Kentucky design firm adds new services and wins more work with BIM and Autodesk Revit

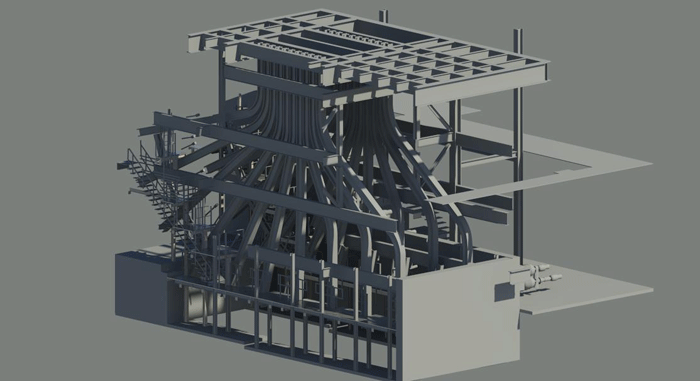

Luckett & Farley engineers had an opportunity to push the limits of its expertise with Building Information Modelling (BIM). “A long-standing client approached us with a problem,” says structural services market director Gregory Buccola. “To meet Occupational Safety & Health Administration (OSHA) requirements, they needed to reconfigure a series of maintenance platforms and ladders within a steam chamber at their manufacturing facility.” The interior of the chamber was a dark and complex web of structural steel, piping and equipment that made development of an accurate set of as-built drawings difficult.

Time was short on the proposed project. “Every day that this chamber was not operational cost our client millions in revenue,” Mr Buccola says.

Luckett & Farley had only two opportunities to enter the chamber before preparing construction documents. Contractors responding to the RFP would have no opportunity at all to verify conditions. “They would have to rely entirely on the accuracy of our designs when preparing their bids.”

The solution

With only three weeks between the creation of as-built drawings and the beginning of construction, Luckett & Farley had to work quickly. “It became very clear that the only way to ascertain all of the as-built conditions and produce a realistic set of drawings was to perform a 3D reality capture,” Mr Buccola says. “That was really the only way to convey all of the constraints to the contractors and allow them to produce bids that did not contain premiums for ambiguity.”

Truescan 3D, a sub-consultant, performed the 3D laser scan of the chamber. “In two sessions, they scanned the entire inside and outside of the chamber and created a point cloud containing literally millions of data points,” says Mr Buccola. Luckett & Farley input the point cloud file into Autodesk Revit to produce a 3D model of the chamber.

Creating as-built drawings from this model was a quick process. “Using Revit, we could slice, dice and manipulate the model to understand the composition of the chamber,” Luckett & Farley vice-president of design technologies and innovation Nick Eckhart says.

Within four days of creating the model, Luckett & Farley had accurately represented about 80 percent of the chamber, including the structural steel, surrounding overhead shield, walls, piping, and drive shafts.

The result

“With help from BIM, Revit and point cloud technology, we were able to put together accurate construction documents and meet our client’s schedule,” says Mr Buccola.

The precision of those documents helped the client put the project to bid without shutting down the plant again for the contractor to verify conditions. “We could not have done this in any other way without impacting the process,” says Mr Buccola.

The firm’s proficiency with BIM and Revit has helped it offer new services, including Scan to BIM services. “We could not have offered that service without Revit, BIM, and point cloud technology,” says Mr Buccola.

Mr Eckhart says: “The ability to win work is our biggest challenge. BIM and Autodesk Revit help us improve design quality and better convey design intent during the bid process and beyond, into the project itself. That enables us to secure more work and to receive early buy-in from our clients once a project begins.”

If you enjoyed this article, subscribe to AEC Magazine for FREE