Starting out as a forum to discuss computational and parametric approaches to design, SmartGeometry now touches all aspects of architecture and construction from concept all the way to fabrication. Greg reports from the recent event, held in Barcelona.

SmartGeometry is one of the most important conferences in the AEC (Architecture, Engineering Construction) calendar. It brings together architects, engineers, programmers and mathematicians from practice, education and research, all of which have a shared interest in developing new computational and parametric approaches to design. There is a core focus on technology that is already in use or in development, but it also offers a chance for brand new ideas to be discussed and debated, some of which are really quite ‘out there’, so to speak.

Now in its seventh year, SmartGeometry has become a truly global event. Previously held in San Francisco, Munich, New York and Cambridge (Ontario and UK) the location for this year’s gathering could not have been more inspirational. Barcelona is the birthplace of Gaudi, who through his many innovative approaches to design and structure was one of the modern pioneers of complex geometry.

Of course, the city is also home to his most famous construction site, the Sagrada Familia and Gaudi’s masterpiece is a regular topic of conversation at the event, with the cathedral’s executive architect and researcher, Mark Burry, updating attendees on the latest progress and innovations in design and fabrication. For those lucky enough to stay on after the event, the organisers also arranged a private behind the scenes tour of the cathedral.

While the original SmartGeometry events concentrated largely on form and structure, over the years the underlying theme has changed to help drive forward other areas of architecture and construction. The last couple of events have focused on the hot topics of sustainability and environmental design, but this year it was the turn of fabrication. The idea was to help attendees engage directly with the fabrication process through design, building and testing of working prototypes.

The event comprises two conference days: a shop talk day, which sets up the stage for panel discussions on a variety of technical issues, plus a symposium day which features presentations on the theory and practice of computational and parametric design approaches. Alongside this, there is the workshop, the format of which was freshened up this year by moving beyond the confines of a computer and challenging attendees to produce ‘working prototypes’ to help solve a variety of design and fabrication problems. This took place in the industrial space of the Institute for Advanced Architecture of Catalunia (IaaC), while the main conference was held at the somewhat more refined environs of the Palau de la Música Catalana.

New digital manufacturing

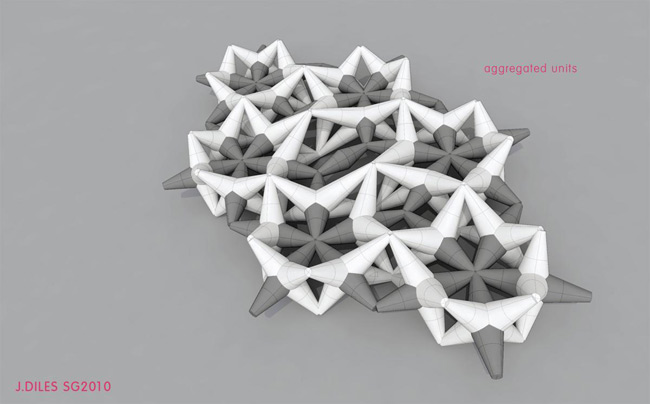

One of the major themes at SmartGeometry 2010 was that of adapting additive manufacturing for construction. Also known as 3D printing or rapid prototyping, the additive manufacturing process typically builds 3D models layer by layer using a variety of technologies.

In the AEC sector, 3D printing is used widely for architectural model making, but with new processes and larger scale machines there are many potential new applications. These include making complex forms that could not be manufactured by conventional means, producing bespoke architectural components, or even printing an entire building.

There are currently many different approaches to additive manufacturing in AEC. Materialise, a company better known for making bespoke components for the automotive sector is already making commercial architectural components with its mammoth Stereolithography machines. More for interior design than actual architecture it makes production quality products from limited edition furniture to customised lighting fittings for hotels.

Interestingly, Materialise said that the only thing that was stopping it making even bigger machines was demand. One would expect that the only thing stopping demand was cost, which is still high for virtually all 3D printing technologies.

Marta Malé-Alemany from the Institute for advanced architecture of Catalonia (IaaC) made the very valid point that adapting digital fabrication processes from other industries may not be the best approach in order for digital fabrication to succeed. Instead, she said that technology needed to be developed specifically for construction, a view shared by many other presenters at the event.

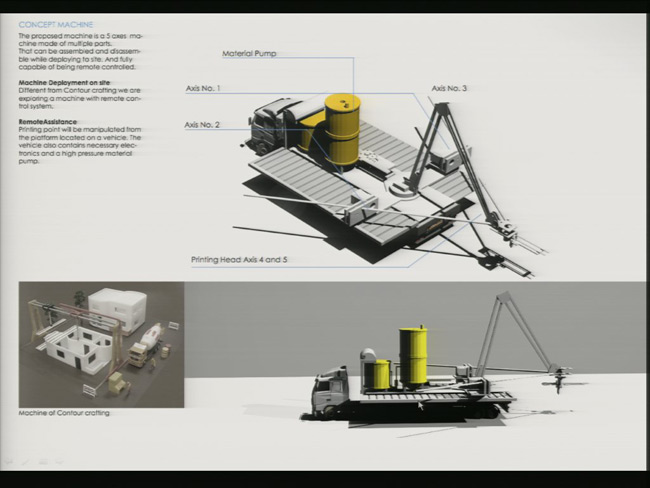

Ms Malé-Alemany went on to show some of the fantastic work her students at the Architectural Association Design Research Laboratory (AADRL), London, have undertaken in this field. One involved a process called contour crafting where a paste-like material is deposited in layers in much the same way a chef applies icing to a cake with a pastry bag. She explained how her students hacked into a CNC milling machine, attached a pump with clay-like material and carried out a series of experiments to investigate the types of geometries that could be built with this technique. They then started to develop architecture based on the process.

Domes were found to be more stable when they had sinusoidal walls and the students realised that by building envelopes within envelopes and spaces within spaces entire buildings could be constructed. Algorithms were then created to help generate actual architectural designs.

The research project has even progressed to the stage of investigating how to develop the mechanics of machines to work on site, with huge robotic arms building entire communities. All of this was illustrated with some amazing videos that simulated the whole process.

Another team looked into the use of phase changing materials to build structures, specifically the use of wax-like materials that would solidify in water. Delivering wax underwater at pressure through air nozzles the initial results were extremely erratic. However, by experimenting with different nozzle sizes and shapes, pressures and material makeup and viscosity more control was achieved. The future vision for this technology was a machine called robo(a)t, swarms of which float on the surface of the ocean and create new inhabitations and environments to promote underwater ecologies.

{mospagebreak}

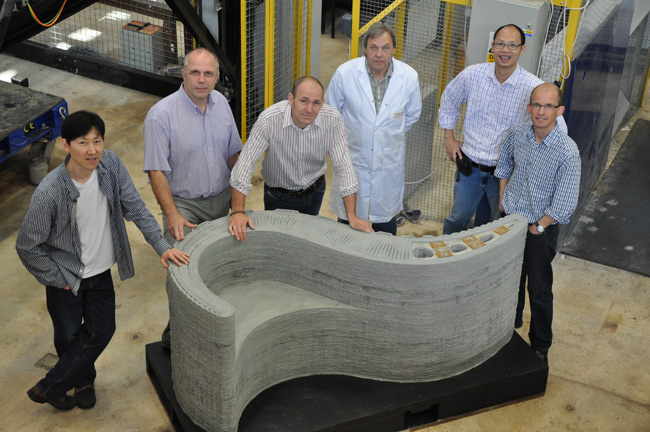

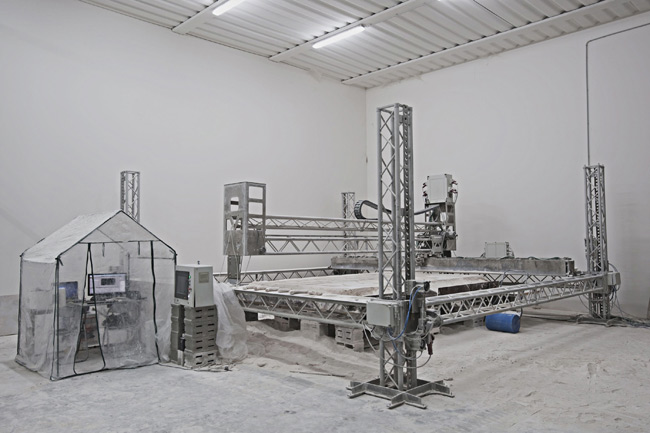

Bringing things back to reality was Richard Buswell, whose Freeform Construction project (www.buildfreeform.com) at Loughborough University is investigating the potential of large-scale additive manufacturing for producing full-scale building components.

A number of additive processes have been investigated, but the project has focused on using traditional construction materials such as gypsums and cement-based mortars. The technique is called concrete printing, but unlike traditional powder-based 3D printing processes, such as that used by Z Corp in its Z Printer machines (www.zcorp.com), it deposits a ‘liquid’ concrete – think squeezing a very big tube of grey toothpaste. The machine uses a gantry and can produce components in a build volume of up to 2m x 2.5m x 5m. The project has already delivered a one tonne reinforced concrete architectural piece.

Dr Buswell explained that the challenge has been to develop components that are not only aesthetically pleasing but can be tangibly used as part of the construction process. This not only means understanding the strengths, weaknesses and physical properties of each process, verified through compression and flexural testing, but the importance of precision in relation to fabrication.

“If we are going to produce real components in buildings that are likely to be components that will fit together, things like tolerance are very important,” he said.

This focus on precision has also resulted in research into manufacturing walls with voids that can accommodate building service requirements such as pipes and cables.

While the Freeform Construction project focuses on the use of additive manufacturing at more of a component scale, Italian born Enrico Dini of Monolite UK, is hoping to take things to new levels with his D-Shape machine that he described as his “crazy vision of making entire buildings”.

Starting out in 2004, Mr Dini has developed the world’s biggest 3D printer, which is capable of building structurally sound sandstone buildings automatically with virtually no human intervention. Unlike Buswell’s concrete printer, Dini’s D-Shape uses a process very similar to that used in Z Corp’s Z printer. However, for powder he uses sand mixed with an inorganic binder.

His largest structure to date is the Radiolaria, a 2m tall structure inspired by the architect Andrea Morgante. The structure was modelled in CAD, then stress analysis software was used to validate its integrity without having to add additional reinforcement. The next stage was to export to STL, the industry standard for rapid prototyping, and then import the file into D-Shape’s dedicated software ready for ‘printing’.

It took ten days to print the structure, which included a containing shell comprising the binded model and loose sand, which was carefully removed by hammer. Mr Dini admitted that he was afraid that the structure would collapse during this process, but to his relief it remained intact. It was then hand finished to add to its aesthetic appeal. A full scale, 8.5m high version of the Radiolaria has been commissioned for installation in Pontedera Italy later this year, but this will be built in parts.

Mr Dini alluded to the fact that funding has been a continual struggle, compounded by the recent economic downturn. He has boosted the project by manufacturing bespoke limited edition furniture, and while this is impressive in itself, you get the feeling it is not these projects that fuels his passion for the technology.

Mr Dini, a very humble man, was honoured to be speaking at the event and was particularly excited about presenting in Barcelona, proclaiming his love for Gaudi and all of his work. With this in mind it came as no surprise to learn that many of his dreams centre on the Catalan architect’s work.

Within five years he is confident that he will be able to build a portion of Gaudi’s Casa Batlo, with a structure ensuring strength, thermal properties, and mechanical properties. His dream, however, would be to complete another of Gaudi’s unfinished buildings, the Church of Colònia Güell in Barcelona. For a man who has put his heart and soul into printing 3D buildings this would be the pinnacle of what looks certain to be a fascinating career. More details at www.d-shape.com. Look out for a more in depth look at the technology in the September/October edition of AEC magazine.

Bringing things back to a more familiar scale for 3D printing, was Adrian Bowyer of Bath University, who demonstrated his RepRap, a replicating rapid prototyping machine that can copy about half of its parts. Arguably the most enthusiastic presenter at the two-day event, Adrian captivated the audience, explaining that 3D printing does not need to be expensive. I wondered what Z Corp, a sponsor at the event felt about this.

Bowyer’s open source machine can print parts out of most plastics, which means they are strong enough to make actual architectural components. The size of printed parts is currently limited to 200 x 200, x 140 mm3 but by changing around some components, he said that the machine could quite easily be made to build bigger parts. I am sure his talk inspired many attendees to give 3D printing a go. Check out www.reprap.com to see the technology and www.thingiverse.com, a place to share digital designs.

Using prototypes for subjective analysis

From acoustics to light and form there were a number of presentations where prototypes were used to communicate fundamentally less tangible concepts to the design team and clients.

Hugo Mulder of Arup’s Advanced Technology and research group, showed an interesting project where both virtual and physical prototypes were produced. The Ijmuiden Wind Sculpture, a permanent art installation in Holland, is designed to hide the industrial backdrop as Amsterdam residents make their way to the beach.

Comprising a 1,000 strong array of 10m high poles that sway in the wind like reeds, local wind data was fed into a computational program, which simulated how the sculpture would react at different winds speeds. This enabled Arup to verify the structural integrity of the design, but also gave a great insight into the movement of the sculpture from an architectural perspective. The aesthetics of the design was further evaluated by building a physical prototype that used a motor to move the individual parts of the sculpture.

Another project where prototypes were used to communicate less tangible aspects of a design was the Louvre in Abu Dhabi, a collaboration between the French and UAE governments to build a sister museum to the Paris art gallery on an artificial island in the UAE capital city.

Al Fisher of Buro Happold showed how full scale mockups were used to communicate both structure and environmental design to different members of the design team. They produced a 15m x 15m section of the roof on site to validate and test something that was quite subjective – how the light would come through the roof.

{mospagebreak}

Tectonic prototypes

Another major theme of the event was the use of tectonic prototypes and how their use is helping deliver innovations in assembly. Russell Loveridge gave an interesting insight into the work he does as Lapa lab at EPFL (Swiss Federal Institute of Technology), Lausanne, where he tests architectural components on a 1:1 scale. This is from the perspective of design, fabrication and materiality, where the lab has close links to industry to test new architectural materials and composites to destruction.

Mr Loveridge showed an interesting example of a mini cinema that was built as a temporary structure for a film festival that not only needed to look good but, with the help of scripting to develop the individual pieces into fabricatable code, could be built quickly.

Martha Tsigkari, associate at Foster and Partners specialist modeling group, gave a very lively presentation on the increasing importance of tectonic prototypes, both digital and physical.

Fosters is heavily into 3D printing and has a huge resource in house to help with anything from form finding, to lighting and daylight analysis. The practice also uses colour prints to communicate different aspects of a building, such as results from solar insulation analysis.

But Ms Tsigkari’s real passion is in making the sure the model, whether a physical or virtual CAD, is used to aid the fabrication process. She explained how she likes working with STLs (Stereoligthography) where models can be used to work out connections, how they fit together and how they will be constructed on site.

To improve the design to fabrication process, she explained how real detail needs to be added to the model to truly understand how the building works, otherwise it is too easy to get a false sense of security. “You see the [3D printed] model, it stands on the table, you are happy with it, but when you go to build it you get a problem because you have not really solved the CAD model,” she said.

All of this is becoming increasingly important, she explained, as we are entering an era where all buildings will be built from information provided directly in the model. However, she also acknowledged that even with highly detailed 3D CAD models that show how complex forms will fit together on site, sometimes this is not in tune with current fabrication processes.

Continuing the theme of tectonic prototypes, Achim Menges of the University of Stuttgart, shared his research into the relationship between material and computation. He showed how his design approach is being driven more by the behaviour of materials, giving a specific example of wood, and less by geometric data. By analysing the behaviour of plywood through computational structural analysis and physical testing, he showed how a building that had been designed to respond to changes in relative humidity by opening and closing louvres all by itself.

Workshop clusters

From robots and CNC machines, to laser cutters and sowing machines, the new look SmartGeometry workshops offered all the tools required for participants to get their hands dirty as they embraced the challenge of proving out computational CAD models with physical working prototypes.

Held at the Institute for Advanced Architecture of Catalunia (IaaC), a world-renowned education and research centre, the industrial space packed in over 180 participants from all disciplines. Together with the huge collection of heavy-duty machinery this created a truly unique workshop atmosphere, complete with a cacophony of industrial bangs, the pleasant aroma of smoking wood, and the not so pleasant aroma of burning plastic and metal.

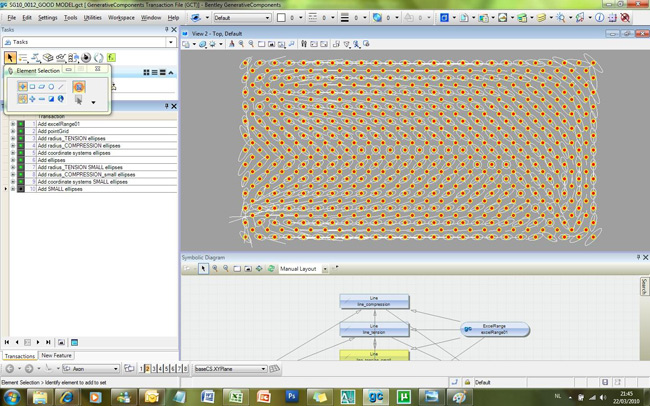

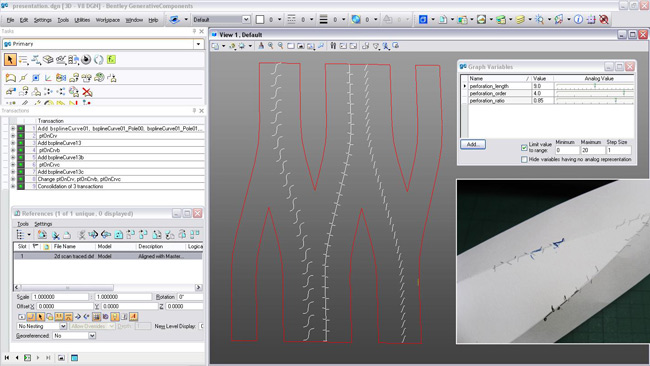

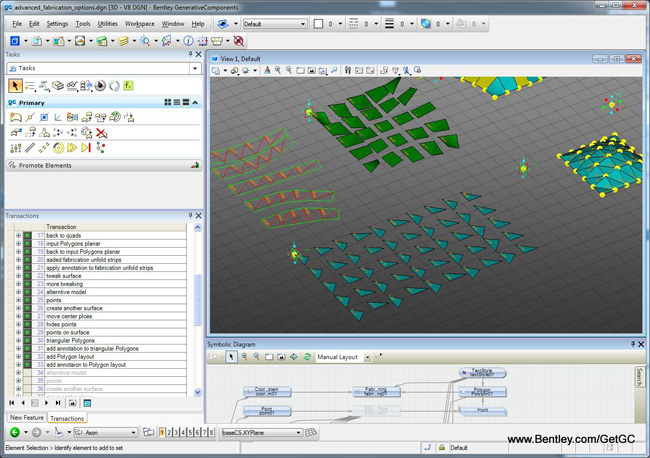

The workshop was organised around ten individual clusters, each tasked with proving and testing a concept and design. Each cluster was given advance training in Bentley’s GenerativeComponents (GC) software, the starting point for many of the clusters, although many of the participants were already well versed in the generative design software as they were in other such tools, including Rhino.

The workshop actually started four days in advance of the conference, and by the time the conference commenced and it was time to present the projects, there were some very tired faces. Considering the amazing amount of work that each cluster had produced in such a short timescale, this came as little surprise. Lars Hesselgren of PLP Architecture, and one of the founding members of SmartGeometry, showed a video that compressed the entire four days into three minutes. I, for one, struggled to see a moment where the workspace was empty.

Despite having burned the candle at both ends, this did not dampen the enthusiasm of the cluster leaders, who presented their projects to the rest of the conference attendees. There were some excellent projects on show and it was particularly interesting to see how architects, engineers and mathematicians exchanged ideas, processes and techniques to come to some interesting conclusions. It was also fascinating to hear more about the lessons learned when moving from virtual to physical prototypes and vice versa.

The rapid assembly cluster focused directly on fabrication and challenged participants to turn their back on mass produced fixings such as nail plates, bolts and screws and draw inspiration from manufactured goods such as cars or phones to create ‘snap fit’ elements that make assembly on site quicker and cheaper.

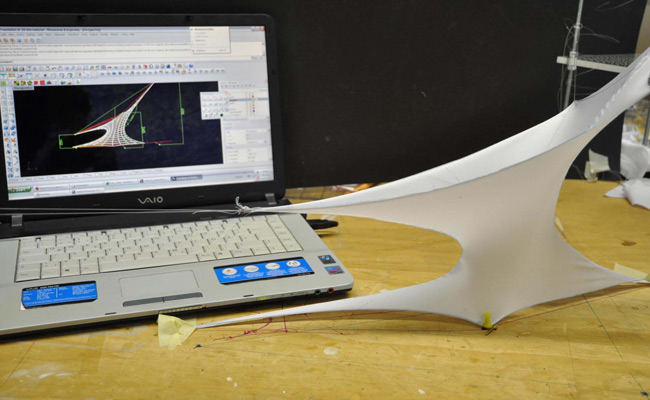

Members of another cluster honed their sowing skills as they swapped computational meshes for needle and thread to turn the theory of tensile fabric structures into working prototypes. This helped them better understand material behaviour as it changed with scale. To develop the complex forms and anchor points of the multi-layered fabric structure the team used a combination of Rhino and Generative Components. Another group armed with sewing machines was that tasked with creating inflatable envelopes. Inspired by structures from the sixties, Grasshoper and GC were used to design the complex cell geometry with the resulting flattened patterns made on a CNC fabric cutter.

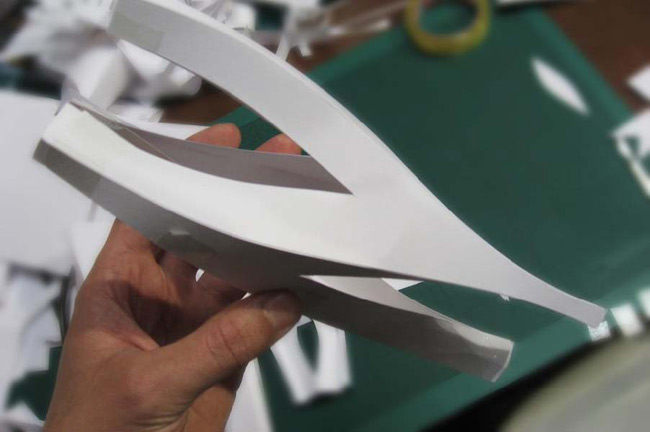

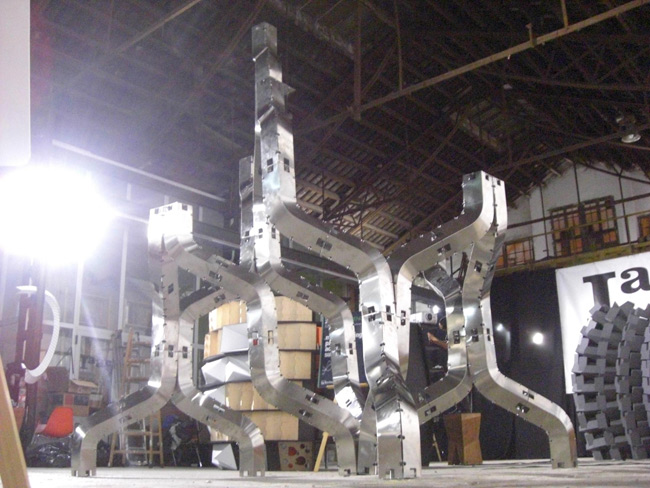

One cluster that initially rejected computers in favour of the traditional ‘prototype’ material of paper was the curved folding group. The idea was to investigate how to design complex sheet metal forms with curved fold lines and build them by robot without any tooling. Hundreds of concepts were worked up with paper and knife, one of which was then scanned in 3D by a Z Corp scanner. The 3D model was worked into a 2D surface inside GenerativeComponents and a range of perforation types and mechanisms for connecting parts together were investigated. The end result was an impressive 3.5m high sculpture that was assembled by robot. Some interesting videos that explain the robotic manufacturing process can be found at www.robofold.com.

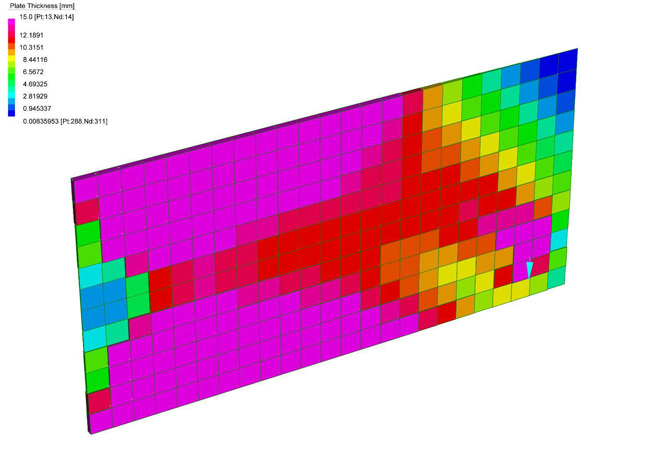

One of the most playful clusters was ‘design to destruction’, where the brief was to design a 1.2m wooden cantilever with voids cut by a laser cutter through an iterative process of computational analysis using GenerativeComponents and small-scale prototyping. Each design was then to destruction by piling some pretty hefty weights to a palette – bringing even more noise to the IaaC workshop. The winning design was the one that had the lowest weight, but highest loaded capacity, and much to the amusement of the audience this was designed by an architect, while the losing entry was made by an engineer.

{mospagebreak}

GenerativeComponents

Software has always been the driving force of SmartGeometry and Bentley’s GenerativeComponents design tool has been an integral part of the event since the beginning. As a primary sponsor of SmartGeometry, Bentley has a significant presence, but this year the developer had some very important news to announce.

Bentley’s Huw Roberts revealed on stage that GenerativeComponents would now be available as a no-charge, stand-alone technology preview release. Previously only available inside MicroStation the move will certainly open the software up to a much wider audience and attendees that I spoke to responded favourably to the move. It appealed not only to those who did not already use MicroStation, but also to Bentley customers who would now be able to free up MicroStation seats inside their practices.

Mr Roberts explained the rationale behind the move was to encourage a broader community and help them explore the real potential of computational and generative design. He also said that feedback from users would help Bentley continue to integrate it with the rest of its applications and platform technologies.

Looking at the announcement from a business perspective one could also suggest that it is a defensive move by Bentley in response to feeling increased competition from other CAD software developers. It has been two years since McNeel released Grasshopper for Rhino and from its appearance in a number of presentations at the two-day event, it is clear that it is gaining traction.

Probably of equal concern for Bentley, is Autodesk’s own generative design software for AutoCAD. Still a work in progress, it is being developed by Robert Aish who was the original driving force behind Bentley’s Generative Components software.

For more information on GenerativeComponents and to download a free copy go to www.bentley.com/getGC

Conclusion

This was my first SmartGeometry event so it is hard to compare it to those that came before. However, from talking to regular attendees there was a feeling that it was the best yet. Much of this was down to the hands-on workshops, which through the chaotic environment of the industrial space at the IaaC gave a real feeling of unity and achievement. Developing an intelligent computer model is one thing but realising these concepts in physical form (and making a racket on an industrial scale whilst doing so) really added to the workshop format.

From my perspective I was somewhat surprised at how the event was less about complex geometry modelling for architecture and more about digital fabrication. I guess this is testament to the success of previous years as most major architecture firms are already progressing well with such technologies. Keeping the agenda fresh is important to not only keep it alive, but to help the industry move forward.

Design for fabrication has always been an important element at SmartGeometry, but this year the event gave a real insight into the future of construction. Printing entire buildings in 3D may be the stuff of science fiction, both now and well into the future, but by providing a forum to discuss such ‘crazy visions’ – on stage, over coffee or over bottle of wine in the evening – it encourages the industry to look at architecture and construction with fresh eyes, which can only be a good thing. Roll on SmartGeometry 2011.

More information, including videos of all of the presentations from SmartGeometry 2010, can be found at www.SmartGeometryConference.com/2010