With our industry’s attention turning to construction, Trimble finds itself as a key player in the battle for the hearts and minds of firms using construction BIM. With a history, and a client base to envy, what advancements has the company been working on? Martyn Day reports from its annual user event

Trimble has travelled far since its early days in 1978, from the greatest proponent for GPS devices, to becoming a key player in construction, site development and the global BIM market. While many might associate the brand with high-end laser scanning, and site survey and development tools, it has acquired a vast array of industry-leading BIM brands, namely Tekla, SketchUp, Gehry Technologies, Vico, Sefaira and Viewpoint.

To date, Trimble seemed to have preferred to leave these brands to operate on their own terms, with little visible consolidation. However, the company has an industry product plan to address all the key stages of building design, from concept through analysis, to bid fabricate and construct, as well as to manage and operate.

Trimble has authoring tools for architecture, structural steel and concrete, analysis and optimisation. But, at the core of this process, are a range of cloud services which connect local and distant teams with fidelity data, linked to constructible information which accurately price out the build from the original digital design. Trimble aims to digitise the construction process, both in the design office and when breaking ground.

Trimble Dimensions is the company’s annual customer event, where users can get their hands on the latest site technology, as well as seeing software developments from the Trimble Buildings team. This year the event was held in Las Vegas, the week prior to Autodesk University. It has been a very busy month for AEC Magazine.

Trimble Buildings keynote

Roz Buick, VP of Trimble Buildings, started off by reminding the audience that Trimble has been working in this space for over 40 years, through many major changes and here again, the industry is on the cusp of the next revolution, a digital transformation. Buick called the company’s solution set the ‘Trimble Constructible process’, which combines a mixture of hardware, software and services built on an open data principle.

The whole point of BIM, said Buick, was to liberate the data, not silo it in proprietary formats. Trimble wants to bring BIM to the field and these models need to be accurate and geospatially placed in context.

Buick highlighted SketchUp as the company’s solution for concept design to constructible modelling. In the last year, Trimble SketchUp for web has added 6 million unique new users, added to the 35 million unique desktop users. Very few of Trimble’s competitors can quote anything like these numbers, although it is worth pointing out here that the subscribers to the professional version of SketchUp have not been filtered out from total users.

The essential elements of Trimble constructible have been called the ‘three Cs’, Constructible, Connected and Content enabled. The constructible phase is where the models are made and enable optimised workflows by driving 5D models. The models can be so accurate they contain every nut and bolt. Tekla Structures, the construction modelling tool, is being specifically called out by Trimble as a differentiator. While other BIM tools struggle with managing models of low level of detail, Trimble sees the fact they can model one-to-one and still maintain performance, as a key component. The more accurate the BIM models, the better the cost estimation, scheduling and completion. Constructible models allow you to plan better and build it right, first time.

Buick claimed that half of the skilled workforce would retire in 3 to 5 yearstime. The industry is facing a skills shortage and will have to rely on technology to fill the gap. Machine learning and analytics can automate workflows, driving efficiency and productivity.

Trimble Connect, its project data management tool, was highlighted as the central platform, which taps into the central ‘constructible’ model. This then sends the right information to project participants, should that be 2D drawing, 3D model or a Mixed Reality session using the Microsoft Hololens. Trimble has established a deep relationship with Microsoft and even took the Hololens and designed a construction hard hat to make it viable onsite. Trimble Connect has the ability to also perform analytics. Learning from past projects and applying that knowledge to future business wins.

To enable the industry to pivot, Buick made the case for connecting all industry stake holders and that was the driver behind acquiring e-Builder and Viewpoint. E-Builder covers capital program management for owners and has over 400 serial customers with 300 billion in projects and connects contractors, project managers and owners.

Viewpoint reaches over 8,000 construction managers with construction management software. To date, Trimble connects over 500,000 machines, over 3,000,000 users of AEC tools and over 10,000 field mobile devices.

‘Content enabled’ in Trimble’s view, points to the company’s development of component warehouses. Buick claimed that Trimble has a bigger cloud warehouse than any other company in the world, over 31,000,000 products and pricing data for architects, engineers and contractors.

Customers can also make their own content in-house and store that online. The SketchUp warehouse for architecture and design had 28 million, downloading 290 million models, while 640,000 new models were uploaded in one year, representing a 17% growth. The MEP team has a library of 18 million fully managed high level of detail models from over 400 manufacturers. Trimble has also launched new cloud-based estimating tools for MEP and Electrical.

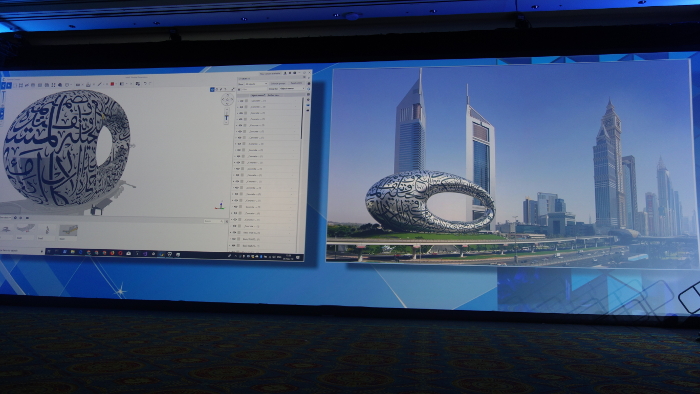

The Museum of the Future

Denis McNelis, engineering manager, BAM, gave a presentation on BAM’s work on the Museum of the Future in Dubai, an incredible building which defies all known concepts of what a building can be. While McNelis was talking about the project, Kim Nyberg, head-technology at Trimble Solutions, was live-manipulating the actual structural and architectural geometry of the museum in the Trimble World Viewer using a laptop. This demo was just as incredible as the building itself, as it was so fast and interactive.

The Museum of the Future is a 250ft high, seven storey steel frame diagrid building. The writing that covers the building’s façade are cuts to the skin and form the windows. There are 1,045 unique doubly curved cladding panels and boat building technology was needed to produce the shape. It was designed by Killa Design, contracted to BAM with AECOM and BuroHappold. McNelis concentrated on just a few of the aspects of the design which required innovative solutions, namely the Ringbeam, Steework, Cladding and MEP.

The concrete component of the building is relatively conventional with three floors of slab supporting the complex steelwork. There is a ring beam which is 75 metres long, 500ft in length. The building was designed in 3D software, which had to be detailed, so they could find a way of producing the rebar. The result meant that they had to change the shape of the beam, which in some instances meant a change of about 135mm.

The beam is 2.4m x 2.4m with 48 bars top and bottom. With so much metal BAM had to develop a 3D reinforcement model to make sure everything fitted. McNelis said that if they had not done this there was no way they could have used conventional technology to complete the job. The pour was 1,200m cubed of concrete and had to be poured in one go.

McNelis then moved on to the steel structure. There are no internal columns and each floor is 30ft high. There is also a spiral staircase which forms a double helix. It was modelled in NURBs surfaces and needed to be manufactured, but steel doesn’t bend quite so easily. The spine of the stairs had to be redesigned so it could be manufactured. Even then, six months ago BAM couldn’t model it and had to get Trimble to help enable the trapezoidal stair spine to be designed in 3D. It turned out that there was only one place in the world that could manufacture it.

Finally, the MEP in the building looks to have been a complete nightmare, as the designers had to avoid the complex and unique windows, with each duct having to be routed so as to not impact the building’s unique design. Spinning the model around in the Trimble Viewer you could see where ducts were moved to avoid a clash. A fantastic talk about a bonkers building.

Matt Hedke, senior VDC manager – Self Perform, Barton Malow, gave a frank and honest talk about the pains his company had gone through to transform itself from a traditional building contractor to a bluecollar BIM firm. Back in 2012, the firm set a goal to double its efficiency by 2024, the firm’s 100th anniversary. Hedke took a very strategic and goals-based approach to adopting new technology and processes each year and he got the buy in of the management, so it was driven top down. It covered every activity in the field and back at the office using Trimble Connect and an array of other applications.

Construction futures

Part of Trimble Dimensions included a trip to an off-site location to see some autonomous machine demonstrations, together with new technology that the company was working on. The area outside of Las Vegas had been turned into a giant construction site, with areas marked out for each of Trimble’s field solutions.

Our area of focus was on the future construction technologies displays. By far the most impressive was the dedicated area for autonomous construction. Trimble had three different vehicles performing autonomously in a controlled space. Simultaneously, the area was being monitored with parallax cameras and artificial intelligence (AI) to identify machines, people and objects within the autonomous workspace. Each machine was fitted with lidar, radar and remote control.

While they worked the designated area, geo fenced out from a controlling computer, they were constantly checking for obstructions and other vehicles crossing their paths. Looking at the AI screen, we could see bounding boxes around each of the identified objects and vehicles on-site. When another vehicle or person walked into the camera’s view, the computer attempted to identify the type of object. This technology could be used in combination with autonomous vehicles, using active sensors to maintain a safe site and avoid any damage. The operator of the machines had a giant red button on his desk. If something drastic happened, by pressing the button, all the machines would stop.

While this was a demonstration, it was clear that the technology was very close to being deployable. In the future, just a few managers could oversee an army of automated machines as they perform key site operations such as grading, digging and rolling. The future of site preparation will be a site being constantly laser scanned and the system being in control of the machines, delivering precise results.

Obviously, things get trickier when you mix automated machines and humans. There would have to be a high degree of reliability in the artificial intelligence and safety mechanisms. This was an incredibly impressive display.

Trimble also showed how augmented reality can be used on a digger, to show the operator what was under the ground, or the intended design outcome. What was especially impressive was the ability to retrofit all of this kind of technology to existing machines.

Another demonstration showed some early beta software which analysed the whole site and could define areas and paths, where earth was being removed to be placed where earth was required. The system would even work out the pathway for the vehicles to blend the surface to requirements. This promises to be a highly efficient site tool and could be available as early as next year.

Conclusion

Trimble doesn’t act like most software companies, possibly because it spans hardware, software and serviced solutions. Companies like Autodesk bundle up their software for the built environment, while Trimble maintains clear and dedicated applications for recognised roles, all connected through its cloud backbone.

This also goes some way to explaining why Trimble has acquired so many applications, as it identifies with many stakeholders with a variety of different needs. Trimble Connect is the central piece which brings these acquisitions together and the company is on a mission to enable design data and cost data to drive business decisions from owners to the contractor on the ground.

Despite millions of users of SketchUp, and a dominating position in conceptual design, Trimble is not a typically strong player in the BIM-to-documentation phase of the architectural market. It does however, have a very clear goal on where it wants to be in the construction BIM market. This is where we are finding the majority of major players in the AEC space are coalescing their investments and development. Everyone, it seems, wants a slice of construction.

Trimble already has established connections with the construction firms and products such as Tekla are industry dominating. In conversations with Trimble representatives, the company is aware of the powerful tool that Tekla offers. As was demonstrated on the main stage, and on the show floor, Tekla has an amazing ability to visualise huge models in full one-toone detail. The majority of Trimble’s competition has difficulty displaying low levels of detail architectural models, let alone high detailed construction-ready BIM. In the future, construction BIM models will need to directly drive digital fabrication processes. It’s clear to me that Trimble is already there.

If you enjoyed this article, subscribe to our email newsletter or print / PDF magazine for FREE