Chuck Hoberman is an unusual mix of inventor, artist and mechanical engineer. He has become internationally renowned for his innovative folding structures, art installations, medical tools and toys.

Earlier this year, I attended the SmartGeometry Forum in London. This group of predominantly architectural designers and computer technologists have formed a research group that explores new ways to design and interact with CAD models based on parametric design principles. The technology being explored here is applicable to all form-based design and one speaker in particular had a very interesting multi-disciplinary approach to introducing mechanisms to structural design.

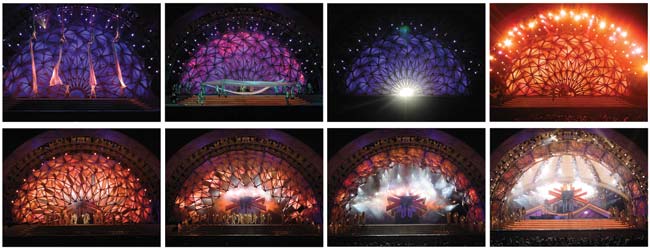

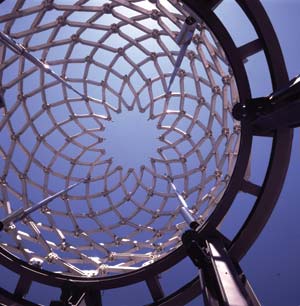

Chuck Hoberman is a New York-based inventor, artist and mechanical engineer. He designs products, toys, art installations and structures that all offer, what he terms ‘transformability’. Hoberman’s designs change shape, size and form, such as a geodesic sphere structure that folds into a 16 inch space, or something the size of a hatbox that deploys as a 5ft tall, two person tent. It’s not just about space saving design, it’s the ability for a design to move and change states, perhaps adapting to climactic conditions or morph through a number of positions as an art installation. The images here give a taste for the kinds of things Hoberman creates but as they all move in some way, a visit to the company website and a look at some of the videos is well worth the time (www.hoberman.com).

On examination, the designs all use an exquisite understanding of geometry, together with standard and unique mechanical components and manufacturing techniques. Hoberman holds both Art and Science degrees and even worked at a Robotics company prior to setting up his design studio to apply his fascination with moving mechanisms within many fields. Hoberman Associates has worked on projects covering military applications, home and office products to stadium and museum installations – in fact wherever Hoberman sees his theories and many patents on transformable designs can be applied. Talking at the SmartGeometry forum, it’s obvious that he sees many applications of his principles to modern architectural design, providing retractable coverings and adaptable fa?ades – perhaps building on the concept of the building as a machine for living in, adapting and changing to the environment or usage. It’s also typical of today’s ‘signature’ architects, like Sir Norman Foster and Lord Richard Rogers, pushing structures of steel and glass to their limits, only made viable from using tools such as Catia to drive the manufacturing process and make technically complex, custom buildings financially possible.

I caught up with Chuck Hoberman on the phone in his New York workshop to find out more about he designs and manufactures his transformable structures.

![]() You have qualifications spanning art and science, together with applied experience of both. What interests you about design?

You have qualifications spanning art and science, together with applied experience of both. What interests you about design?

Chuck Hoberman: The starting point of my whole career was looking at this transformability from the most general perspective. What I was interested in from the onset was working at a systems level, that is to say, working with the fundamental geometry and really trying to elucidate mechanical and structural principles, where all these areas come together. It’s really an outcome of my education which is in the arts and sciences. It’s an inherently multi-disciplinary role.

I didn’t start out as, let’s say, an expert in tent design, looking to improve the design of tents. It was more from a general design perspective and I’ve been going from general to specific application through the course of my career. I think one would come up with a different solution to the problem if I were to approach the design from a specialist point of view.

![]() I guess you have come up with a range of ways to transform structures through the years. Is this knowledge always the starting point for your designs?

I guess you have come up with a range of ways to transform structures through the years. Is this knowledge always the starting point for your designs?

CH: It’s a combination of these principles that form part of the 18 or so patents pending that I have. It’s a library of geometric techniques. Certainly when a client comes to us for a design, I dig into those techniques. On the other hand it’s also about a highly rationalised, engineering-based approach but at the same time open to new creative directions and inspiration. In many cases while my team and I are always drawing on the core principles that we share, often when a client comes to us with a problem, we only have part of the solution at hand, so we have to develop something new. It’s a combination of the two.

![]() Typically, what kind of customer comes to you for a ‘Transformable’ solution?

Typically, what kind of customer comes to you for a ‘Transformable’ solution?

CH: The critical factor is that there is a need and enthusiasm and a requirement that our technology can address. In the case of the rapidly deployable military tent, the requirements were very stringent but we felt from the onset of that project we could meet those requirements and the result is now a product on the market has raised the bar.

![]() Your solutions are unique. How do you work with clients and manufacturers?

Your solutions are unique. How do you work with clients and manufacturers?

CH: It’s a process that parallels other types of design. We set up a team with a client, a small group to really understand the aspects of the brief in-depth. We then go back and work with my team, develop two or three preliminary approaches to the problem and then the challenge for us is to find the intersection between the brief, the programmatic requirements, the pools of solutions and technology that we already have to bring. We will usually develop lots of tools to convey our ideas, which could be some rapid prototypes, CAD designs/models, renderings, or flythroughs.

We are small company and we are very hands on. Our approach is very grounded; we get a lot of mileage out of standard software, and standard techniques. Once we have what all sides consider is a suitable direction then we will always play a significant role in subsequent design and engineering of the product. Primarily we will handle the engineering from a design and mechanical standpoint and from a structural view we will work with one of the many structural engineering firms out there, like Buro Happold, Ove Arup or local firms in and around New York.

We have a number of fabrication houses that we work with, some are large, some are small. Very often they are firms working for the Aerospace industry or maybe theatrical, working on theme parks.

![]() You mention working with Aerospace manufacturers, is that due to tolerancing of your designs?

You mention working with Aerospace manufacturers, is that due to tolerancing of your designs?

CH: From a construction point we are working with very close tolerances. In the manufacturing world, many fabricators are used to working to the tolerances we need. There are process issues and there is an equilibrium to be found with the tolerance and scale of the project. Very often if you are building large structures you have to be aware of the economic costs of over-tolerancing a design.

We mainly get our projects machined, with some casting. Our toys are injection moulded, of course. Sometimes we can use surprising low-tech solutions for fabrication. For the piece we did for the Utah Winter Olympics, we needed a big arch to support our mechanical curtain and that was a series of large welded trapezoidal frames that bolted together. These had slides on them, which had to be oriented carefully to keep the mechanism aligned. The actual layout was done on the factory floor, they laid out a grid, 4ft by 8ft, which is the size of sheet of plywood. They took these sheets of plywood onto the CNC machine and etched the outlines of these trapezoidal shapes and laid them out across the grid, so there was a big one to one image of this arch on the floor (around 80ft long). They used this as their template and it gave perfectly adequate tolerancing for what we were looking for and the cost was minimal. Our fabricator came up with that, it was a smart practical solution.

![]() Many of your designs use hinges and joints, are these bespoke or standard parts?

Many of your designs use hinges and joints, are these bespoke or standard parts?

CH: We really don’t need to develop components; most have been pre-manufactured for us. It’s all out there – they aren’t all that ‘standard’ but they are out there. I am happy that we don’t need to innovate at the detail level! We are about the global integration of all these components, at a systems level, to get something that performs.

You use Autodesk Inventor as your modelling tool. How do you use 3D CAD?

CH: I’m not an advanced CAD user but I have been using CAD for 20 years and when I started designing my structures I had no access to any 3D software at all, so I just wrote code to create the geometric representation, as well as render the output. This was on a Macintosh. I had to do the transforms to project the geometry onto a picture plane and come up with my own shading and hidden line algorithms. It was ridiculous, but it was out of necessity. If I wanted to show someone a picture, I’d print this stuff out on a dot matrix printed and tile the plots out! But it was a good experience as I got to know what all these tools are about.

The use of Inventor is a legacy as we grew up with AutoCAD – it’s a natural follow on. We take advantage of the parametric capabilities at a component level, which means we can adapt the design easily and most of our structures use families of parts, or parts that have similar features but are geometrically different, so that’s useful.

We build assemblies with mechanical constraints so we can simulate the kinematics, the mechanical action of our structures. However, we don’t include the forces or do force analysis in Inventor. Instead we do a fair amount of paper, pencil and spreadsheet calculations!

As the project is being finalised, that’s when we go outside to a structural house and generally speaking, even then, they are not doing a full-motion dynamic calculation, they will do a static analysis. If, for instance, we have a cable driven structure, they will pin the structure into one position, by ‘fixing’ the cables, then run the analysis, get the forces and repeat that in a series of positions. It’s actually going into a fairly standard analysis package from their point of view.

Internally, we have a prototyping shop where we will use laser cutting, STL, machine parts, any technique that’s useful for a given project. To be honest on the software side of what we do, we tend to stay with fairly standard packages.

![]() Do you send 3D CAD data to the fabricators or 2D drawings?

Do you send 3D CAD data to the fabricators or 2D drawings?

CH: It still depends on the fabricator but things have certainly improved over the last five or six years. We can hand them the 3D file and most have the software to generate all the tool paths. I am of the mind that if we understand the manufacturing technique we can have a meaningful dialogue with manufacture and work out how to do it economically.

It’s impressive to see that there is a strong intent to unify Autodesk’s wide variety of solutions and have all these huge development teams work within a well defined standard framework.

We don’t just do the mechanisms, we also produce the electrical wiring controls, and the flow chart for integrated programming for lighting and motion. I am a mechanical engineer, I worked for six years in industrial robotics. There is so much of what we do that is similar to that industry, we are working with the same firms that do motion controls systems, robotics systems but putting it into a different context.

![]() Where do you see your Transformable designs being used in an Architectural context?

Where do you see your Transformable designs being used in an Architectural context?

CH: There’s a spectrum of architectural possibilities; a quick rapid set-up and modular approach, a fixed installation that offers variability and movement of the building over time, or something structural, like the roof may open and close. The process that these ideas share is the fundamental way of looking at changeability and movement. It’s a very complex equation with design, functional, and economic issues to be assessed. The role that I am trying to play is really to seed the discussion offering new practical, technical solutions and also just trying to spark people to think about design in a broader way.

![]() SmartGeometry appears to be about complex form and shape development. What is it that is applicable to transformability.

SmartGeometry appears to be about complex form and shape development. What is it that is applicable to transformability.

CH: The reason we are interested in SmartGeometry is to push parametric design to a much earlier part of the design process. So, instead of using our specialised techniques for form finding and creating geometry, we can automate that process and hopefully get to design solutions a lot quicker and in an easier way.

I’ve been aware of smart geometry for about a year, from some of the engineering firms here in New York. There could be enormous value for us, as we work with highly defined rule-base systems for developing designs. Since we know our rules really well, they may not be that simple and have many steps but it could be possible to develop algorithms for these. If what you can do is find a free form for a building shape by easily adjusting that form, and have the computer take care of the geometry and connections, then our approach is a poster child for that. We have been doing that in a more low-tech way because that’s where the current technology is at.

SmartGeometry is a different mindset for design. If you are starting with an algorithmic approach to design, where the first thing you set up are the rules, then you are in a different place than a paper and pencil sketch. I think it’s a matter of time, until people become accustomed to the techniques. The other area where this whole highly-parametric approach interfaces with the transformability of designs, is the time component. When we design a structure, it has an infinite number of states, which in a sense in just one more parameter, but you can bring that transformable shape parameter into direct relations with any other design parameter that you may be looking at. It’s a powerful idea for us. For instance, if you see people working in these parametric programs, they generate a field of variable design possibilities. Within each of these possibilities there’s this time component, where any one of those designs can be set into motion, going through all its changes in configuration. What this does, is takes what is inherently complex and breaks it into a very rich experiential design process giving many different possibilities and automatically optimising for all the different constraints in the project. Everyone here in the office is intellectually engaged with the concept.

![]() So do you think this highly-parametric and algorithmic approach will impact your designs?

So do you think this highly-parametric and algorithmic approach will impact your designs?

CH: When I present to designers, they say ‘Your stuff looks pretty symmetrical. What can you do that’s asymmetric, that has more complexity or more interesting forms?” I think certainly, there would be a benefit from deploying these kinds of extremely parametric systems. Our transformable design techniques are adaptable to asymmetric systems but the time to design is higher and there’s a cost penalty for going in that direction. However as designers our job is to respond to the vision of the architect. Transformable design is not about a particular look or feel or design, it’s a flexible design approach that will fit with many types of designs. If the architect is looking for blobby, we can do blobby, if the architect is looking for something curved, our techniques are adaptable and that’s what interests me.

![]() So what do you hope for transformable design in the future?

So what do you hope for transformable design in the future?

CH: With regard to Hoberman as an entity, we are technologists and technology holders. The future is to move it more towards a design tool, approach and philosophy that is accessible for advanced designers and forward looking designers. I’d like it to have a much broader base.