In order to facilitate the use of advanced automated drilling on the Crossrail project, surveying company Plowman Craven came up with an innovative way to map out the work that lay ahead

At the heart of the Crossrail project lie 42km of tunnels, running east to west beneath the heart of London. The 6.2m wide tunnels are a feat of engineering, created from 26,250 concrete rings, each of which consists of eight discrete segments. That’s 210,000 individual pieces in total.

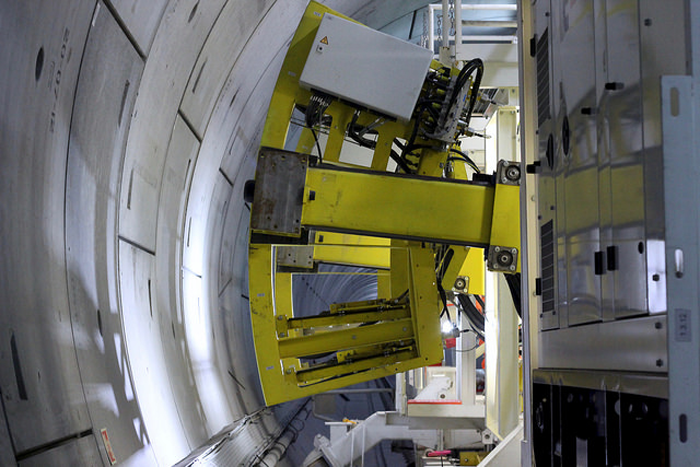

But there’s a vast difference between tunnels, however cleverly executed, and a fully operational railway system, which is where the ATC Joint Venture comes in. This is a consortium of three firms – Alstom, TSO and Costain – charged with fitting out and commissioning the Crossrail tunnels. One aspect of that work involves drilling around 250,000 holes to enable the installation of an emergency escape walkway, a cable management system, overhead power lines and all the necessary signalling and lighting. In a world-first, ATC is using an automated drilling machine developed by Swiss company, Rowa.

Leading chartered surveying company Plowman Craven is playing an important role here, working with the ATC joint venture to improve working practices and productivity on Europe’s largest infrastructure development project.

In order to programme the Rowa machine to drill the holes in precisely the right places – avoiding the segment corners and ring joints – an as-built survey was required to produce the necessary 3D CAD wireframe model and coordinate schedules. Plowman Craven Rail Team Operations Manager, Tom Wren, takes up the story:

“Scanning and surveying companies were invited to tender for the job, but because the drilling machine was new and no existing spatial data solution was in place, the challenges were myriad,” he says.

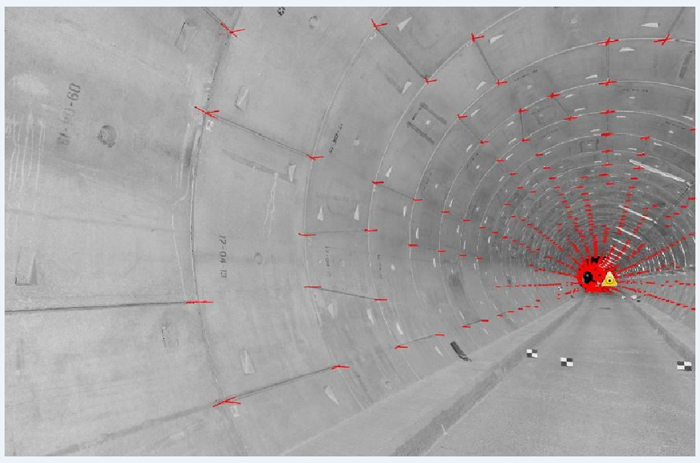

“With 42km of tunnels and 840,000 points to model, it was abundantly clear that deriving each segment corner position from the point cloud would be an incredibly complex and time-consuming process. There had to be a better way of doing it – we just needed to find it.”

Wren and his team set to work on a plan to speed up the CAD processes and enable these unique drilling machines to be deployed. In simple terms, the 3D point cloud was to be transformed and unwrapped into a 2D surface, enabling the CAD drafting to be undertaken far more quickly, before being re-wrapped back into the original 3D coordinate system.

That, at least, was the theory. To put it into practice, the team from Plowman Craven worked with Atlas Computers to add a number of bespoke routines to their Survey Control Centre software that would enable a more efficient method of rapidly producing the wireframe and coordinate schedule. The process was finessed to deliver optimum results – and after weeks of rigorous testing, the team was satisfied that this complex new process was robust enough to tender.

Providing proof points

The client was impressed with the solution and work began in Summer 2015. It was soon delivering even better results than had been anticipated. From the outset, 500m was being covered each day, representing a 50% improvement on previous techniques.

The human impact has been significant, too. In the past, the point-cloud data would be used to physically mark the position of every hole in the tunnel lining before it was manually drilled. Thanks to the automated drilling machines, underpinned by the new processes, human workers are no longer in physical contact with drilling tools. And as such, there’s none of the risk associated with vibration through the arms and hands; no danger from working at height; and using a highly advanced dust suppression system, the risk of inhalation for staff has been reduced by 99%.

“ATC’s decision to commission two drilling machines for the mechanical, electrical and power fit-out was substantially founded upon a conviction that surveying could be efficiently used to map out the tunnels and establish the guidance required,” says Jim Douglas, ATC chief surveyor.

“The subsequent partnership with Plowman Craven is delivering these requirements and has established best practices for the efficient scanning and modelling of bored tunnels for the purposes of drilling,” he continues.

Of particular note has been the development of this process that unwraps and projects the 3D tunnel into 2D CAD and allows simple and rapid extraction of the segment positions, he notes. “Drilling is now being undertaken at record rates, with unprecedented levels of quality control, thanks to the success of the drilling machine project.”

If you enjoyed this article, subscribe to AEC Magazine for FREE