Level of definition (LOD) matters because, without a clear idea of how much information is needed at each stage of a project, BIM benefits are likely to be compromised, writes Duncan Reed, digital construction process manager at Trimble

The promise of BIM is that it makes it possible for everyone on a design and construction team to collaborate faster, more accurately and with more transparency.

But to maximise the efficiencies BIM brings, each member of the project team must clearly understand how much information is required for each different stage of the project.

Too little information, and risks may not be managed effectively. Too much, and the result could be that the process is hampered by waste.

This is where the term ‘level of definition’ (or LOD) comes into play – but also where some potential confusion is introduced. LOD is a UK BIM term defined in PAS 1192-2:2013, and is used to refer to both ‘level of model detail’ and ‘level of information detail’.

(It’s worth noting that the ‘level of model detail’ is the description of the graphical content of models at each of the defined stages. The ‘level of model information’, meanwhile, is the description of non-graphical content of models at each of the stages defined.)

In essence, LOD refers to both the amount of graphical and non-graphical detail that may be required at different stages of a project, so a clear understanding of its meaning and purpose is important.

An important difference

It’s also considerably different to the way the term ‘LOD’ is used by the American Institute of Architects, where it refers to ‘levels of development’ and deals principally with graphical detailing in models. That said, prior to the publication of PAS 1192-2:2013, many UK organisations were using this US terminology.

So there’s clearly potential here for confusion – but it’s actually pretty easy to determine whether a project is using the UK or US definition.

That’s because here in the UK, LOD is aligned with the Digital Plan of Work (DPoW) created by the UK BIM Task Group. This provides the UK industry with an eight-stage design, construction and operation plan, running from zero to seven, and encompassing the information requirements throughout the whole life of an asset.

By contrast, the US system defines the stages of evolving model development – as increasingly detailed graphical representations — from LOD100 to LOD500.

For those who require further assistance in the UK, the NBS BIM Toolkit provides high-level guidance as to what level of detail and what level of information should be produced for all project elements at each stage, by the various members of the project team. There is also the RIBA Plan of Works, which uses the same eight-stage approach and offers guidance on what data is needed at each stage.

Managing expectations

So when a company starts on a project that is using BIM – at whatever stage of the DPoW – it needs to know how much information it is expected to provide. To get the best out of BIM, it’s vital that noone on the project team over- or underdelivers on information. If they do, the wider lean principles that underpin BIM are unlikely to be realised.

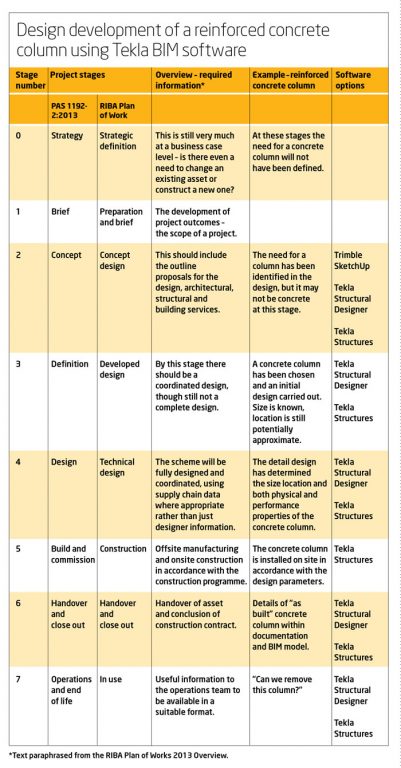

This point is illustrated in the table below, where software has been used to develop the information for a concrete column; it shows the process of designing and detailing a building structure using BIM.

In the early stages of the project, structural analysis is the most important factor. By stage three, the size of structural members should have been determined — but their exact location may not have been fixed.

As the project progresses to stage four, the location of members needs to be accurately defined, along with their physical and performance properties, as any constructability or coordination issues must be resolved at this stage.

At the end of stage five, the level of model definition needs to be complete. This is the point where the structure is procured from a specialist supplier; in this case, from a pre-cast concrete frame manufacturer. To allow for the lean processes that BIM espouses, accurate member sizes and geometry, as well as details such as embeds, couplers and reinforcement fabrication information are required and should be generated directly from the 3D models.

By adopting this staged approach to develop a design and using collaborative processes to share and coordinate the digital information, the project team can deliver much greater value and accuracy in a far shorter timescale.

In contrast, detailing the reinforcement required for a concrete column at stage two would be pointless, as the framing material has not been decided and the scheme may ultimately choose a steel frame solution at stage three.

It is actually very easy to produce too much information, too soon on a project, so for BIM to be used successfully, the team should define from the outset what information is important to them and when it is needed in the lifecycle of the project.

This is one of the key requirements of the Project BIM Execution Plan (BEP). In the BEP, the correct level of model definition over the life of a project should be agreed and recorded at the outset, so that all parties involved understand what they are being asked to deliver.

Using software that is capable of delivering a model to the required levels of definition is important. The Tekla suite from Trimble provides support through the eight stages of the DPoW and offers a high level of transparency for all project team members – ensuring clarity, removing the need for rework and ultimately driving waste out of the construction process.

If you enjoyed this article, subscribe to AEC Magazine for FREE