From civil site design to construction planning, Bentley Systems is embedding AI across more of its tools, enabling engineers to explore thousands of options, automate workflows and retain full control over outcomes, as Greg Corke and Martyn Day report

As AI continues to permeate all software companies, Bentley Systems wants to show how it can redefine infrastructure delivery by threading it through civil design, modelling, subsurface analysis, construction planning, documentation management and more. Intelligence is being embedded across much of the company’s portfolio – not as a bolt-on, but as a structural shift in how engineering data, models and organisational memory connect and how future engineering workflows will be shaped.

Customers can expect to see AI acting as a practical companion to engineers, capable of optioneering, interrogating models in natural language, automating laborious workflows, and delivering recommendations that remain anchored in engineering logic, codes and lived project constraints. Crucially, Bentley’s message is that users retain full control over these outcomes.

At the company’s recent Year In Infrastructure (YII) event in Amsterdam, delegates were shown an AI future that is built around an ecosystem of specialised agents, engineered to perform site-grading optimisation, hydraulic calculations and drawing automation, as well as coding assistance and data discovery within ProjectWise. Bentley’s new ‘Plus’ generation of iTwin-native applications sits at the centre of this strategy, designed from the outset for AI-driven workflows.

Discover what’s new in technology for architecture, engineering and construction — read the latest edition of AEC Magazine

👉 Subscribe FREE here

The AI message

At YII, Bentley Systems CEO Nicholas Cumins cited examples of infrastructure projects that are using AI to compress schedules by as much as 80%, as well as analyse thousands of design options that were never feasible before.

He acknowledged that it’s still early days for AI. Firms must be patient, “Not every project that adopts AI sees transformative results yet,” he told attendees. “Many teams are experimenting, learning and iterating, but that’s exactly how progress happens.”

But as the AECO industry leans on AI for more critical decisions, how do practitioners ensure that those decisions are trustworthy? “Engineers work in a creative profession, but one where precision is not negotiable and consequences are real,” said Cumins. “That’s why, at least for the foreseeable future, AI and infrastructure will remain a collaborative process with the human in the loop.”

In order to make AI recommendations truly useful, they must be grounded in a very specific kind of context, he explained. “AI needs to understand our intent, what we’re trying to achieve, and the constraints we operate under in design and construction,” he said. “This means understanding the desired outcome and performance, along with limitations such as budget, schedule, safety and carbon impact. If we ask AI to help lay out a new transit route, or optimise a bridge design, AI needs to be guided by what we try to achieve and what rules it must respect.”

Real-world context that reflects both the built environment (existing assets) and the natural environment (terrain, water and climate) is also essential, said Cumins. Of course, Bentley customers have plenty of tools at their disposal here, from reality modelling above ground with iTwin Capture, to modelling and analysing subsurface conditions with Seequent.

Firms will also get crucial context for AI by learning from experience, tapping into what Cumins describes as an organisation’s “collective memory”.

Here he took the opportunity to hammer home a point made several times at YII last year, on using customer data for training AI.

“Your project data remains your data, always,” he said. “Only you decide if and when you want to use your data to train AI. Our role is to help you unlock the full potential of your data.”

Cumins went on to explain that firms can train AI assistants on decades of product documents, standards and expert insights, allowing engineers to ask questions in natural language, such as, ‘How did we design the foundation for a similar bridge last year?’ And receive relevant information in seconds.

“It’s like having the most experienced engineer available to every junior team member, on demand,” he added.

Of course, AI can only tap into institutional knowledge if that data is accessible and not trapped in proprietary formats and siloed systems. “We must not only unlock access, but also organise the data in consistent schemas, so AI can interpret and apply it across projects,” said Cumins.

This provided a natural segue to the Bentley Infrastructure Cloud, a central store for all manner of infrastructure data including models, PDFs, inspection forms, photos, IoT sensors and more. “It frees infrastructure data from closed formats, aligns it to open schemas and prepares it for AI to deliver better outcomes across the entire lifecycle,” Cumins said.

In Bentley’s view, this lifecycle approach is essential for infrastructure AI. Executives at the company believe AI must also understand how designs perform once built. This involves maintaining a digital thread from design through construction to operations and feeding performance data back into the system. To this point, Cumins explained how the Bentley Infrastructure Cloud will evolve to support “full lifecycle integration”, enabling AI to make performance-based design recommendations.

Finally, he explained the importance of engineering context, “AI must operate within the bounds of engineering logic and physical principles,” he said. “This means recommendations generated by AI must align with established engineering practices and be validated by design codes and sound judgement. Whether it’s proposing a foundation designed for a high rise or recommending reinforcement details for a bridge deck, AI must respect engineering constraints, physical laws, safety standards and construction requirements.”

His words came with a warning, “Left unchecked, a purely data-driven AI might propose solutions that appear optimal in simulation, but are unsafe in the real world.”

Bentley is not undertaking this AI journey alone. Cumins introduced the Infrastructure AI Co-Innovation Initiative, whereby Bentley is inviting its users to help it create the next generation of AI-enhanced workflows, prioritising which APIs should evolve and how to better support AI use cases.

Cumins addressed the looming challenge facing all software firms: how to stay profitable amid rapid change “We will also explore new commercial models that reflect the evolving balance between AI-driven and human-driven work,” he said.

The ‘Plus’ generation

Last year, Bentley unveiled civil site design software OpenSite+, the first in a new generation of AI-powered, iTwinnative desktop applications that are fully connected to the Bentley Infrastructure Cloud. All of Bentley’s ‘Plus’ products write data directly to a Bentley iModel, without having to go through an intermediary format like DGN.

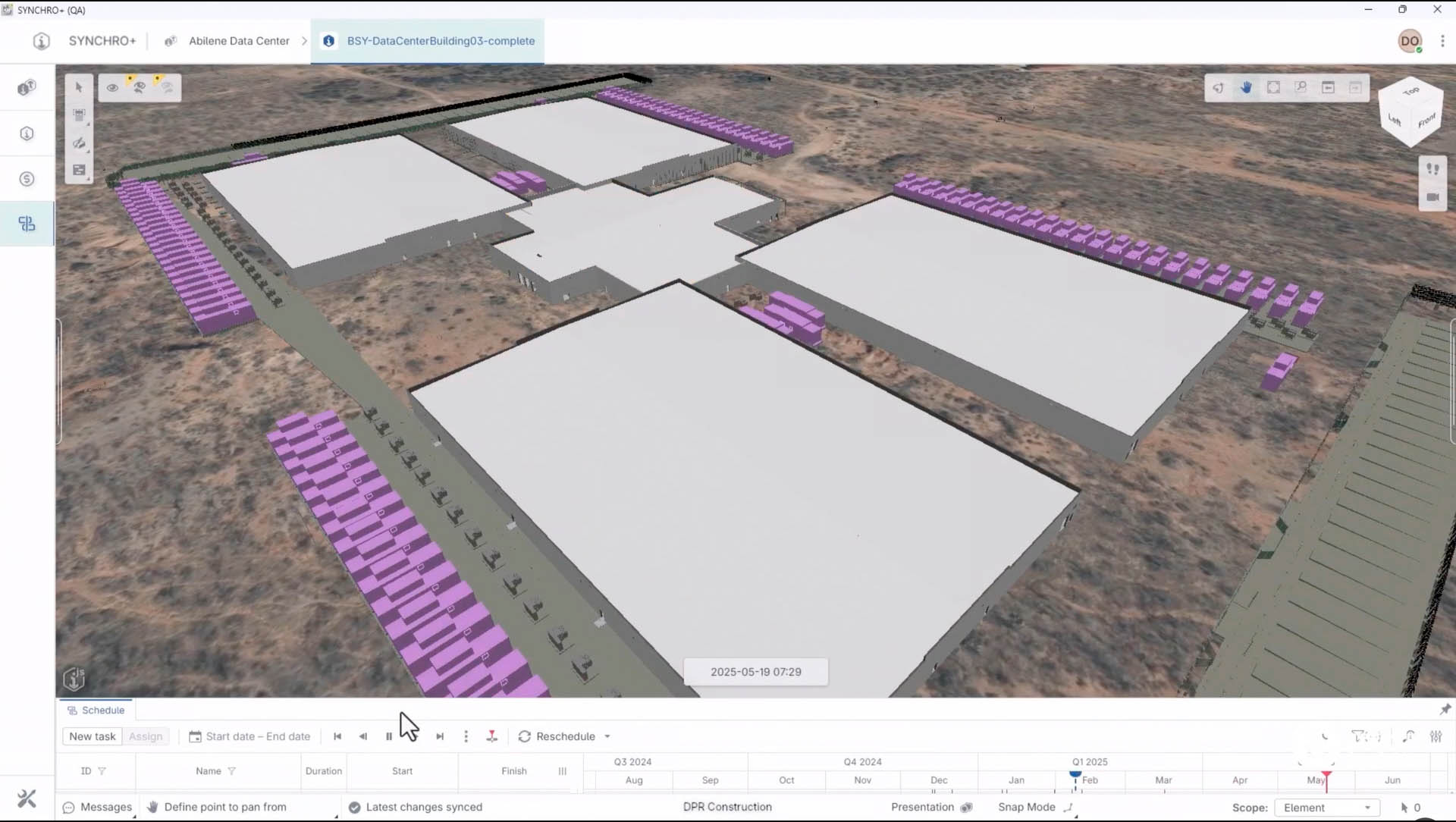

OpenSite+ is designed to automate routine tasks such as drainage design and earthwork optimisation. Generative design allows users to evaluate thousands of site grading scenarios with a single click, optimising for both cost and constraints. OpenSite+ is now being joined by two more ‘Plus’ products: OpenUtilities Substation+ for substation design and maintenance; and Synchro+ for 4D construction planning. While OpenUtilities Substation+ serves a niche market, Synchro+ has significant growth potential.

While Bentley’s mature Synchro 4D products are currently used primarily on larger projects, Bentley is betting on Synchro+ to lower the barrier to entry by delivering a single collaborative platform for planning and estimating.

Success will rest on a simplified UI, with AI-powered features enabling nontechnical team members, not just BIM managers and schedulers, to engage directly with 4D planning. “A site manager can navigate a model, run a simulation or visualise sequences without needing deep technical training,” said Morgan Hays, senior director for construction product management at Bentley Systems.

AI is being used to bring new efficiencies to construction sequencing, automatically querying the model to quickly generate a 4D schedule, as Francois Valois, senior VP for open applications, explained: “The schedule might exist in Primavera or Microsoft projects, but linking it is something that is tedious.”

Bentley Copilot, meanwhile, is a context-aware AI assistant tailored to the needs of the engineering disciplines and infrastructure sectors. It relies on a large language model (LLM) that understands what engineers want to do and then leans on multiple AI agents trained on discipline-specific knowledge to do the actual work.

“It can interrogate requirement documents, interrogate the model, make complex changes that would have taken a lot of steps previously – and all of that by talking to the Copilot,” said Valois.

Bentley Copilot started out life as an experiment for the new generation of ‘Plus’ products but is now being rolled out across Bentley’s more mature MicroStation-based engineering applications as well, starting with OpenRoads Designer and OpenRail Designer for model-based road and rail design.

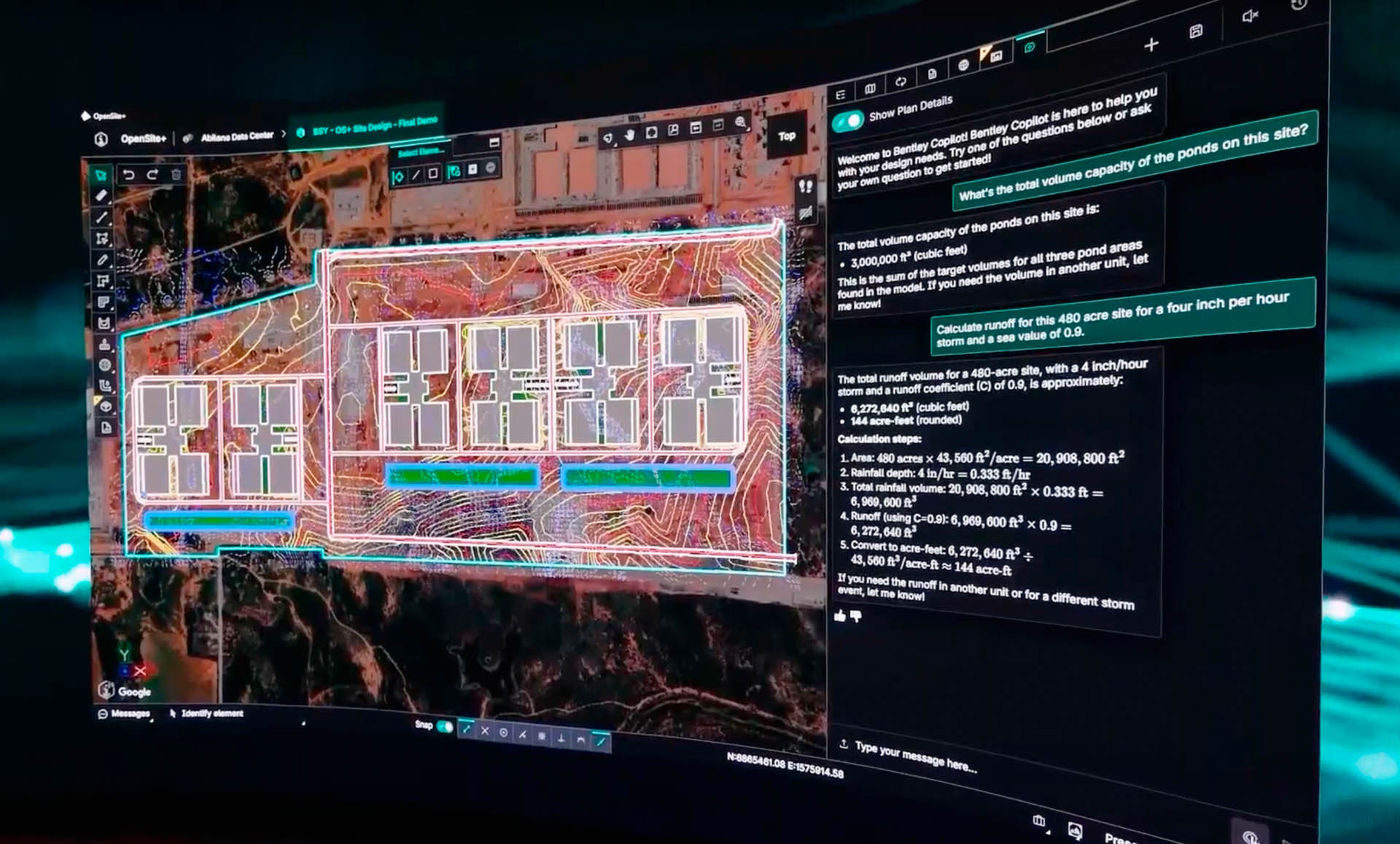

Bentley Copilot shares common core components across Bentley products, while an AI technique called retrieval-augmented generation (RAG) provides the specific contextual intelligence for each application. For example, in OpenSite+, Bentley Copilot understands site-civil workflows because Bentley has embedded additional domain knowledge directly within the software.

Valois explained that each Bentley Copilot is built around four key capabilities.

First, they can understand product documentation, so users can ask natural language questions such as, ’How do I place an alignment in OpenRoads?’. The Copilot will respond based on relevant documentation.

Second, they can understand uploaded project requirements and tailor responses to the project context.

Third, and perhaps most importantly, they allow users to interact with design data. Because the ‘Plus’ generation products feature “intelligent models”, the Copilot can query those models directly, essentially generating SQL queries in the background to extract and interpret data.

Fourth, Bentley Copilots can be used to execute commands, and because they have spatial awareness, they can understand design element relationships and intelligently modify models based on natural language prompts. Commands can even be chained together to carry out multi-step tasks. “It’s kind of creating that code in the background, and executing those commands,” said Valois.

It’s still early days for Bentley Copilot, but at YII, we saw how engineers can instruct OpenSite+ to perform tasks such as adjusting the angle of parking bays, checking car park designs against local standards and calculating site run-off.

Furthermore, as the Copilot LLM in OpenSite+ has also been trained on Haestad Methods, it can perform complex calculations for hydraulic design and analysis from a simple voice prompt, instead of having to manually extract data, apply formulas and validate computational steps.

It’s easy to see how Bentley Copilot could automate certain workflows, but the human remains firmly in the loop. Users retain full visibility over all decisions that are made, as Ian Rosam, product management director for Bentley’s civil engineering applications, explained. “It maintains a history, so your conversations are recorded for posterity, but it also means that we can jump into previous conversations where the LLM perhaps has been used to make a change in the model, to preserve that history, to create that record and index of that change,” he said.

Of course, in the AI world, things are moving incredibly fast, so Bentley Copilot is not tied to a single LLM. “We have a layer of interaction between the large language model that we use and our software, so we can switch from one provider to the next easily, based on what is the flavour of the next six months.”

Bentley’s Julien Moutte spoke at NXT BLD 2025 on open data

Watch the full presentation here

Agents and automation

As Bentley Copilot evolves, it seems inevitable that users will increasingly interact with their design tools through natural language – written or spoken – rather than relying solely on keyboard and mouse. This shift is likely to have a significant impact on user interface design. However, traditional methods of interaction aren’t going away any time soon.

Perhaps the biggest impact that AI will have on user interface design is through agent-to-agent communication. Bentley CTO Julien Moutte explained that he is hearing from more engineering firms that are hiring data scientists to create their own agentic AI workflows. “They’re saying, ‘Is there any way for me to tap into some of the capabilities of your engineering products, so that I can combine this with my own agents that I’ve trained with my previous knowledge?’”

Moutte explained that, in the future, there will be a user experience and an agent experience within Bentley products. The challenge will be how to make the engineering capabilities of Bentley’s software approachable and discoverable to all types of AI agents. “In many cases, people might not see the user interface of our software, but they will be using the engineering capabilities of it,” said Moutte.

Last year, Bentley announced its first forays into automated drawing production through OpenSite+, using AI to deliver significant time savings to a workflow that Bentley executives say can account for up to 50% of a site design project’s time.

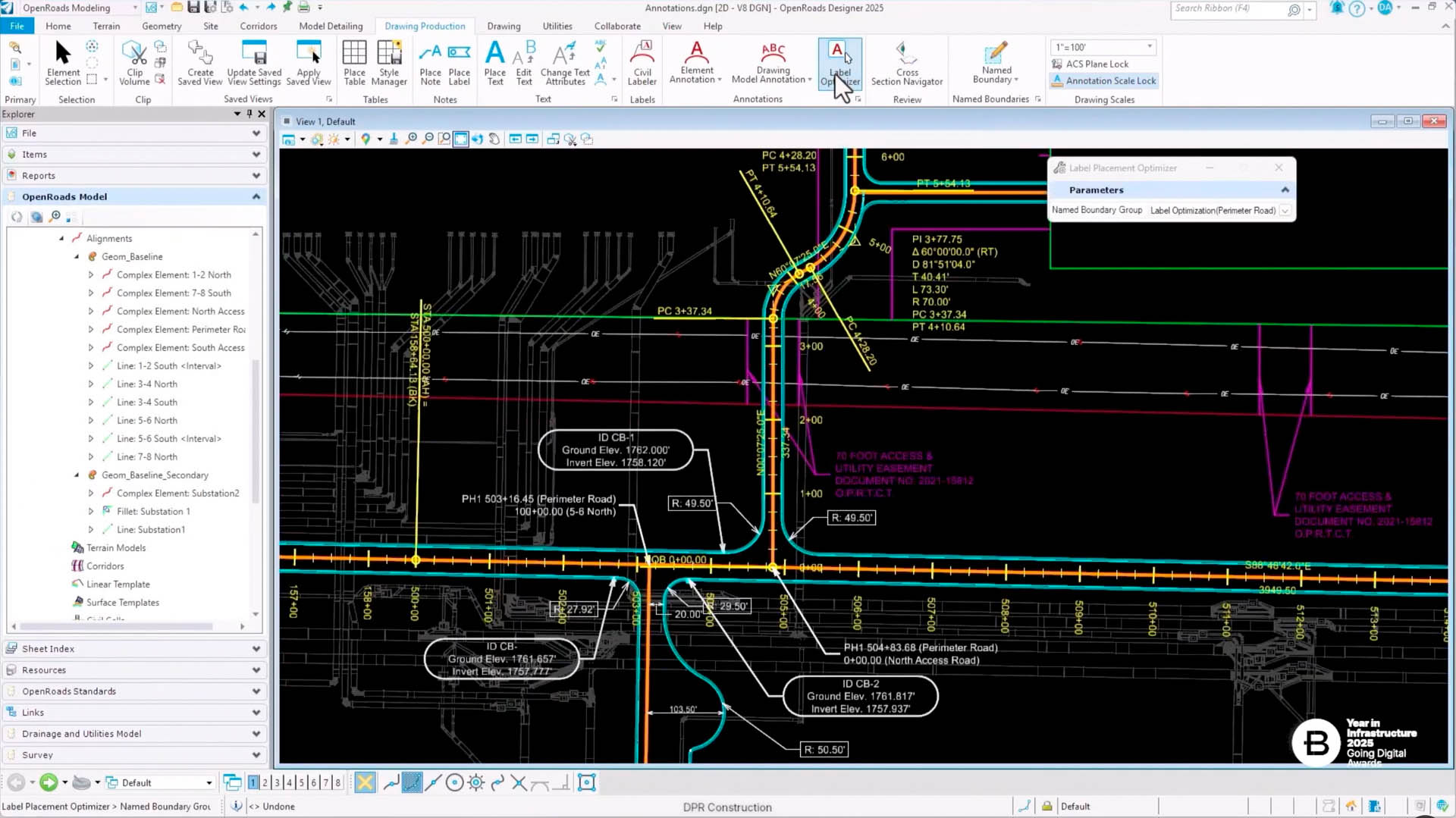

That effort has now evolved into a formal feature called Label Optimizer. This is also being applied to Bentley’s MicroStation power-platform-based products, including OpenRoads Designer, OpenRail Designer and OpenSite Designer.

Label Optimizer uses machine learning to annotate drawings, automatically organising labels and eliminating overlapping text. In short, it makes drawings easier to read. It handles label placement, leader line length, text rotation and spacing, all without manual intervention.

“[With] the neural network that we built, we were able to get a much higher level of quality – just as good as a human could do, sometimes better,” explained Valois. He added that, by using AI rather than traditional algorithmic approaches, the software is able to factor in aesthetics as well.

Of course, label optimisation is just one facet of autonomous drawings. We asked Valois if Bentley plans to tackle drawing layout as well? “We haven’t done that yet,” he replied. “At the moment, it’s the text itself.”

Tenets of training

Unlike some other software companies, Bentley Systems is crystal-clear in its messaging around AI training and customer data. To return to an earlier Cumins quote: “Your project data remains your data, always.”

Bentley has trained its AI models using data that has been purchased and/or licensed. This can include data contributed by users and organisations that have explicitly agreed to share their data for the purpose of developing AI models that benefit all Bentley users.

Cumins explained that this is typically carried out in the context of Bentley’s early-access programmes, which was the case for OpenSite+, adding that customers tend to contribute data that is not that unique to them, while data that is unique to them is held back and used for their own fine-tuning.

AI models are finessed in the Bentley Infrastructure Cloud, but Bentley executives state very clearly that data specific to each account is utilised solely for the benefit of that account and is not incorporated into broader models or product enhancements.

But how does fine-tuning work in practice? Bentley CTO Moutte gave the example of using AI for drawing automation. “There is a Bentley default model that has been trained with data that has been sourced from third parties, but you also have all [your own] past drawings in your ProjectWise data source in your Infrastructure Cloud Connect environment, which are all potentially relevant for that AI model,” he explained.

“We let you pick the ones that you would like to use, because the design might be the client’s or the data might not be good enough. You don’t want to put garbage in.”

While some vendors’ restrictive EULAs are causing consternation, the transparency offered by Bentley executives when it comes to AI training stands out

Bentley then retrains the AI model with the foundation data, and the private data, but that new private AI model is only available to the customer. The impressive thing here is that Bentley provides full control over data governance.

“We provide an audit track of every time that [private model] was used, and what data was used to train that model,” said Moutte. “So, if you change your mind and you tell me, ‘Oh, that drawing that I’ve used to specialise the model, I don’t have the permission after all’, you opt it out and we retrain the model. And we can even tell you which were the inferences that have been potentially contaminated by that data.”

Project intelligence

Bentley Systems is also using AI to uncover information in ProjectWise, part of Bentley Infrastructure Cloud.

In 2026, users of the project collaboration and information management platform will get AI-powered search capabilities, designed to significantly reduce the time they spend searching for information across project folders and data sources.

“Historically, a ProjectWise search was just a straight keyword match,” said Jason Slocum, director for ProjectWise. “If you misspelled something, you got nothing back.”

That has now changed, as Moutte explained. “Say you need a document from a past project, and you’re not sure what it’s called or who created it, or even where it’s stored. With the redesigned Projectwise interface, you can stop digging and you can start finding. The new AI-powered search understands what you mean, not just what you type.”

Once a document is found, users can also receive “instant, concise summaries” generated by AI, without needing to open files or switch between applications.

Bentley is also using AI to help users develop their own automated workflows. In MicroStation, for example, the new Python Assistant acts as an AI-powered coding tool, allowing users to create scripts without having to learn Python themselves. Instead of writing code manually, they can simply describe what they want to do, and the assistant generates the Python code for them.

Cloud connect

For years, Bentley Systems has talked about digital twins, the iTwin platform and “connected data environments”, but the practical reality for most users has been scattered repositories, inconsistent schemas and workflows still anchored to desktop silos.

At YII the company launched Cloud Connect, which is a new foundation layer of Bentley Infrastructure Cloud and attempts to solve the industry’s biggest operational drag: infrastructure data remains locked inside PDFs, proprietary formats and legacy file servers.

Bentley’s Cloud Connect solution offers a unified web interface, to a single, governed environment where design models, inspections, reality capture, geospatial and IoT streams remain queryable and interoperable across the lifecycle.

Connect can ingest more than 50 engineering formats and integrate with enterprise systems, effectively acting as a federation layer rather than a file store. Collaboration tools such as feedback, mark-ups, correspondence and deliverables management are built in, making it relevant to day-to-day project operations.

“Infrastructure data lives everywhere – in models, PDFs, inspection forms, photos, IoT sensors and more – and it’s rarely connected,” said CTO Julien Moutte. “That changes with Bentley Infrastructure Cloud Connect. Infrastructure professionals can access and manage all project and asset data in one place, fully contextualised and connected, from design through construction to operations.”

Geospatial meets engineering

Since acquiring Cesium last year, Bentley has been working to bring the geospatial and infrastructure worlds much closer together. This is being realised through tighter integration between the Cesium Ion platform and Bentley Infrastructure Cloud. Users can now see their projects, comprising CAD, engineering, iModels, PDF drawings, reality models and more, all within their geospatial context.

This convergence is also happening in Bentley’s desktop tools. MicroStation, and those tools built on the CAD platform for road, railway and bridge design, now includes support for Cesium 3D Tiles, allowing engineers to integrate a range of content directly into their design projects, including Google Photorealistic 3D Tiles and their own high-fidelity reality data.

The big news coming out of YII was that Bentley has integrated its iTwin Capture reality modelling services within Cesium ion, creating what Patrick Cozzi, founder of Cesium and now chief platform officer at Bentley Systems, describes as a fully automated pipeline from data capture to geospatial visualisation.

iTwin Capture generates engineering-grade reality models from imagery and applies AI-powered feature detection, while Cesium Ion enables developers to host and stream 3D content in the cloud.

The handling of point clouds and photogrammetry meshes is standard fare, but Cesium has now added support for Gaussian Splats, a relatively new technology that uses AI to identify key features from photos and videos.

“Think of Gaussian Splats as a point cloud, where each point is expanded and then blurred with the surrounding points to create a smooth, photorealistic surface,” said Cozzi. “Hence the name ‘Splats’ – each point is splatted.”

According to Cozzi, Gaussian Splats provide superior visual quality compared to traditional photogrammetry, especially for thin objects like power lines and antennas, and refractive and reflective materials such as glass. At YII, Bentley demonstrated some of the benefits that Gaussian Splats can bring to engineering, inspection and digital twins, in a showcase of its R&D hub, the iLab (Innovation Lab).

Using an app developed using CesiumJS, an open-source platform for building web applications using Cesium 3D Tiles, Daniel Wikstrom, senior software engineer, presented a model of an Amsterdam cable bridge generated using Gaussian Splats.

Wikstrom explained that compared to photogrammetry, which often produces noisy, incomplete meshes with lots of holes, Gaussian Splats can capture the cables on the bridge much more accurately and cleanly.

Photogrammetry also struggles with transparency, he said, because it generates solid meshes, so see-through surfaces are lost. With Gaussian Splats, however, transparent elements are preserved, giving a much more faithful representation of the original scene.

Bentley executives clearly believe in the technology and are helping to establish Gaussian Splats as an open standard, collaborating with the Kronos Group and the Open Geospatial Consortium. According to Cozzi, the goal is to bring the reality modelling technology to glTF, an efficient 3D web format, and 3D Tiles, an open standard pioneered by Cesium that streams only the data needed for any given view, making large geospatial datasets much easier to handle.

The reality modelling capabilities in Cesium Ion will be generally available before the end of 2025.

Bentley’s opening AI chapter

Bentley’s AI direction is still in its formative phase, and the company is clear that what exists today is only the opening chapter.

Copilot, for example, remains an evolving layer, rather than a finished assistant. It already shows promise in site design, drainage and documentation tasks, but it is not yet obvious how far it can stretch into more demanding domains such as detailed road design or structural workflows.

Bentley itself acknowledges that more discipline-specific agents will appear, each tuned to particular engineering tasks rather than one monolithic ‘super AI’.

This shift also coincides with a more subtle software architectural transition inside Bentley: moving from the long-established MicroStation DGN-based files to the new ‘Plus’ generation of applications. These are AI-powered, cloud-connected by default and write directly to iModels without passing through a traditional file-based workflow. This marks the beginning of a desktop that behaves much more like a connected cloud service tied directly to Bentley Infrastructure Cloud.

While some vendors’ restrictive EULAs are causing consternation, the transparency offered by Bentley executives when it comes to AI training stands out. In conversations with the company’s CEO and CTO, the message was consistent: foundational models are trained on licensed datasets, while customer data is only used for private fine-tuning, never rolled back into global models.

For customers, the bottom line for AI in design software is simple: what are the benefits? Bentley has shown a suite of really useful capabilities, from the subtle to ‘this looks like magic’.

A great example given was Staad, a Bentley finite element analysis tool: while the software still performs the authoritative simulation, AI can be used to narrow the search space for results by putting the software in the right ballpark, reducing computation and time.

Meanwhile, iTwin Capture applies machine learning algorithms to automatically extract features and detect defects in images, such as cracks in infrastructure such as tunnels or bridges, and can rate the urgency of repairs like a seasoned professional.

The same approach extends across Bentley’s portfolio. It’s already visible in acquired tools like Blyncsy, which applies computer vision to assess roadway imagery at scale.

Bentley’s emerging ecosystem will be a constellation of specialised agents working across inspection, design optimisation, compliance checking and documentation. AI becomes not a bolt-on, but a network of deeply embedded capabilities reshaping how infrastructure work gets done.