Identifying and calculating the embodied carbon in proposed structural designs is increasingly an area where technology can take the strain, leaving engineers free to take the decisions and actions that will help reduce it.

As we edge closer to the 2050 Net Zero deadline and the world becomes more environmentally conscious, increasing attention is being paid to how the construction industry can build greener. Embodied carbon may be an important part of the sustainability puzzle.

The current spotlight on construction isn’t without just cause; it’s a shocking statistic that the built environment and construction currently accounts for around 40% of global energy-related CO2 emissions, according to the World Green Building Council (WGBC). As such, we are all under pressure to reduce carbon footprints and improve sustainability, from manufacturers and suppliers to contractors and engineers.

Already, we have seen a number of initiatives that aim to encourage change within the construction industry. For example, 2019 saw UK structural engineering consultancies declare a ‘climate and biodiversity emergency’. In 2020, the UK government published The Construction Playbook, outlining green initiatives for the sector; and earlier that year, Institution of Civil Engineers president Rachel Skinner launched her ‘Shaping Zero’ campaign.

According to RIBA, clients in all sectors are increasingly commissioning whole life carbon (WLC) assessments as part of project requirements, driven by both environmental and economic considerations. We are also increasingly seeing more contractors instigate positive change too, with many of the UK’s largest construction companies pledging targets around carbon emissions, including Willmott Dixon, Kier, Mace and Balfour Beatty.

Explaining embodied carbon

There are many factors that feed into this greener, more sustainable future of construction, with embodied carbon being just one of them. The embodied carbon of a building is defined as the greenhouse gas emissions (GHG) generated from the building’s construction lifecycle. This can include carbon emissions associated with all materials, products and systems, from raw material extraction, manufacturing and transportation, the construction process itself and right through the building’s entire lifespan.

Conversations around embodied carbon are becoming increasingly common, with clients and developers asking the right questions and showing a desire to build greener, whether they’re driven by a ‘moral’ change in mindset or a genuine interest in understanding the environmental and carbon impact of their building

Embodied carbon assessments are not yet a legislative requirement, although that’s not to say there won’t be some form of regulation or carbon tax in the future. Either way, conversations around embodied carbon are becoming increasingly common, with clients and developers asking the right questions and showing a desire to build greener, whether they’re driven by a ‘moral’ change in mindset or a genuine interest in understanding the environmental and carbon impact of their building.

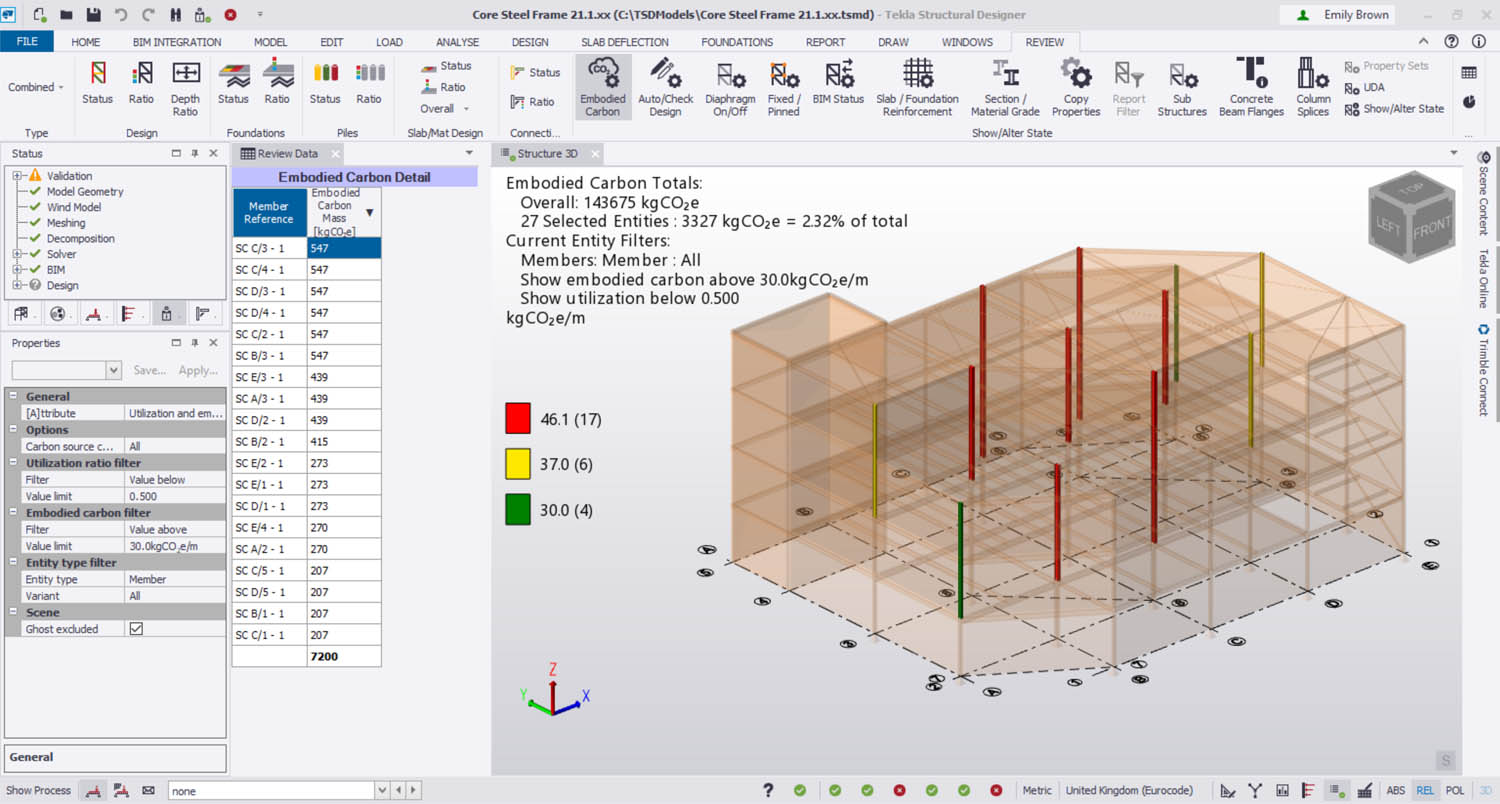

With a significant portion of a building’s final embodied carbon value often determined as early on in the construction sequence as the initial design stage, it’s clear that the sooner action is taken, the better. With that in mind, carbon modelling and assessments can be invaluable, helping engineers and contractors to reduce the level of embodied carbon within their structures and, ultimately, build greener.

Of course, in order to design smarter and greener, you need to have an understanding of the carbon levels that you are dealing with from the outset. By calculating the embodied carbon present early on in the construction sequence, engineers and other project stakeholders can have a detailed understanding of the level of carbon that the proposed structure contains.

And thanks to advances in digital technology, it is also possible to take this further, drilling down deeper, measuring intelligently and providing a live overview of the carbon contained within a structure’s individual components.

Having access to such detailed data early on can be invaluable, providing the information and, most importantly, the time savings necessary to consider, assess and evaluate how this carbon figure can be minimised, in order to reduce building’s environmental impact.

Design optimisation

In many ways, the task of reducing a structure’s embodied carbon boils down to design optimisation. This, of course, is a challenge that engineers already face on every project, and it’s typically associated with decisions around materials and resources used, the type of foundation or column support grid chosen, and the delivery of the architect’s brief – all without impacting overall structural stability. The same is true for carbon. In many ways, it’s just one more factor to consider in this balancing act.

In other words, along with building strength, structural performance, design efficiency and cost, engineers must also take into account the amount of embodied carbon present. And to reach the most efficient and optimised design, they will need to compare different designs, materials and approaches.

Now engineers must balance the building’s strength and structural performance with the amount of embodied carbon present too, as well as the design efficiency and cost. By comparing different designs, different materials, different approaches and calculating and contrasting the carbon within each design iteration, engineers can work to settle upon the most efficient and optimised design from all points of view.

Reducing waste

Of course, in addition to being smarter when it comes to embodied carbon, there are other things that can be done. First, rather than building new, we should look to reuse and repurpose existing buildings, structures and infrastructure where we can. Where that isn’t feasible, we should work to design and build multiuse, multipurpose developments that are adaptable for the future, as well as reducing the amount of raw materials required for their construction. While this all stems from the efficiency of design, as already discussed, material wastage can be another big contributor to the carbon problem within construction.

Here, it’s all about the importance of accuracy and correct first-time fabrications and assemblies. We all know that an unresolved issue at the design stage of a project can have a snowball effect as the construction sequence progresses, leading to errors at the fabrication stage, the component not fitting correctly once it reaches site and then requiring subsequent rework or refabrication.

Incorrect quantities and over-ordering can be another issue, again leading to material wastage and unnecessary CO2 being pumped into the atmosphere. With a 3D digital environment, material wastage can be avoided. Thanks to the high levels of detail and visualisation offered by a 3D model, and the digital rehearsal that it offers, project teams are able to really see design issues and clashes and resolve any potential issues before a project progresses to the fabrication stage.

What’s more, thanks to the data integration that BIM software supports, teams can benefit from the automatic generation of accurate material quantity take-offs, as well as data from the model automatically being transferred to the fabrication shop floor, minimising the potential for human error.

It’s clear that there is much still to be done if we are to hit the Net Zero 2050 target and slow down the effects of global warming. As we continue to create the buildings and infrastructure of the future, working to reduce the embodied carbon they contain could make a big difference in the global fight against climate change. It’s a big opportunity for the sector’s engineers to make a noticeable positive impact.

Stuart Campbell is business development manager for engineering at Trimble (UK).