As Bentley Systems continues to bang the digital twins drum, it may be missing an opportunity to engage with the wider AEC industry and help optimise their fragmented BIM workflows, writes Greg Corke

As regular readers of this magazine will know, Bentley Systems has bet the farm on digital twins. And for the last – couple of years, infrastructure digital twins have been at the heart of all of its messaging.

With its powerful iModelHub backbone, which focuses on change, and an open strategy which acknowledges that no single vendor could ever supply everything needed for a digital twin, Bentley is certainly making all the right noises.

However, while the company’s digital twin messaging may resonate with forward thinking infrastructure owners and the larger AEC firms, in its quest to establish itself as a digital twin technology leader, it has perhaps forgotten the importance of using language that will resonate more with the wider AEC industry – firms that simply continue to struggle with fragmented workflows.

The fact is, in the early stages of development, a Bentley ‘digital twin’, which it calls a ‘project digital twin’, is essentially a hub for the BIM process. It brings together data from a variety of cross disciplinary 3D tools – architecture, structural engineering, civil engineering and more – and other sources, into a federated model that resides in the cloud.

As the model evolves, new data can be streamed in, and every change that was made throughout every phase of the design process is tracked, giving insight into how it came to be.

This is not just from Bentley products, such as MicroStation, ContextCapture OpenRoads, and OpenBuildings Designer, but third-party products as well, including Autodesk Revit and AutoCAD Civil 3D.

The constantly evolving model can then be used to seamlessly feed other processes such as design review, planning and construction. In the most optimised workflows, manual file-based transfer is a thing of the past.

From desktop to cloud

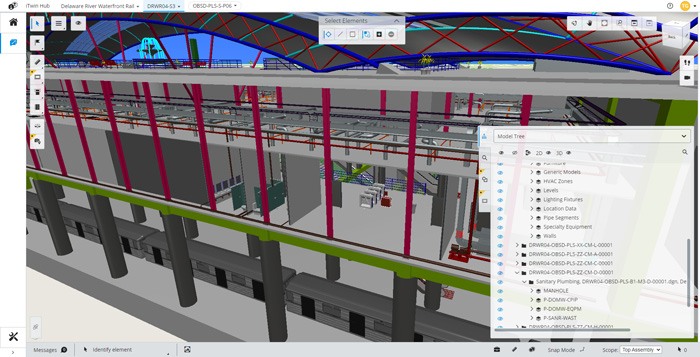

To get CAD, BIM or reality models into the Project Digital Twin, data can be streamed from desktop applications to the cloud, where everything is represented by a common data schema stored inside an iTwin (iTwin.js).

Most of Bentley’s desktop modelling and simulation tools are now ‘iTwin Enabled’, so models can be automatically synced to the cloud. Any subsequent changes made can be continuously ‘pushed’ to the iTwin to keep it up to date. And each time this happens, only the deltas are sent, not the entire model.

It’s not all one way traffic. MicroStation and Bentley’s open modelling applications can also consume and reference digital twin content, just as they can consume reality meshes produced by ContextCapture.

At the moment, syncing is largely a manual process, and even when it is automated, the end user will still have control. To keep the data flowing, users will be able to schedule when this happens or let the system choose, by detecting changes in the BIM model.

Once inside the iTwin, design changes are recorded in a timeline, providing an audit trail of who changed what, when, which is unique in the industry. Team members and project stakeholders can also view, validate, and analyse the data from any location using a web browser.

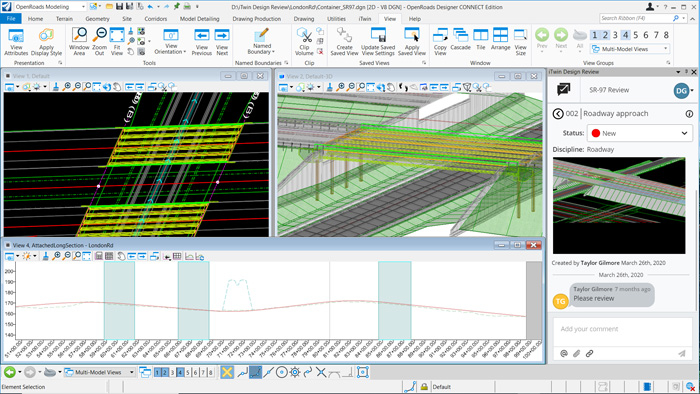

For team collaboration, Bentley offers iTwin Design Review, a browser-based 2D/3D design/review environment that provides tools for comments, clash detection and version comparison, as well as workflows to help resolve issues that can be assigned to individuals. For Bentley’s engineering simulation applications like Staad, there are design/review capabilities to measure quantities, areas, volume, geometry, and cost.

To explain how this might work in practice Raoul Karp, Bentley Systems VP of engineering simulation, gave an example of an engineer collaborating with an architect or a geotechnical engineer around an issue. “From their desktop product they can create a design/review session, create an iTwin, create a cloudbased collaboration session, invite the other attendees directly through inbox email notification, and then collaborate in the cloud directly.

“And what’s great about it, at the end of those sessions (and those sessions live in perpetuity until closed) you can actually go back into your desktop product and you can see the session issues directly in the desktop experience.

“You can start to see if there’s action items that are decided in the review session, and they can kind of pull that session back up directly and then see what actions need to be taken.”

Not all Bentley desktop products have this level of integration yet and, at the moment, the focus is very much on geometry and collaboration between disciplines. However, as capabilities build in the future, we could see iTwin Design Review extended to handle other data types, such as structural performance data, including deflections and stresses.

Of course, Bentley takes a pragmatic approach to collaboration and acknowledges that it’s not only data from Bentley tools that need to contribute to the iTwin. With the iTwin Synchronizer, models can also be fed in from third party applications, including Autodesk Revit and AutoCAD Civil 3D.

Data propagation

The beauty of an iTwin, is once the data is in the cloud, it can be used to feed other workflows. A good example here is campus and city planning, enabled through Bentley OpenCities Planner, a web-based tool that combines GIS, reality, and BIM data to create 3D city-scale digital twins for collaboration and public consultation.

To bring in 3D CAD models, OpenCities Planner used to rely solely on file-based workflows. This was a manual process and did not include metadata. If metadata was then added in OpenCities Planner, but the design subsequently evolved and an updated 3D CAD model was reimported, then everything had to be redone. Now that the software is ‘iTwin Enabled’ data can stream in direct from an iTwin, enabling architects and engineers to seamlessly bring in their BIM models to give them a city context.

A great example of this technology in use is the City of Dublin, which adopted the web-based tool to carry out public consultation on a project in the Docklands area. Due to Covid-19, the traditional Town Hall engagement model of gathering people together to view development plans was not possible, so Dublin went digital. Not only did it solve the problem, but it managed to get an incredible 160,000 views of the project, with feedback gathered digitally via polls and comments.

From design to construction

iTwins have also enabled Bentley to dramatically improve the flow of data from design to construction. Synchro, Bentley’s construction management software, was recently ‘iTwin enabled’ to not only allow ‘as-designed’ BIM models to be brought in more easily, but for 4D models and fully detailed schedule simulations with animation and sequencing to be viewed entirely in a web browser.

Like OpenCities Planner, Synchro previously had to rely solely on file-based import, as Mark Hattersley, Bentley Systems senior director, construction operations, explains. “Within the Synchro Pro session, rather than saying, ‘I’m going to open from my [desktop Synchro] .SP file’ I simply connect to my Synchro project, which is managed in the cloud, and I stream that BIM data in.

“One of the great benefits here is, because it’s in the cloud, we can now take it onto our Synchro Control Web app, so we have a web view of the of the 4D model, and we also can take it to our Synchro Field mobile app.”

If issues are identified on site, these can be logged in the Synchro Field mobile app. Then, if the project team decides it needs to go back to design, any changes made inside the 3D design tool can be automatically fed back through into Synchro via the iTwin.

The beauty of this workflow is the software can give the project manager insight about what has changed, as Hattersley explains. “That’s the magic of the iTwins database – [it] tracks every change. It’s what they call a change set, so it’s basically every difference that has been published, is recorded and so what we’re actually seeing is a collection of differences. And that allows you to roll back and roll forward and see [and compare] what it used to be, to what it is.”

“We actually show a report that lists those changes, but also visually shows the changes,” adds Rich Humphrey, Bentley Systems vice president construction. “So, you’ll see the model and it’ll highlight like a clash detection, that tells you ‘hey the geometry changed’. And that either impacts or doesn’t impact what you’re doing with the construction model,” adding that with this information the project manager can then decide the most appropriate action.

“You’re no longer really importing and exporting anymore, you’re just live streaming and live connected to the cloud. That’s a default for us,” concludes Humphrey.

Conclusion

It’s hard to fault Bentley for going hard after digital twins. It wants to be to infrastructure digital twins what Autodesk is to BIM, and with its technology and open strategy it certainly has a good chance of achieving this. But one can’t help but wonder if it’s missing a trick by not hammering home the message that it can simply help AEC firms that are still struggling with fragmented workflows.

In many ways, what Bentley is offering AEC firms is an optimised BIM workflow, built around a sophisticated Common Data Environment (CDE) that looks to eliminate traditional file-based workflows, with live streaming of data.

While Bentley customers might get it, there’s a huge number of AEC firms that could potentially benefit from iTwins, including those looking to better connect design with construction.

What’s more, by solving current challenges around data interoperability and data flow, AEC firms could be creating a digital twin without even knowing it. So, in the future, if the decision was made to add more value to an asset once in operation, by connecting real-time IoT data or using AI-based analytics, then the foundations have already been laid. And with seamless integration with Microsoft Azure Digital Twins, Azure IoT Hub and others, this doesn’t have to exist solely in the world of Bentley Systems.

However, while openness offers countless possibilities for customisation, it also brings potential complexity and a need for consultancy. Autodesk Tandem is the complete opposite; it’s a much simpler concept for architecture and construction firms, with the onus on them to seek out new business opportunities by repurposing their Revit BIM data to clients as a digital twin. The same can be said for TwinView.

If you enjoyed this article, subscribe to our email newsletter or print / PDF magazine for FREE