The use of Robobat FE software at Structural Engineers evolve has enabled optimised design of laminated wood structures, writes Nick Lerner.

The aesthetic beauty of laminated wood is only part of its appeal. As the sole renewable construction material wood reduces building ownersÝ carbon footprints with the added bonus of enhanced design options. Because of its almost endless design possibilities an FE based 3D frame analysis programme is a must.

One Structural engineering consultancy that is pioneering the use of laminated wood in mainstream and alternative construction is Evolve of London and Glasgow.

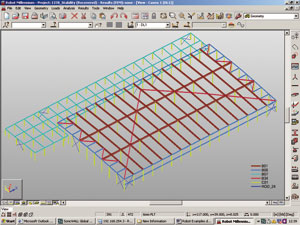

The company has been using Robot Millennium FE software from Robobat for six years and has recently been working on new-build retail stores and innovative structures in timber around the UK. Mark Sinclair, Associate at evolve, described how Robot Millennium is used in this application. ýOur work in this sector has been in conjunction with Tesco and other major retailers that are introducing measures to reduce their carbon footprint in new buildings by specifying laminated timber rather than steel in the building frame. Robot allows design and analysis of 3D frames to be created that incorporate different materials i.e. steel & timber and accommodates their properties. This optimises the use of materials and allows the substitution of steel members within the standard 18.0m x 12.0m grid for timber with the minimum of effort. Aside from the structural engineering data that the software produces, one of the significant advantages of using Robot has been the output of material quantity and specification report schedules that we pass on to our suppliers and others in the supply chain. These reports which would be time consuming to produce manually are generated automatically by the software as the design develops allowing us and other stakeholders to understand the cost and quantity implications of design variations at an early stage.¯

{mospagebreak}

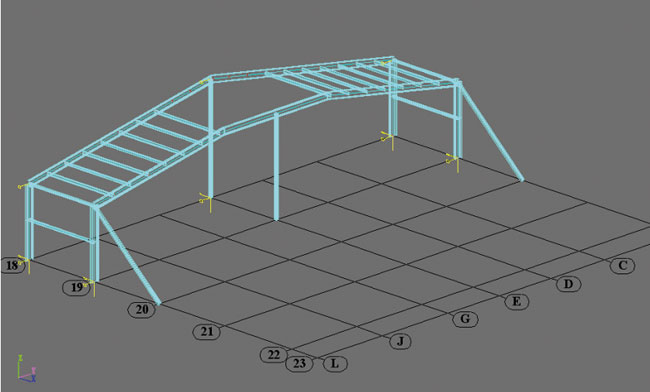

Using Robot Millennium, evolve designed the timber frame for TescoÝs eco-store in Wick, Scotland. This was the UKÝs first sustainable supermarket, following this they worked on the second in Shrewsbury, England, and are now designing other timber-framed projects around the country.

Branching out

Mark Sinclair continued, ýWe use Robot Millennium to calculate stability analysis for vertical and horizontal bracing, applying wind loads and other project specific loadings to the main structure and its component details. Having calculated the deflection of long span elements and designed their fixings, the automated quantity report scheduling is a real time saver that allows us to spend our time very productively. The software allows us to optimise designs speedily and produce solutions that use optimal amounts of material – no more and no less. Wood gives us many more fixing possibilities than steel and we have developed systems for temporary and removable fixing to make the construction process far simpler. For example, we can fix frame elements temporarily and put them in position before permanent fixings are used. Robot is used to calculate the extent to which this methodology is practicable, and also allows us to look at alternative design options within this technique.¯

The ability to optimise a design and its construction methodology often leads to more elegant solutions with greater visual appeal to shoppers as well as a positive impact on the ownersÝ carbon footprint.

{mospagebreak}

Leaves the past behind

It is likely that as more companies realise the environmental benefits of laminated wood in their buildings the market will adapt to meet demand. evolve plans to capitalise on this trend and has been working to secure its already strong position by exploring the potential of optimising designs with Robot Millennium.

Mark Sinclair explained, ýWhile the design of a supermarket to a pre-existing grid plan presents several technical design and methodology challenges, the creative design element is relatively straightforward. This is not the case with other projects where innovative design is at a premium and new ways must be found to ensure structural integrity.

ýBecause laminated wood is easy to shape and bespoke cross-sections are easy to fabricate, the achievable design possibilities are endless. One of the advantages of designing for this material using Robot is knowing, in real-time, whether a design will work in practice while having a fully reported understanding of the cost implications of design modifications. ýWe can import 3D models into Robot from other CAD systems, such as such as AutoCAD, Digital Project, or MicroStation, or produce designs using the systemÝs own modeller. Either way, we are assured that the software verifies our design options and choices for final construction in the knowledge that they cannot be bettered from a technical standpoint.¯

Seeds of change

A recent project for FinnforestMerk, designed in conjunction with Alsop Architects, involved evolve producing finished designs for an exhibition stand using LVL Timber Wall. Taking an original Alsop design and adapting it for construction without any loss of design intent was crucial for this industry showpiece. It was important to retain the dramatic double waveform while ensuring full structural integrity and material optimisation. Since the project was produced to the tightest of deadlines evolve took a copy of Robot software on site to the exhibition and ran Frame Analysis calculations on a laptop computer as the waves were built. Throughout this process new calculations were made and appropriate modifications developed for the construction.

evolve has certainly not left steel & concrete behind and uses Robot Millennium every day in its structural design work for a range of projects. The company has recently worked on steel designs for Gatwick Airport and T5, Tottenham Hale Retail Park and concrete structures at Thomas CubittÝs former works, Grovesnor Dock in Chelsea. ýBut¯ says Mark Sinclair ý While traditional steel and concrete construction forms the majority of our work, the use of laminated wood is fast growing, not just in retail, but also in other commercial and domestic construction. Laminated wood offers so many design options that it effectively gives a new palette to designers. As seen in our supermarket projects it makes a very interesting alternative to steel and in other applications the design freedom and restraints that it presents are very exciting. There is no stopping a fashion once it gets started and laminated wood is very much in vogue right now.

ýSince a great deal of the appeal of laminated wood is the reduction of carbon usage that it offers, it makes sense to optimise its design and so generate further savings through efficient use of resources. Our use of RobobatÝs Robot Millennium in the design process allows us to reduce material quantities by optimisation, develop new construction techniques that save both labour and energy, and keep track of costs throughout. When these factors are added to the ease of producing verified designs that are right first time, the appeal of using Robot Millennium, as we do, is significant.¯