Berlin-based CAD software developer Gräbert has been developing DWG CAD tools since 1994, now spanning Windows, Mac, Linux and cloud. Martyn Day talked with company CTO Robert Gräbert and business development & marketing director Cédric Desbordes on the company’s efforts to better link 2D to BIM

Building Information Modelling (BIM) was sold as a way of get ting automated drawings by modelling a building in 3D. – What we actually got is more drawings. We now model a building to get drawings that need 2D editing, and if the model changes, we need to do the edits again.

In our conversations with AEC firms there are growing calls to get rid of drawings completely and work only from 3D models. The bad news is that in manufacturing, which is a decade further ahead in adoption of modelling virtual prototypes, they still produce and rely on 2D drawings. There is also the issue that the contractual framework for AEC is still the drawing. What needs to happen first is smarter 2D drawing tools.

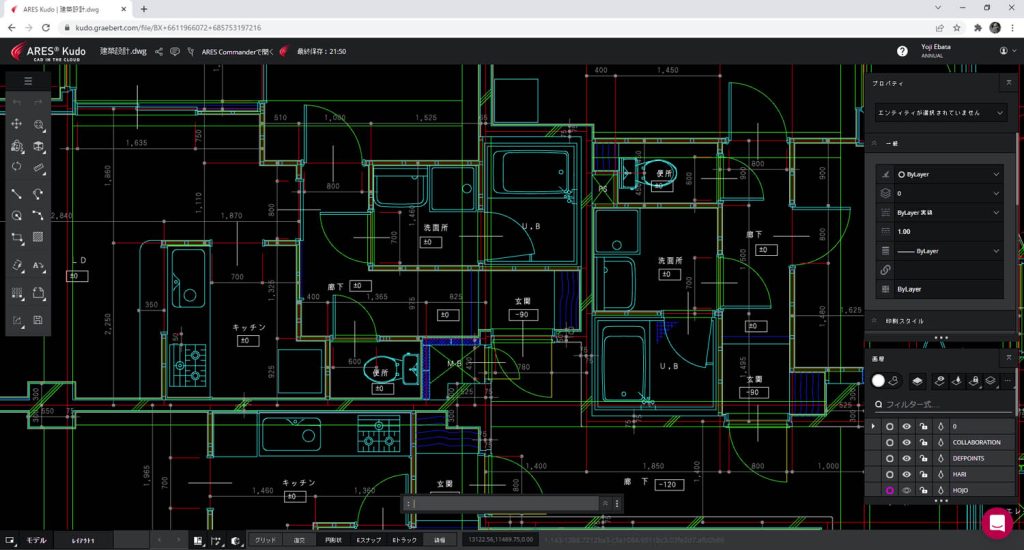

Gräbert develops its own drawing tool under the ‘Ares’ brand. It also licenses its core engine to the likes of industry heavyweights Dassault Systèmes (Draftsight) and PTC (Onshape) to name but two. The company is innovating in its drawing tools, not just in functionality but also in platform, with Ares Kudo – its DWG engine in the cloud – and also looking at how to connect to BIM modellers and get better automation, even when there are changes to the model.

Martyn Day: Many of the large firms I talk with either want to automate their drawings or get rid of drawings completely. They see it as a great bottleneck, a drain on resources and a bottom-line cost.

Robert Gräbert: We want to give the users productivity tools so that they can create drawings efficiently. But if you have a motivated client that has enough volume, and wants to automate (drawing production) all the way, if that company decided exactly what their drawings look like, this type of document, to that level, you could go all the way.

We could automate a system that gives you a full drawing set every single night just for them; you can just do it on the cloud.

It could be done but it would not be very configurable. I think that is an interesting vision, especially for the top of the market. I see so many hours wasted, customers that have similar positions, that might have over 1,000 designers working on drawings every month.

If you just solve that and give very good productivity data, they know how much time they are spending on that problem. But if you solve this for one company, it might not be valuable for the industry.

I think there’s still tonnes of easy gains that have not been explored yet. I don’t want to take out the engineer or the architect from that equation. I still hear really dumb stuff that needs fixing, like the visibility of annotations. Those are really nice computer problems; what you put on the drawings and for what reasons, and that’s sort of the skill.

Martyn Day: In our recent interview with Keith Bentley, CTO of Bentley Systems predicted 2D drawings will be gone in twenty years (or at least the time spent creating them). Where are we now?

Robert Gräbert: I think we’re in the middle of this transition, where there’s still some drawings that are being produced in their own right. Architects still sit down and start to sketch something out, whether it’s a floor plan or something else. But I do think we are transitioning the point where the drawing documents the model. This is what Revit and the other tools have always done, with AutoCAD finessing 2D content and you create annotations.

I think what we are doing, especially with BIM stuff, we are saying you are still going to have drawings, you are still going to produce drawings, but you’re not going to start with a blank sheet. You’re going to start with a source model, and I think we have a chance of saying, not today, in two or three years, we’ll hopefully be able to produce something more productive than you have today.

Martyn Day: Firms that have been experimenting with mechanical CAD tools like Inventor, Fusion and Onshape have all been impressed with working at 1:1 and seeing the automated 2D output for manufacturing. But AEC drawings and mechanical drawings are not the same.

Robert Gräbert: First of all, obviously there’s more stakeholders in an AEC process. You might want a drawing for prefab, for construction or [applying for] permits. There’s all these different use cases where MCAD [mechanical CAD] drawings typically are designed for manufacturing, inspections, contracting – it’s much more focused. But if anyone thinks that all manufacturing drawings are automated, there will be no need for us to partner with PTC on the Onshape drawings, no need for integration, right? It is still a very important part of an MCAD product that you can create your own drawings.

Every IFC object has a GUID; every Revit object has its own handle; so if the model does change, the work you have invested in annotating a drawing or model is not wasted

You don’t start with a blank sheet. You start with a view into the model. And then you create derivative views like detail views, section views or whatnot. And then you annotate those and add additional documentation, inspection symbols, tolerances, etc. I guess, just going through that experience was the inspiration for what we’re doing with BIM.

The difference between what we’re doing today, versus what we did, maybe a couple of years ago, was that previously we could always bring in 2D geometry (or 3D geometry even) right. And you could always cut it, and you’d be fine. This is what we do with BIM drawings today. We get IFC content, we cut it, and then we get 2D and that’s fine. But now we are saying the source data is not just geometry, but now has added data. Then you can start doing interesting things. You can auto-swap-out the representations for doors, you auto-label all the rooms, add fireproofing information, add different materials, different shading or different symbols.

Brics [BricsCAD] has gone down this way [route] as well because this is where the productivity comes in, in mechanical CAD systems, as they know that the underlying model is not just a shape but shapes that are driven by features. So, for example, in Onshape, you can say ‘I’m going to document holes differently than other curves because I know there’s a hole feature and we know what a hole is.’

So, I think that’s the main point, we want to take the non-geometric (BIM) data, and inform the drawings, to enable automation. So one thing today, if you use our BIM drawings, we still make you put in your own sections. Users select the floors.

We actually know the original hierarchy of the BIM model from Revit, we know what floors, what wings of buildings you have. So, one of the things you’ll see very soon, as it’s not finished yet, is a button that says ‘create my ceiling grids and floor plans for every floor in the model’ because we know the extents of your model.’

Obviously, there will be some weird cases, like when we have a curtain wall, other things that span multiple floors, but I think we can guesstimate it. Now that you have the BIM data available, I think we can drive that automation as far as you want, right. Today, we spend a lot of time, building from the principles. For instance, we just added the ability for every multi component wall to autocreate all the things for all the rooms, for all the windows etc. We basically have tools that you just press a button and bam!

The final thing is, because we are capturing that original data about that object, we can also capture the unique identifier of those objects. Every IFC object has a GUID; every Revit object has its own handle; so if the model does change, the work you have invested in annotating a drawing or model is not wasted.

Firms try and delay the drawing phase as long as possible, because once you start doing the drawing, you know it’s really difficult to go back to the model and you can’t model everything. So by having access to the data, to drive the drawings, by having access to them, GUIDs, we can now keep BIM models and drawings in sync – or at least attempt to do so. It gives us a chance that the drawing, that investment, isn’t wasted.

ARES Windows and desktop

Gräbert undoubtedly has the strongest pan-platform DWG suite, which offers editing and drawing creation on desktop, cloud and mobile – pretty much anywhere you want. This goes up against Autodesk ‘AutoCAD anywhere’ offering which also has desktop, mobile version and an AutoCAD web application. The thing to note here is that the mobile versions do not match feature for feature the full desktop experience from any of the CAD developers.

Martyn Day. Why is there a difference in functionality?

Robert Gräbert: Some of it, I would say are organisational reasons. We have all sorts of interesting projects coming in and sometimes we don’t get to fill out all the last corners of what the desktop product has. It’s not because it’s technically hard. It is simply that sometimes I just have to pull resources away. And you know, the usage graph of CAD features on the desktop, it’s like the top 50 features are 95% of all usage. There are some features which we need to think about. For example, we recently introduced in the last two years, the sheet set manager. We have to think about issues like – if you don’t have a local file system, how do we map to that? And there are some things we just haven’t figured out yet.

We’re actually going to do some interesting things about collaborating around library management which doesn’t exist today. We’re balancing the idea of bringing in existing stuff, and also re-envisioning certain ideas that make sense in a cloud-enabled environment, both on desktop and the cloud.

There’s also some third-party dependencies we have, which we don’t want to bring over to the cloud product right now. You’ll notice we don’t have ACIS modelling today. Technically, we could offer it, but the demand has not been strong enough for us to bring ACIS to that port yet.

Cédric Desbordes: The kind of user that is interested in Ares Kudo (cloud) is not exactly the same kind of user who is interested in Ares Commander. The user that is working with Ares Kudo is more out of the office, or managing projects, or collaborating on projects, and this is not the kind of user who creates a drawing; they might modify them [instead]. They bring value by commenting, collaborating on the files. But they are not the kind of heavy user we see using Ares Commander.

Robert Gräbert: The common example is the construction manager, not the architect. We have companies now that are using Kudo only. They decide to only purchase a cloud product because they don’t want to deal with installing software, don’t want to manage licences. They just want this to work. And most of the use cases are to add a dimension or to create a PDF. That’s really all they want, in and out.

Cédric Desbordes: We have come exciting news to be announced on April 7 with regards to licensing that will mean customers can be much more flexible in what and how they use our tools. You can register now for the live event.

Martyn Day: Typically you have licensed your DWG technology to software firms and dialled back the promotion of your own brand of drawing tool. This now seems to be changing. Are you still committed to the component play?

Robert Gräbert: If you look at the types of partners we have, they’re on the desktop side. We still get the classic ‘I don’t want to work with AutoCAD anymore, can you help us run our application?’ It’s something that we still do and it’s a well-established business model for doing OEM.

The second type of business is, for example, a partnership in India, where we have the Indian Institute of Architects as a customer. They have their own brand; it’s basically white-labelling a product meant for that user group. So, it’s a targeted channel for us to sell.

Our third, and what I’m most excited about right now, is that we are getting tonnes of inbound inquiries for those that just want cloud CAD, right. For example, I am right now working on a very small project in Germany for fire proofing. Some companies decide they’re going to build a new fire proofing solution, and they need CAD components inside that allow you to draw rooms and place fire symbols. It’s super interesting, because these are all novel, projects, and that’s from both established and start-up companies.

Our challenge is how do we scale with that demand? I think, for us, the future is also being able to deal with smaller firms, as well as large. I think that’s one thing, for example, that Autodesk Forge does extremely well, or has shown that this sort of piecemeal embeddable component is a great opportunity.

We just don’t have that scale that Forge has; the one thing we do have is an embeddable AutoCAD-like experience in the browser. And that’s something that Autodesk does not offer. AutoCAD web doesn’t have the capabilities and it is not part of Forge.

Martyn Day: With the OEM model and now with a cloud version of Ares, how easy is it to port their AutoCAD applications to your cloud solution?

Robert Gräbert: When we talk to them, we try to understand how they built their AutoCAD app, what kind of third-party dependencies they have. Then we look at all the code that they have written to integrate with the CAD content to ensure it all works – the biggest issue being they might use some Windows libraries for dialogues and whatnot.

We have alternatives for that; some are easy, some are a little bit harder. For example, everything we build today, like this fireproofing project I mentioned, they don’t have the resources and don’t know anything about the cloud product. They have just been building it for the desktop right now. It was basically half a day’s effort to get it running in our cloud version. The commenting features we have developed, they’re all the same code base across all our different platform solutions.

Martyn Day: Gräbert is doing particularly well in Japan. Autodesk has even got rid of AutoCAD LT and dropped the price of full AutoCAD to LT pricing, the only place in the world. Who have been the movers and most interested in adding cloud?

Cédric Desbordes: Big construction groups. We’ve done a lot of promotion for Ares Trinity. Two of the five construction firms have worked with us for a long time and aided our research. This long-term effort promoting the Ares concept is now paying off. Also, the fact that Robert and his team are able to offer the level of service which OEMs, large accounts expect, as well as adapting to very specific local requirements.

When it comes to cloud, in terms of security, many firms want to deploy files in the cloud on mobile devices, but in a very secure way that the user can even never take a screenshot of on a mobile phone. We are really customising our products for large accounts and this is paying off in Japan and Korea, where there is this logic of very large companies [that] tend to dominate the tools used in a market.

Robert Gräbert: I agree with everything that Cedric said, but I would add that one of the other pieces that we’re really good at is local support. Customers can get really direct access into our product and quality teams. So, we’re not as far away. As a company, we’re not ‘the management’ separated from other parts of the company. Our structure is very flat.

Also, licencing is not to be underestimated. Some of these companies want to be able to run network floating licences, it’s just a model they’re very familiar with; they understand the cost structure. We are happy to support our customers with that. And so, yes, we might want to move them to a ‘cloudy future’. But only when they’re ready.

Martyn Day: How did COVID hit Gräbert’s operations?

Robert Gräbert: I have to be completely honest, I think we were hit like everybody else. The initial phases of COVID, where people [were] just unsure what’s going to happen, we saw a slump. We just couldn’t reach people or get a demo done! But we always saw at the end of each year, that we were able to catch up because the overall demand is so high, and people needed to figure how to react to the amount of pressure Autodesk was applying to the market. That was helpful to us.

Ares Commander revenue, in every single market ended higher, and I don’t want to quantify but it’s, of course, on a nice trajectory!