Closer collaboration between Bentley design and engineering products and Trimble’s software platform means translating design models into construction models has just got easier.

The first week of November 2014 was a busy time for the growing relationship between Bentley Systems and Trimble. In simultaneous user conferences 5,000 miles apart, key customers of both companies were being briefed on recent advancements which allow users of Bentley design and engineering products to transfer data directly into Trimble’s construction software platform. The goal is straightforward interoperability of construction modelling data from design to construction.

Industry research quoted by Trimble claims 90 percent of vertical buildings are delivered late, with 40 percent of them over budget. As Rob Painter, general manager of Trimble Buildings, told attendees at his company’s user conference in Las Vegas, the alliance with Bentley seeks to counter the three root causes of such problems: ineffective planning, communications and collaboration.

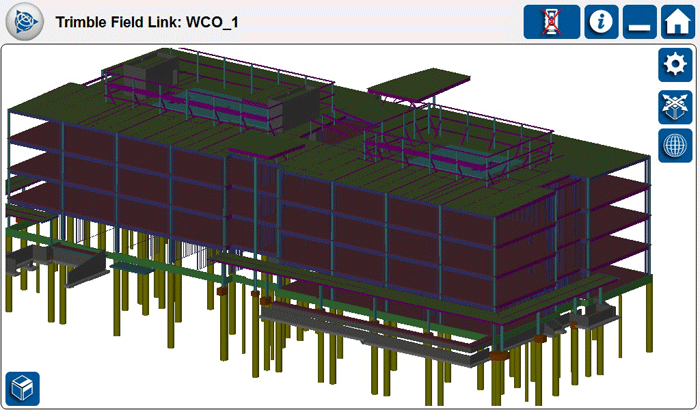

As defined by both companies, aspects of construction modelling include modelling of temporary works, intelligent positioning, “splitting and sequencing”, detailing for fabrication, workface planning, construction work packaging, and support for distributed construction — referencing and supplementing design modelling deliverables.

Bentley has assembled a large software portfolio in recent years that make it a leader for enterprise-class design and engineering projects, with some of its software being used by construction firms. Trimble has also been acquiring and building an extended software portfolio from its roots in construction and related field work, with some of it extending toward design/engineering. While they compete in a few areas (notably in structural engineering), there are many other areas in which joint customers move from using Bentley products to Trimble products in the design/construction cycle.

“Users are coming to us, saying they use both Trimble and Bentley software,” says Bentley’s Harry Vitelli, vice-president for construction and field products. “They are telling us to make our products work better together.”

Mark Nichols, New Zealand General Manager for Trimble adds: “The construction industry is demanding much better integration between the office and the field. People want it easy to move data around.”

An alliance was first announced 12 months ago at Bentley’s annual Year in Infrastructure conference. This year attendees in London were updated on the progress. Bentley and Trimble are jointly contributing to what they call a construction modelling workflow with four specific initiatives:

Jointly developed data schemas to ensure data maintains semantic fidelity as information is passed.

The use of Bentley iModels for construction deliverables to and from each company’s products when used together for project delivery.

Working together to advocate for improvements to industry interoperability standards.

Leveraging the other partner’s technology when it makes sense to improve workflow.

Interoperability is at the heart of this alliance, but both parties prefer to call it information mobility. “Information mobility transcends interoperability,” says Mr Vitelli. “It is about moving data to construction, with iModels being the transport mechanism.”

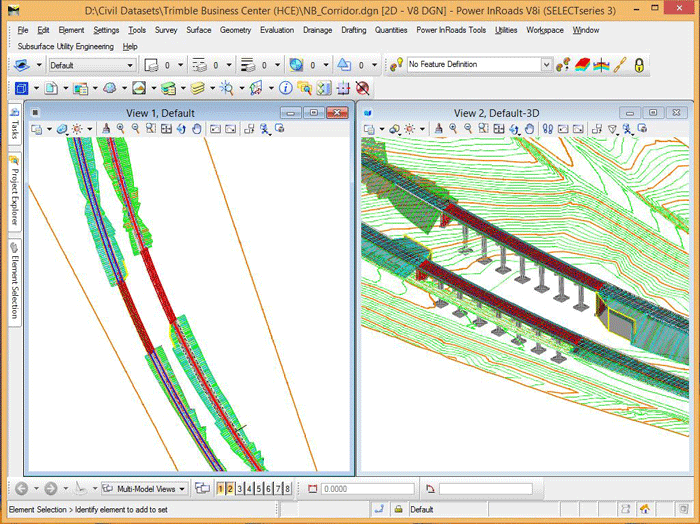

The quintessential application — and the first one made available to customers — is the use of road design data to drive an earthmover or other piece of heavy construction equipment. The section of road is designed in Bentley Open Roads; the model includes all the elevation data Trimble needs. The information is packaged by Bentley ProjectWise as a Bentley iModel, a data container designed to share BIM information in a variety of neutral and proprietary formats. The iModel is transmitted to Trimble Business Center, where the right data can be forwarded to the field as needed.

“At a deep engineering level, we work closely, in person, to work out what goes into the iModel,” says Mr Vitelli. “Working through the iModel is the essence of our alliance.” So far Bentley and Trimble have co-released two schemas, one for field layout and another for fabrication. A third will be released “soon” says Mr Vitelli, but they are not ready to talk about it yet.

Two new links in the chain are cloud-based data exchange technologies called Bentley Connect and Trimble Connect. (Both companies say the shared naming convention is not intentional). The data is sent from ProjectWise by Bentley Connect to the construction unit’s installation of Trimble Business Center, which has been updated to understand the incoming data from the Bentley iModel. Bentley and Trimble have agreed on a software development kit that allows Trimble Business Center to link to an installation of Bentley ProjectWise, or directly accept a Bentley iModel.

“iModels give us improved fidelity,” says Trimble’s Mr Nichols. “Too much important information has been transmitted in paper plans, or as digital models in PDF or Land XML that must still be translated for machine guidance. Using iModels we can now move more information with high fidelity, richness, and integrity.”

The first users of the schema for field layout are “taking hours — and sometimes days or weeks — out of the data preparation process,” says Bentley’s Ron Gant, industry marketing director for roads. “They are getting all the intelligence” of the original terrain design model, “more than with Land XML.”

For years paper plans have been the contractual documents between a design agency such as a regional department of transportation and a construction company.

“Why would we want to hand paper drawings to contractors instead of digital data?” asks Trimble’s Mr Nichols. “With the evolution of machine control, contractors must bring on board expertise to turn drawings into software tools to drive machines.”

With early attempts to make the project digital, Mr Nichols says the export formats “were not of the fidelity needed, especially at the contractor level”.

Now with greater fidelity possible in the handoff, the design teams are providing the more detailed landform information as horizontal, vertical, and cross sections. Construction teams are able to import the exact data they need for machine control without a second data input step.

iModels are a data packaging scheme created by Bentley. Some have compared iModels to PDF documents, but Mr Vitelli — a former employee of PDF inventor Adobe Systems — says the comparison is weak.

“iModels are meant to be published for a specific use case; PDF is published to normalise documents to the printed page. With iModels we can publish for earth works or publish for simulation. It is expected that the data will be used when it arrives.”

By comparison, Mr Vitelli says PDF is a closed container where the goal is not interoperability but readability. “This is about function more than documentation.”

In the course of interviewing Trimble and Bentley representatives, the term “BIM” almost never came up in the conversation. It turns out building information modelling as it is commonly understood in AEC today is a touchy subject for both companies. Too often BIM “ends with construction documentation”, says Mr Vitelli. “We are extending it to construction execution.”

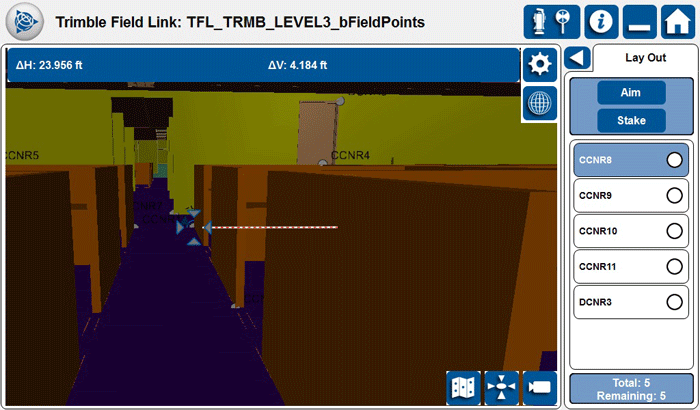

The preferred term used in the alliance is “construction modelling”. The data-driven execution of construction tasks is the common goal. “We want our users modelling knowing the data will go to the path of construction, to lay points, shoot lasers, install infrastructure, and remove earth, all on the back of that BIM model,” says Mark Nichols.

On a practical level, there is not one all-defining BIM, says Mr Nichols, but three: a design BIM, a construction BIM and an operations BIM. Bentley and Trimble want their alliance to move beyond naming the different uses of information and get straight to the useful integration.

“Different people need different data,” adds Mr Nichols. A structural beam will be specified by an engineer who had taken the time to determine what class of steel, the dimensions, the style, etc. “But when the handover to construction happens, only certain pieces of information are needed — the start and end of the beam, and a subset of properties.”

The consensus schema built by Bentley and Trimble, in this example, would identify information common to both parties and make sure it flows freely.

“Bentley and Trimble engineers sit down and agree what information both parties need, then structure it so it is usable at the next function in the process,” says Mr Nichols. “We sit at the table, figure out the handoffs, and develop the consensus schema.”

A variety of Trimble and Bentley products have so far been included in the construction modelling alliance:

- Bentley Navigator for project review and construction management.

- Bentley ProjectWise for content management and project collaboration.

- Bentley Open Roads for civil engineering design.

- Trimble Business Center, a geospatial design and delivery suite.

- Trimble Field Solutions for connecting design intent to the field.

- Trimble Field Link for connecting data to field tools.

- Trimble Quantm, for corridor planning and value engineering.

Kiewit Construction is an early adopter. Andy Kayhanfar, director of Virtual Construction, Kiewit explains how the convergence of Bentley / Trimble is helping his business.

“One of the challenges we face in construction is translating design models into meaningful construction models for survey utilisation in the field. Bentley and Trimble have provided a solution that helps drive greater efficiencies and reduces rework and risk when translating the design model to the survey. The Bentley-Trimble integration helps us better deliver the information created during the design process in Open Roads to the project survey team through Trimble’s Business Center. With a greater amount of information passing through, the field has more confidence in the model, while the risks that come with multiple translations are significantly reduced.”

Randall S. Newton (author) is Principal Analyst at Consilia Vektor. He has been writing about AEC since 1987.

If you enjoyed this article, subscribe to AEC Magazine for FREE