Looking at the latest batch of design-oriented start-ups, it’s easy to think of these new BIM applications as shiny new replacements for their older, more monolithic predecessors – but in fact, many of the newcomers are engineered to work with existing BIM tools to shrink project timescales, writes Martyn Day

We are living at a time in which the software gods have finally deemed it appropriate to rejuvenate the design tools available to the AEC industry. For many, it feels like it took eons to move from 2D drawings to 2D CAD and millennia to move from 2D CAD to BIM. But fundamentally, the end goal of the process is the same: a 2D drawing.

If you are model-centric and a BIM techie, by now you will have come up with workarounds and tricks to deal with the limitations presented by the current generation of BIM tools. At the same time, it’s likely you’ll still be longing for productivity benefits and ways to speed up the process.

Startup companies such as Snaptrude, Arcol and Qonic ultimately aim to compete head-on with the Revits of the world, but it will undoubtedly take time for them to achieve feature-by-feature equivalence. Snaptrude and Qonic are now commercially available; Arcol is still in beta.

However, other tools are emerging that aim to deliver time-compression benefits within traditional workflows and these may be easier to digest. The main goal is productivity in areas such as massing, detail modelling and drawings creation, using automation technologies to leapfrog phases of traditional BIM processes. If this is of interest to you, then we will be discussing this in-depth at our NXT DEV conference in London on 26 June.

One such firm is Skema, headed up by Marty Rozmanith and Richard Harpham, who were both early Revit employees and subsequently Autodesk alumni.

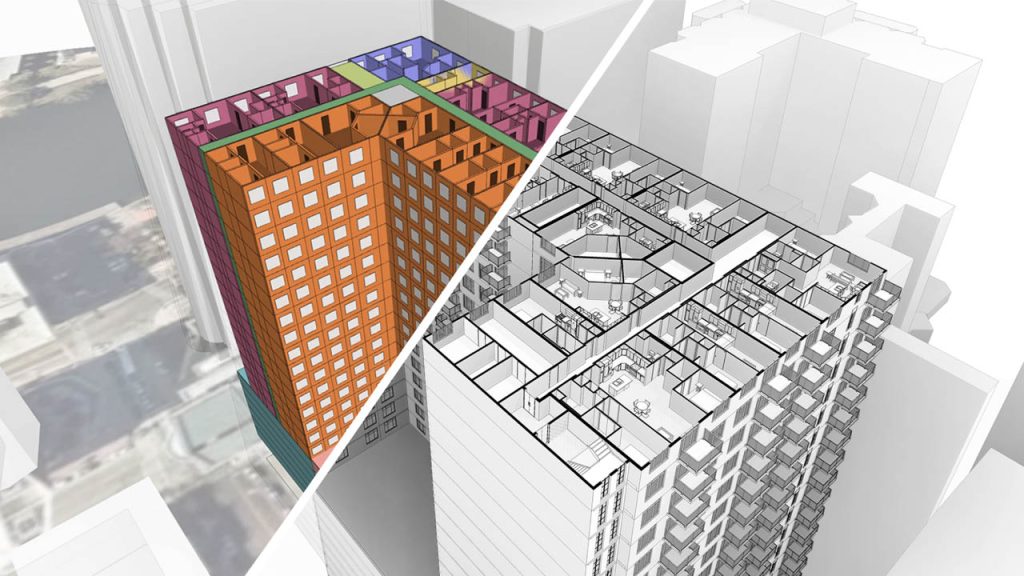

Skema’s promise to users is to help them ‘get BIM in minutes’. In other words, it’s about moving rapidly from schematics to detailed BIM models that adhere to corporate design standards.

This is a big claim. If proven valid, it could deliver huge productivity benefits.

Skema starts off with a consultation phase, examining your workflows, your standards and your building styles. You then create smart detail assemblies, called ‘catalogues’, so that when you move from masses to detailed models, you are actually ‘modelling’, in the sense that you are replacing dumb masses with highly detailed auto-generating assemblies.

This removes a lot of detail design work. For standard buildings, this can drastically reduce the detail design phase. The way Skema is written, it can be used in Revit, Archicad or even SketchUp. AEC Magazine recently sat down with Marty Rozmanith to discuss the technology.

AEC Magazine: What can you tell us, Marty, about the thinking behind Skema?

Marty Rozmanith: The manufacturing industry has compressed times, lowered costs and also increased quality at the same time. The fallacy in the construction world is that you can only achieve two out of three of those goals at any one time. Cars today are relatively cheaper, higher quality and produced faster than they were in the 1980s and 1990s. This was achieved through process optimisation of the system of production. However, in construction, we still have a craft-based business.

It’s not like we’re trying to compete against Autodesk Forma or SketchUp, or any of those things. We’re trying to compete against tracing paper – Marty Rozmanith, Skema

There are certain very time-driven buildings that are already doing this [process optimisation] before everyone else. Data centres are a great example. Everybody industrialises chunks of a data centre to be delivered in a much faster, much higher quality and much more predictable way. And they’re doing that at LoD 400. This is now happening in multifamily modular and residential in the US, and other building types like student housing.

The big problem with trying to make that transition, as [strategy firm] McKinsey has stated, is that everything about construction delivery gets faster, but design gets slower, because now designers have to think about the way the building is produced and design that in.

What we’re trying to do at Skema is make something where design doesn’t get slower and designers don’t have to think about all that stuff, because we give them a bunch of puzzle pieces that can naturally be executed in a modular or panelised fashion. Architects just think about it the way that we would have once done this on tracing paper – but now they do it on a web browser.

AEC Magazine: You are focussed on accelerating early-stage design to detail modelling. Why start with massing?

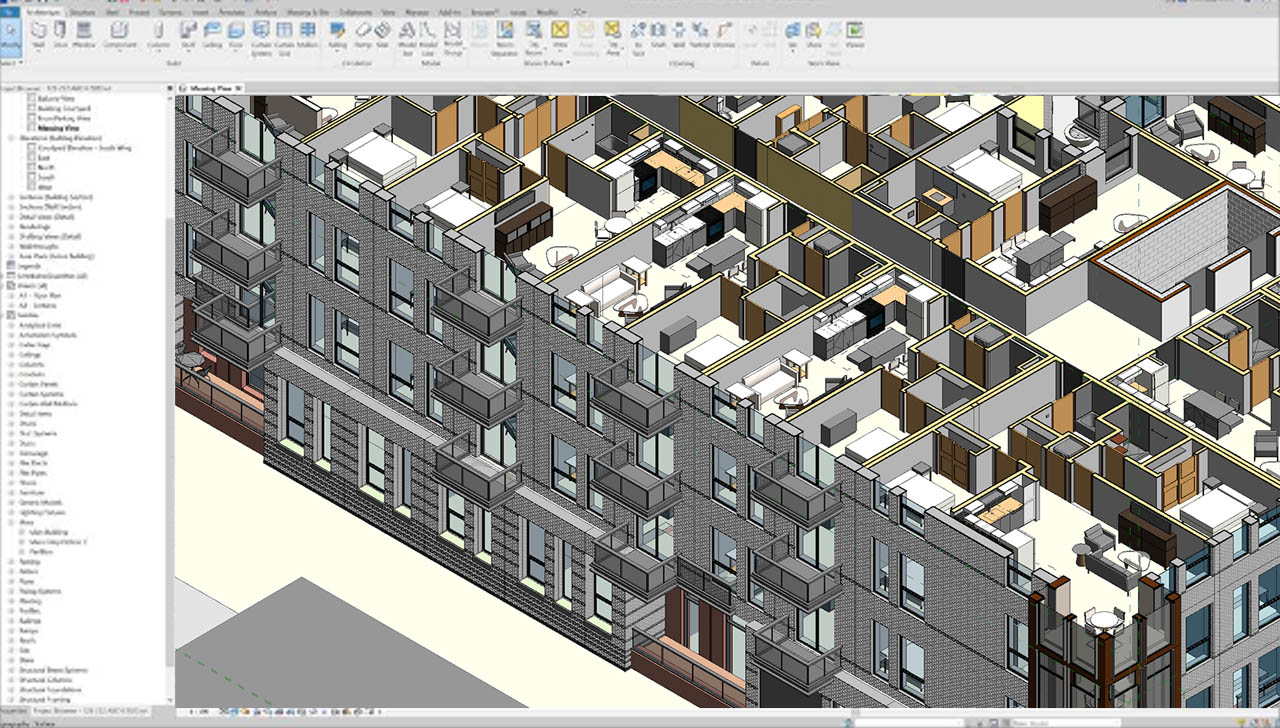

Marty Rozmanith: The reason that we’re doing it at early stage design is that this is where people who are the partners in the firm make those decisions. It’s not like we’re trying to compete against Autodesk Forma or SketchUp, or any of those things. We’re trying to compete against tracing paper. We have gotten into projects where people may have used SketchUp once or twice, but mostly, they do things on tracing paper. After a couple of hours of work, they can generate a Revit model at the press of a button, two minutes later. As I said, they have zero idea how to use Revit. They just get a well-structured Revit model from Skema.

We hold workshops before the customer has even bought. It’s not a big lift for us to give them their assembly pieces. We take their ingredients, so that when we produce the Revit model, they see their typical wall assembly and floor assemblies, their furniture, fixtures, equipment, casework, all that stuff. They want to see the ingredients their firm uses and their standards in the Revit data that we produce. That’s what the system pushes out. We just sort of rationalise the parts in between.

Skema is a fast-forward button for architects, using a BIM system. We have one customer who told us that their design development phase is usually 24 to 28 weeks. Now, with Skema, it’s never going to be that long anymore. It’s going to be significantly shorter, because we can solve it much faster using our workflow.

AEC Magazine: These are big promises. In an industry based on billable hours, how do you see this playing out?

Marty Rozmanith: Our argument is that your model is based on charging for delivery to a certain scope. Your goal is to deliver that scope, so that the owner can get their permit and get the thing built. You should charge that fee, for that value. And if you can do it in half the time, then you can figure out how to spend the extra time or pocket the fee, because the owner is happier to get it faster and at higher quality.

Find many more articles like this in AEC Magazine

👉 Subscribe FREE here 👈

AEC Magazine: It’s a different way of thinking – almost systems-based, where a room is a system – as opposed to manually modelling and editing walls, windows and doors. Does that sound right?

Marty Rozmanith: Our whole ethos is trying to do it so the designers don’t notice that they’re dealing with larger chunks of ‘stuff’. When designing a healthcare facility, performance is usually driven by patient rooms or surgery suites. In early design, designers think about things as, ‘Here’s a surgery suite’’, or, ‘Here’s a nursing station’. That way, they have to take whatever they laid out on tracing paper and manually draw all those things, one by one, in Revit.

The AEC industry has been behind in 3D modelling compared to the manufacturing industries. Because that whole Catia 747 digital virtual prototype, I saw that at Stanford in 1994, well before Revit was ever even an idea. That was being modelled in chunks and assemblies at that time, because in those industries, you have a parts bin to work out of. In many of those assemblies, you’re only going to do 10% custom edits to fit it in your product.

That whole idea of having a parts bin and working with chunks of buildings was actually described in a book by Stephen Kieran and James Timberlake, Prefabricating Architecture, which came out around the time as Revit in the late nineties. You can almost think of Skema as a direct implementation of the ideas in Prefabricating Architecture, which is basically designing things in chunks and having those chunks already pre-engineered, so that when you actually make the building, you just ‘interface’ it together.

When we were designing Revit, my firm belief was that whatever’s easiest in the software is what people are going to use. So if we want them to do a certain thing, that’d better be the easiest thing. This is why I’m saying we’re trying to compete with tracing paper, we have to be easier than tracing paper. This is actually hard!

You can almost think of Skema as a direct implementation of the ideas in [the book] Prefabricating Architecture, which is basically designing things in chunks and having those chunks already pre-engineered, so that when you actually make the building, you just ‘interface’ it together

AEC Magazine: There is always the issue that modelling skills are poor and nobody trusts each other’s models, so will redo the work. We guess automated modelling offers a higher degree of certainty?

Marty Rozmanith: People don’t realise this point about the variance introduced by a parametric system like Revit. If you are working on a hospital, and in one of the surgery rooms, you move a wall, now the dimensions of that surgery suite are different from all the other ones. So now you have a problem, because you wouldn’t be able to prefab that surgery suite, because it is now an exception.

When you use a parametric system, and you’ve got dimensions that drive object layout, Revit tries to keep things coordinated, so it will shift things based on user interaction. This is great at the beginning, when you’re trying to coordinate things and rapidly evolve the design, but as you try and lock things down, you can get that behaviour working against you, in that things might move. The net result is that the people building don’t trust the model, because they realise variants have been introduced that are hard to find.

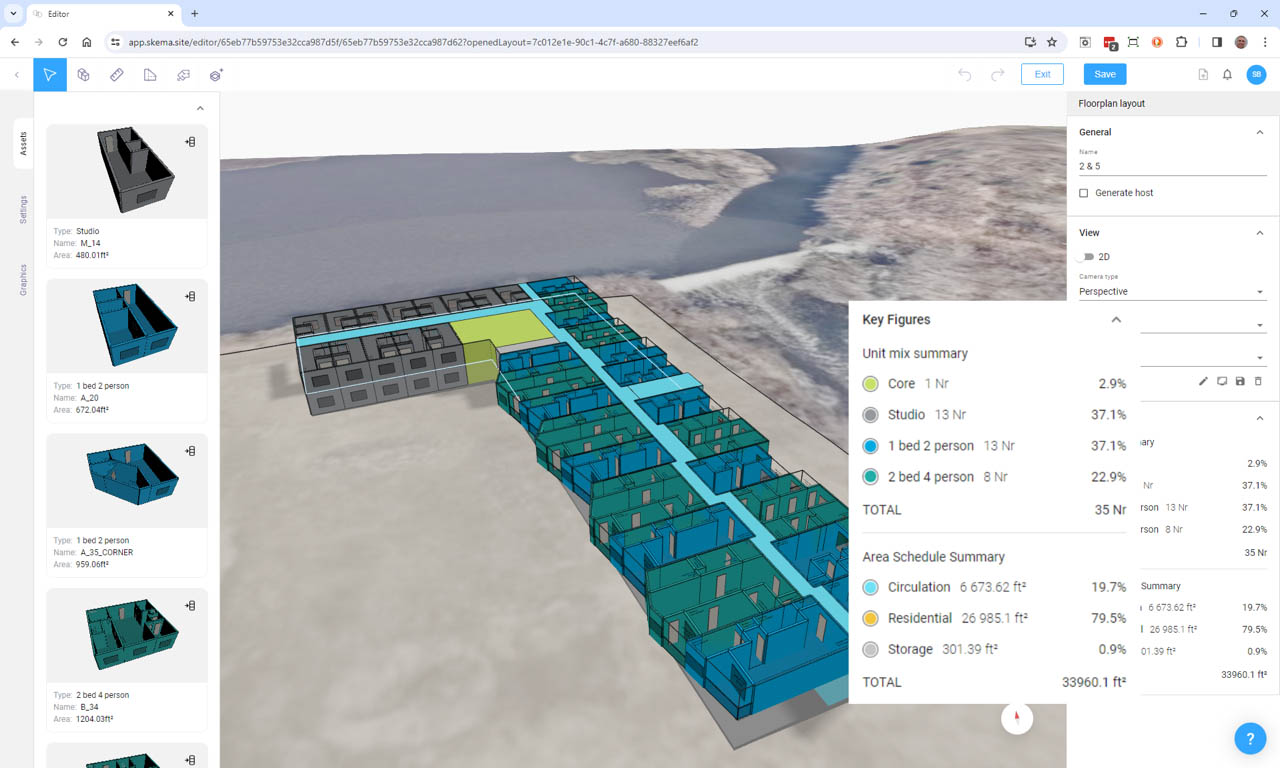

One of the things about Skema’s way of doing it is that all the puzzle pieces are the same. And when you want to force something into a different layout, you have to explicitly decide to do that. In that situation, we actually generate the different puzzle piece, so that you can easily see when the data goes into Revit.

There’s a lot of confidence that whatever I do in the conceptual environment will work when I generate the Revit model, because the two are identical. When we have partners that have a design firm in front of an owner, their confidence increases, knowing these numbers are right. It’s a material change, being able to project confidence to the owner, knowing that they don’t have to have a whole BIM team look at the model for two or three months.

AEC Magazine: Not only do you handle substitution massing to detail modelling, but also you have a solver. What can you tell us about that?

Marty Rozmanith: Usually, the solve is based on the brief for the building. We have solvers for multi-family, which is popular in America, and we can solve based on percentage unit mix — how many single or double bedroom apartments in a given design. We will move on to solving for multiple conditions, automated solves and dealing with graphs of graphs.

AEC Magazine: How do you deal with design variance in predefined rooms?

Marty Rozmanith: We take a chunk of building and we understand the edge conditions and the graph inside of it, which is not dissimilar to how Testfit or Finch3D handle this. But what we do is pull the data out of Revit and we inherit some of the constraints and analyse the layout logic. These become catalogue assemblies for use in design. You can stretch the design and Skema morphs the entire graph of the space and tries to preserve the layout logic.

Conclusion

For now, Skema is not applicable to all building types. But the more repeatable and prescriptive a brief, the more likely it is that Skema can be usefully applied to accelerating massing to detail.

We know Skema has lots of additional technologies in the pipeline and also aims to assist in taking designs to digital fabrication. Come to NXT BLD and NXT DEV in London 25/26 June to meet Marty Rozmanith and Richard Harpham to find out more.