There’s been plenty of hype surrounding the use of AI for AEC design, but so far we’ve seen little of substance. However, green shoots are starting to appear. Martyn Day caught up with Augmenta who has a brand-new product that can electrically wire up a BIM model in one go

It is very difficult to gauge the impact of AI and Machine Learning (ML) on any specific AEC discipline. It’s made even harder when the applications that claim to be AI are in fact several different computing automation strategies compiled together, with AI contributing the least. This will remain the case for a long time as developers of automation tools will use the best / fastest computational strategies for the right problem, and AI may well not be the centre or main contributor to the magic you will see before your eyes. However, it will increasingly come into the mix.

We first talked with Augmenta in October 2022. At the time, the company didn’t have a shipping product but was making noises about the automation of building systems such as mechanical, electrical and plumbing (MEP). Many of the team, based in Toronto, Canada, were ex Autodesk-developers who were responsible for the generative design code that was impressively applied to Autodesk’s manufacturing-focused CAD tools – Fusion and Inventor. They had big ideas as to how generative design could be applied in AEC but couldn’t find any takers within that Autodesk division, so set up Augmenta and started working on the problem of building services.

I dream of wires

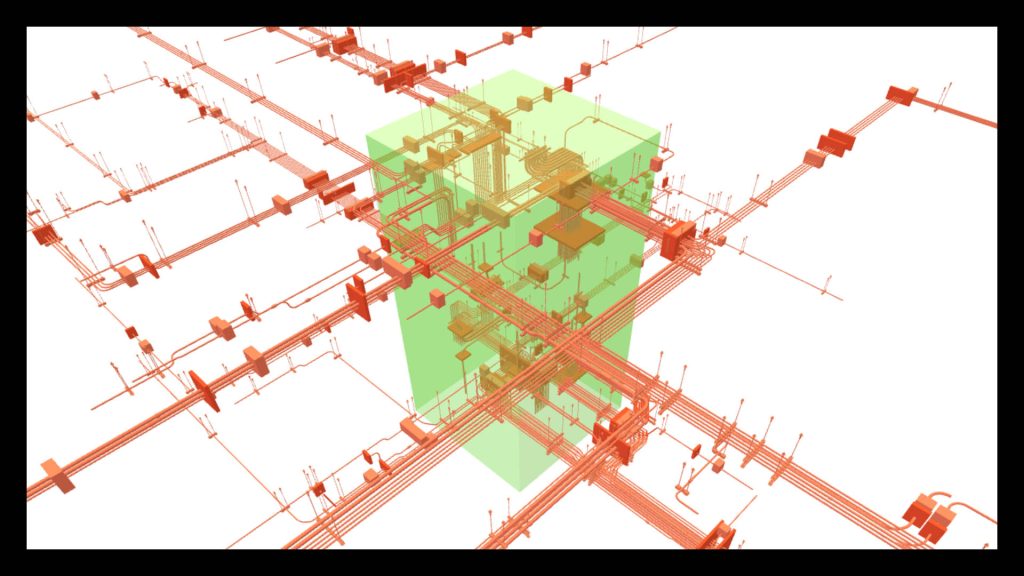

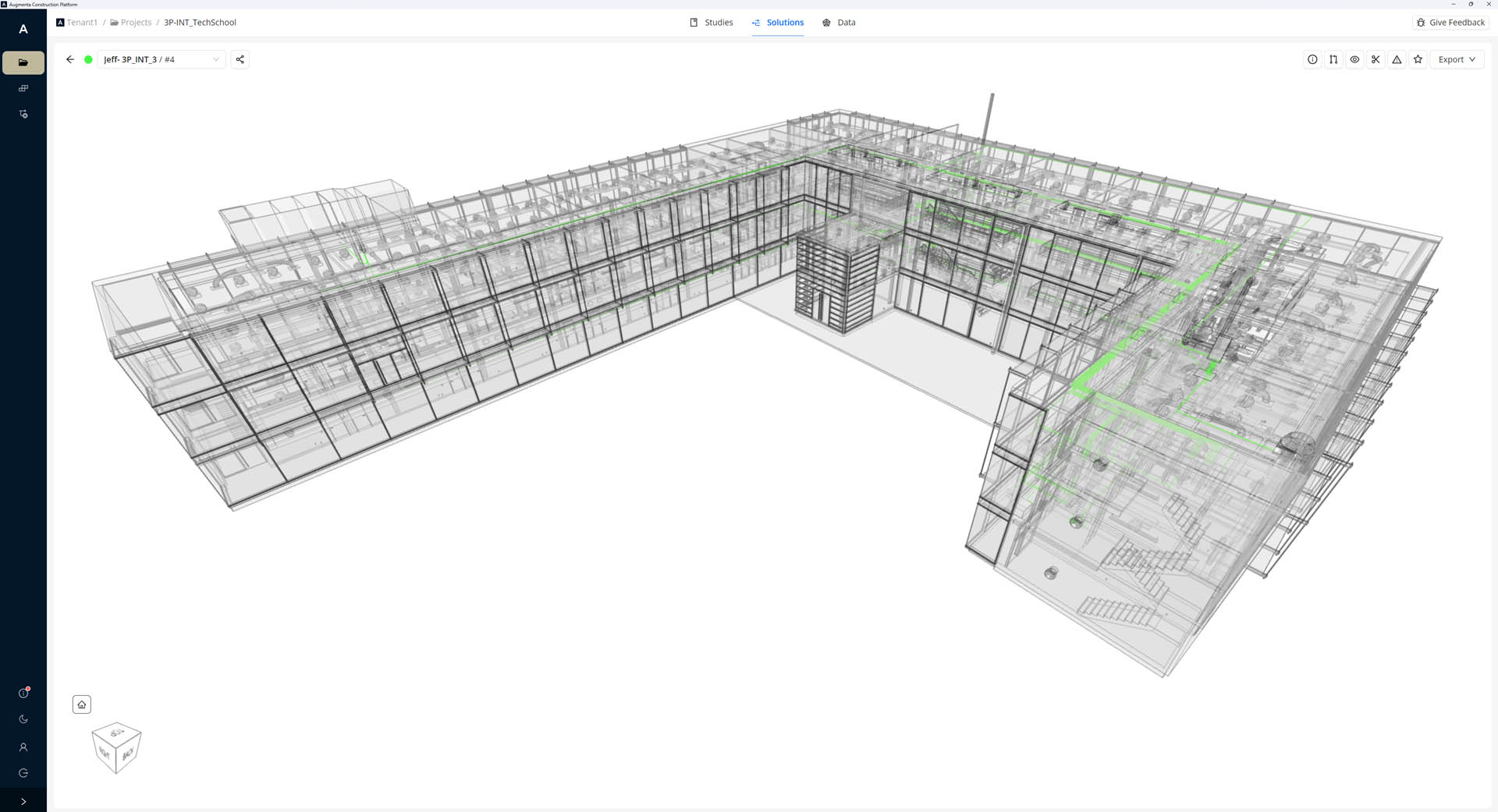

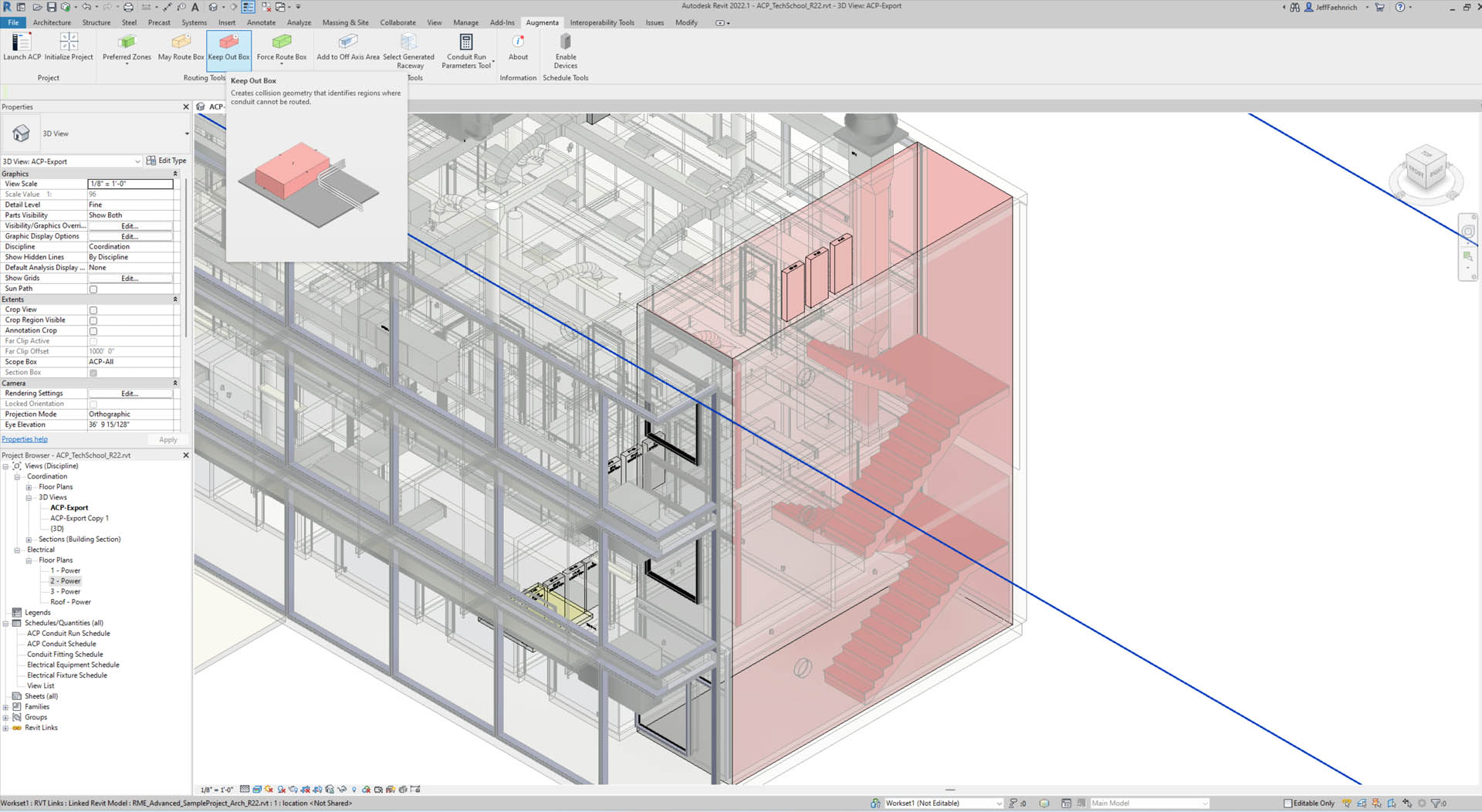

Augmenta has ‘shipped’ its first cloud product, aimed at wiring up electrical components in BIM models. The software is currently limited to USA projects, as the team has coded in US standards first. It automates the routing and coordination of conduit systems across an entire building, through multiple floors based on user-defined rules, with the specification of device and panel locations, no-go zones and run schedules.

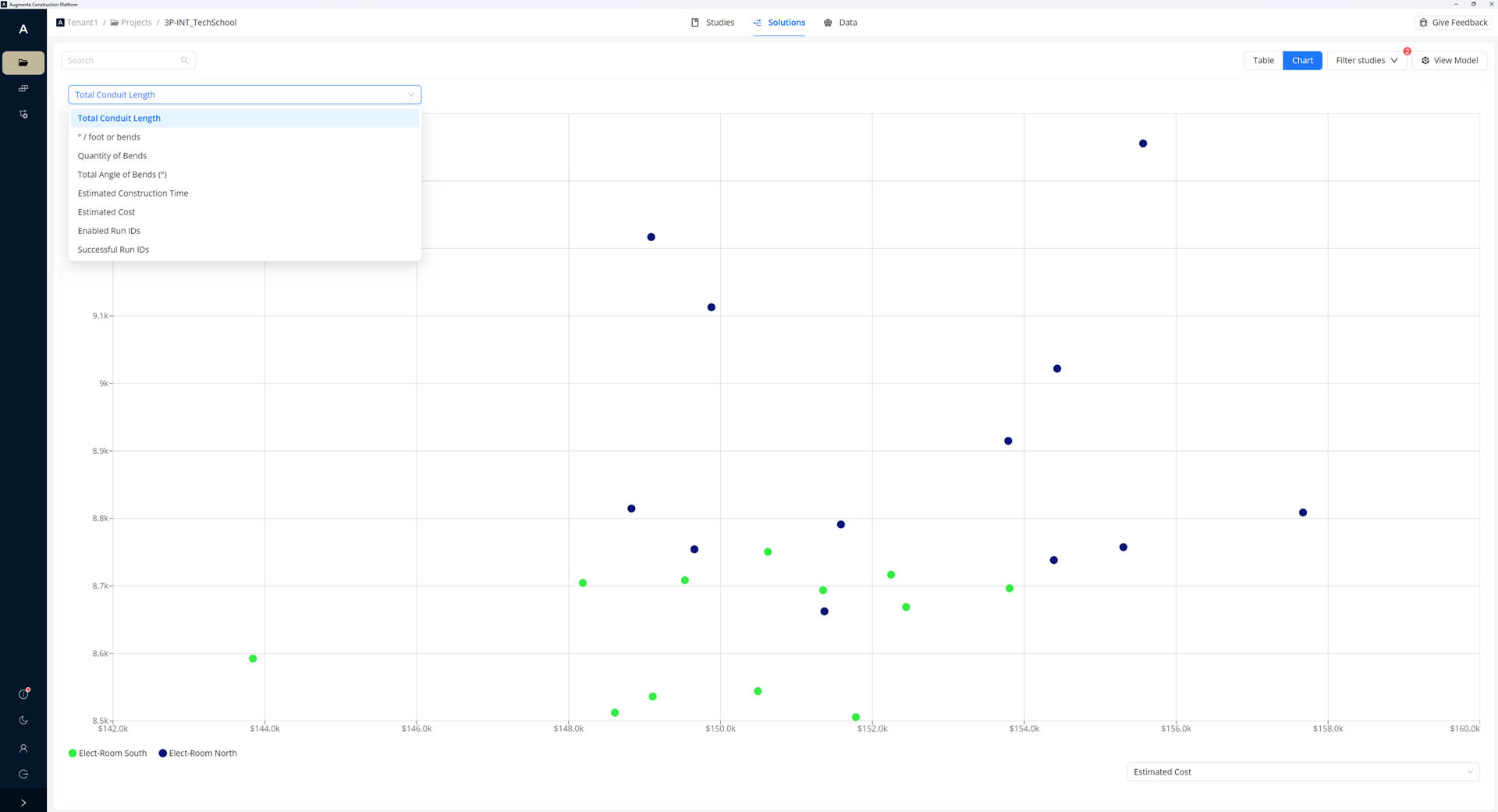

When the BIM (Revit) model is uploaded, Augmenta wires up all the electrical components, puts holes through walls for conduit, models everything in 3D, and provides an estimated cost. It’s possible to run several strategies at once and compare the price difference. Typically, this would take an expert days or weeks. Augmenta does it in hours.

Find this article plus many more in the Nov / Dec 2024 Edition of AEC Magazine

👉 Subscribe FREE here 👈

Once the electrical design is completed this can be exported to Revit for editing, detailing and clash detection. As the solution is in the cloud, development is ongoing and will eventually expand out to other countries.

Augmenta is simultaneously working on its auto-plumbing application which may come out this time next year. It will be possible to run a solve for both wiring and plumbing simultaneously. Eventually, when MEP is ready, Augmenta could do the whole lot in one pass. However, obviously the results need to be checked by a professional and perhaps altered for reasons not yet built into Augmenta’s system.

Augmenta is one of the poster children for BIM 2.0. These expert systems, which are coming to assist professionals, rapidly crush specification and detail design times. HighArc is another example that has built an automated house detail designer and drawing production system for American residential house builders.

If you extrapolate what these applications can do today, ten years into the future, you should be able to realise that the AEC design space is going to look very different. The levels of industry knowledge that will be built into ‘intelligent’ software will mean smaller teams will become highly productive, with automation perhaps completing 90% or more of each discipline’s detail work.

Add in ten years development of conceptual AI design tools, autodrawings, digital fabrication strategies and we have to consider very different tech stacks and team skills within AEC. From an initial concept, it could be hours or minutes to get a fully detailed model, with drawings and costings.

Thoughts from the team

To coincide with the launch of the new product we had a wide-ranging talk with Francesco Iorio, CEO, Aaron Szymanski, co-founder and head of product, and Matthew Hernandez, VP of Growth.

Iorio spoke at AEC Magazine’s NXT DEV conference in 2023 (watch his presentation) and was part of our mainstage demonstration in 2024 showing a non-Revit BIM workflow (watch the presentation).

CEO, Augmenta

Co-founder / head of product, Augmenta

VP of growth, Augmenta

AEC Magazine: Why did you start with electrical?

Iorio: Electrical is actually the hardest from a technical perspective. It may be easier in the sense that electricity doesn’t fight gravity like water but other than that, from a purely computational geometric perspective, it’s by far the hardest because electrical systems are made from conduits.

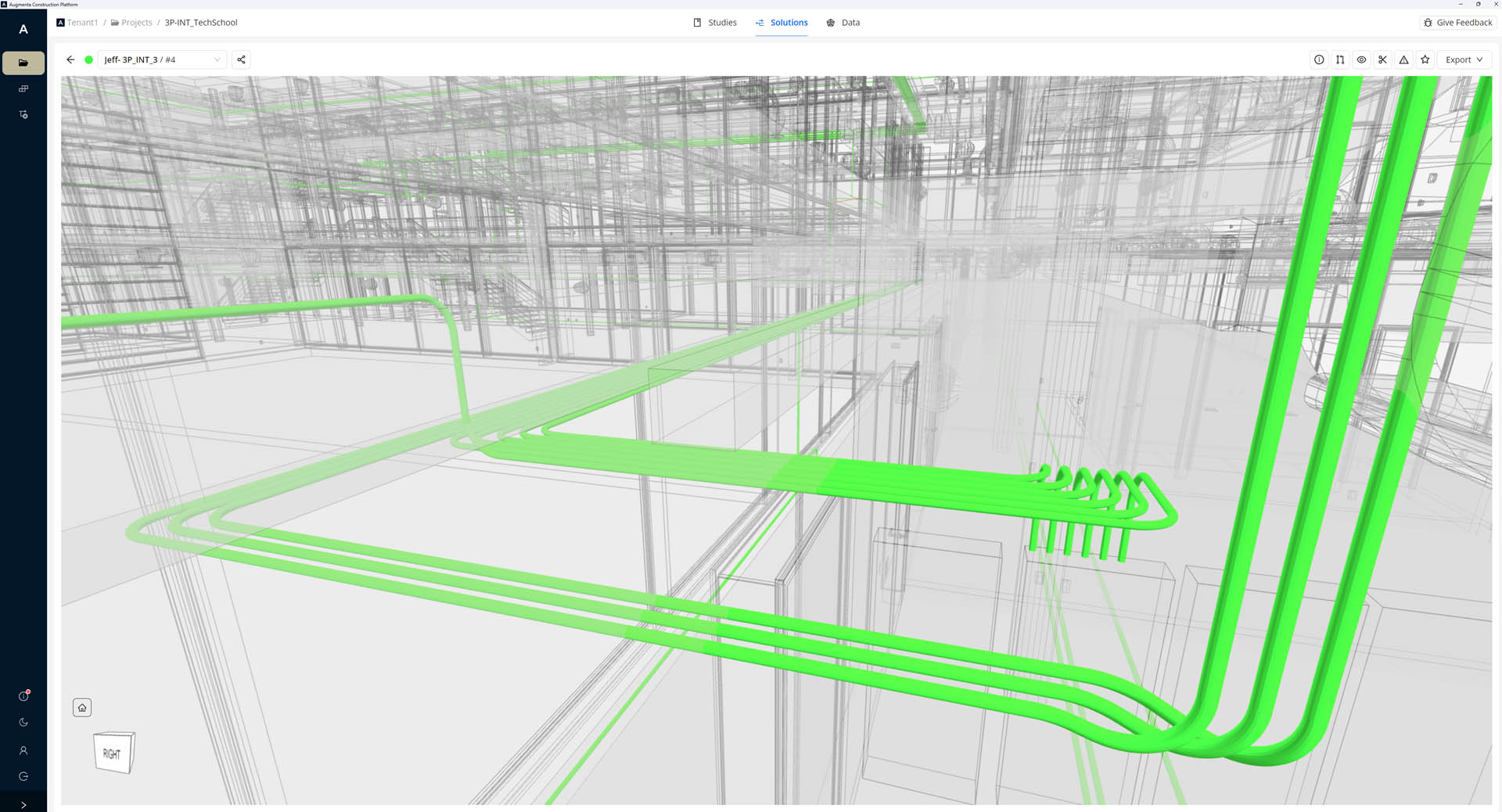

The number of parts that need modelling are even ten times what you need for MEP. We aren’t aiming to output a diagram or a high-level conceptual model. We want to output everything, something that’s constructible. We generate miles of raceway in one shot. This isn’t an assistant, it’s an automated system.

To do plumbing we will have to consider pressure, easiest transitions. You need to consider pressure drops, differentials and we would have to do some simulation. And of course, you must think about slopes for drains, which are a constraint.

MEP, in terms of geometry and topology, is much easier if you think about it. There are these giant ducts that take up a lot of space but essentially with mechanical it’s all about performance. You need to think about flow rates, take into consideration thermal losses, noise, vibration. It’s something that would apply computational fluid dynamics too.”

AEC: What kind of benefit will Augmenta offer electrical engineers and Revit workflows?

Szymanski: At the moment we’re not producing 100% perfect designs. There’s still the need for human cleanup involved at the detail level. The system might add an extra bend here and there, and there could be a self-collision somewhere.

We’re tracking all this and reducing the incident of errors over time. Today we will get you that initial population, will get you from a model that has nothing, to something that has 80% and customers are going to have to clean up that model themselves. Over time the amount of human intervention will reduce. We kind of think of ourselves as like a self-driving car startup, trying to reduce the amount of human intervention.

We have a broad scope for electrical, we cover a lot of the details like supports and couplings and we will eventually detail that functionality providing a full BoM. We can wire up a small hospital in just three hours – that’s the whole design – and eventually we’ll get to the point where there’s effectively no clean up. That means zero to fully detailed BoM, fully coordinated, ready to build in just a couple of hours.

AEC: What data does Augmenta need to start modelling electrical systems?

Szymanski: Basically, there are three main inputs: Revit model with just the most basic setup in terms of electrical equipment, the conduit run schedule, which defines your ‘tos an froms’ and what you want to run between that equipment, along with the design rules.

We really want to be able to get to the point where it’s just requirements, just tell us how many lights are in the building, tell us what sort of loads are in different parts of the building, [then] we’ll place the panels, we’ll pick the equipment for you, we’ll route everything and coordinate everything.

Once we have the mechanical and plumbing, we just run all that concurrently, so you have a full MEP system, that’s fully designed and coordinated, just based off high-level requirements. We’re moving upstream.

Today the way that the industry works is by prioritising some systems over others, so mechanical has top priority, like ducting over plumbing. Ducting has priority over pressure piping and those together have priority over electrical, because electrical can go up down around etc. So electrical is effectively just routing around in whatever space it can find. It’s why we started there because we can solve that problem for them, without anyone having to be aware they’re using a radically new way of designing their systems. Once we get into mechanical and plumbing, we’re going to build those out all at the same time and at once solve the same problem in three or four hours.

We understand that iteration is an important part of the process and must support that feedback loop. Our system means you can go through two full iterations of the entire building in a day as opposed to that happening over the course of months. Now [at the moment] with each iteration it’s a whole rebuild, going from scratch every time which we know is not ideal, so we’re looking at user-defined iteration, whether users can lock parts of the design and keep everything else unlocked for the next iteration. But we want to be able for this to happen automatically. Every user might load in a new background model and the outcome is that everything is the same except for one duct. Our software should recognise that and assume everything else is optimal.”

AEC: We suspect that the makers of conduit, MEP and plumbing might be interested in Augmenta specifying their products?

Szymanski: We’re talking to the main providers of conduit, and there’s a bunch of conversations we’re having on that topic. The most straightforward interest is that they want to be included in our default library, they want to be in that end BoM.”

AEC: How will you sell Augmenta? Is it a SaaS service, on demand?

Szymanski: We have two ways to get to market at the moment. The first is we’re offering design services through a partnership with ENG. ENG is the largest big modelling firm in the United States. We are now running our software on their entire pipeline, so they are still kind of the front end from a consulting model. With the back end of it we do the solution generation, make the user models and do the final editing on top of them and deliver those to our customers, but we’re not expanding that right now.

We have been using our software long enough to have actually built buildings. Our first was an elementary school in Michigan, we have another school where construction kicks off soon too. We are just building a flywheel for ourselves, where we’re running on as many live projects as we can, learning and building a product to produce real value for the industry.

AEC: How does Augmenta use AI/ML?

Szymanski: We use a combination of methods; our solution generation pipeline combines machine learning and various algorithmics methods in different parts. Right now, from a machine learning perspective we’re training primarily not on customer sites or in customer models, but on our own models. So, for example, when we generate a design, we generate a number of designs, a user picks one of those and we record that preference. We start to learn what is a higher quality design and what is a lower quality design, and then obviously there’s where those additional edits are made.

We learn from those edits as well and all this is about driving internally a higher quality score reducing the amount of human intervention. So, there’s a machine learning component that’s really about fine-tuning our internal weights and biases to produce higher quality results. The other thing we are using machine learning for is site interpretation. We’re not training on customer sites, but we’re really interested in using machine learning to interpret the sites to understand what’s a bathroom, what’s an elevator shaft, so we’re starting to extract that context data sites so that there’s less and less human setup required at the front end.

The biggest challenge we face, and it’s no surprise at all, is how messy Revit models are. They are so inconsistently modelled; people are not using the right elements and categories correctly. It’s no surprise to anyone I know in the industry, but it causes a massive headache when you’re trying to programmatically make sense of that site.

We’ve done a pretty good job of that but there are still specific things that need to be defined like firewalls, as we shouldn’t be cutting through them.

AEC: To come out with a good solution for a design, you really need to make sure you have a good quality BIM model to start with. From talking with others, the rather random nature of quality and precision in architect’s BIM models is a problem.

Hernandez: Unfortunately, too many people don’t see the value in model fidelity or use the best practices and that’s pervasive in the industry. We see the way of changing this is by making people incredibly more efficient than they are today by automating and optimising the design.

When you control the design, you control virtually all the downstream workflows, even to the level of construction and constructability. We don’t want to just speed people up – that’s just one benefit – we literally want to transform the construction industry and change the 25 years of no productivity gains that has plagued our industry for many reasons.

When you control the design, which is essentially the data from which everything else flows, you unlock advances in estimation, in procurement, in construction in safety on the job site, because you can prefabricate more. We are partnering with people who model well, are into prefabrication, and are willing to spend time to use our innovative tool fully so they’re the ones who are going to become more efficient. We already know there’s a huge labour shortage gap in construction, let alone to get into BIM VDC.”

AEC: When people think of AI in AEC, they tend to think of Midjourney. How is Augmenta different?

Hernandez: Right now, customers are saving about 60% but that’s just literally the tip of the iceberg. We’re working on some incredibly hard challenges – geometry, clashes coordination, path choosing, all in 3D. This is very different to the LLMs of text-to-render.

And a lot of the solutions that are built for construction today only address the symptoms not the problem. Ultimately, multidisciplinary firms using this technology will be able to estimate within a percent, which is incredible, which makes that available to the rest of construction – lowest carbon emissions, embodied carbon lowers construction costs etc.

Business model

All this automation could transform the way AEC firms work, but it also has a huge potential impact on software firms. To date, software firms have charged per user per licence, or token-based systems for usage estimated over years. Automation systems are going to remove the need for many licences of software that firms rely on today. And yes, while others will say there will be new jobs, the correlation between automation and smaller design teams, and fewer licences is going to have real consequences in future decades. We asked how software firms like Augmenta are reinventing the software business model?

Hernandez: Our product is still very, very early. It’s not our goal to go out and sell a bunch of SaaS licences. The pricing model that we use is to measure as closely as we can how much value customers are getting out of our software. For example, like the 60% increase in speed, with routing, modelling, coordination and then we take a small percentage of that as a fee. So as our scope increases, our fee will increase, but we would still be leaving the user, whether that’s a services firm, an engineering firm, or contractor with 90% of the value that we create.

Conclusion

Augmenta is a fascinating addition to the design landscape and the team is taking on some very big challenges – not just by discipline, but by country; not just attacking incumbent systems and workflows, but by having to trial new business models.

We hope the team’s opinions have stirred some thoughts and ideas of your own, as to what is coming down the pipeline for this industry with automation. The key takeaway seems to be that for the AEC industry to fully reap the downstream benefits of these advancements, it must significantly improve the quality of its BIM models.