For Version 11 StruCad has been brought bang up to date with a brand new Windows-style Graphics User Interface. But there’s much more to the latest release of the steel fabrication software than a simple face-lift says Greg Corke.

Product: StruCad Version 11

Supplier: AceCad

Price: On application

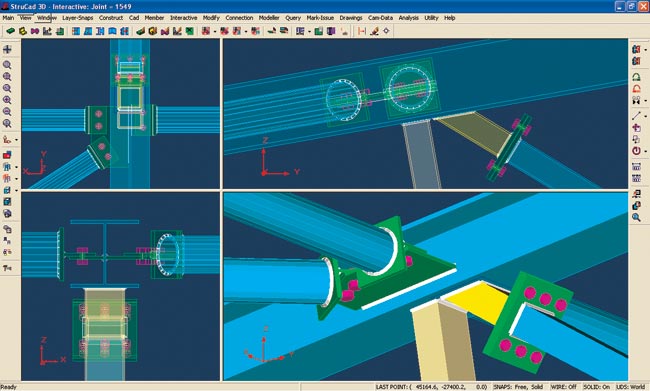

StruCad is one of the most respected Structural Steel detailing packages on the market today. It provides an extensive array of parametric modelling tools, enabling users to model entire steelwork structures in 3D – down to the last notch, plate and bolt – then automatically generate drawings, material lists, and CAM data. This level of functionality is something you don’t obtain overnight and it’s taken its developer, AceCad, many years to achieve. However, while the program’s capabilities have evolved considerably, development on the GUI (Graphic User Interface) has remained static for some years, making the product look a little dated.

The good news is that for Version 11, which has just started shipping this month, AceCad has given the GUI a complete overhaul, giving StruCad the look and feel of a modern Windows application, complete with enhanced usability. StruCad V11 includes standard Windows toolbars, complete with tooltips. These can be docked, icons can be displayed in two sizes, and new toolbars can be created or edited to suit an individual. Once set up, ‘users can transfer their customised interface to other machines simply by copying a couple of files.

The enhancements to the GUI also extend to other areas, including dialogues, pop up menus, and the new Dynamic Ports Splitter. Here, StruCad’s four port views, which typically contain views in plan, elevation and 3D, can be resized simply by dragging and dropping at the intersection of all four viewports.

StruCad’s new look and feel is sure to make it a much more welcoming environment for first time users. However, AceCad still has a huge installed base to keep happy and not all users welcome change with open arms. As a result, StruCad V11 still supports the old style interface, though AceCad believes that it won’t take long to win over veterans, once they give it a go. But beyond cosmetics and user interaction, where else has StruCad been enhanced?

Model limits: One of the major new enhancements is the increase in the number of members that are supported. Previously limited to 10,000, those working on huge projects would often have to split their models up into bite-sized chunks. Now due to a major re-write in Version 11, modelling limits have been virtually removed across the board. In addition, many of the key limits are now dynamic, only using the memory necessary for the number of items currently in the model, thus reducing the memory footprint of the model.

Xref: StruCad now has the ability to reference external drawings into a session. Xrefs can be inserted in both 2D and 3D, in SPF or DXF formats. This is particularly useful for bringing in architectural models, non-standard steel, or when working on structures made from a combination of materials.

Detail Views: Drawings generated by the detail command can now contain embedded data, which can be displayed on screen. Once a detail has been created, users can now label the drawing with the required part information such as stock size, mark, grade etc.

Nested Drawings: A new nesting system will allow the nesting of multiple drawings onto single sheets. While this will be of less interest to UK users, who typically deliver drawings on individual A4 sheets, the ability to place multiple drawings is sure to appeal to steel fabricators overseas.

Import/Export: StruCad has seen a wide range of enhancements to the import/export functionality available in StruCad’s Analysis and Design option or StruCad Analyser. V11 now supports the new CIS2 (CIMsteel Integration Standards) analysis neutral file, which is designed to lay down standards for electronic data exchange between different steelwork projects and software packages. Also new for this release is a direct link to STAAD, which enables users to import/export files to and from the popular analysis package.

Cold rolled Systems: AceCAD has been working closely with Kingspan to improve its cold rolled macros. In addition to a new side rail support system, dialogue boxes have been made much clearer across the board.

Estimating: For the past few years AceCad has been concentrating on providing tighter links to its StruM.I.S fabrication management system. Building on this, Version 11 sees the introduction of a dedicated estimating module, a wizard style utility built into StruCad that can be used to calculate the cost of a model. In addition to calculating the price of steelwork, the estimating module can be used to determine fabrication, painting, transport, and erection costs.

Despite all these enhancements, AceCad still has a little way to go before completing all of its ambitions for StruCad V11. In our December 2004 preview of Version 11, Acecad had scheduled in StruConnect, an integrated or standalone moment connection design program for structural engineers. This should be ready later this year, alongside multi-user capabilities, enabling the automated synchronisation of the work of multiple users.

Conclusion

For StruCad Version 11, it’s clear that AceCad has paid a great deal of attention to usability. The updates to the GUI are long overdue and help bring the product in line with StruCad’s more ‘Windows centric’ peers. Other significant updates, like the lifting of restrictions on the number of members, give StruCad users the power to work more effectively with increasingly complex structures, while the enhancements to detail views and nested drawings help improve 2D drawing production.

However, despite this attention to ‘usability’, a better indication of where AceCad is looking to take StruCad, and steel fabrication software in general, comes with the integration of the estimating module from its StruM.I.S fabrication management system. By providing the tools to produce a full cost estimate of a job, AceCad is looking to introduce more users to features that are available in StruM.I.S, such as project timings, budgets and planning. The end goal is to homogenize the software and provide an integrated software suite, which can deliver real time feedback on steelwork. For example, should an architect decide to change the spacing between columns part way through a project the steel fabricator will be able to right click on a steel section in the model and get instant feedback on where it is in the plant, whether it’s been sprayed, whether notches have been cut, or even whether it’s gone off to site. It’s all about all about giving the fabricator widespread access to data in respect of the model he’s already created, which is where considerable productivity savings will be found in the future.

www.acecad.co.uk