eXtended Reality (XR) solution can now combine data from Revit, Navisworks and IFC with 3D CAD across a range of AR, MR and VR devices

Theorem-XR, an eXtended Reality (XR) solution that enables design, engineering and manufacturing firms to optimise, visualise, and collaborate around 3D design data regardless of location, now supports Revit, Navisworks and Industry Foundation Classes (IFC) formats.

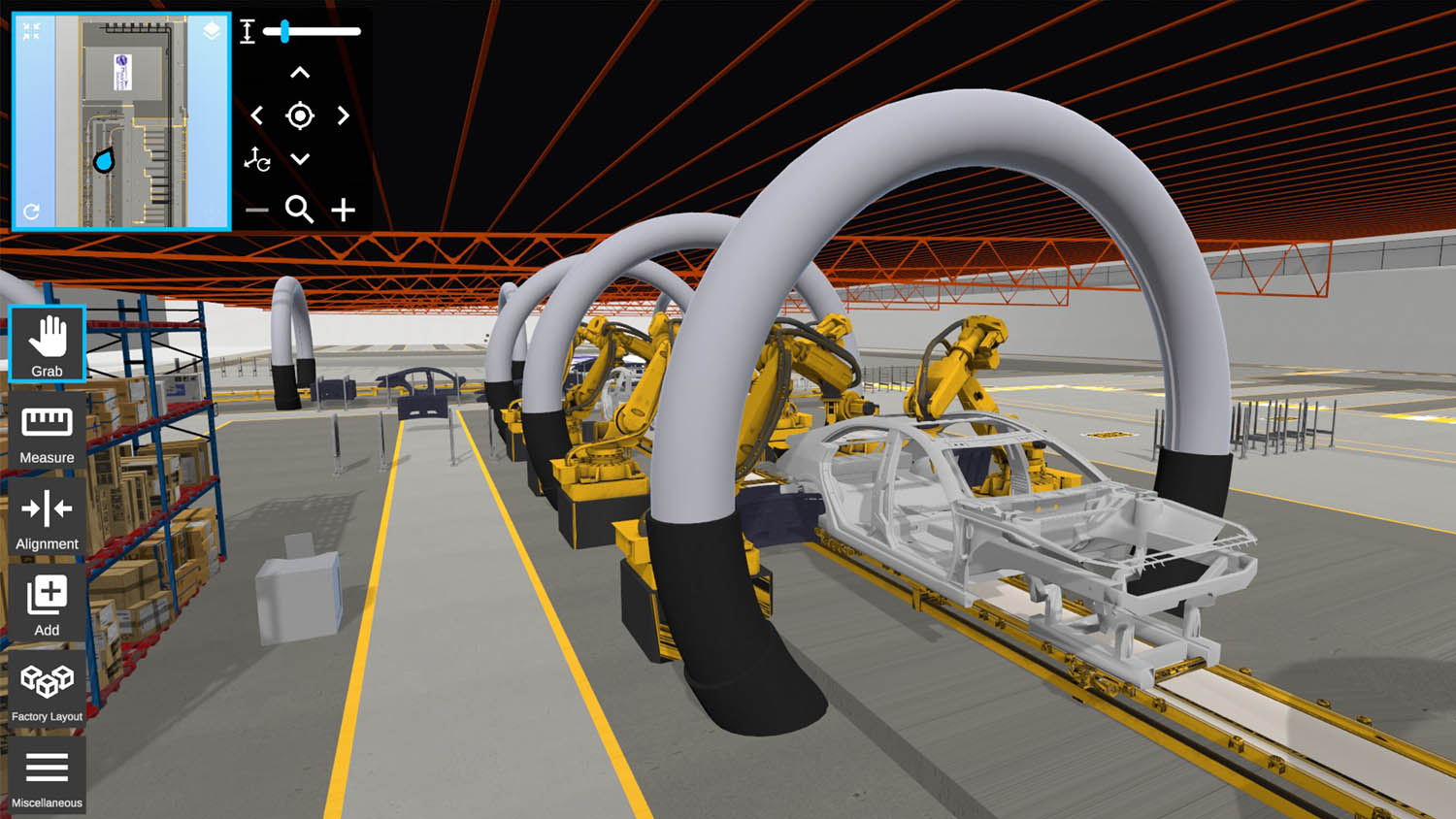

With the new Q2 2022 release users can also load data from multiple sources into a single session. In addition to BIM, this includes 3D CAD (3DExperience, Catia, Alias, Creo, FBX, Inventor, NX, Solidworks, STEP and VRED), Product Lifecycle Management (PLM) data (JT) and scanned data.

According to Theorem Solutions, preparing data for Theorem-XR is a ‘seamless, fully automated process’. Users can ‘save as’ from their CAD session, drag and drop from the file system or drive it directly from their PLM workflow. Data can also be used for the creation of Unity or Unreal assets for internally developed XR solutions.

Theorem-XR works across a range of Augmented, Mixed and Virtual Reality devices, including Microsoft HoloLens 2, HTC Vive, Oculus Rift, Magic Leap, Oculus Quest and Android and iOS devices. To support large datasets across multiple devices, Theorem-XR uses Azure Remote Rendering (ARR).

According to Theorem, being able to offer remote rendering across all devices is especially beneficial to construction and factory layout, as it removes the barriers associated to working and interacting with huge quantities of design data.

Other new features of Theorem-XR Q2 2022 include support for the new location features in HoloLens 2, where users can define where 3D models appear in relation to a QR code.

According to Theorem, being able to render data in this way brings ‘greater accuracy and flexibility to the review process for tracking digital content against physical objects.

Another new feature for Theorem-XR with HoloLens 2 is the ability to markup digital design data in a live session using a ‘holographic pen’.

Choosing the pen tool from the system menu enables users to add annotations to highlight required changes, potential clash issues or to leave a note of requirements for users unable to attend collaborative sessions.

Finally, users in VR can now view the assembly structure as they would in CAD. The option to highlight specific parts and components is designed to make it easier to navigate designs and go straight to the components they need to review with their scene.