Mariusz Gorczyca, R&D structural engineer at Kingspan, wonders if we are ready for the level of digital ingenuity promised by AI and neural networks

As part of the Kingspan research team, my passions lie with the development of structural mechanics and how we can further enhance the technological development of the built environment. As a part of my masters thesis I was working on the applications of Artificial Intelligence (AI) and Machine Learning (ML) in the AEC industry. My research looked at how AI and ML are shaping the way we work, how projects are managed and delivered and most importantly, the question of whether the industry is ready to embrace this level of digital ingenuity.

AI for architects and engineers

It’s no secret that public attention on AI has rapidly increased recently, despite the fact that the technology has been slowly developing for the past 70 years.

If we consider that structural mechanics has been developing accurate theoretical models for predicting strain and stresses for the past few decades and that these theoretical models require a fixed set of input parameters such as material properties, boundary conditions etc. to produce results such as deflection, stresses etc. – it comes as no surprise that this is a pretty complex and time-consuming process. Therefore, because of these complexities, experienced engineers are often needed to interpret the results for other parties. This is where AI can support this level of development, by using ready collated data to predict behaviours and streamline research processes.

We can also look at how the iterative nature of architects, engineers and contractors working together with a limited project budget has its complexity. Proven solutions for overcoming project hurdles are generally preferred over innovative and ground-breaking ideas, however such situations could be changed by introducing tools which would offer fast yet accurate predictions of actual results – once again, a job for AI.

Models which give fast yet accurate results are termed Reduced Order Models or Metamodels and can be based on AI methods. Metamodels typically require less input parameters and offer results in shorter time. Some examples of metamodels could include predicting wind loads on complex building geometries [1], estimating remaining structural service life [2] or predicting concrete strength based on mixture ingredients proportions [3].

Introducing such methods will without doubt generate project efficiencies on both time and cost. Whilst still in their early adoption stages, it won’t be long before this becomes a proven preferred solution.

AI and neural networks

The most crucial element for any AI-based solution is the underlying data used for the process. Data contains examples of inputs and outputs which can be both collected or generated. What’s important, is the data must be representative of the task in order to create a reliable model. Out of several different types of models, Artificial Neural Networks (ANN) have been proven to outperform other models in most cases.

Artificial Neural Networks are computing systems inspired by biological neural networks that effectively replicate elements of a living brain and are one of the most commonly used tools in ML as they are designed to replicate the way humans learn.

Such systems “learn” to perform tasks by considering examples of activity and measuring repeated outputs – they are excellent at finding patterns which are often too complex for a human programmer to extract and teach the machine manually.

The architecture of an ANN contains neurons organised in a three-layered structure – the three groups of layers are generally named: input layer, hidden layer(s) and output layer.

Neurons are connected between these layers by weights which are unknown at the beginning of the process. Those weights are adjusted in the learning process.

So far in the industry, using ANN, only “exclusive” metamodels have been created. This means that a metamodel built for a specific structure can not be reused for a similar structure or any other altered asset (this limits the practical value of the metamodel).

However, research by M. Nourbakhsh of the Georgia Institute of Technology, proposed a set of 25 parameters describing any structural element within any structure with 1D structural elements. This approach led to a metamodel which could be applied to a wide range of different structures and thus is “generalisable” [4]. The potential of this solution is enormous. Such a metamodel could work as an intelligent assistant helping designers make better decisions. The assistant could run in the background and provide near instant feedback on each decision on multiple projects.

Work environment and data flow

The idea of building “generalisable” metamodels was introduced only recently. Therefore, before any practical application it needs to be exercised and tested since nobody in the AEC industry can rely on a black-box mechanism! Thus creating a perfect opportunity and place for my research to start.

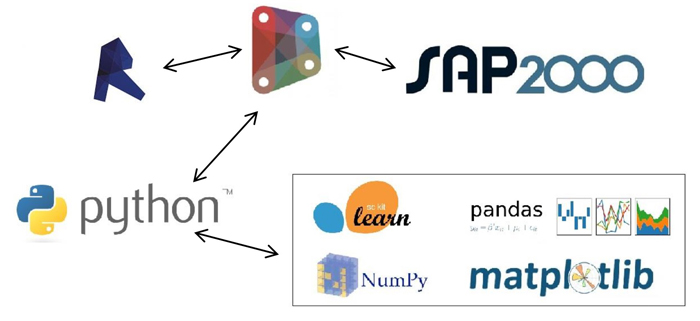

The lack of publicly available data meant I had to acquire new data for the purpose of my study. Creating structural models and extracting data manually would have been extremely time consuming and probably impossible within a given time frame. Instead, the required data was generated in a semi-automatic manner with the help of Autodesk Dynamo and its connectivity with other applications. The software use and how I exercised the connectivity between different pieces is shown in figure 1, hence creating a parametric environment.

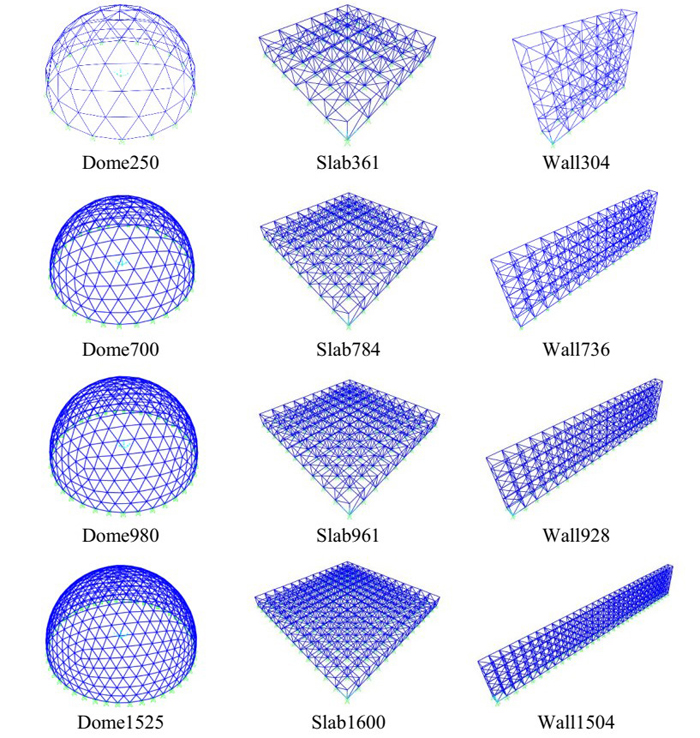

This new parametric work environment allowed for a highly automated process, for which, in total, 12 different geometries of example structures were created using three unique parametric models, each controlled with a single parameter. My models contained 3D space frames and 3D space trusses (examples of these structures can be seen in figure 2) with the same boundary conditions assigned to structures of the same type.

The number of structural elements in the models ranged from 250 to 1,600. In total, more than three million members were created, analysed and eventually used in model training. To ensure variability in data, each member was assigned a random cross section before running the structural analysis. With that in mind, you can see that there was literally no chance to generate two models exactly the same.

Training data / building metamodels

Once the environment was set up, data generation could begin. It took approximately 48 hours on an average laptop to generate 500MB of data saved in .csv files. Each data point contained a set to 25 input parameters with information about location of the member in space, applied load and supports, cross section characteristics and summarised stiffness of members close to the analysed member. For each data point one additional feature was saved, namely maximum von Misses stress in the member.

Further work continued outside of Dynamo with a help of the python programming language and available external libraries. These libraries are already well developed and make working on AI solutions easier. It is highly recommended to get an intuition about the data by checking different statistical properties at the very beginning.

In order to build a metamodel with help of ANN the data needs to be split into two different sets: training set and testing set. Further ANN models should be defined and trained, here a single hidden layer with 30 neurons was used. After which the model can then be tested with “unseen” data from a saved test set.

Predicting stresses with AI

One of the tests we carried out verified that metamodels can be used to predict results of “unseen” structures but within the same class of structures (dome, slab, wall, etc.).

This means, for structures in two classes high quality predictions were achieved showing the R2 score as high as 0.75 (where the maximum is 1.00). On the average, predicted stresses in members varied by 10% to 20% from true values. For one class, where less complete structures were included in the training data set, predictions were arbitrarily wrong. It demonstrates how the quality of data is important for AI-based solutions.

Another test checked if a single metamodel combining knowledge from 12 various structures can predict results of “unseen” structures. The result showed that the amount of generated data was not sufficient for the model training and the ANN algorithm was not able to recognise patterns in the training data. It shows the importance of the data quantity against model generalisability. This means that a metamodel for general application would need a data set bigger than available to any individual but can be generated in a cumulative effort of the industry.

The application of AI in the field of structural engineering brings as many opportunities as challenges. Civil responsibility of engineers sizing structural systems requires accuracy and confidence much higher than it was achieved with metamodels in this work. At the same time results predicted with metamodels give a good indication of structural performance which otherwise would need to be consulted with a structural engineer.

This is but one element of my research, intended to show benefits from AI-powered solutions in the hands of engineers and architects. The above demonstrates a potential for a new generation of engineering tools which will help work smarter and more efficiently. It will help engineers and architects shift their attention to the creative parts of work while computers complete the remaining mundane parts.

Mariusz’s research is the basis of his talk at BIM Show Live 2019, on Thursday 28 February; Application of artificial neural networks in static structural analysis where further examples will be shown on how AI and ANN are effective solutions for providing efficiencies on construction projects from the initial concept stages, and enabling soft landings.

References

[1] S. Wilkinson, Approximating Computational Fluid Dynamics for Generative Design, University College London, 2015

[2] W.Z. Taffese, E. Sistonen, Machine learning for durability and service-life assessment of reinforced concrete structures: Recent advances and future directions, Automation in Construction, 77/2017

[3] M. Słonski, A comparison of model selection methods for compressive strength prediction of high-performance concrete using neural networks, Computer and Structures, 88/2010

[4] M. Nourbakhsh, Generalizable surrogate models for the improved early stage exploration of structural design alternatives in building construction Georgia Institute of Technology, 2016

If you enjoyed this article, subscribe to our email newsletter or print / PDF magazine for FREE