How structural BIM software helped streamline the modelling of the permanent and temporary works for the new stations for Luton Airport’s fully-automated light rail link

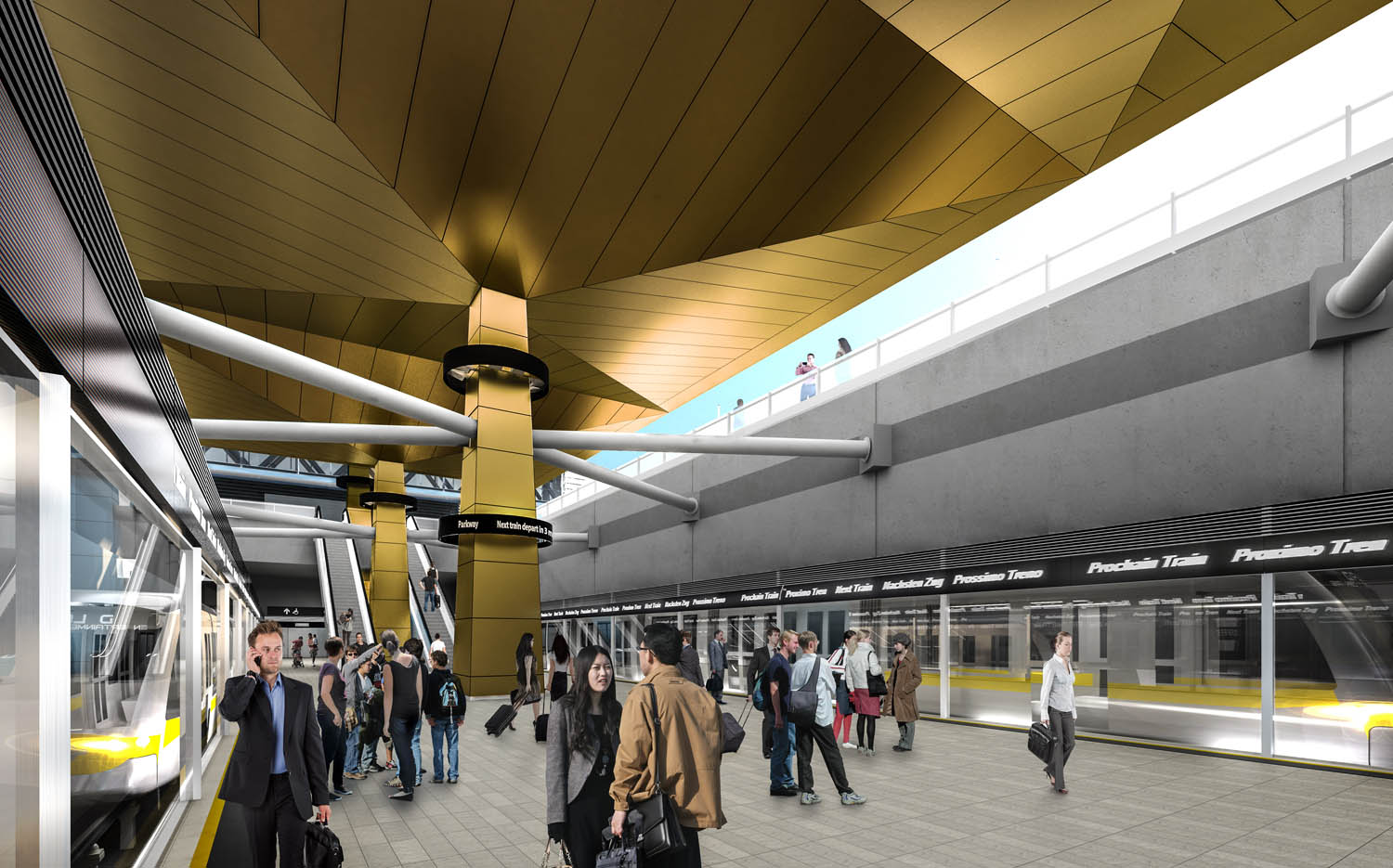

Designed to provide travellers with a speedier, greener and more efficient journey to the UK’s fifth busiest airport, the Luton DART marks a significant investment in the town’s civil infrastructure by Luton Council’s airport company London Luton Airport Ltd (LLAL).

The £243 million Luton DART is a new fully-automated light rail link, designed to transport travellers from the Luton Airport Parkway railway station to the terminal of London Luton Airport in well under four minutes. Currently, passengers making the journey use a shuttle bus service, which can be unreliable, especially in heavy traffic.

This project, being constructed by main contractors VolkerFitzpatrick-Kier joint venture and Doppelmayr, will solve that problem. The DART supports sustainable growth of the airport and employs an energy-efficient cable-pulled system.

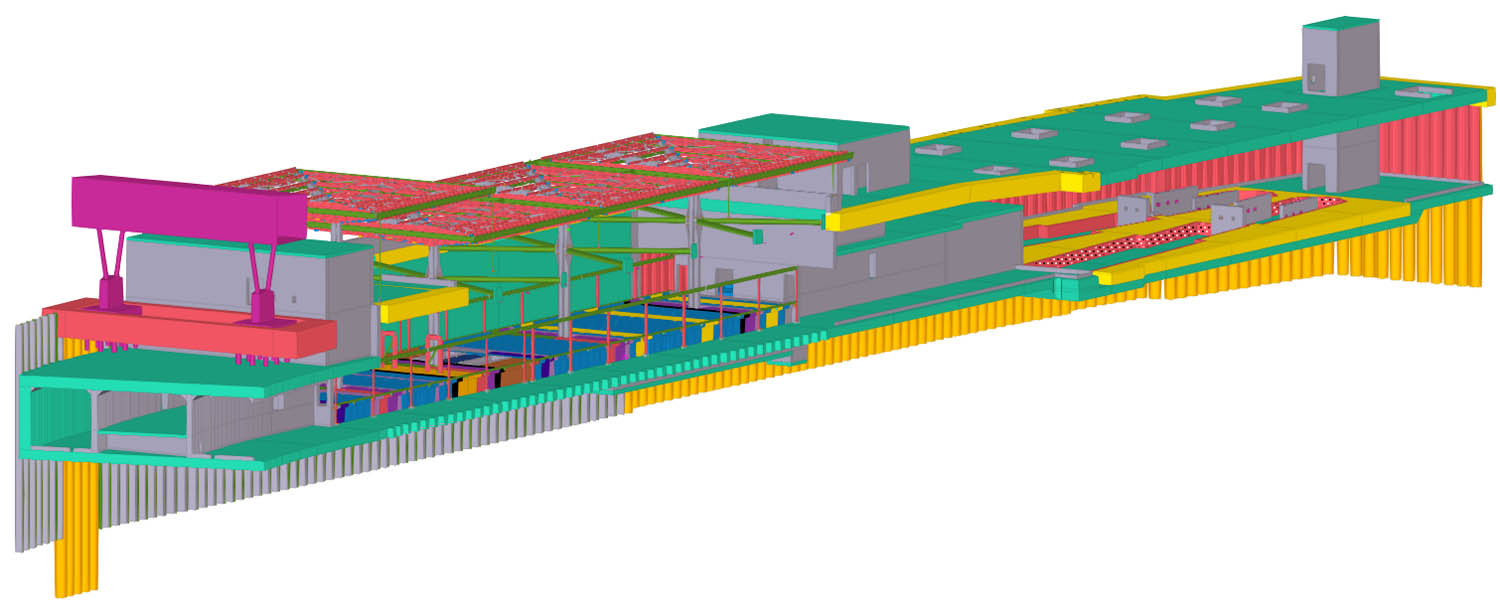

As part of the project, two new stations are being constructed. Parkway Station – designed to provide connectivity between the DART and mainline rail services, including a direct link to the existing railway station at high level – and the Central Terminal Station, located underground within the airport terminal.

Hewson Consulting Engineers was appointed as structural designers for the two new stations, tasked with modelling both permanent structures, including all concrete, reinforcement and steelwork, and some temporary works elements. Hewson worked closely with RPS, who were Architects for both stations, and with Tony Gee and Partners who were the overarching scheme-wide design lead. Prior to the detailed design phase, concept designs were developed for the client by Arup and Knight Architects.

Richard Scantlebury, director of major projects at Hewson Consulting Engineers, said, “As specialists in civil, structural and geotechnical, we’re perhaps best known in the industry for our bridge work, which, in turn, has recently translated into large-scale metro and station projects, such as Luton DART. We’re a technologically advanced company, enabling us to offer extra services to our contractor customers and deliver added value.

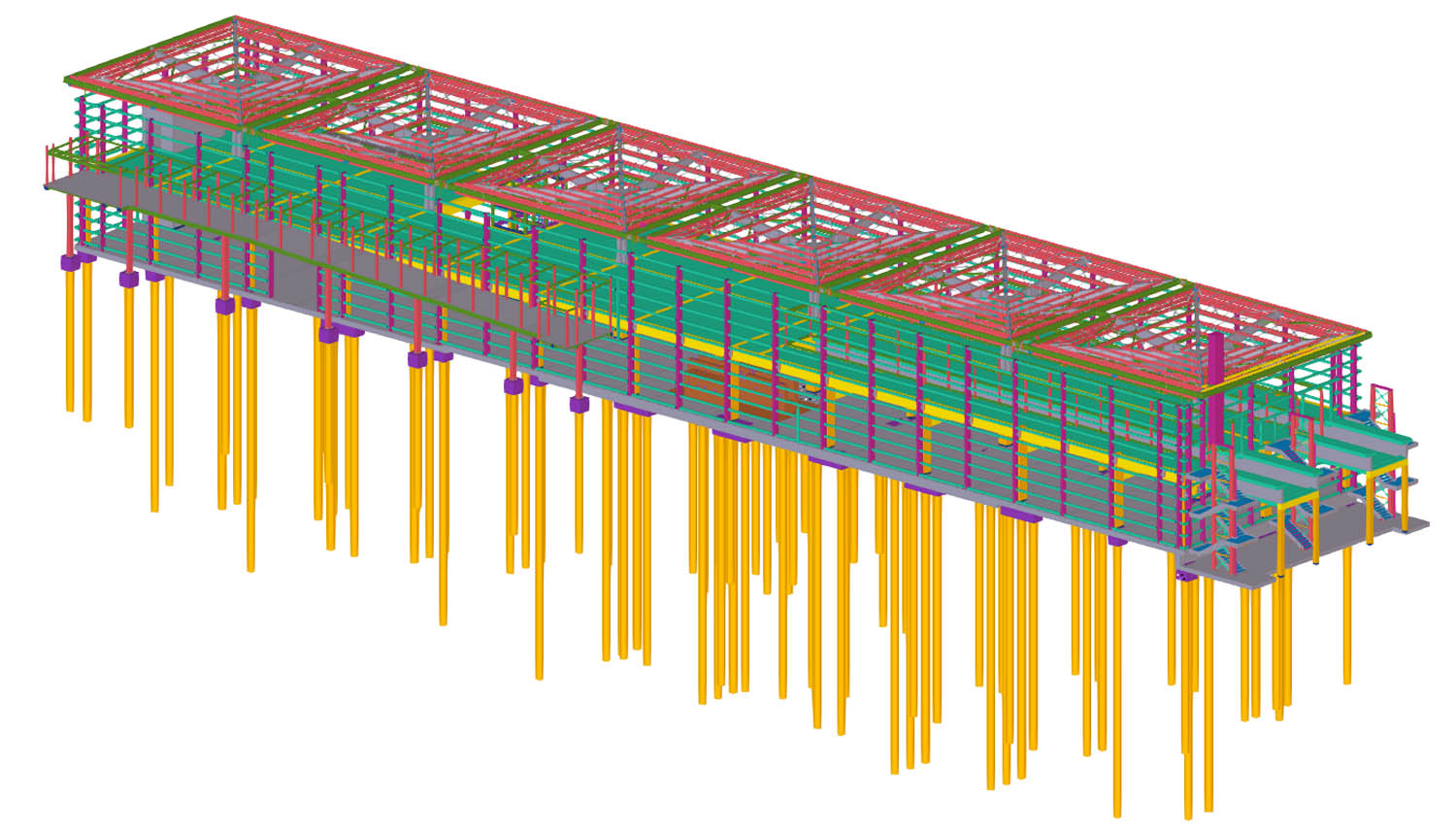

“Initially, we had searched for a long time to find the right BIM tools for the business, looking for a software that would bring value, as opposed to just ticking a ‘BIM box’. When we discovered Tekla Structures, it was just what we needed. The majority of our workload is design and build projects for contractors and Tekla Structures is ideal for this, able to be used for both permanent and temporary works. Luton DART is definitely one of the biggest projects we’ve worked on with BIM, with approximately 42,000 tonnes of structural concrete, 1,660 tonnes of structural steel and 2,400 tonnes of reinforcement to be modelled.”

Overcoming site constraints

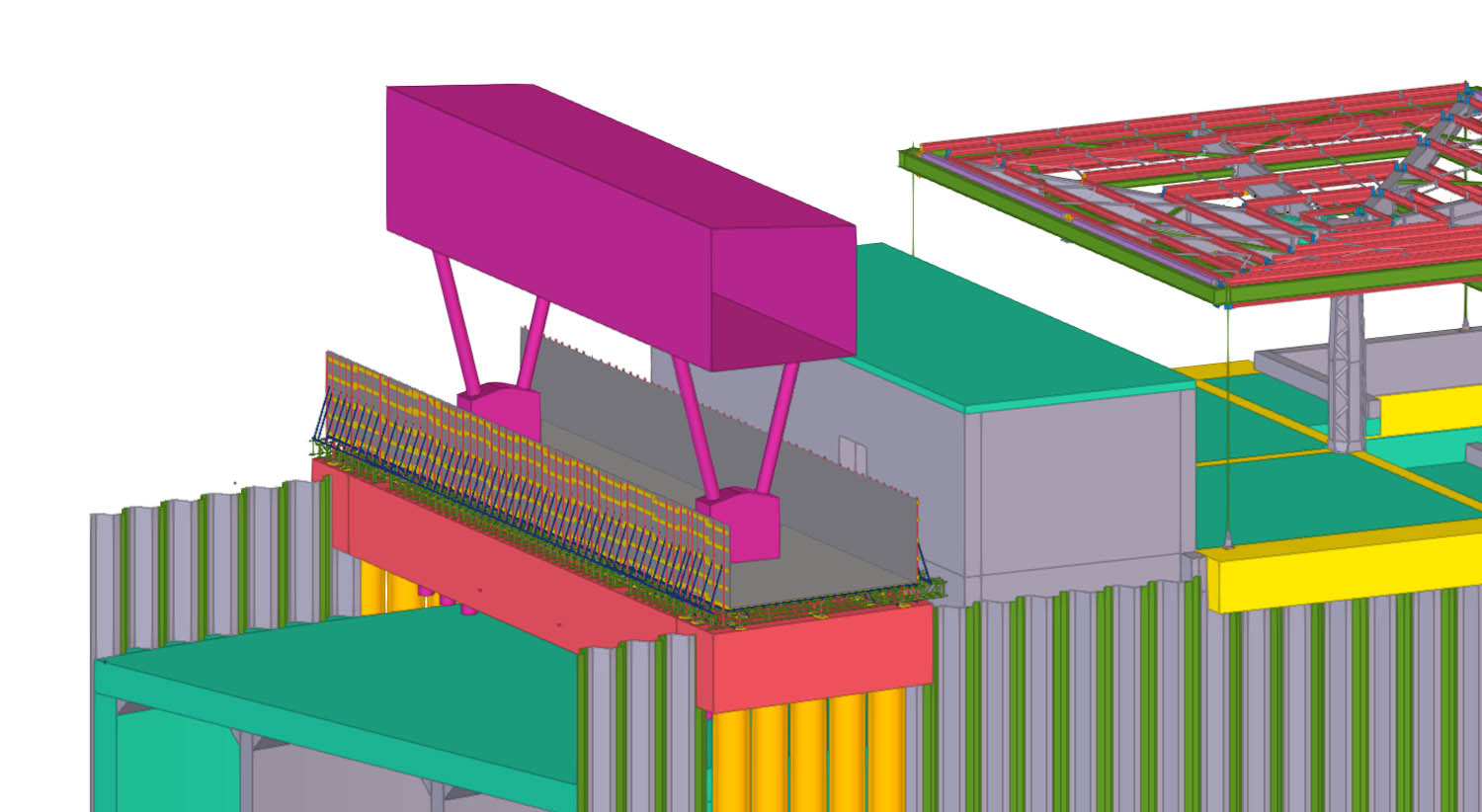

Unsurprisingly, a construction project of this size was not without its challenges, with Hewson Consulting Engineers presented with numerous site and space restrictions. Perhaps the biggest challenge in terms of corresponding the new with the existing was at the new Central Terminal Station. Directly above the footprint of the new station was an existing airport footbridge, connecting the terminal building to a multi-storey car park.

With the bridge’s piled foundations passing through the proposed new rail tunnels, a complex series of temporary and permanent works were required. The bridge’s intermediate piers were to be underpinned, piled foundations removed and a new load path constructed, before excavating the tunnel underneath.

Richard explained: “Through the use of Tekla Structures and BIM, we were able to incorporate the existing footbridge structure within our 3D model. This meant that we were able to then better visualise both the temporary and the permanent works in the context of the existing footbridge and its foundations, understanding how it would all work and interact together. When each element is so intertwined and dependent on the other, as was the case here, being able to detail and view it all within one single model was a huge help, aiding effective coordination and minimising the likelihood of clashes.

“Not only that but we were also able to use the 3D model to better plan and communicate the construction sequence, providing an assurance of design. This is one of the areas where BIM really stands to benefit complex projects such as this, providing us with a digital rehearsal and enabling us to plan out the works in a digital environment, before getting to site.”

Easing congestion

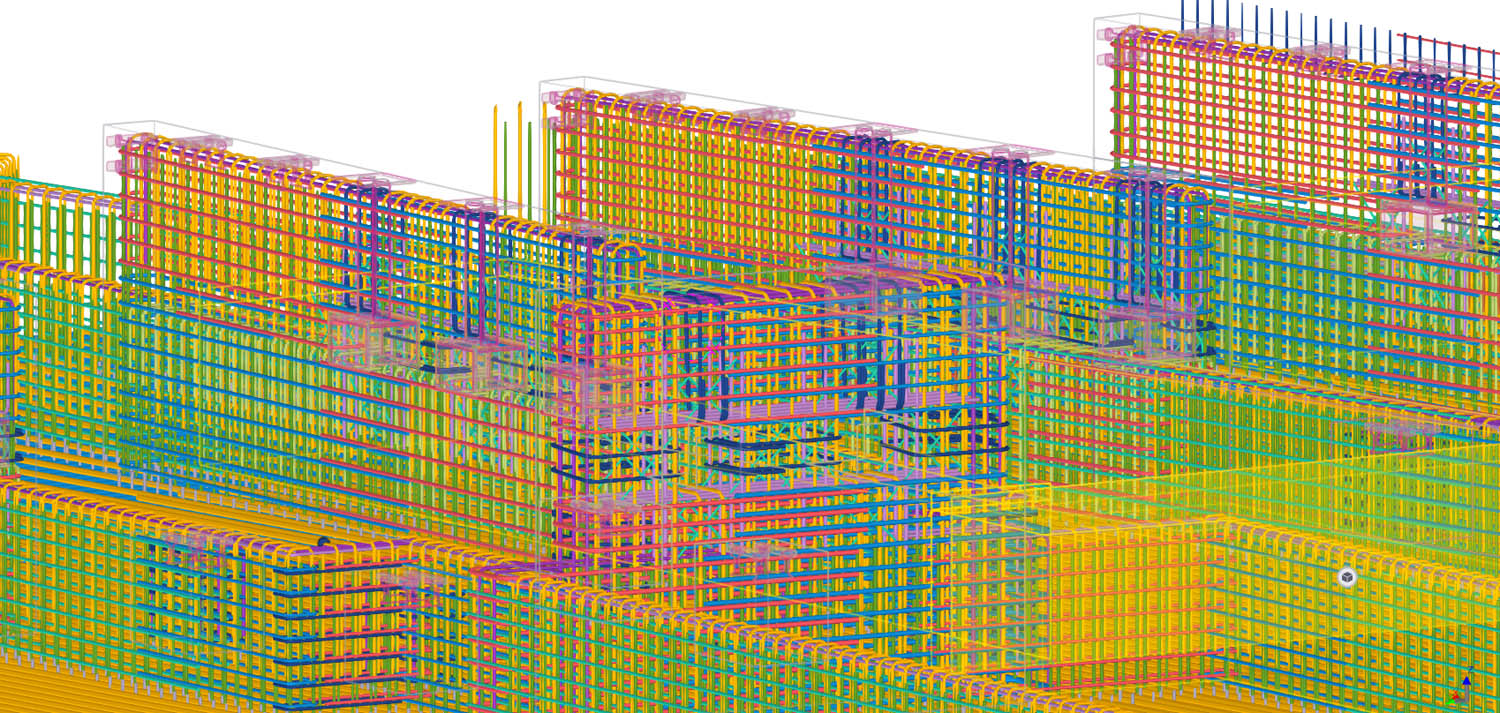

Another challenge that faced Hewson, again as a result of the size and complexity of the project, related to the complex concrete reinforcement required at the Central Terminal Station site.

Richard explained: “Congested areas of reinforcement can be a common problem, especially on large underground structures due to the increased loads and forces at work. Fortunately, through the use of BIM and reinforcement detailing within the Tekla model, we were able to easily and swiftly spot potentially congested areas of reinforcement early on in the project, as well as look at alternative design solutions where needed. If congested areas of rebar are not detected at the design office, the next time you would notice it or have the opportunity to rectify it would be on site, where, not only are you more limited in terms of alternative options, but costs can also rise exponentially.

“The use of BIM enables you to assess concrete reinforcement in a more visual way – can this be built? Is that rebar placement possible? Is it constructible? In many ways, it forces you to confront potential design issues head on, as you can physically see the structure in front of you in 3D.

“Interestingly, the contractors also noted that not a single bar bending schedule error occurred on the project – a direct result of the automation within BIM and serving to showcase the benefits of modelling rebar in a 3D digital environment. All dimensions are automatically generated from the Tekla model, as opposed to being manually calculated and listed, meaning less likelihood of human error.”

On UK projects using BIM, 3D reinforcement detailing is usually not a client requirement. However, given this consistent feedback across multiple successful projects, Hewson now propose it as standard since the benefits on site are so clear.

Clear communication

In addition to the high levels of detail, enhanced visibility and automation within Tekla Structures, another significant benefit of BIM is better communication. Especially beneficial on large construction projects, where there can be any great number of contractors and sub-contractors employed, effective communication and collaboration are key to a successful project delivery. As well as Tekla Structures, Tekla BIMsight (now Trimble Connect) and Tekla Model Sharing were also used by Hewson on the Luton DART project.

“The use of both Tekla Model Sharing and Tekla BIMsight on this project was a real gamechanger for us,” said Richard. “Through the 3D viewer, we were able to pull in all of the different models in the various formats and have it all available in one place, opening up communication between the different teams. By the end of the project, we had lots of people using the open collaboration tool on site, proving especially useful with regards rebar placement.

“However, it was perhaps Tekla Model Sharing that truly transformed the modelling process for us. At the start of the Luton DART project, we relied on dropbox to transfer and share zipped model files. However, not only was this an unnecessarily long process, it was also limiting in terms of who could work on the model. In effect, it hampered us – one person couldn’t go on and edit a drawing if, for example someone else was already working on the model. That’s why, a few months in to the project, we chose to introduce Tekla Model Sharing.

“We found it a really powerful addition, helping to facilitate a more collaborative and coordinated way of working – not only within our own team of engineers but also the wider project. At one point, we had six people working on the same model from three different companies, all seamlessly. Since introducing Tekla Model Sharing to the business, we’ve used it on a lot of other projects, all to the same degree of success. More recently, it’s also been a big help with remote working, offering us a far faster and efficient way of working, compared to accessing a model file via our remote servers.

“In terms of the Luton DART stations, it’s safe to say that the project would been far more challenging to deliver without Tekla Model Sharing, with the collaboration tool proving extremely helpful in our meeting the design deadlines.”

Scheduled to open to passengers in 2022, Hewson Consulting Engineers’ work on the London DART project resulted in it winning the Public Project category in the Tekla UK 2020 Awards.