With a reputation for solving the most challenging 3D geometry wrangling problems, ITI takes on the process plant workflow with its new, easy to use CADfix PPS system, writes Al Dean

When it comes to process plant there are key data translation issues that are regularly encountered across the entire industry. Many of these are caused simply by the sheer size of the datasets typically found in process and plant design.

Consider what the typical dataset contains; framework, skids, equipment assemblies, sub systems and all of that glorious pipe work. If each area of work is held in its native, unsimplified and full resolution form, we could be talking about 100,000s of faces and gigabytes of data. However you cut it, whatever format you use, this is going to cause problems when you’re looking to communicate and collaborate based on that data.

Then you have the requirement of the different design systems used by various teams and disciplines. Moving data between 3D design systems is fraught enough, but trying to shoehorn a gigabyte of data from one system to another can provide more than a few headaches.

It’s into this arena that International TechneGroup (ITI) has recently launched its CADfix PPS system (PPS standing for Plant and Process Simplification). If you haven’t come across ITI and its CADfix tools before, the global firm has an excellent reputation for providing robust and reliable tools for data repair, repurposing, translation, migration and validation for some of the biggest names in manufacturing.

The first stage in the CADfix PPS process is to read in your dataset. Here, ITI’s experience and long-standing relationship with all of the major vendors pays dividends as the import options are pretty rich. You have the usual array of standard formats, including DXF/DWG, STEP, JT, ACIS and Parasolid. There are also a range of good quality native formats including Catia, Creo, Inventor, Siemens NX, SolidWorks as well as CADDS 5i (a legacy system that is still particularly useful for those in the shipbuilding game).

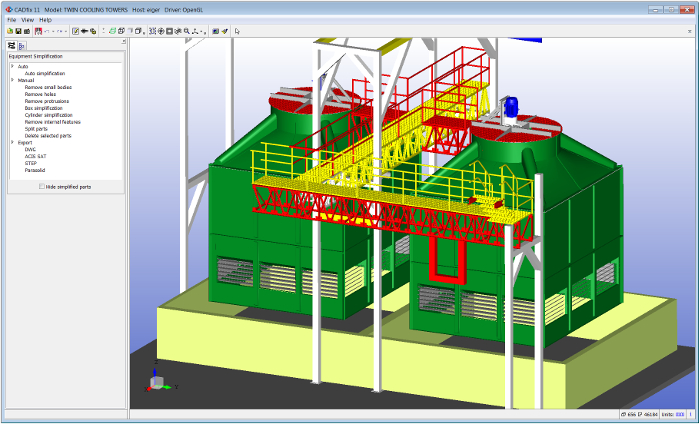

CADfix PPS is able to read in and quickly display these datasets, even in the large, complex forms that they typically arrive in.

Reducing complexity

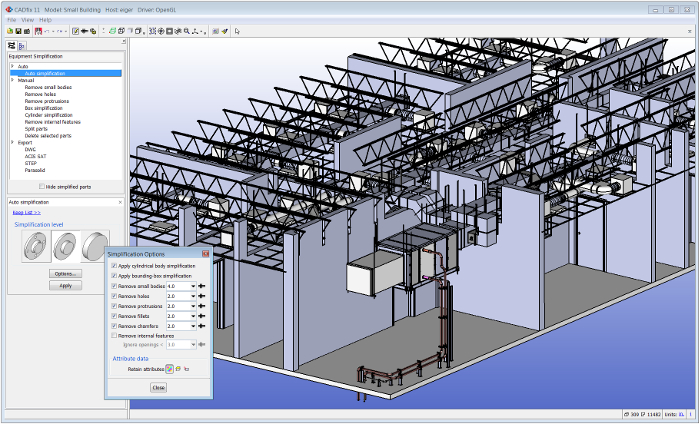

Once the data is loaded in, the system can be used to remove detail by either deleting or simplifying parts or sub-assemblies to reduce the complexity of the data. This can happen in one of two ways. Firstly, there are a set of pre-baked, ready to go simplification routines in the CADfix PPS automatic simplification Wizard.

The system can quickly find and remove small parts based on bounding box size (useful for dealing with those assemblies that feature every last nut, bolt and washer). You can also select a part of a certain shape and size and have the system find matching components (useful for dealing with those non-standard components or those that you know you don’t need).

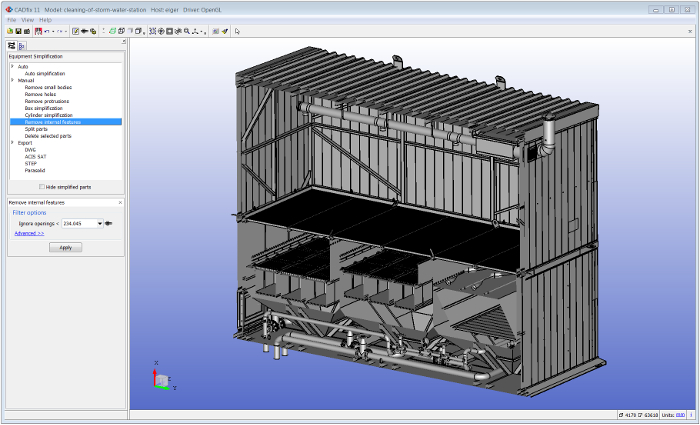

Perhaps one of the most useful tools is the automated removal of internal details. This will inspect your model and find parts or assemblies that contain internal detail which can’t be seen from the outside; consider the internal working of a pump assembly, complex motor or generator, or a small portacabin full of equipment that is not required or seen in the overall layout model for clash detection. The operation will automatically remove all of that internal detail, rapidly reducing the complexity and size of the data.

As well as the removal of whole chunks of geometry, CADfix PPS also includes several tools to help remove geometry detail (rather than whole parts). There are tools to assist with the removal of holes or bosses as well as design features such as fillets and chamfers.

Alongside the automated tools for the removal of data, there are also a number of operations that can assist with further data reduction through the simplification of complex geometric shapes. In many cases complex equipment represented in mechanical CAD models with the level of detail required for manufacturing, can be replaced with simple bounding boxes or cylinder primitives for use in the building layout. These tools can be used in an automated manner or carried out manually to provide more control over the simplification process.

Once you have arrived at your stripped back, lightweight model, you’ll need to be able to export it to your system of choice. Once again, ITI’s expertise in the data translation field comes into play. CADfix PPS comes with export options for ACIS (.sat), DXF/DWG, STEP, JT and Parasolid. The company is also exploring the potential for exporting to a range of faceted model representations such as the FBX format, that seems to be gaining some traction in the process plant space, as well as STL, OBJ, and XGL/ZGL.

Conclusion

CADfix PPS is a gloriously focussed application. Its goal is to enable the removal of any extraneous complexity from increasingly complex data and reach a more efficient, more lightweight model that still conveys the intent to solve the downstream challenges faced by industry.

The results, which ITI says can see up to a 95% reduction in data complexity after only a few minutes’ work, will enable your team to work more efficiently and get the mission critical data to those that need it, in a lightweight optimised form that suits their purposes.

With ITI’s background of doing this for decades in the manufacturing space, you know it has the tools to do it in a reliable, robust and repeatable manner. First class stuff.

If you enjoyed this article, subscribe to our email newsletter or print / PDF magazine for FREE