Following the 2022 launch of SitePrint, the plan printing robot, HP’s Construction Services Division is expanding its focus on software. Its new cloud platform offers enhanced collaboration, site reporting, and uses AI to automate the vectorisation of legacy construction drawings, writes Greg Corke

In construction, it’s easy to get swept up in the buzz around emerging technologies like robots, drones, reality capture, XR, and AI. Yet, despite these advancements, significant inefficiencies remain in everyday workflows – particularly in how the industry manages and collaborates on documents and drawings.

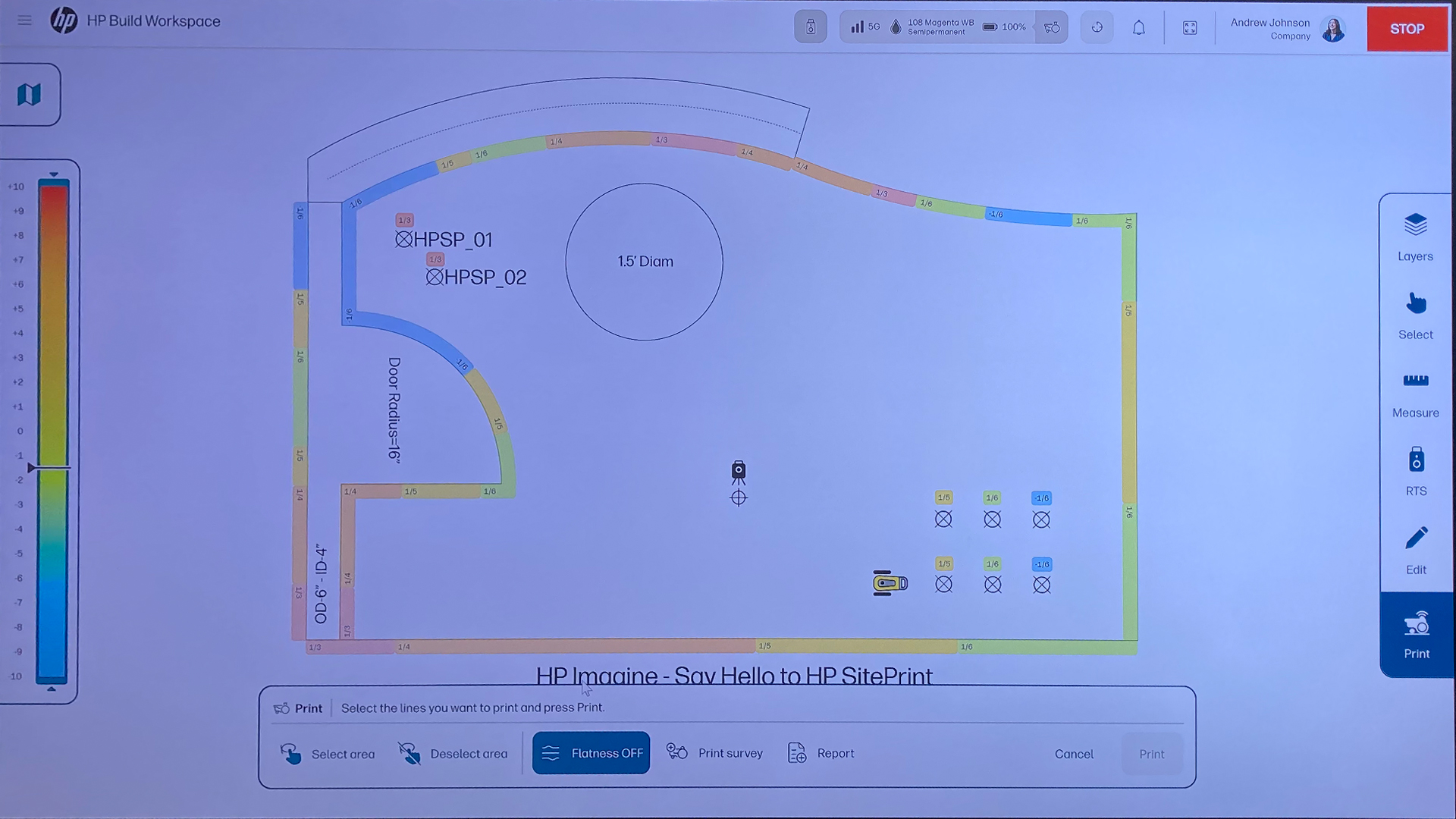

While established project management platforms like Procore and Autodesk Construction Cloud (ACC) offer more sophisticated solutions, HP sees a gap in the market for a simpler, more cost-effective alternative. Enter HP Build Workspace, a new cloud-based platform developed by HP’s Construction Services Division in Barcelona, which works closely with the company’s DesignJet large-format printing team.

“We identified that there were a lot of people that just weren’t using those tools [Procore, ACC] precisely for those reasons [cost, complexity], and therefore there was an opportunity to really simplify the process,” explains Daniel Martínez, global head and general manager, HP large format.

HP Build Workspace aims to tackle a range of common pain points in construction, from managing and distributing drawings to documenting site visits, generating site reports, and converting legacy drawings into editable vector CAD files.

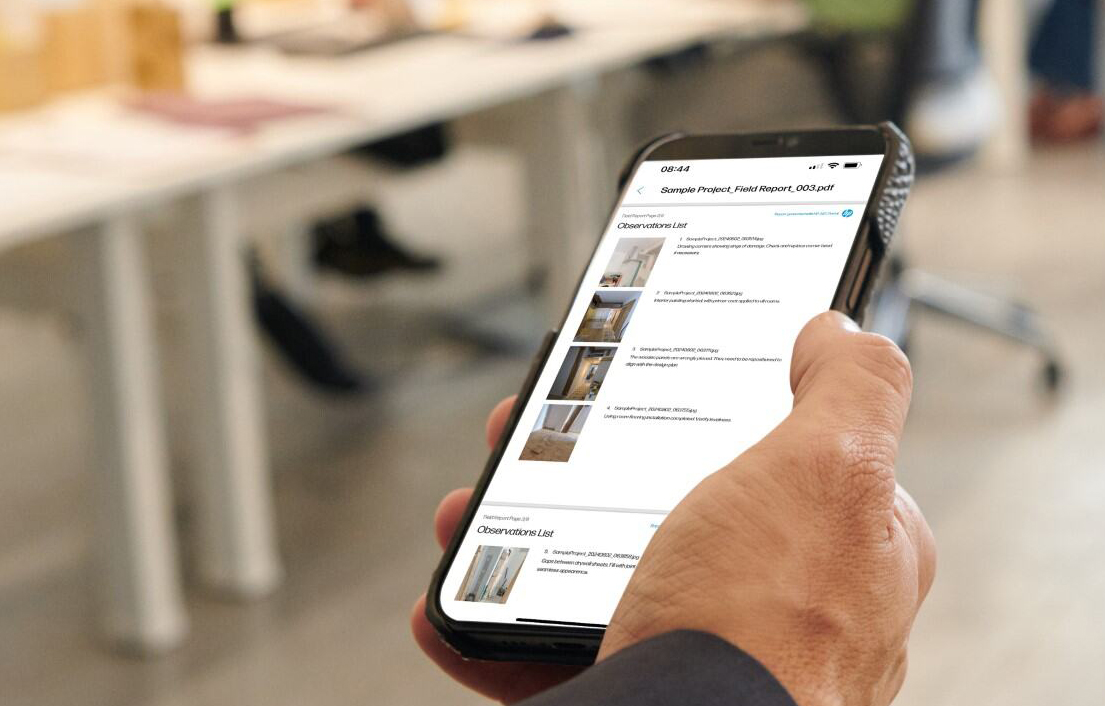

The team behind HP Build Workspace spent several months embedded at construction sites to better understand workflows and pinpoint areas for improvement. One key observation was the time-consuming and fragmented way site conditions and issues were documented and communicated, as Martinez explains, “[They are] basically taking photos on their phone, going back to their office, downloading the photos onto their desktop and sorting them out. They’re then spending hours preparing the reports.”

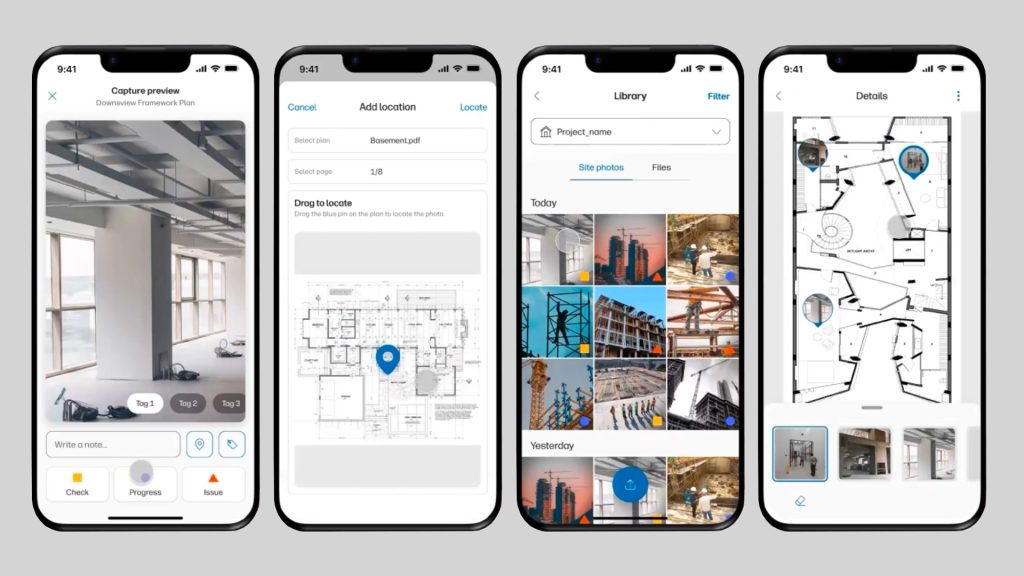

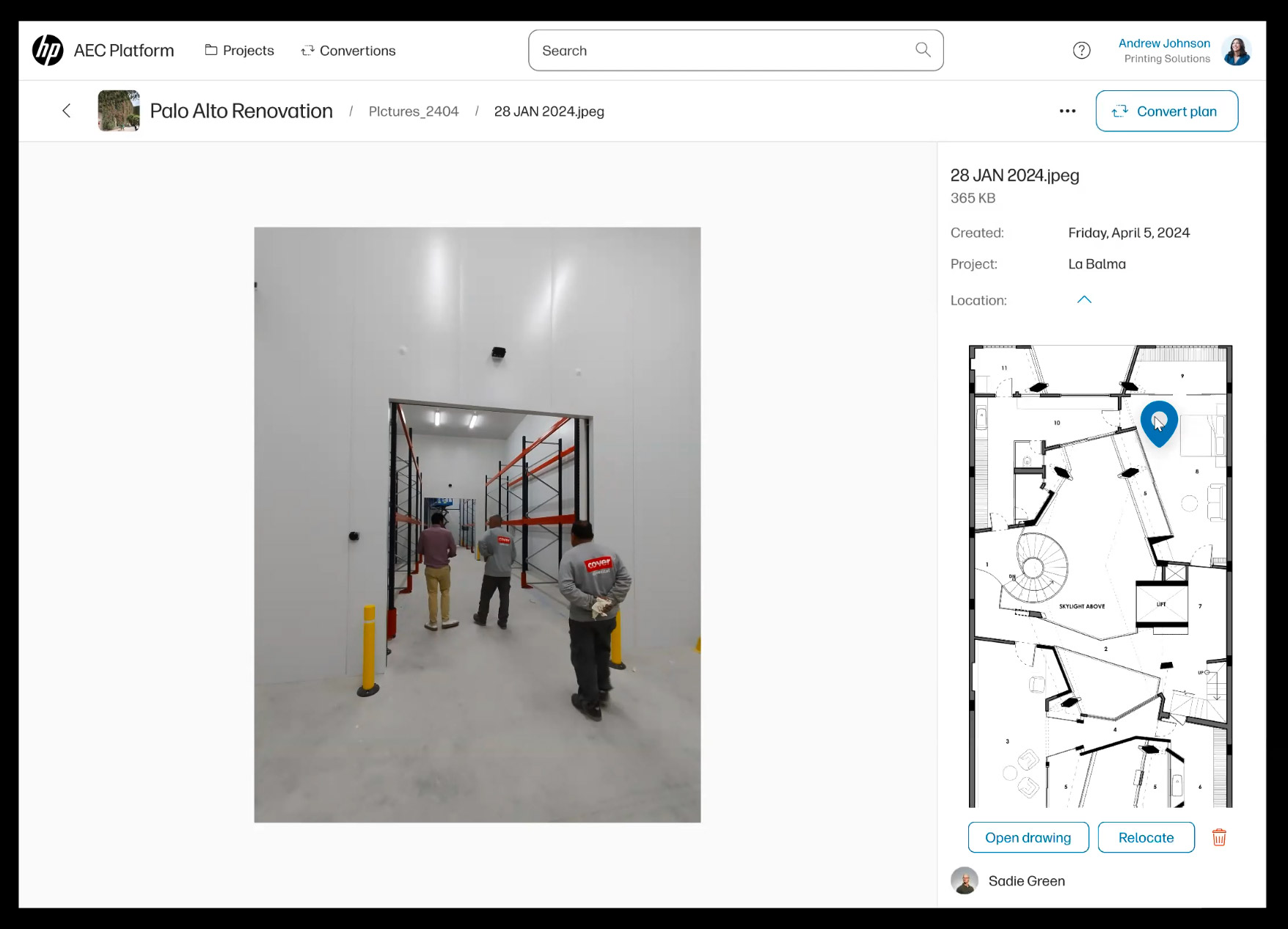

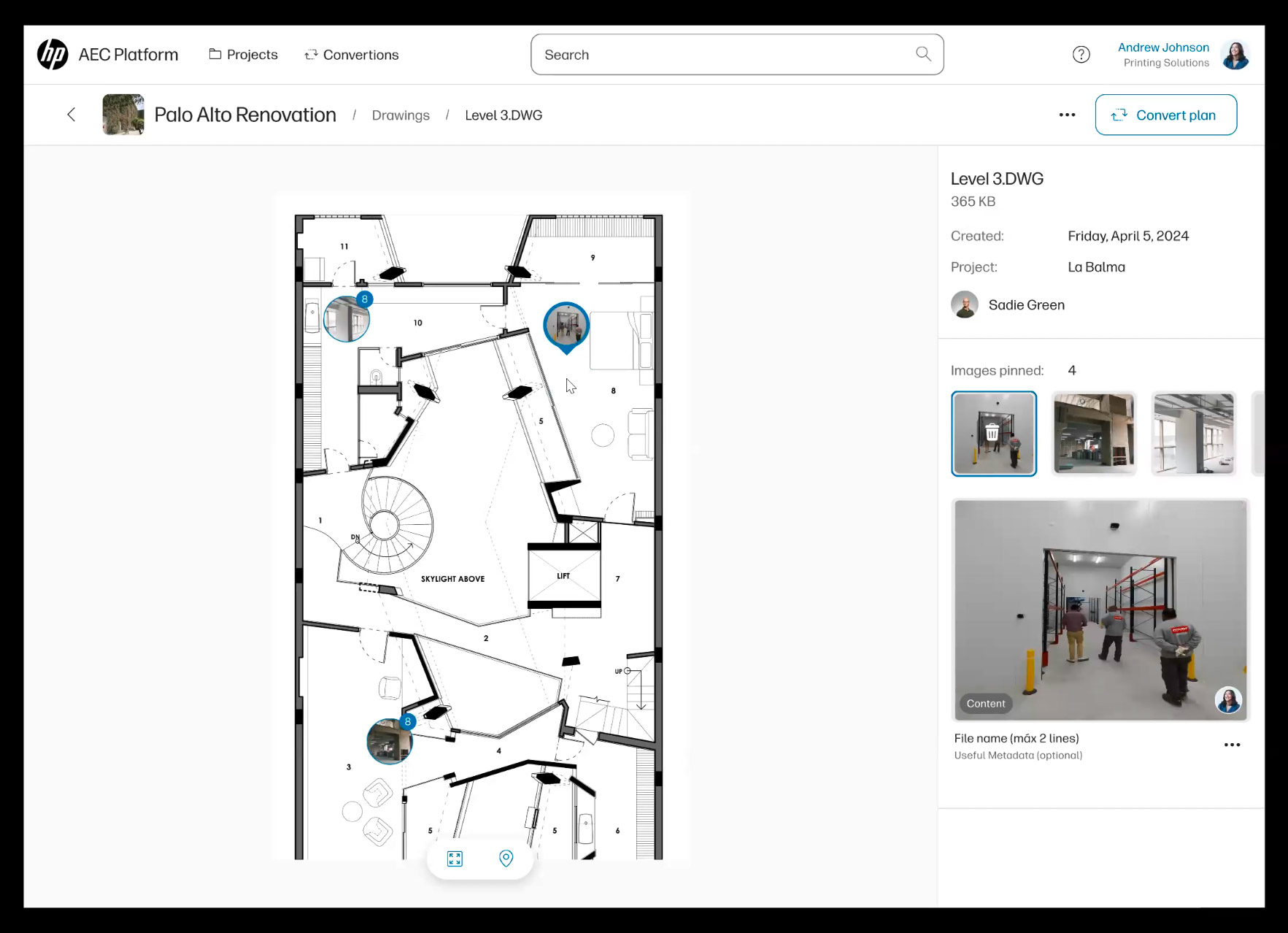

With HP Build Workspace, photos taken on-site can be immediately linked to specific locations on floorplans through an iOS or Android mobile app, significantly simplifying documentation. Observations can be categorised, augmented with text or voice notes and then automatically fed into reports that can be shared easily with other project members.

HP Build Workspace provides a centralised hub for document management, enabling teams to access files / drawings from anywhere. Everything is managed through the cloud platform, ensuring a single source of truth and providing an audit trail. In contrast to relying on isolated communications via WhatsApp or email, all stakeholders are directed to the platform via a link. In the future, HP Build Workspace will also be able to sync to cloud storage services including Google Drive, Dropbox and OneDrive.

A new life for legacy drawings

Perhaps one of the most innovative aspects of HP Build Workspace is its ability to convert legacy construction drawings into CAD-editable vector files with much higher accuracy than before.

“It’s a big pain point today,” explains Martinez, adding that most companies ship their PDF or scan files overseas, or hire drafters locally. “It’s a very expensive process, very time consuming,” he says.

“We scan millions of drawings a year, and [automatic conversion] is a service that our customers have been asking for, for years. We just hadn’t necessarily focused on it or felt that we had the right technology to address it the way that we felt that it should be addressed,” explains Martinez.

The technology that Martinez is referring to is, of course is AI, specifically machine learning (ML).

HP has been refining the AI behind this capability for over three years, using a combination of real-world customer data and synthetic files to train its models. The system applies a combination of AI models – some remove noise from the initial image, others separate different elements into layers.

“We have very high accuracy on certain types of CAD files,” says Martinez. “Imagine old archive drawings that have a lot of image noise in them, or are not very, very clear as you get them scanned, we can apply ML to get a higher level of accuracy than anything existing on the market today and the more people that use it, the more accurate it gets.”

The system can detect lines, polylines, arcs, and text. Once text has been extracted and indexed, users can search on that data. Outside of HP, there are several AI systems currently in development that enable firms to use Large Language Models (LLMs) to make sense of and recognise patterns within large sets of unstructured data. It’s hard to imagine that HP isn’t planning something similar with the data extracted from drawings, such as title blocks, notes and dimensions.

The conversion service comes with a simple editor. Here users can change lines that were incorrectly converted from dashed into solid, connect lines that should have been snapped together, as well as clean, remove or add elements. This isn’t just to improve the quality of individual documents – all this information gets fed back into the system to improve the AI. “The customer can define if it’s accurate enough for them, and we get real time feedback from that,” says Martinez.

Customers get to choose to opt-in or not, but as Martinez explains, HP only looks at the process. “The fact that you’re sharing the files for ML doesn’t mean that we have access to the content in any way, shape or form,” he says.

By tracking conversions, HP can understand what percentage of files have been accepted by the customer and, as new versions of the training model are released, if it’s improving or not. Martinez admits there have been cases when the success rate went down. “We’ve then been able to course-correct and eliminate whatever it was in the system that was affecting the quality of the output,” he says.

The big question is: will things ever get to a stage where the end user doesn’t have to check for accuracy? Martinez responds, “PDF files that were converting back into vector that have that vector layer information embedded? Yeah, we’re very close to 100%. If it’s a very old drawing that’s done by hand, the success rate is obviously much lower than if it’s a very clear line drawing that we can convert quite easily.

Physically connected to site

HP Build Workspace also integrates seamlessly with HP SitePrint, the three-wheeled robot that prints 2D plans directly onto construction site floors, with a view to replacing slow, error-prone manual layout processes (read this AEC Magazine article).

The aim is to enable general contractors, specialist contractors, and construction management firms to quickly and accurately set out the locations of building components. This streamlines site preparation, ensuring everything’s ready for the various trades to come in.

Since its launch in 2022 there have been several improvements to the technology, including the recent addition of a Revit plug that allows SitePrint-ready plans to be exported from the popular BIM authoring tool.

The new HP SitePrint Value Pack 3.0, announced this month, is said to deliver a 30% boost in print efficiency compared to its predecessor, which had already introduced similar performance enhancements earlier this year.

Most of these improvements are around navigation – moving from A to B – which is how the robot spends much of its time. Previously, it did this at 0.4 m/sec, but now it’s nearly doubled to 0.7 m/sec. Meanwhile, the print speed has seen a slight increase, from 0.33 m/sec to 0.35 m/sec.

HP Smart Navigation gives the robot a new integrated front-facing camera which creates a 3D representation of the robot’s surroundings, allowing it to detect unmapped obstacles on the job site and intelligently adjust its navigation route in real-time.

HP SitePrint Value Pack 3.0 also introduces shadowing, a new feature designed to prevent the robot from navigating into areas where it might lose line of sight with the robotic total station.

HP is also turning the robot printer into a device that can be used for reality capture. It is working with HP SitePrint customers on a proof-of-concept to check surface flatness, to help ensure surfaces are ready for construction. And it can do this while printing. For example, it can measure the flatness of a drywall / partition track, and then print notes in reference to the corrections that need to be done when installing on site.

The HP Reality Capture Technology Flatness Check will be sold as a service for HP SitePrint through subscription and is due to launch in 2025.

Conclusion

When HP Build Workspace was announced last week, it raised a few eyebrows. Does the AEC industry really need another collaboration platform, and will HP be stepping on the toes of established players?

The reality is that many AEC firms still rely on manual workflows, and these are the companies HP is targeting. The goal is to streamline and automate familiar processes like document distribution, site reporting, and vector conversion—bringing efficiency to areas where it’s often lacking.

That said, there are some gaps in the current offering. For instance, there are no built-in drawing markup tools, and while users can annotate plans with notes and site photos, it would be even better if these were automatically geolocated.

Of course, there’s significant potential for future enhancements. Right now, the platform focuses largely on 2D workflows, but could it evolve to support BIM workflows? Instead of just a camera, could it use a smartphone’s LiDAR sensor to capture site conditions as 3D meshes? And could reality capture with SitePrint extend to basic construction verification?

While some competitors offer more advanced features like these, it seems likely that HP will stick to simplicity. After all, many AEC firms are still wrestling with getting the fundamentals right, and HP Build Workspace might just be what they need to bridge that gap.