The cloud is already being used to optimise designs for performance and cost. Now, Bentley Systems is helping engineers ‘design out’ delays before they happen, by giving them access to real-time supply information. By Greg Corke

Bentley Systems has been investing heavily in the cloud. This is particularly evident in its structural software division, which now has a number of services that run on the Microsoft Azure platform.

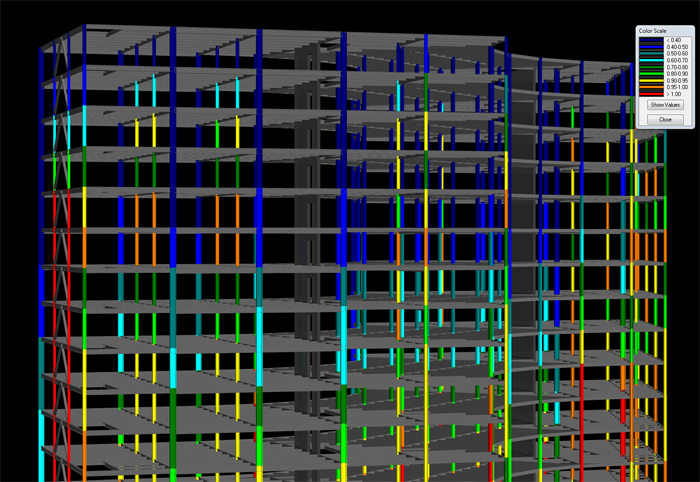

Design optimisation is a key focus. Scenario Services, for example, allows engineers to simultaneously analyse vast numbers of STAAD or SACS models, then compare the different options.

The impact on the industry could be huge. “Engineers are only going to put in as much work as they have time to,” says Raoul Karp, VP of development, analytical modelling, Bentley Systems. “And, if you don’t give them the time, they are going to come up with a solution that is probably going to be overkill and conservative.”

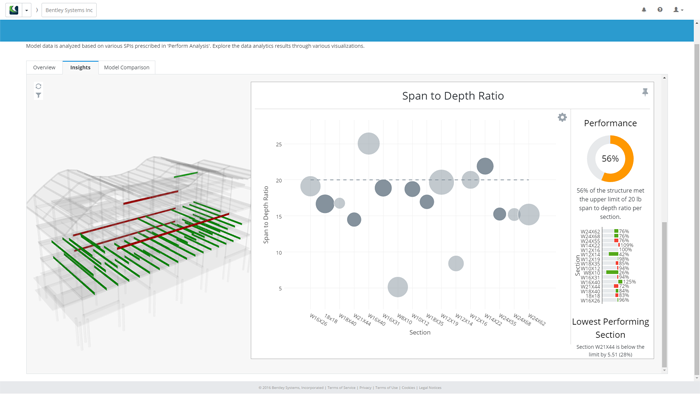

Bentley is also looking beyond cloudbased analysis engines. Analytical Insights (previously called Structural Insights) is a new beta cloud service for automated quality assurance.

The software can capture the knowledge of senior engineers, giving those less experienced the tools with which to check designs against pre-defined rules (such as length-to-depth ratio, beam weight, and so on) then offering recommendations on how they might be improved.

With Analytical Insights, Bentley is not just looking at ways to create better designs, but also to address common bottlenecks that occur when moving from design to construction. The idea is that by giving engineers visibility into downstream processes, they can minimise delays resulting from engineering decisions that they have made.

The initial focus is on the availability of steel in the supply chain. Bentley is working with Steel Central to get real-time inventory information from steel mills. Currently, this service is only available for steel manufactured by Gerdau in North America, but Bentley hopes to roll the service out globally.

If the engineer knows what steel is available, close to the site, in the timeframe that it will be need ed, designs can be adjusted in advance before it becomes a major bottleneck. Mr Karp shows an example project on screen: “These three sections that the engineer has specified are not going to be available in 45 days [when they are needed on site]. They are not in the mills. Not available in the local vicinity,” he says. “Let’s take those sections out, let’s maybe even put in a heavier section that’s available and help ensure there’s no delay.”

Steel mills can also benefit from improved data sharing. Designs can be tied to participating suppliers much earlier on. Also, by getting advance warning of what steel might be in demand, mills can adjust their rolling schedules accordingly.

Bentley also has plans to offer additional services for engineers. Currently, steel is rolled and sold in large lots, so if a project only needs a couple of beams of a certain size, there can be a lot of wastage. In the future, the software will be able to assess how much scrap a design will produce and identify how it might be optimised to match the stock.

There are other potential uses for sharing construction information. “During construction, cranes have certain capacity. And you can only lift a certain weight over a certain height,” says Mr Karp.

“If you [the engineer] knew that you had specified four beams on the top storey that would require the contractor to get a whole different, more expensive crane, wouldn’t you go about downsizing those beams, so the contractor can avoid a $500 a day cost for that crane?”

Putting analysis engines in the cloud and giving engineers access to huge processing resources is a powerful way to optimise designs. But why consider design in isolation? By giving engineers access to valuable downstream information, delays can be ‘designed out’ before they happen. The potential benefit to the construction industry, in terms of cost and time savings, could be huge.

While the obvious beneficiaries will be design / build firms or those involved in Integrated Project Delivery (IPD), engineering consultancies could also offer value-added services to clients. Breaking down data silos and sharing information via the cloud can benefit us all.

Structural analysis: licensing and education

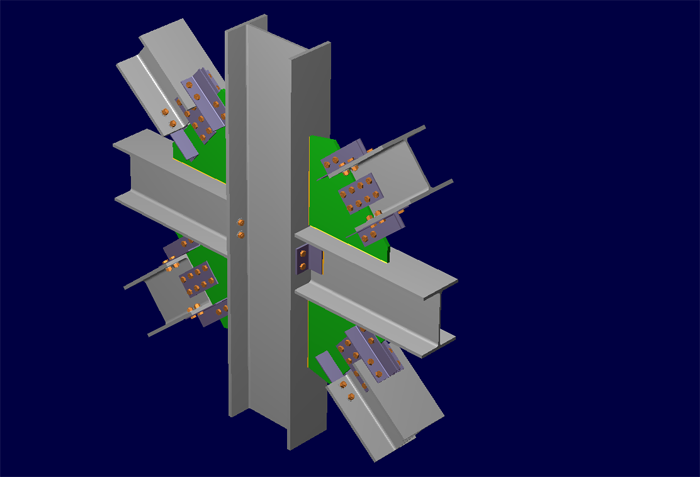

With a number of acquisitions over the years, Bentley has built up a huge portfolio of structural analysis products. It now covers the whole gamut, including slab design, building design, general purpose, foundation design, connection design and more.

This broad set of tools has established Bentley as one of the leading providers of structural analysis software but, for an engineering firm to buy standard licenses of all of these products, it would have to invest somewhere in the region of $35,000.

To make its structural analysis software more accessible, Bentley has now bundled all of these applications under a single Structural Enterprise license.

This, as Raoul Karp, VP of development, analytical modelling, Bentley Systems explains, gives single-user access to all products for a fraction of that cost (around 15%).

But will your average engineer be able to make use of such a broad portfolio, which includes more than 20 dedicated software tools? Mr Karp believes so. “75% or 80% of those products in the suite, every single engineer would have an opportunity to take advantage of,” he says. “There might be an occasion where [with] our advanced post-tension slab design product, maybe you have a specialist that just focuses on that area but, by and large, all of those products are things that engineers need to do.”

The big challenge for engineers is to learn how to use such a broad range of tools. Bentley has always invested heavily in education — it already offers several learning opportunities, including the Bentley Institute and special insider groups, where users can interact with product experts. Next year, however, it will release a new Connect service that gives users in-product access to a whole range of information that is directly relevant to specific project workflows.

Bentley Connect Advisor aggregates all sorts of data and content, including YouTube videos, hands-on classes, community content, manuals and workshops. Users can also subscribe to updates, so relevant information is streamed as a service. Bentley Connect Advisor will come online in Q1 next year and works with both V8i and Connect Edition products.

Bentley acknowledges that it also needs to increase visi – bility of new technologies. Mr Karp admits that his team often receives ‘wish list’ requests from customers for functionality that already exists in the products.

One way Bentley is tackling this is by embedding beta tools inside commercial products.

Indeed, a beta version of the quality assurance cloud service Analytical Insights is currently available from within RAM Structural.

This article is part of a Bentley Systems Year In Infrastructure special report. Read the other articles below

The age of the reality mesh: Bentley Systems is forging ahead with Reality Capture by embedding reality meshes into its foundation platform.

OpenRoads Designer: This new breed of civil design tool combines mesh data with detail design in one dynamic environment.

The future of AR: The HoloLens and the use of reality meshes have got round tracking issues, paving the way for new AR applications.

LumenRT embraces VR: LumenRT, an easy-to-use real time viz tool with a powerful ‘game engine’ environment, now offers VR support.

Bentley Systems futures: Bentley Systems may still be preparing for an IPO, but there has been some important news on its relationship with Siemens that could have big ramifications in the future

If you enjoyed this article, subscribe to AEC Magazine for FREE