The humble drawing finally comes of age with Bentley introducing automated drawing production in its new-generation civil design tool, writes Greg Corke

Bentley has a bold vision for civil engineering and construction. Its ‘constructioneering’ partnership with Topcon presents an entirely digital future, where engineering models drive autonomous construction vehicles and reality is captured in real time for QA and as-built asset records.

It’s a compelling narrative, but in an industry that is often slow to embrace new technologies and processes, the humble 2D drawing continues to be the essential deliverable in civil engineering projects.

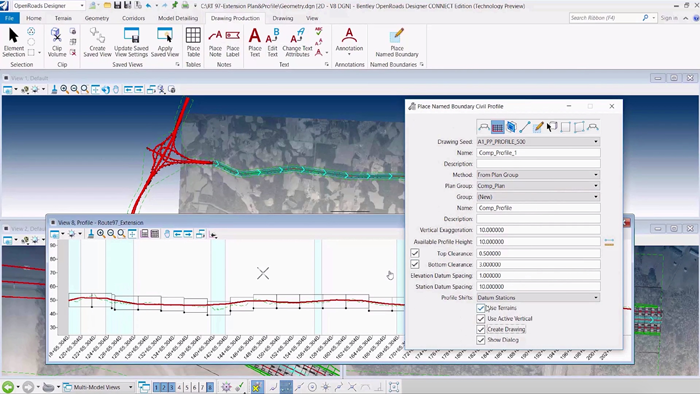

This has not been lost on Bentley’s civil design software development team, which has dedicated considerable resources to automating drawing production in OpenRoads Designer Connect Edition, the successor to Bentley’s civil engineering stalwarts: InRoads, Geopak, MX, and PowerCivil.

Laying the foundations

OpenRoads first appeared in 2013 as a common modelling technology for InRoads, Geopak and MX, acting as a stepping stone to a unified civil engineering detail design tool. It delivered intelligent 3D design tools with parametric constraints and dynamic civil cells that adapted to the design as it changed.

At the time, standards-based 2D deliverables were still handled by the individual applications. This remained the case until the launch of OpenRoads Designer Connect Edition last month.

The big difference with this new-generation software tool is the level of automation that has been built into drawing production. Previously, while drawings were derived from 3D models, they still required a fair amount of manual finishing and management.

“[OpenRoads Designer] is more interactive, in that a user can set up different ways of looking at the same information dependent upon the phase within the project that they’re at,” explains Steve Cockerell, industry marketing director, road and rail, Bentley Systems. “You might have a very simple view with a minimal amount of geometry showing whilst you’re designing, but a country or a project requirement might dictate that you need a very distinct set of information export for all of the intersection points — so it’s literally just picking a style for that particular phase for the same information to be drawn or exposed.”

Cockerell’s use of the word ‘exposed’ is important here as, in OpenRoads Designer, the drawing is inextricably linked to the 3D model. “It’s looking back to the geometry and extracting that information and presenting it in the style, as opposed to the more manual process that we’ve gone through before where you’d have to annotate your plan and other items. It was semi-automatic.”

In OpenRoads Designer, the new documentation centre can deal with different changes in scale in different areas within a single sheet and manage that for you.

“It gives us complete flexibility to stitch drawing sets together, to federate them with a set of named boundaries that control the drawing set in a ‘motif’ file,” adds Bentley’s Ian Rosam, director, product management, civil design. “And we can utilise that motif file to produce the drawings for different series and requirements.”

Importantly, any changes made to the model automatically ripple through to the drawings. Edits can also be made directly in the sheets and OpenRoads Designer updates the source geometry accordingly.

This ripple effect extends to annotations — so long as the user snaps them directly onto geometry and they are not left floating in space.

Drawing title blocks can also be automatically populated, as Cockerell explains, “I know it’s a simple thing, but every drawing has got to know what it is and be referenced back to a plan set. Then, if the design changes, you’ve got to go back and change every set of plans that are affected by that, so it [OpenRoads Designer] allows those design changes to automatically ripple through to the drawing production end of things.”

Conclusion

With OpenRoads Designer Connect Edition, Bentley has developed a fully automated drawing production system. This means that once the drawing sheets are set up, engineers can concentrate on the model, without having to worry about the knock-on effect that last-minute design changes might have on documentation. In essence, modelling and detailing can become much more fluent.

Working in this way, the time savings alone could be huge. However, by making a drawing a 100% by-product of a model, trust in the model will likely grow, encouraging its use as a key deliverable. And this could open doors to ‘constructioneering’ workflows, where the design model is digitally connected to construction and beyond.

If you enjoyed this article, subscribe to AEC Magazine for FREE