Working in ArchiCAD, Fife Architects have created a unique family home on the Firth of Forth that pays tribute to its industrial past and a greener future

From the outset, it was clear that this complex rural, industrial and historic site would present some unusual challenges. Located just outside Charlestown, close to Dunfermline and offering striking views across the Firth of Forth, the Iron Mill Bay House site is adjacent to a disused railway line and bordered by woodland where the derelict remains of a former steel foundry on the Lyne Burn river still stand.

With a strong industrial heritage, the foundry dates back to 1795 and is where pig iron and lime were smelted to produce anchors and goods for the railway, ships and pits, before being shipped worldwide from Charlestown Harbour. The site, meanwhile, was to become the location for a family home with an ‘industrial meets rural’ design concept.

As Lucy Beltran, a partner at Fife Architects and the project’s lead architect, explains: “The site was complex and challenging in itself and the surveyors needed to complete a detailed site survey before we could start our designs.” And once that survey had been completed, the next challenge was to translate that survey data into a useful and usable format for architects to work with.

“This was no problem for us, as one of the things we love about ArchiCAD is the ability to create a 3D point model from a topographical survey of the site,” says Beltran. “With ArchiCAD’s mesh tool, it’s very straightforward to take the surveyor’s data and model the site to automatically create a 3D mesh. With other software, either there is no mesh tool available or the process is much more complicated.”

An iterative design process

Once the survey was completed and a 3D mesh created, Fife Architects carefully examined the site constraints and drew up some initial designs. Using ArchiCAD, the team could immediately produce both 2D and 3D versions, helping the client to quickly visualise what the spaces would look like.

“With the option to view a 3D model early on in the design process, it really helps both architects and the client to visualise the design,” says Beltran. “This meant we could work through a number of iterations and versions to analyse the different options. For example, before opting for the distinctive, jagged sawtooth roof, we’d designed the building with a flat roof, but it didn’t seem industrial enough.”

In addition to computer-generated models, Fife Architects also made three different physical models of the designs. These were created by printing the elevations from ArchiCAD onto cardboard, before cutting them out and assembling them.

“In addition to the 3D designs and physical cardboard models, we used Graphisoft’s BIMx to show a virtual reality version of the model to our client,” says Beltran. “Using 3D glasses and an iPad, we could walk them through the model room by room, which was extremely well received.”

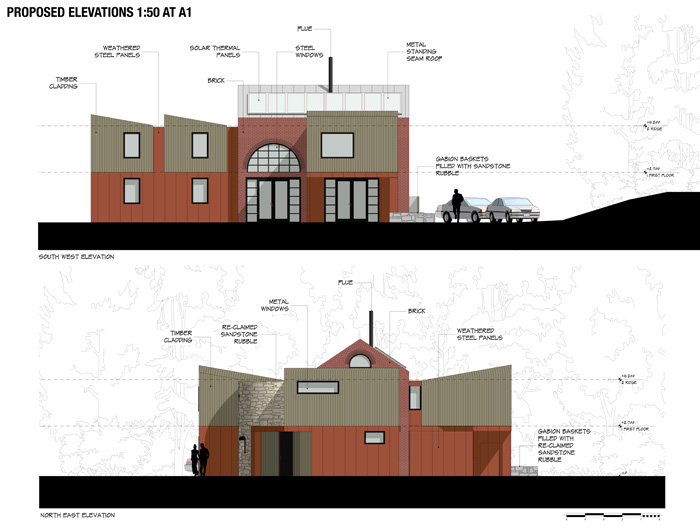

The result of all this work is a unique family home, in which the design and materials are strongly influenced by the site’s past, with its sawtooth factory roof profile and steel cladding. The T-shaped floor plan is oriented to maximise the views across the Firth of Forth, while bringing in as much natural daylight as possible. At the heart of the home is a large, brick doubleheight space with factory-style windows.

The design draws its inspiration from the old foundry, with a cylindrical sandstone stair tower and weathered steel cladding at the ground floor. Meanwhile, timber-clad bedroom accommodation with a sawtooth profile reflects the industrial style.

The client wanted to create a home that would perform as efficiently as possible in terms of energy and impact on the environment. The team created a highly insulated house and used renewable energy sources including an air source heat pump and a rainwater harvesting system.

A few clicks

Fife Architects has been working with ArchiCAD since the practice was established in 2011, says partner Fermin Beltran. “Using ArchiCAD, we create a schematic design with the planning, design and detailed drawings all contained in the model. We find the parametric objects particularly useful, as we can select any product and immediately anticipate how large it will be,” he says.

“In addition, it’s very quick and easy to make changes. For example, on this project, when we wanted to edit the roof shape and levels of insulation, we could do that in just a few clicks. Throughout the project, we worked with a full design team, including a mechanical engineer, structural engineer and quantity surveyor. Although this wasn’t a full BIM project, the structural engineer found the BIM information that we extracted from ArchiCAD very useful.”

Following a collaborative and iterative design process, the project received full planning permission in June 2016 and work started on the build in October 2017. The home is expected to be completed by Autumn 2018.

■ fifearchitects.com ■ graphisoft.com

About Fife Architects

Established in 2011, Fife Architects is an award-winning rural architectural design studio specialising in bespoke house design and full architectural services for all building types

If you enjoyed this article, subscribe to AEC Magazine for FREE