Innovate UK funded project to help drive down industry carbon emissions and meet Government’s green targets

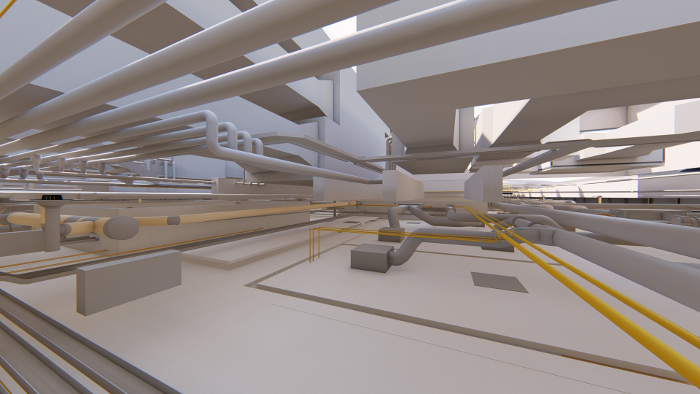

A cross-sector multidisciplinary research group in the UK is developing an embodied carbon analytics AI system that predicts the carbon output on building and infrastructure projects, based on BIM data, materials carbon data and lessons learnt on past projects.

The consortium, which comprises Winvic Construction, the University of the West of England (UWE Bristol), Edgetrix and Costain, has secured £800,000 of Innovate UK funding to deliver the ASPEC [AI System for Predicting Embodied Carbon in Construction] project over the next two years.

According to main contractor Winvic, while construction organisations continue to make advances in how they address both embodied and operational carbon emissions, current calculation methods for the former are onerous; with no design support calculation solution, there is no efficient way for design teams to proactively drive down the embodied carbon and carbon footprint of projects.

The ASPEC technology, adds Winvic, will therefore be crucial in propelling constructors and material manufacturing firms to meet the UK government target removing 10MT of carbon dioxide by 2030. Furthermore, a 50 per cent reduction in carbon emissions has been set through the Construction 2025 strategy and the target for 2050 is to bring all greenhouse gas emissions to net zero.

“Following the announcement of government targets paired with BREEAM sustainability requirements, construction organisations and clients have worked hard to reduce emissions, but the task certainly isn’t simple,” adds Tim Reeve, Winvic’s technical director and project lead. “That’s why we believe that utilising the most up-to-date AI and advanced big data analytics techniques in a way that has never been done before will be transformational for Winvic’s green agenda and pave the way for significant changes across the whole industry.

“Having the ability to optimise schemes and see embodied carbon costs as real-time design and material changes are applied will naturally lead to quantifiable reductions in greenhouse gas emissions, and having technology that automatically estimates the embodied carbon cost of any digitally designed project will make the delivery of many project tasks much faster.”

Winvic and its project partners will develop a Common Data Environment (CDE) to eradicate the challenges that arise from having multiple, siloed datasets. The huge amounts of data that are generated from different phases of construction projects will be documented and stored in one system; it is this data nucleus that will facilitate the machine learning technologies, providing industry professionals with the insights to make more eco-friendly decisions on materials used.

If you enjoyed this article, subscribe to our email newsletter or print / PDF magazine for FREE