Three professionals from global engineering, architecture, environmental and construction services firm GHD explain how they are embracing design automation and applying it to real world projects

Paul Murphy is GHD’s global technology and technical applications leader, focused on evolving GHD’s skills, tools, workflows and delivery models to adapt to changing trends.

Q: How is automation changing the design process?

A: It’s liberating to free our people from painful and repetitive tasks, and enable them to spend more time doing true ‘design work’, be creative and deliver a real benefit for the client and the community.

Essentially, any task that’s computable and rule or algorithm based can be automated. But our focus is on developing new workflows that can be applied on many different types of projects regardless of location and maximising their use across our organisation.

Q: Are new technologies making automation easier?

A: Our partnerships with technology providers are helping us automate some design tasks. For example, Dynamo is a visual programming platform for computational design and Building Information Modelling that extends the capabilities of Revit and other Autodesk software, without necessarily needing specialist programming skills.

While the technology makes it easier for us to use automation there is still considerable effort required from our teams to adapt these solutions to the tasks and requirements of our projects. This is where the passion of our people comes to the fore as they share experience around the world, learn from each other, develop new workflows and solutions and most importantly consider how these automations create value in our project delivery.

Q: Dynamo is a relatively new application for design automation. Do you or your team have any experience with other tools like Grasshopper for Rhino or Generative Components? And, if so, what are your experiences with those products?

A: We do use these as well as other tools. Without going into a product comparison, the reason we have invested so much time and effort with Dynamo in particular is because it offers a more scalable solution for automation thanks to its native integration with many of the core design applications in use across the company. We have also found it is easy for people to learn and this speeds up adoption. We have set up a global Dynamo Development Group to help our people share their experience and upskill as well as pushing commonly used scripts to users to aid wide-scale implementation.

Q: How do you decide which processes will benefit most from design automation?

A: We are focusing on processes that have broad applicability across multiple teams, locations and projects. If something is really painful for our people to do over and over for different clients around the world, chances are automating it will maximise the benefits across our entire company.

Q: What QC processes do you have in place to make sure results are as expected?

A: Our current use of Dynamo is focused on the automation of conventional design tasks and processes. We are using Dynamo in particular to automate the interaction between various design and analysis tools. This enables us to continue to use the underlying rule or algorithm in its native environment and validate the results before a broader adoption of the script.

Q: Has there been any cultural resistance within GHD to using design automation and how have you managed that?

A: Resistance is not something we have experienced. In fact, many of our people are learning Dynamo or Python and are starting to explore the new possibilities, asking, “What more could we be doing?”.

No one likes doing highly repetitive tasks. Once people see the value and time savings being created by the new way of working, they naturally gravitate to it. There is an immediate benefit in being able to redirect your time into other design activities that are more creative and personally fulfilling.

Q: What’s next for automation?

A: There has been a lot of discussion in the media recently about the potential for robots to take over many tasks currently undertaken by designers and engineers. I expect that we will soon be using ‘expert systems’, leveraging the power of machine learning and artificial intelligence to make better design decisions or to help manage the mass of data being generated and consumed across the project lifecycle. For some people this causes a fair degree of anxiety, but I believe this is going to be a largely positive change for our industry, because it means we can devote our time and attention to more productive or more creative activities.

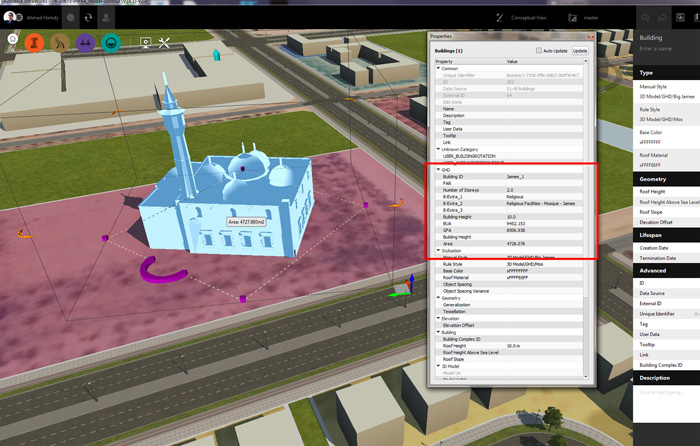

Rapidly testing ideas for cities of the future

Warwick Hatfull manages GHD’s Urban Planning & Design team in the United Arab Emirates, which delivers significant large scale urban developments.

When we work on a masterplan, we calculate a significant amount of interconnected data, from the gross floor area, built up area and gross leasable area to name a few. Automation enables us to rapidly test different spatial arrangements and concepts. We can easily change the width of a road or the size of a residential plot, increase a plot’s gross floor area and see what the implications are for the development as a whole.

Each time we make an adjustment, no matter if it’s large or small, our workflow automatically calculates and tabulates all the different statistics for the development, from how much land area is allocated to each type of land use, to the population and parking requirements for each use. Previously, completing all of these tasks manually was extremely time-consuming and was susceptible to human error.

This solution has been made possible thanks to the latest generation of design tools and our engagement with Autodesk under its enterprise business agreement. We have drawn on the support of Autodesk technical specialists to help share and reuse data between different products, such as Infraworks, Civil3D and Dynamo, and this has enabled the new masterplanning workflows.

Being able to automate these tasks is making a huge difference to efficiencies and timely delivery of projects. We can spend more time on what’s truly important: the design. This helps us meet client and community expectations, because we are able to create truly robust designed solutions that are environmentally, socially and economically viable.

Most importantly, optimising the design of new urban areas is improving the quality of the life for residents and employees.

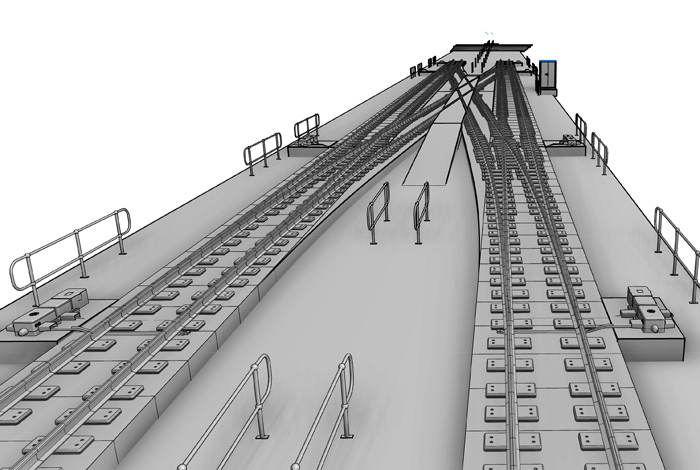

Streamlining workflows for major infrastructure

Daniel Moodie, BIM project lead in Western Australia, explains how GHD is using design automation to streamline workflows for major infrastructure projects We have used Dynamo and other Autodesk software to automate the development of an integrated model of the rail environment for a large infrastructure project.

For example, our workflow automatically generates rail track profiles, rail sleepers at desired intervals, kinematic envelopes and turnouts from 2D data.

Once the geometry is within a 3D environment we can check for clashes with other elements within the project, allowing for better coordination with other disciplines. We can also export 2D information, which is still required for some rail design and construction tasks.

The model is like a highly-realistic “digital twin” of this project. It helps designers, constructors and operators to better understand how different elements come together. We are better able to work together to solve design issues, improve construction sequencing and find operational efficiencies.

Traditionally, the design of rail projects has a very complex workflow, switching between different software. A lot of the design and documentation is still done in 2D.

When we decided to move our workflows into a BIM model based on Revit, we had to make a number of changes to get the transition right.

One of the first challenges we encountered was the lack of rail content for the model, such as tracks, sleepers, slabs, overhead wiring and electrified equipment. All of these had to be created from scratch – luckily I’ve had a lot of experience in content creation.

Another challenge was working out how to bring mostly 2D data from different sources, such as CAD drawings and custom software, into a BIM environment.

For example, we created custom Revit families and Dynamo scripts to replicate 2D symbols for chainage, curve positions and transitions between different track profiles in a 3D environment. We can now use them on other infrastructure projects.

If you enjoyed this article, subscribe to AEC Magazine for FREE