At a recent Revit User Group meeting staged by Excitech a comment by one attendee kicked off a discussion which has continued since. The question raised was ýwhy donÝt we detail in 3D?¯

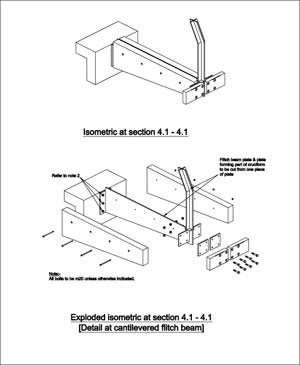

ExcitechÝs Revit User Group meets to discuss and exchange ideas about how they are using one of the most innovative building design software tools ± Autodesk Revit. The September meeting included a presentation of ýTips and Tricks¯ including one on ýarchitectural detailing with Revit¯. Doug Bevan, Technical Director at Halcrow immediately asked why we all assume detailing should be in 2D. ýSurely¯, he said, ýif we have a 3D model then we can make clearer the design intent with detailing in 3D¯. Alan Ogden, an Associate at Arup agreed and pointed out that if companies like IKEA see the need to explain assemblies in 3D to ensure their furniture is built correctly then maybe we should be exploring this within the construction industry.

The 2D/3D challenge

According to Doug Bevan when design was prepared on drawing boards nearly all drawings were composed of 2D views. 3D views were occasionally produced but because they were time consuming they were only undertaken to communicate complex assemblies. With the advent of computer aided drafting, the status quo was maintained as computers did not have the necessary power and we maintained the focus on 2D output. As PCs became more powerful 3D started to become a reality, but as Alan Ogden pointed out this was not for the main design; it was used to embellish and produce architectural impressions and visualisations. And this has had the negative effect that the understanding of 3D on computers has come to be associated only with these tasks. Doug Bevan also feels that ýwithin the industry producing 3D output has come to suggest extra work. This myth is perpetuated by peopleÝs understanding of old 2D and 3D workflows where two parallel workflows, one for 2D construction documentation and one in 3D for co-ordination and visualisation still being attributed to modern 3D workflow methodologies.

But ýnow 3D design is easy¯, says Alan, ýif you use the right tools in the right way¯. And Doug Bevan adds ýit is easier now to design in 3D yet we still produce details separately in 2D ± so once again we lapse into doing things twice!¯

Both individuals seem convinced that 3D is the way to go from an overall design perspective and at a detail level. But they also recognise that this will take time to become common. According to Doug, ýpeople tend to be set in their ways even if they are less efficient than they could be¯, and Alan agrees but suggests ýsuch people should not hold organisations back¯.

Putting it into Practice

Already Arup and Halcrow are moving in this direction either in exploration or in actual projects. According to Alan, ý3D detailing is happening now but only amongst a small group of people ± those who thrive in using the newest technology to the fullest.¯ But they use it where appropriate, and from a 3D model extract the 2D or 3D information to place in a drawing according to need. To quote Doug, ýthe electronic or printed drawings are just a way to communicate the design intent¯ and according to Alan ýthese new tools and techniques provide an opportunity, not a necessity, to present information in either way at no extra cost.¯

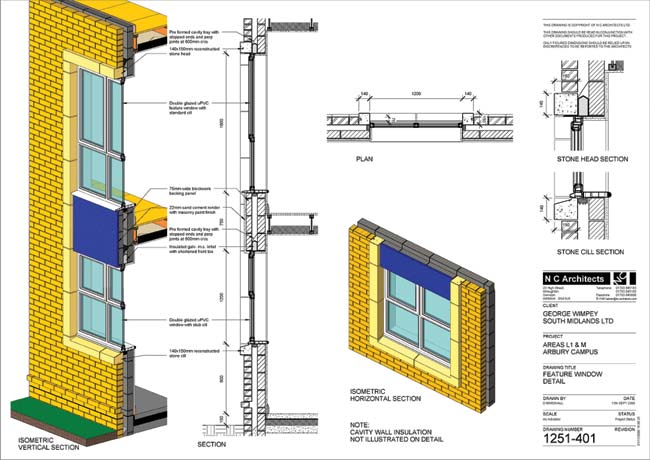

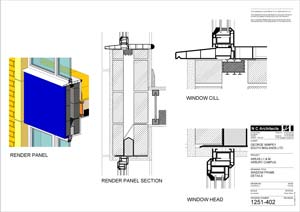

However, this vision of 3D detailing is not solely the suggestion of big multinational corporations. At the same user group meeting NC Architects, a practice of nine architects and technicians based near Swindon, were also presenting some of their work. One aspect of this was 3D detailing which they had been experimenting with and now using! Practice Director Derek Marshall, was keen to show how far they had pushed Revit and how they were now producing detailing from Revit models including 3D detailing. His view is that ýthe drawing is all about communication and the use of detailing in 2D and 3D with illustrations is fantastic ± not just pretty but a practical explanation and one which reduces the risks of wrong interpretation on the site¯. Of course he realises that the entire building model cannot have the highest level of detail as that would make the data too clumsy and slow to work with. However, the use of call-outs and of detailed Revit ýfamily¯, component with parametric values that NC Architects are creating can be efficient and reduce risks. Also the utilisation of Revit for 3D detail design forces you to think more about how it will be built on site as to quote Derek ýyou focus more on the component and construction issues than the basics of how to draw something – and itÝs fun¯. Derek acknowledges that at present it is taking time to build the library of parts but he is confident it will save time in the long run while also ýsaving the client money and aiding the practice by ensuring more repeat business¯. Like Doug Bevan and Alan Ogden he believes that it is inevitable that every organisation will go down this route; and they all suggest that within five years they expect most to be working in this way.

So a discussion prompted by what might have been dismissed as a visionary thought from one company rapidly turned into not just a shared view, but one where real work was being done and benefits derived. If, as all those present agreed, ýthat itÝs all about communicating design intent¯ then techniques which make that communication easier using software which allows the architect or technician to focus on the design more than the drawing and have fun must be a good thing. So maybe 3D detailing is not so radical after all and it could become common a lot faster than even the five years predicted.

This article was written by Bob Garrett, Marketing Director, Excitech.