This Autumn, CADS unveiled Version 6.1 of its AutoCAD-based steel fabrication solution, AdvanceSteel. The new release adds greater depth to its modelling and connection tools, and aligns the product more closely with complementary structural software solutions.

Product: AdvanceSteel 6.1

Supplier: CADS

Guide price: ú3,995

Over the past few years the steel fabrication software market has become an interesting place. Long terms market leaders, AceCad (developer of StruCad) and Tekla (developer of Xsteel) have faced competition from new areas. Products like Catia and more recently SolidWorks, which are better known for designing consumer products, cars and widgets, have offered steel fabricators an interesting proposition due to their ability to model highly complex steel forms. At the same time, Dorset-based CADS, has been offering steel fabricators a lower-cost solution in the form of its AutoCAD-based, Advance Steel.

AEC magazine has been tracking AdvanceSteel since its entry into the UK market circa 2000. Back then it was known as Hyper Steel, and over the years has gone through an extensive UK localisation and customisation programme which cumulated in CADS unveiling AdvanceSteel, 6.1 this Autumn.

Back to basics

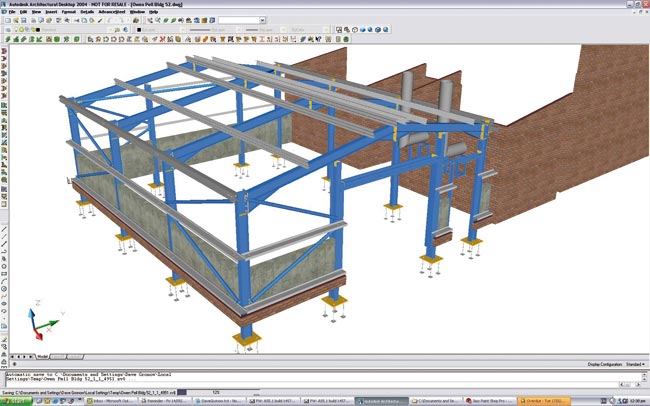

For those not familiar with the product, AdvanceSteel is a 3D steel modelling package that runs inside AutoCAD. It provides a set of intelligent structural modelling tools for hot rolled and cold rolled steel to build a master model, which can then be used to automatically create detailed construction drawings (General Arrangement and Shop details), lists/bills of quantities and NC (Numeric Control) files for automated workshop machinery. AdvanceSteel also provides a range of parametric macros for modelling all commonly used joint types.

Built on AutoCAD’s Object ARX technology, elements within AdvanceSteel’s building model are intelligent objects. This means that every beam column, plate and bolt knows how to interact with each other, and should an alteration be made to any one of these components, then the changes can be propagated throughout the design, right down to individual connections, bills of materials, and fabrication drawings.

The product comes with a comprehensive library of hot and cold rolled sections. Standard UK, European, and American hot rolled sections profiles are all included and compound and custom sections can be created as required. AdvanceSteel also has close links with Ayrshire, which provides an extensive library of cold rolled building products, automatic connection macros and CAM data production.

Highlights of version 6.1

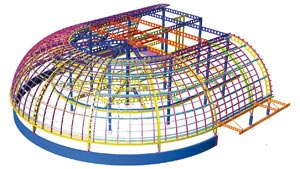

Modelling: A new curved grid has been added, which is ideal for circular buildings, or those contained on a curved suite. You can now create a 3D folded plate of any shape, simply by joining different plates together. Version 6.1 also introduces a new copy tool, which is designed to make it easy to perform multiple copies.

Of particular interest to those that import DWGs and DXF from other sources, AdvanceSteel can now automatically convert AutoCAD lines to Advance beams and AutoCAD arcs to Advance curved beams. This feature also applies to 2D and 3D polylines.

Welded beams, including column, hollow, I Asymmetric, I Symmetric, and T, have been given additional functionality including the ability to configure the welds between the different elements and save out to a library. In previous releases these weren’t intelligent, and were essentially a collection of plates. Compound beams have also been given an update and users can now create their own sections and store them in a library.

Joints and structural elements: The portal frame design tools in AdvanceSteel have been updated in this release with the ability to choose the unit for the slope of the roof in degree or percentage. You can also choose whether or not to make the portal frame’s roof symmetrical and the sections for the two columns can be different.

Stair design has also been given an overhaul, with a number of new tools to make their creation more complete. It’s now possible to define if treads are welded or bolted, what position these fasteners are in and whether or not they are assembled on site or in the shop. Treads themselves can now be user defined, as well as picked from a standard library. There have also been some enhancements to hand railings, and users can now add a whole rail around a mezzanine floor (an area in which AdvanceSteel provides a number of specialised modelling and connection macros) in one go.

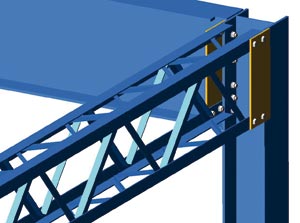

In addition to a number of improvements to existing joints, Advance Steel 6.1 includes a whole host of new ones. To name but a few, these include a new haunch joint, new splice joint, plate to plate, double side end plate, single side endplate, clip angle, moment connection, and flat bracing. As always these are provided in simple to use dialogue boxes, each of which is accompanied by a clear diagram.

Model browser: The new Model browser is a handy little tool which allows users to view the properties of all the members in a model from a single dialogue box (previously users would have to look at members individually.) Users can group by properties such as thickness, length or justification, and then if required edit properties. This is particularly useful if you want to make edits to a number of elements at the same time, such as changing the material property or the coating of members.

Drawings: Version 6.1 sees major improvements for custom automatic detailing, and better automatic label placement. User modifications will also remain (such as labels, symbolsÍ) if the drawing updates from the model.

Import/Export: The import for SDNF files, generated by analysis applications, has been enhanced. AdvanceSteel also includes import/export from STAAD and the industry standard CIS/2 format. In addition, links have been improved to CADS’ portal frame design software, Smart Portal, which was reviewed in the July/August 2005 edition of AEC Magazine. The end goal here is to be able to import a model from Smart Portal and create a complete GA drawing without the need for any member tweaking. This would just leave the steel detailer to add connection details.

Conclusion

The launch of Version 6.1 sees AdvanceSteel continue its evolution into a capable steelwork modelling and detailing solution and many of the enhancements for this latest release are focussed on adding depth of functionality, specifically to its modelling and connection tools. The product’s ability to work directly with DWG and DWF files, undoubtedly one of the key attractions for some users, is also enhanced and the ability to automatically convert lines and polylines to beams will be welcomed by many (but only those that trust the accuracy of their source data!) Reuse of data is also high on the agenda when it comes to working withy external applications and it’s encouraging to see the product build closer links with structural software applications in other areas of the market.