Over 20,000 pieces of equipment tracked and managed in real time across multiple sites in France

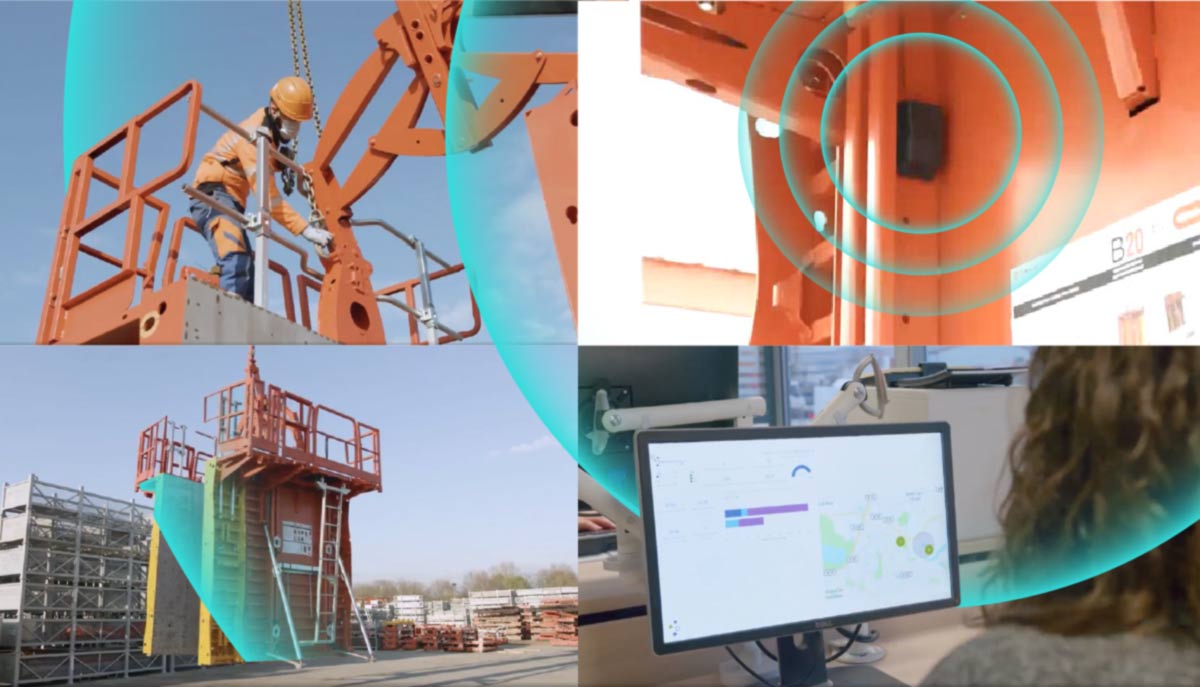

Bouygues Construction Matériel, an offshoot of Bouygues Construction, is implementing an Internet of Things (IoT) asset tracking solution for Smart Construction, developed by Omniscient, a start-up incubated by Bouygues SA.

This solution connects twenty thousand pieces of equipment for remote real-time management and optimisation, using an IoT network from Bouygues Telecom, the expertise of Objenious and intelligent sensors from Actility.

Bouygues Construction Matériel is in charge of managing the group’s entire fleet of equipment and must ensure that each site is equipped with compliant equipment, in good working order, that is made available on time across all construction sites in France.

To solve this problem, Omniscient has designed a turnkey solution for Bouygues Construction Matériel, using multi-technology trackers from Abeeway, a subsidiary of the French company Actility that specialises in ultra-low power geolocation solutions, and Omniscient’s site operations optimisation platform for data collection and analysis.

Bouygues Construction Matériel’s first major IoT in construction project will support the operations and formwork departments.

Omniscient’s solution is being deployed on its entire French fleet of bungalows and consoles, on the main components of the tower cranes and on the new B20 formwork.

This large-scale project involves around a hundred employees, assigned to monitoring the equipment on more than a thousand sites, spread over five technical bases. It represents the installation of Abeeway sensors on more than 20,000 pieces of equipment and millions of GPS data to be processed by Omniscient.

Omniscient’s platform allows the digital management of an entire fleet, from electro-portable to multi-tonne cranes. With one click, the fleet manager can navigate on a virtual map and view, in real time, the location and tracking sheet of each piece of equipment, including, among other things, the site configuration of the equipment, as well as links to the quality control sheets.

The in-house algorithms take the analysis one step further. The information sent by Abeeway’s sensors allows Omniscient to calculate performance indicators, dedicated to fleet management, equipment turnover and utilisation rates, inventory by technical base, inventory by worksite and number of billable days.

According to Bouygues Construction Matériel, one of the unique major innovations of the solution is that, by combining various geolocation technologies, it allows to use the same devices for big and small objects and in all kind of construction environments, instead of investing in different devices for each use case.

“Abeeway technology is adaptive as it can use Wi-Fi in dense urban environment, GPS in the countryside, and BLE indoors, to scan the environment and detect other BLE devices on some small equipment, for example with a tracker placed in a toolbox and BLE tags on each tool”, added Stephane Sisse, sales director at Abeeway.

By adopting this new data-based approach, the equipment division of the construction giant is projecting direct annual savings of 5 to 10% on maintenance and fleet management and a ROI of this technological solution over 3 years. According to Bouygues Construction Matériel, these savings will be generated by easier billing process, better allocation of resources, precise and reliable monitoring of equipment life cycle, a reduction of inventory costs; and data-driven real-time management.

IoT in construction

The partnership between the three companies is not limited to fleet management. According to Bouygues Construction Matériel, there are very good prospects in areas of construction: measuring machine productivity, optimising travel, worker safety and more.

In particular, Abeeway sensors used on badges can accelerate the adoption of social distancing through alerting, creating specific work zones or areas of limited density monitored in real time by the downstream system, warning workers when they enter forbidden areas or when occupancy density is too high.

“The “IoTization” of our equipment enables us to achieve two types of gains in parallel, the first in the optimisation of intrinsic management performance within the Matériel structure with traceability and visual indicators in real time, the second by providing the Travaux with additional levers for action on their use on site thanks to configurable alerts,” said Patrick N’Kodia, Director of Bouygues Construction Matériel.