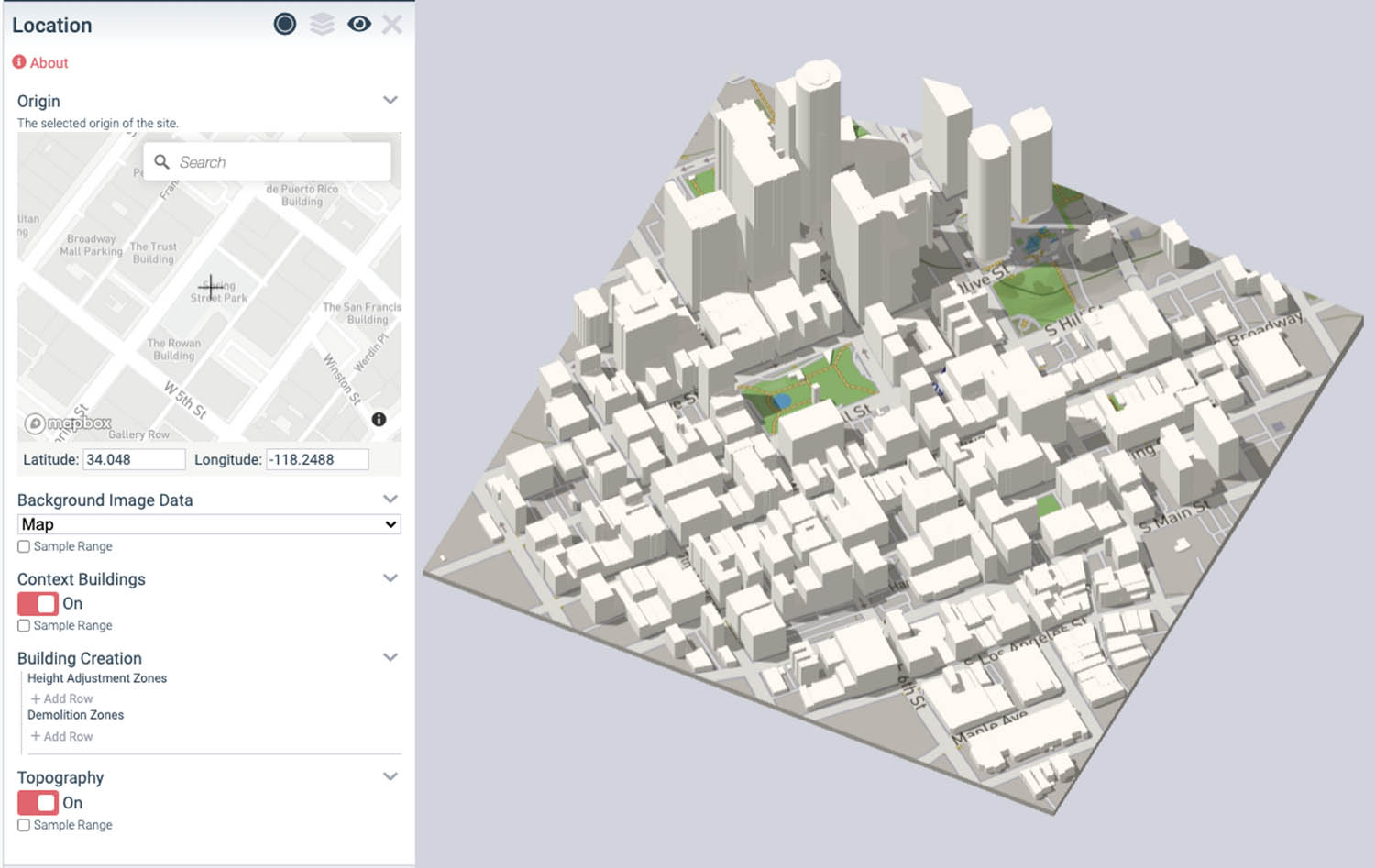

This led to the eventual emergence of Hypar — a self-contained, web-based cloud platform and API, which executes code (in Python and C#) to swiftly generate hundreds or even thousands of designs based on design logic. Users can preview resulting 3D models on both desktop and mobile, along with analytics data.

Hypar’s special feature is that it provides a common user interface that isn’t reliant on heavy data sets, in the way that many of today’s BIM tools are, while also supporting open IFC (Industry Foundation Class) files.

Additionally, it is open to communities of tool developers who may wish to share or sell algorithms, or benefit from Hypar’s suite of ever-evolving tools and growing number of open-source resources. This makes it a popular choice for generative tools development. These generative tools can then be used by non-programming designers to experiment with different design variations with a single click. Output from Hypar can also be connected to other processes through commonly used formats and scripts.

The core Hypar team now numbers twelve people and the company has raised a couple of rounds of seed funding, totalling over $2.5 million, from AEC specialist VC firm Building Ventures and Obayashi Construction of Japan.

On a mission

“Our mission from the beginning, and still to this day, is to deliver the world’s building expertise to realise better buildings.” explains Keough. However, he adds, there have been twists and turns along the way.

“When we started Hypar, I thought that, because I came out of the computational design community with Grasshopper and Dynamo, we would sell to computational designers. It turned out that, for a lot of different reasons that I’ve been bloviating about on Twitter and elsewhere, we had built ourselves into a cul-de-sac,” he says.

“We had our own visual programming languages; we were kind of off on our own spur of computational history, which the AEC world had created for itself. Anthony and I identified that as a dead end.”

The challenge with selling into architecture firms, he continues, is that they are already highly saturated with Grasshopper and Revit. Any newcomer has to fight against this deeply entrenched competition.

“What we recognised is that from one project to the next, programmers couldn’t take the logic that they had created, representing some sort of automation for the purpose of the project, and turn that into a repeatable system that could be used from one project to the next, to the next,” Keough continues. The dream with Dynamo Package Manager, he says, was to make a routine and share this back.

“The problem was, all of those systems — Rhino, Grasshopper, Dynamo — were built on top of hero software, but the underlying premise of BIM was flawed.”

Hauck and Keough’s thinking is that while you can automate a certain amount on top of a BIM model, you’re essentially still automating on top of a flawed premise. “What ended up happening was Dynamo was used very effectively for automating the renaming of all the sheets in drawing sets, instead of automating the creation of a specific, novel type of structural system,” he says.

“Even in the cases where people did do that, you couldn’t then take that structural system generator that you had created, and easily couple it with somebody else’s mechanical system generator, or somebody else’s facade system generator. These ‘janky’ workflows had everybody writing everything out to Excel, then reading it from another script.”

Systemic thinking

Analysing the problem alongside customers from the building product manufacturing world, Hauck and Keough decided to “climb the ladder of abstraction”, he says, going beyond the BIM workflow where customers build things with beams and columns, manually, and instead, thinking systemically.

“The product manufacturing partners made this very clear — the value of systemic thinking — because they have highly configurable systems, for which they have experts sitting, pouring over PDFs, measuring things, looking up specifications in their product books, to achieve fully designed systems, to make a sale,” he says.

Every building product manufacturer who came to Hauck and Keough had this same problem. From 2019 to 2022, the pair underwent a shift in thinking, from seeing buildings as projects to instead seeing buildings as products and as assemblies of systems that work together.

Says Keough: “Why do clashes exist? Clashes exist because everyone sits in silos and they operate without interacting with each other. They don’t see what each other has been doing for a couple of weeks, until they merge the Revit models together. Then they find that these components run into other geometry. We need to make systems that can interoperate with each other and understand each other.

Text-to-BIM

So what’s happening when a request is entered in the chat box? Behind the scenes, Hypar is magically mapping the natural language input (for example, ‘2-storey parking garage’) onto Hypar parametric functions. This isn’t AI, but AI informed through natural language input.

Not only does it create the architectural model, but also flipping to a structure view will reveal the steelwork skeleton structure that has also been modelled. Carrying on modelling, we might add a glass façade, a 10-storey residential L-shape tower. It’s possible to section and view an interior model, complete with residence layouts. All this takes seconds.

To change a fully detailed building option in Revit from an L-shaped building to a U-shaped building might typically take three weeks of work. In Hypar, it takes a couple of seconds — not bad! On top of this, all sessions can be shared as collaborative workflows.

Contrary to popular belief, Hypar is not based on Grasshopper or Dynamo. Instead, it is built from the ground up, from the geometry kernel to its generative logic, to do everything itself. The reason for this is because, as a cloud application, it runs on microservices in the cloud and could not be created using historical desktop code. The results are fairly rectilinear, as the software does not support NURBS yet, although there is a tight integration with Grasshopper, where Grasshopper scripts can be turned into Hypar functions.

All of Hypar’s BIM elements are defined using the JSON schema. This is very similar to how Speckle (https://speckle.systems) defines entities that stream across the Speckle Server. Ultimately, it has the ability to export to IFC, but IFC is not native to the platform itself.

Regarding Revit support, Keough explains, “We have really rich support for Revit, in both import and export. We knew we had to do that from Day One, because that’s where people are and that’s where people are going to be for a while, at least in the production of documents.”

That said, Hypar is working with a lot of customers who use Revit for now — not because it’s the perfect system, but because it’s what they have at their disposal, he says. Oftentimes, they’re building functions on Hypar to export a particular type of panel drawing, things that are really hard, if not impossible to do in Revit without some sort of accessory automation, like Dynamo.”

Over time, as buildings increasingly move to prefabrication and modular construction, and the primacy of drawings is reduced, he says, there will be a corresponding increase in the need for custom types of drawings and outputs to robotic fabrication. “And we’re vectoring to have Hypar on a trajectory to meet those needs,” he says.

One of the biggest issues with BIM 1.0 was that it failed to cross the chasm from scaled drawings to 1:1 fabrication models. Hypar is designed to represent data at multiple scales. As Keough puts it: “We have customers working at every level of detail, from design feasibility all the way through to construction. We have customers who are actually making building construction drawings and specific types of fabrication drawings out of Hypar because, just like the systems that generate the actual building stuff, structural systems, the systems for generating those visualisations are just another sort of extension on top of Hypar.”

Recently at the Advancing Prefabrication conference, Hypar announced the integration work it has carried out with DPR Construction in the US, in order to automate the layout of drywall. “Imagine that, as an architect draws, a wall generates all the layout drawings, and all of the pre-cut fabrication drawings for off-site fabrication of the individual drywall pieces, as well as the stockpiling information about exactly how those pieces of pre-cut drywall are going to be stockpiled on site,” says Keough.

Imagine a CAD system that can model a building from a written definition. The user simply types their request into a chat box and in seconds, a model appears

But with increased detail comes performance issues — so how does Hypar cope with large amounts of data? He responds that the size and complexity of workflows that customers are trusting to Hypar are beginning to test the system. “This is a natural progression, when you build any kind of software,” he says. “When Anthony was building Revit, back in the day, and when I was building Dynamo, there’s always a point at which your customers start using this thing you created for larger and larger and larger models.”

This means that one of the things he and Hauck need to consider very carefully is performance. “If we are inviting all these people to play in this environment, and we can represent all these things with this level of detail, then the compute and your interaction as a user within that compute must operate at the level of performance that historically you’re used to. That’s going to be a challenge, because we’re going to be representing a lot more on this platform.”

Future of building

Our conversation then moves on to the future of building — and how buildings are becoming products. As Keough sees it, a building is comprised of materials and components from a bunch of different manufacturers, just like a laptop. All of these systems must fit tightly and snugly into a clearly defined chassis. From fans to motherboards, the interfaces between them are agreed upon and codified, in order to allow that to happen.

“That’s how buildings are going to start being delivered — and there is not a software out there on the market right now that thinks of buildings in that way,” says Keough. “We all still think of buildings as a big muddy hole in the ground that we fill with sticks and bricks. It’s going to be software like Hypar and others out there which are starting to evolve to think of buildings systemically, getting the system logic and interfaces with other systems in the code. There is a future in which clash coordination is not the way that we coordinate any longer, because it’s not required, because all the systems in a building understand where each other are and really understand how to adapt around each other.”

The demise of drawings

I tell Keough that I am hearing from more AEC firms that they want to move away from producing drawings and get better automated output. It’s something he hears a lot, too: “Increasingly our customers are asking for drawingless workflows.” His colleague Anthony has a “wonderfully concise and pithy” way of describing this problem, he adds. “He says that, for many of the people, Revit is a tax. They do the Revit thing, because they’re in some way required to do it. They have to deliver it.”

Take, for example, virtual design and construction, or VDC, the act of turning a design model into a constructible object. It typically encompasses millions of hours of labour, producing increasingly detailed versions of models, so that firms can coordinate tasks such as putting studs in a wall. But as DPR Construction has demonstrated, a very large contractor can use Hypar to automate the layout of all of its drywall.

“Millions of square feet of drywall, the most mundane kind of thing in the world — but DPR is turning this into a highly optimised, efficient process, which starts with CNC cutting every single piece of drywall, then robotic layout on a slab,” he says. “If you are CNC cutting all the drywall and you have an automation engine that will do all of that for you based on the architect’s model, it will automate everything when the architect model changes as well. Why do you need drawings?”

Drawing-less building delivery is already possible today, says Keough. Some firms have already embraced it. “And I think if you swim even further back upstream, you actually start asking the questions that we’re asking. If you go to model-based delivery, but you don’t take a huge amount of work out of the process, if all you do is go to model-based delivery, then why are people still manually building those models?”

A faster horse?

Every new company emerges because someone is banging their head against a wall in frustration with an existing process, Keough believes. Hypar is no different, he says. “It came out of Anthony and I banging our collective heads against the wall and deciding that the industry needed something better. ‘There will be drawings’ is the first assumption, not ‘There will be a building’.

As Hypar stretches from concept to fabrication, it has the potential to replace BIM 1.0 workflows with highly tailored solutions, but more importantly, reduce workloads from weeks to seconds

But with start-ups such as Snaptrude emerging, with the goal of taking on the BIM market leaders, what does Keough think about software that sticks to BIM 1.0 workflows, but aims to speed things up? For him, it’s just a “faster horse”, rather than anything truly revolutionary, he says.

“I think there should be some faster horses. There’s a natural sort of regenerative cycle that needs to happen in software where people build the next version of, say, SketchUp. Even though SketchUp is amazing, maybe somebody can innovate on that just a little bit. But I think the next generation of tools in this industry is about the automation of the generation of building systems, and the encoding of expertise that’s carried around in the heads of architects and engineers right now as software.”

In a world where software tools fully detail most building models and automatically produce drawings, one has to wonder what happens to all the BIM seats out there. Will firms only need a few seats to do the work provided by thousands of seats in the past? There is already a slow shift to different charging models, like per project, or based on the value of projects. If less software is needed, surely the price will go up?

“At the point at which that happens, the cost of software will, I think, necessarily need to increase, yes, because there will be fewer seats sold,” agrees Keough. “But it will also often open all kinds of opportunities for software to be sold by value. And by that, I mean right now, for instance, we’re working with a lot of building product manufacturers. We automate the generative logic around which a building product manufacturer’s system is designed.”

For these customers, the value proposition is that they sell more of their product. That means that the value proposition for Hypar must also be more of their product sold, too. “We make more money, because they use the software as part of that sale. I try and figure out a number that works that you’ll pay us, and it’s the highest number that I can get you to pay us every year. Yes, we’ll see all kinds of interesting effects in the marketplace of software becoming generative and some of those will be the actual business models of the software.”

Conclusion

Over the last year, AEC Magazine has focused on highlighting small new innovators working to disrupt established BIM workflows and drive big jumps in productivity. The common thread in nearly all next-generation tools is that developers are looking to automate 3D geometry creation and provide some level of detailing and drawing production. A number are even looking to a time when the industry dispenses with drawings all together. These efforts typically have a sweet spot — the ‘bread and butter’, rectilinear, everyday buildings such as offices, residential, retail, hospitals, schools and so on.

From what I have seen so far, Hypar is aiming to potentially save weeks, if not months, of time, with far-reaching consequences for the industry, in terms of software usage (how many seats of BIM tools are required), how the industry bills its clients, and how much software companies bill us.

Hypar is the culmination of all the years of industry experience that Keough and Hauck have collectively amassed, with its blend of expressive programming and ease of use. As it stretches from concept to fabrication, it has the potential to replace BIM 1.0 workflows with highly tailored solutions, but more importantly, reduce workloads from weeks to seconds.

Individual licences of Hypar are just $79 per month, per user, with discounts available for customers buying groups of five licences or entering into Enterprise deals.

Keough on IFC

Hypar’s Ian Keough (@ikeough) is always good for an interesting tweet on software design and BIM. He also has occasional comments to make about IFC and the inherent problems it brings to the table. We asked Keough about his views on IFC.

“Going way back to the beginning of Hypar, we always thought that the sort of open standards and protocols that we have in our industry are severely lacking,” he tells us.

“The standards that we develop should be accessible to anybody with an even basic knowledge of computation. It shouldn’t require Autodesk’s resources or Trimble’s resources or anyone else’s resources to be able to use the open data standards that we have in our industry.”

He’s a software programmer with 10 to 15 years of experience now, he continues, “and I still find IFC almost impossible to use for any day-to-day sort of thing. A lot of what we’ve done, like the opensource library that sits at the heart of Hypar, just makes that stuff easier and more accessible.

Main image: Text-to-BIM: Hypar can model buildings from a written definition