It’s been a year since HP first announced HP SitePrint, a robot that prints 2D plans onto the floors of construction sites. Now that the product is shipping, Greg Corke caught up with HP to find out what makes this neat little three-wheeler tick

Robots for construction have had their fair share of headlines in recent years. We’ve had robots that 3D print buildings, robots that tie rebar, robots that lay bricks, robots than bend metal, even robots that walk on all fours with a laser scanner strapped to their back.

HP’s take on the construction robot, HP SitePrint, is unassuming – less C3PO and more R2D2, if you like. It’s essentially a printer on wheels that prints site layouts directly onto the floors of construction sites.

The aim is replace slow, error-prone, manual layout to help general contractors, specialist contractors and construction management firms set out the location of building components quickly and precisely, making the site ready for the trades to come in.

The initial focus was on internal partitions / drywalls, but has since progressed to formwork structure, pre-cast concrete, and Mechanical, Electrical and Plumbing (MEP).

“We’re taking the digital file, which was printed on paper, and now printing it directly on the site,” explains Daniel Martinez, general manager, global head of large format printing at HP.

“All those lines are being done manually today, with chalk or with pen. It’s a very tedious process.”

Find this article plus many more in the September / October 2023 Edition of AEC Magazine

👉 Subscribe FREE here 👈

It’s also hard to find the people to do this work. According to HP’s recent ‘State of Construction Productivity’ survey, which canvased the opinions of construction workers and decision makers from the US, UK and Germany, 88% have had challenges staffing layout tasks – a combination of both a lack of skills and a shortage of labour.

According to Martinez, it is this labour crisis that has in part led to productivity in construction declining since the 1960s.

“We think that with HP SitePrint we can really start to change that trajectory,” he says. “On the one hand we’re able to do layout ten times faster than the manual process, but we’re also now able to bring a lot more information into the layout process.”

By this, Martinez means arcs, circles and text, which are difficult to do by hand, especially if lacking the necessary skills, but also ‘smart text’, as he explains, “Imagine a case where you’re able to print a QR code, for example, and now suddenly you have all the services that you can start to build on top of that capability.”

‘Smart Text’ could be used to show which specific door or window needs to be installed. “The communication process now is going to be relying much more on the information that you can lay on the ground,” says Martinez.

“We also think that it’s going to have upstream implications in terms of how the CAD drawings are designed, in order to better take advantage of that capability.” In other words, firms will begin to create CAD drawings specifically for HP SitePrint, introducing best practices. This is especially relevant to general contractors that handle multiple trades, and whose drawings can become incredibly complex.

Best practice drafting could be as simple as drawing all the constituent parts of a drywall on different layers. It means that any data that does not need to be printed on site can be easily turned off, rather than having to delete unwanted parts manually, line by line.

Getting connected

HP SitePrint can currently work with DXF and DWG files, the latter of which is pushed to the project-based cloud platform via an Autodesk AutoCAD plug-in. The next step is an Autodesk Revit plug-in, which is coming in a few months.

While many contractors still use AutoCAD or an equivalent 2D CAD tool, support for Revit is an interesting addition. It should automatically help streamline data preparation thanks to having object-based modelling at the heart of the BIM tool, plus there are many potential uses for the metadata that can be embedded within those objects.

Of course, all file-based workflows have limitations – the people that typically use SitePrint don’t have access to desktop CAD and BIM tools (nor the skills to use them) and there’s no automatic revision control or traceability. So, are there plans to integrate with construction management platforms like Autodesk Construction Cloud, Procore and others? According to Martinez, the answer is yes.

“We’re definitely working with Autodesk. We envision it [HP SitePrint] sort of expanding to become more of a connected platform where it will communicate with Procore, it will communicate with the likes of Dropbox and Box and that sort of thing,” he says.

Speed and accuracy

According to HP, SitePrint can improve construction productivity up to ten times compared to the manual process. But what about the firms that have been using it?

General contractor Skanska says 45 mins instead of 7 hours; framing and drywall contractor PDC quotes three days instead of three weeks; specialist contractor L5 Drywall says seven or eight rooms laid out, instead of two or three, and that it can be done with ‘one guy instead of three’.

Accuracy is also critical. HP quotes that prints are accurate to within plus or minus 3mm, but this in only part of the story. According to Shaun Carollo, VDC manager, Hoar Construction, using the HP SitePrint robot also cuts down a lot of the room for error. “If we can be more precise, more accurate, we can be faster and more efficient, then the owner and architect’s design intent is going to be a lot closer by the time we are done with the project.”

This sentiment is shared by Garret Wheat, project manager, Hoar Construction. “Being our first time we double checked almost every single point and we’ve been within, I believe, one sixteenth or one sixty-fourth of an inch on every single point, well within tolerance.”

Of course, not getting things done right, first time can have much bigger implications, as Gerado Rivera, VP operations, L5 Drywall explains, “Challenges that typically come up on the jobsite [using manual methods] are delays due to walls not being in the right place, measurements not being accurate. If a line is in the wrong place, then that wall might have to get torn out. That’s costly for companies like us because four or five errors like that, your profit margin shrinks.”

HP has shared some industry numbers to put everything in context. According to its ‘State of Construction Productivity’ survey, on average, impacted construction employees saw delays of over 15 days caused by layout (or setting-out) errors, with some (5%) enduring interruptions as long as three months. The cost of these reworks amounts to 9.4% of the total project budget on average and a fraction under a fifth (19%) of the project’s profit margin.

Conclusion

While HP SitePrint might not grab the imagination in quite the same way as a robotic dog from Boston Dynamics, its beauty lies in its simplicity. In many ways, HP is mirroring what 2D CAD did for manual drafting, except on a much larger scale, and forty years later.

Because SitePrint is easy to use and should fit quite seamlessly within established 2D workflows, it seems likely that it will deliver immediate productivity benefits for contractors. And since layout is on the critical path for construction projects, any time saved from speed of layout or reduction of errors can deliver huge rewards.

HP is not the only company doing this – Dusty Robotics and Rugged Robotics also have similar offerings. We don’t know much about these firms, so can’t comment on their products, but one has to imagine they will have their work cut out competing with the might of HP.

HP not only has the name and the pedigree in printing but, perhaps more importantly, the clout to make important connections within major construction software platform vendors. Loading up 2D DXF files is one thing, but the biggest efficiencies will surely come when data flows seamlessly from platform to platform in an optimised design to construction workflow.

The four elements of HP SitePrint

1) The Robot

The HP SitePrint robot is basically a printer on three wheels. It has a 50mm print head on the underside, in a fixed location so no calibration is required.

There’s a single ink cartridge to make changing easier (rather than an ink tank which was used in early prototypes). The robot uses water or solvent-based inks so it can work in a variety of environments and surfaces. This includes porous (concrete, tarmac, plywood, pavement) and non-porous surfaces (terrazzo, vinyl, epoxy). Solvent is more durable, but harder to rub out if it needs to be reprinted due to last-minute design changes. Inks come in different colours – red, blue or black – which can be useful for marking up different trades.

The robot has an integrated prism, which is used by the robotic total station to track, and a total of seven sensors. Four of these protect against falls. If it senses a ledge more than 2.5-inches high, it cuts the drivetrain. The other three are for detecting unknown obstacles that are not in the CAD file, such as tools or building materials left on site, or even people!

If the robot spots an obstacle, it simply stops printing, moves around the object, continues on the other side, and flags it up in the software. The operator can then move the object and send off the robot to reprint that small section.

The robot comes with two batteries. According to HP, each of them can perform constant construction layout for up to four hours. There’s also a 4G modem inside to connect to the HP SitePrint cloud platform

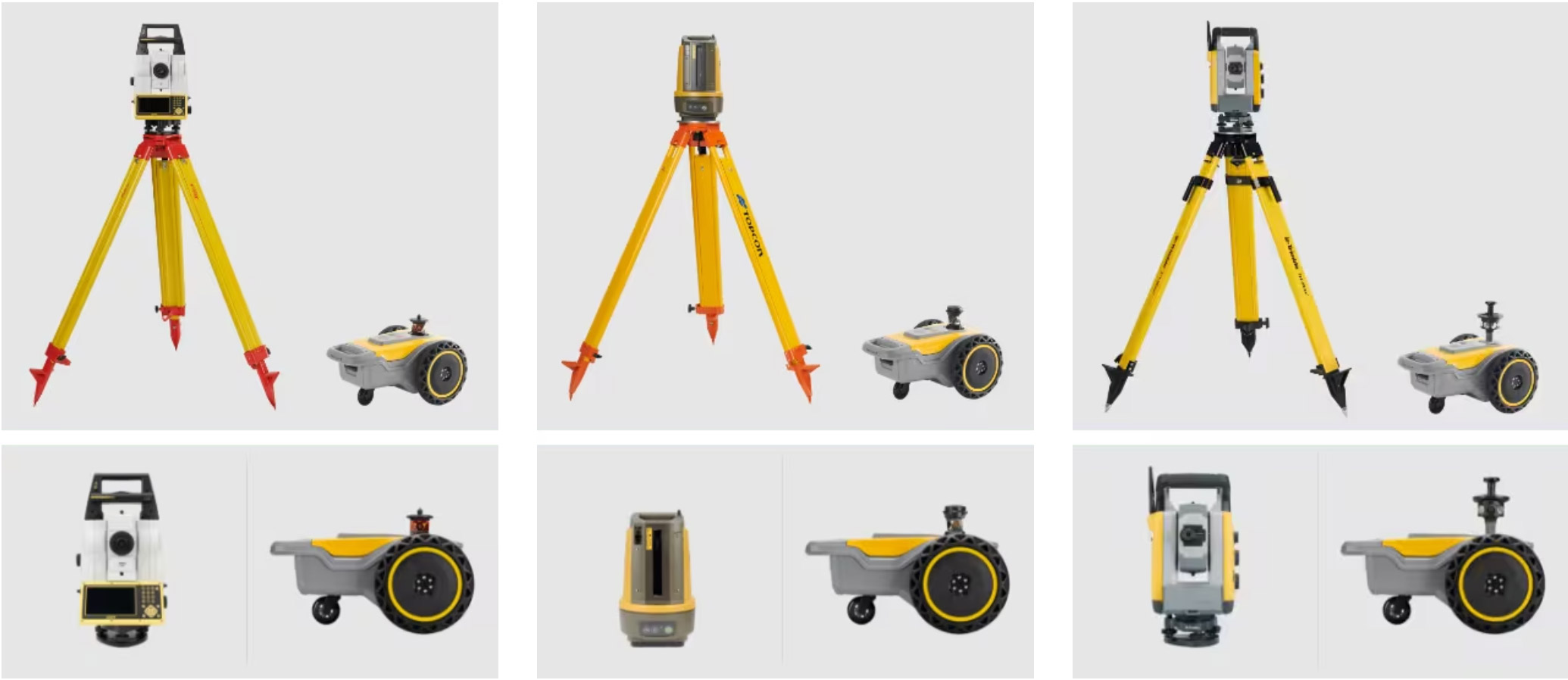

2) Robotic total station

To control the robot on site you need a robotic total station, a survey tool that measures angles and distances from the instrument to a specific point (in this case the robot’s tracking prism). Here, HP has partnered with the major players and supports the following devices: the Trimble RTS 573, Topcon Layout Navigator (LN-150) and Leica TS16 and Leica iCON iCR80.

For orientation on site, two to three control points are required – typically prisms or acrylic targets. These can be placed within the CAD file, and you then use the total station to lay them out. The total station needs to be between 15 feet and 300 feet from the robot. For longer distances, you’d typically move the total station and set up in a different location.

3) Web-based UI

The robot and print jobs are controlled through a simple web-based interface, which typically runs on a tablet. HP doesn’t provide one, a ruggedized tablet typically come with the robotic total station.

You can use the software to set up the robotic total station, although this can also be done through the Trimble, Leica or Topcon software. You then select the print type, which dictates how much ink comes out. To print you can select the whole job, individually pick which elements you want to print, line by line, or sketch out an area with your finger.

From there it creates a flight plan of sorts, working out the most efficient way to print the area. Then after a quick calibration to orient itself on site, it will start to print the first element.

4) Cloud platform

The HP SitePrint cloud platform manages all of the project data. It can be used to estimate the cost of the print job (HP Site Print charges per square foot – see later), how long it will take to print and how long is left at any point in time. If obstacles have been defined within the CAD drawing, such as an internal walls, lift shafts or the perimeter, it will tell you how many times you will need to set up the total station, in order to maintain line of sight with the robot. According to HP, the robot can usually run through columns. If it breaks line of sight for less than three seconds, which is usually OK thanks to predictive tracking on total stations, then it just carries on. If it doesn’t regain it after five seconds, the robot will stop.

How much does it cost?

HP SitePrint combines capital outlay with a pay per use model. In the US, the robot costs $50,000 and then most users pay 20 cents to print per square foot, which includes software, service, maintenance and supplies. There is also special ‘per day’ pricing for firms that just print points or low-density – large areas without a lot of linework, for example, such as a data centre.