Autodesk gallery showcases a snapshot of innovations currently shaping design from small-scale jewelry to giant infrastructure projects.

Autodesk’s One Market headquarters in downtown San Francisco is charged with inspiring innovation. It is used for monthly, themed ‘Design Night’ events and engagement with start-ups and the local community. It also acts as a design gallery for the display of customers’ work.

Outside the Bay City area, and in Europe in particular, however, ‘Autodeskers’ have long complained of a lack of similar outreach facilities. But in October Autodesk capitulated in style, opening a pop-up gallery in the heart of Paris. The free three-week event was held at the Galerie Nikki Diana Marquardt on the edge of Marais.

Autodesk branding was kept to a minimum, alongside a combination of interactive and static displays. The space had a 3D print zone and Fablab, an artist in residence and evening events. It showcased customers’ work in architecture, product design, fashion, automotive, aerospace, 3D printing and laser scanning. Autodesk’s top brass flew in for customer meetings and evening events with talks on a wide variety of design topics.

With over 1,500 visitors in the first four days, Autodesk is considering other pop-up galleries in Germany, Italy and the UK. Local projects were prominently displayed alongside attractions from Pier 9, which is likely to be replicated at future events.

Welcome, Spark

Visitors were given a chance to try out Autodesk’s new 3D printer, Spark, which was designed in the UK and made at Pier 9. Autodesk is using Spark as a testbed for its own 3D printer software development and to promote its brand. It is expected that at some point, fabrication will be moved to a provider with great capacity.

Pop into 3D printing

Autodesk gallery showcased a snapshot of innovations currently shaping design from small-scale jewelry to giant infrastructure projects. It was inspiring and educational and, above all, there was no hard sell, which made it a relaxing entry point for industry folk and the public alike. It is a shame the pop-up element means that it will never be in town for long. One wanders what ever next for Autodesk? From this successful gallery outing, I would expect another to pop-up sometime soon.

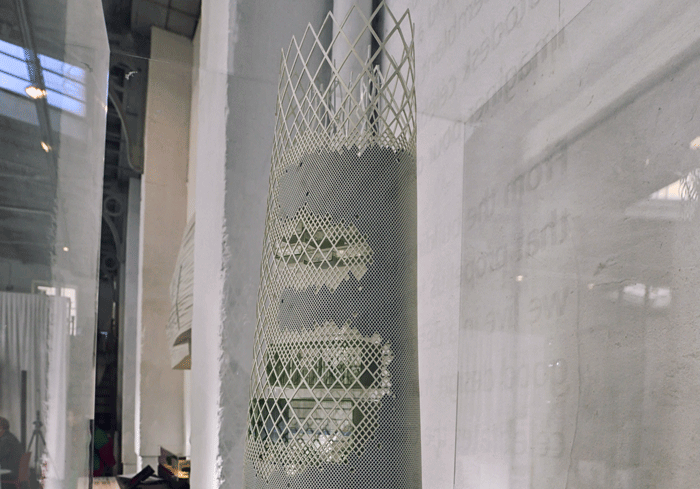

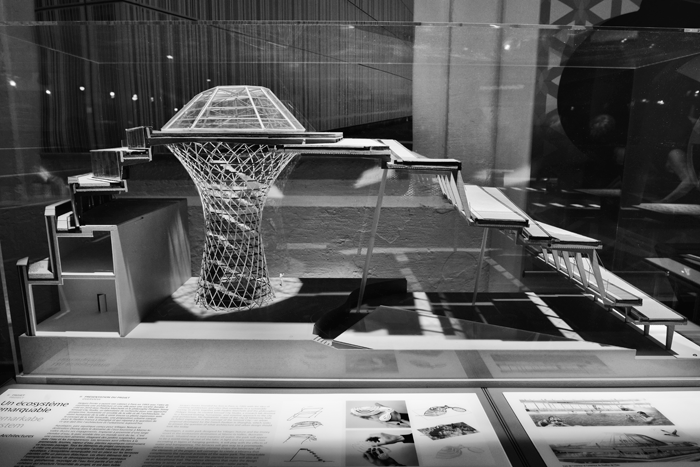

HyperGreen Tower

The first thing attendees saw on entry to the gallery was a highly detailed 3D printed model of the HyperGreen Tower, by Jacques Ferrier Architectures. Standing 246 metres tall, the tower design has a curved, concrete, exterior lattice facade that acts as the building’s primary structural system. The design featured solar cells, wind turbines, a geothermal heating system and a rain water harvesting system.

San Francisco Museum of Modern Art

The highly impressive San Francisco Museum of Modern Art expansion building took up a whole wall with a façade relief specially created to show the design’s styling and innovative fabrication techniques.

Smoke Dress — Anouk Wipprecht

Ms Wipprecht’s 3D printed dress has built-in LED lighting. Should you stand too close to the wearer, the built in sensors trigger the lights to flash, warning the interloper to move away. Should this fail to get a reaction, the dress emits a cloud of dry ice smoke from a necklace/tube. This is either for the wearer to escape into the fog or to irritate the ‘close talker’.

Airbus concept plane

Airbus set out to revolutionise the structural design of aircraft.

Nike analysis and 3D printed trainers

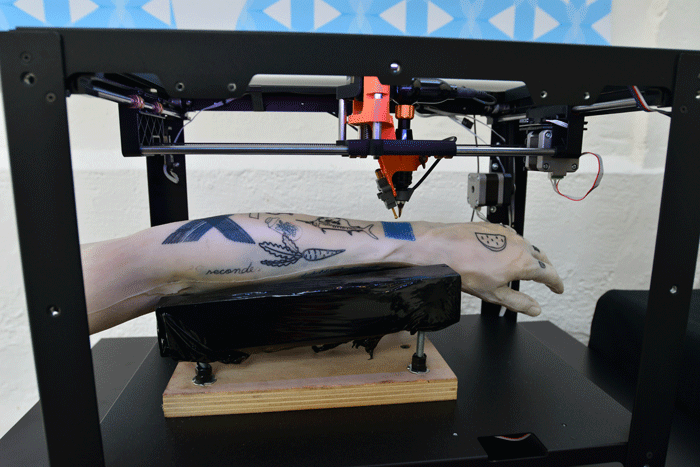

Hacked 3D printer and tattoo machine

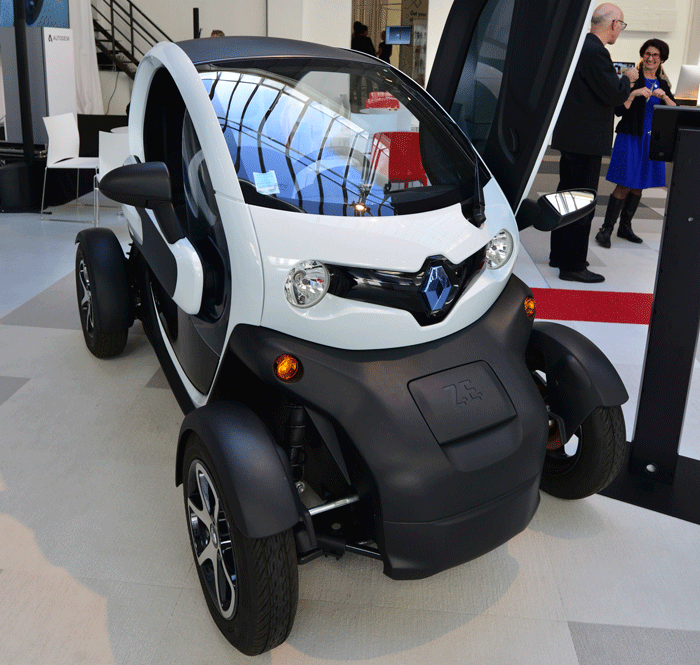

Renault Twizy

Makers

Robot programming

If you enjoyed this article, subscribe to AEC Magazine for FREE