Bentley Systems launched its new CONNECT technology at its annual Year In Infrastructure conference in London, laying the ground for engineering data and applications to be much more dynamic and pervasive.

The recent Bentley 2014 Year In Infrastructure (YII) event in London provided the platform for the company to launch its next generation MicroStation, CONNECT Edition, together with updates to its comprehensive range of engineering products and services. The last generation, MicroStation V8, was launched in 2001 with subsequent editions V8.5 and V8i.

Even though Bentley hasn’t changed its file format since 2001, the DGN format stays the same with this new generation, which is an impressive feat. That said, in the company’s pitch for the new release you would be hard pressed to hear much about all the work that has gone into the new geometry engine. Bentley’s portfolio of solutions is now more about project management, data mobility, connecting teams and information modelling.

After 30 years in operation, Bentley Systems has pretty much nailed CAD drawing and modelling so is now aiming to tackle both higher and deeper problems, such as information longevity from concept to a facilities operation as well as to provide compute-intensive ‘optioneering’ analysis to find the best performing or more cost-efficient design solution.

With this change in focus, Bentley’s vision and messaging shifts to centre on ProjectWise. This is the company’s project integration environment, either hosted in the cloud or behind a firewall. ProjectWise manages and distributes information on demand to all project participants, in a controlled manner.

In large, multi-billion pound engineering projects, such as London’s Crossrail, ProjectWise has been used as a data backbone throughout all phases, and was attributed to saving more than 5,000 man-hours in just 12 months on the tunnel project alone. Bentley CONNECT Edition is project centric, rather than file centric, so every model or piece of content that is created has to be part of a project.

MicroStation CONNECT features a brand new user interface. There are specific ribbons for different workflows, such as drawings, modelling, and visualisation and context-sensitive menus where a related stack of tools pop up at the cursor.

When the new MicroStation CONNECT is launched the user is taken to a welcome screen where they are asked to sign into the CONNECT server. Each profile stores information about the kinds of projects or discipline the user is involved in and this will allow Bentley to make recommendations of which products to use, what learning content to watch or what features the user may be missing out on based on what their peers are using.

MicroStation CONNECT is project centric, rather than file centric, so every piece of content or model or piece of content that is created has to be part of a project. This will be the case for all of the new Bentley CONNECT products, MicroStation or otherwise.

The system will warn the user if he or she attempts to use content that is not officially part of that project — the idea being that it should aid conformance to project standards.

Data can still be stored locally; it is only the information about the project that is held on a central server. For example, i-model representations of models can be shared so participants can view models or shared content. It is also possible to see who else is working on the same project, helping connect often dispersed teams.

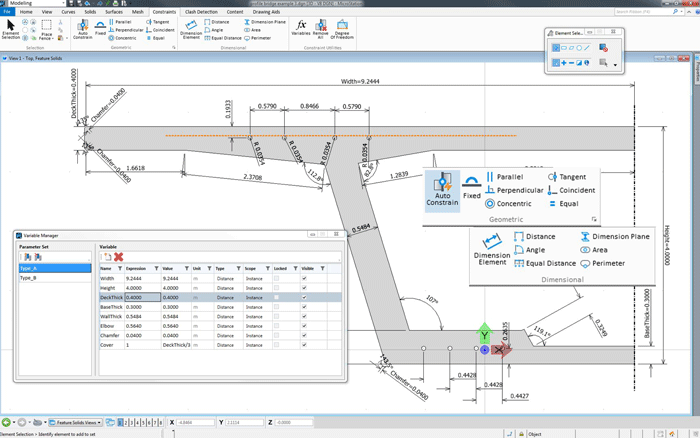

MicroStation CONNECT features a range of powerful new constraint tools that allow users to capture design intent and create functional components.

Whereas in the past you may have needed dozens of different variations of a particular cell type, each with different heights, widths, etc, these can now be represented with one parametrically variable functional component that can adjust to changing geometrical conditions.

Functional components can also be managed and made available to project participants in the new ProjectWise Catalog Service, a cloud service.

According to David Huie, Product Marketing Manager at Bentley Systems, in theory this will allow components to live and persist through the lifecycle of a project. For example, as-built information or installation details could be added to components as the project moves from construction and into operations.

Of course, catalogue content does not have to parametric. It can also be from standards bodies, manufacturers or indeed from Bentley.

CONNECT Editions

With this new generation of products Bentley moves a step closer to providing a more seamless, integrated end-to-end environment, where data is created in projects, managed and distributed to wherever it needs to be viewed, edited, interacted with and marked-up. Similarly the data can be searched and filtered from any point of access with a choice of architectures, behind the firewall, private cloud or public cloud.

While much of the finesse appears to be in the new modern interfaces, a lot of the development work is in the background, connecting up the applications, hiding product silos and making a hybrid cloud/server project backbone.

Bentley calls the products ‘software at your service’. The company’s flexible licensing provides access to its entire product suite through configurable application ‘playlists’, flexible licensing and hourly usage billing.

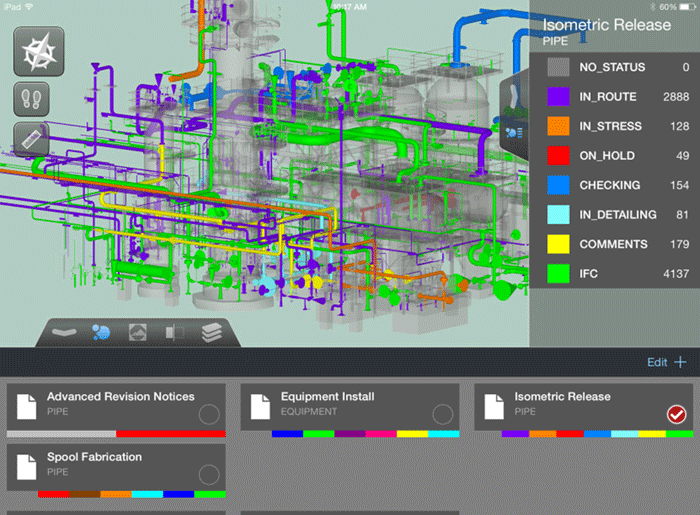

For mobile, Bentley has built up a pretty extensive portfolio of apps over the last few years with a view to putting data into the hands of the site worker. Greg Bentley’s ‘data mobility’ mantra, the theme of YII 2011, has become a reality.

Two of the mobile applications demonstrated at the launch were of special interest. ProjectWise WorkSite CONNECT Edition provides comprehensive remote access to data stored in ProjectWise and supports file viewing, mark-up, forms, and complex searches. Users can access latest project documentation with review and redlining capabilities. And they don’t need to worry about where data is stored as every user is given a single task-based view to all of their project data. Bentley Navigator, for viewing, analysing and augmenting, has been completely rewritten for CONNECT Edition. It has a very slick, minimal touch-enabled interface, which is virtually the same on all platforms — iOS, Android and Windows. This lends itself to handheld tablets as well as large touchscreens for collaborative design / review

Both applications use Microsoft’s Azure cloud platform and are the first instalments of a brand new underlying architecture for the company’s product development teams; but more on that later.

The new generation of connected applications will be made available in the coming 18 months, starting at the end of the year. The first to reach customers will be MicroStation CONNECT Edition (the successor to MicroStation V8i), ProjectWise CONNECT Edition, the completely revamped Bentley Navigator CONNECT Edition and ProjectWise WorkSite CONNECT Edition.

Trimble and Siemens

Bentley’s partnerships, even with direct competitors, is continuing to blossom, especially so with Trimble and Siemens

With Trimble the alliance focuses on construction with i-model and laser-enabled site layout. With Siemens it’s all about bringing Pointools point cloud technology into factory and process design.

The Bentley/Trimble announcement implies a much deeper coalition between the two firms to work together to extend the benefits of the design BIM model into construction. Areas include temporary works, intelligent positioning, detail for fabrication, workface planning, construction work packaging and providing support for distributed construction.

Both firms feel that, to date, BIM tools do not deliver for construction firms, who usually have to rebuild the BIM model, and often just for construction visualisation. This results in the loss of valuable engineering information that is actually useful to the construction firm and for operation post completion.

Bentley and Trimble have announced that they will work together to develop a ‘construction modelling’ schema to preserve and reference architecture and engineering data with a construction overlay together with as-built changes.

■ Bentley CONNECT The successor to Bentley’s V8i software generation will feature a common project environment and offer cloud-based capabilities to deliver a new ‘connected user experience’

■ Bentley and Trimble Two firms now working even closer together to extend the benefits of the BIM model from design into construction

■ ProjectWise Essentials Cloud-based, industrial-strength collaboration application for smaller firms (up to 40 seats) that is leased by the quarter

■ MicroStation CONNECT A brand new user interface, a project-centric workflow, 64-bit support for larger models, plus a range of constraint tools for creating functional components

■ Codename Graphite A brand new platform technology which Bentley Systems is using to create new products for multiple operating systems

■ Scenario Services Using the power of the cloud to test out hundreds of different designs in the quest for a truly optimal solution

The two firms have said they will pool resources for product development and sharing schemas across design and construction applications. When necessary they will use common modelling software for virtual and physical alignment and construction deliverables will utilise Bentley’s i-model portable document format.

Bentley has included support for Trimble Total Stations at platform level and, by combining Bentley Navigator and ProjectWise with Trimble Field Solutions via Trimble Field Link, it is possible to position points from the construction model in the design office and positioning devices in the field.

This year is the 30th anniversary of the founding of Bentley Systems by brothers Keith and Barry Bentley in Pennsylvania.

In 1985, they introduced the commercial version of PseudoStation, which allowed users of VAX mainframe systems to use low-cost graphics terminals to view and modify the designs on their Intergraph IGDS (Interactive Graphics Design System). In 1986, with the advent of the IBM PC, Bentley developed MicroStation Version 1, which allowed users to view and plot the files generated on the mainframe and introduced the DGN file format. This eventually became a full 2D/3D CAD package, which to this day is the foundation platform for the comprehensive design ecosystem that Bentley Systems has created.

Today, Bentley Systems is headed up by CEO and brother Greg Bentley and has an annual revenue of $593 million, and over 1 million commercial users in 165 countries. Typical Bentley customers tend to deliver large infrastructure projects, including Plant, Civil, Architecture, Roads, Rail, Army and Power.

An early proponent of the subscription ownership, Bentley has a 97% subscriber retention rate, which provides around 70% of total revenue.

Spending 25% of income on R&D, the firm continues to focus on solving technically complex engineering problems such as Building Information Modelling (BIM) and has been at the forefront of connecting project teams with industrial strength collaboration tools under the ProjectWise brand.

Greg Bentley explained that this partnership would enable engineers to work “from BIM to bulldozer”.

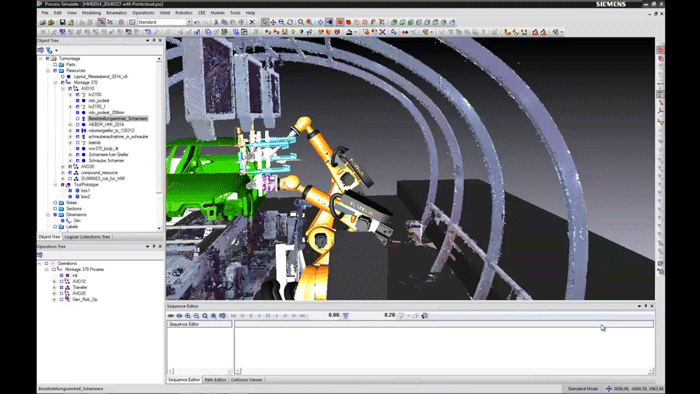

Bentley has been working with Siemens to provide a solution for factory design and facility management for quite some time. Siemens is now embedding Bentley’s Pointools point cloud technology within its popular process simulation tool Tecnomatix, which will allow the import and display of factory laser-scans in its ‘as-operated’ configuration. This can be used to model product process lifecycle or test new production designs in a ‘reality modelling’ context.

Siemens also has the potential to use the Pointools Vortex point cloud engine in other Siemens products such as NX for product development or Teamcenter for product lifecycle management (PLM). This would be a big coup for Bentley if this happens as Siemens has millions of users.

Road, rail and underground

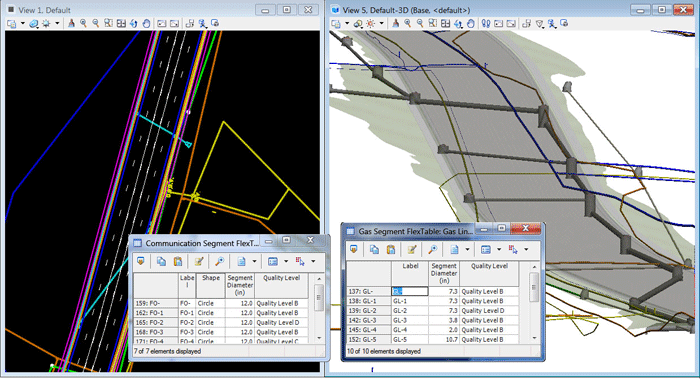

In June Bentley released Subsurface Utility Engineering (SUE), specifically designed to build and manage intelligent 3D feature-based models of underground utilities.

Built on OpenRoads technology, the foundation for Bentley’s road, rail, drainage and bridge modelling tools, the software is designed to create models that are spatially accurate so hard and soft clashes can be ironed out underground, helping saving construction costs downstream.

While it is still early days for this technology senior product manager Ian Rosam highlighted how Michigan Department of Transportation has implemented SUE to help standardise the way utilities are captured, presented and analysed. The Geospatial Utility Infrastructure Data Exchange (GUIDE) will be used to manage the assets throughout their lifecycle as well as reduce risk and construction delays.

Bentley has big plans for SUE and is already extending the reach of the product. The new Subsurface Utility Design and Analysis (SUDA) software gives the SUE model more intelligence by including hydraulic design and analysis capabilities for drainage networks.

Civil Cells, one of the key features of OpenRoads, is a set of graphical macros that capture design intent through the use of constraints and relationships. The result is a functional component that can be used again and again, automatically adapting to changing environments.

Civil Cells are typically stored in DGN libraries that can be shared between projects. This lends them perfectly to the new CONNECT Edition products and its shared project environment where users can get easy access for current and future projects.

Ron Gant, industry marketing director, road, told us that the Bentley Civil CONNECT releases would be rolled out over the next 18 months.

Mr Gant also touched on the growing relationship with Trimble and how ProjectWise is helping to manage the flow of project information from engineering (OpenRoads) to construction (Trimble Business Centre) through the use of i-models.

Here the major focus is on producing constructible models, which harness valuable engineering design and analysis data for use downstream in construction. The end goal is to produce a complete model that can then be handed over to the operations team.

Data is also flowing from the conceptual to detailed design phases thanks to a new link between the Trimble Quantm Alignment Planning System and OpenRoads. Mr Gant explained how Quantm, which specialises in corridor planning and routing analysis, can now publish preliminary design information in an i-model that can be used in OpenRoads.

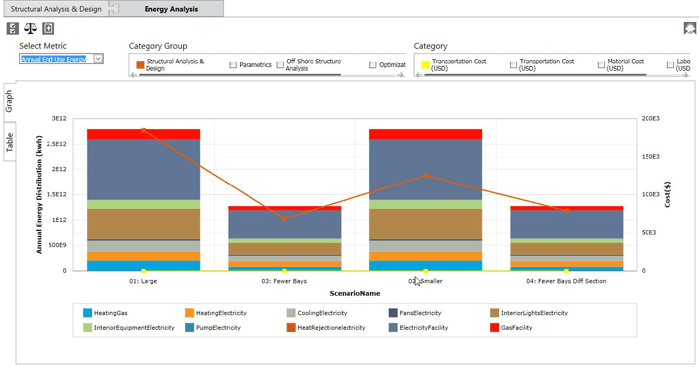

Bentley ProjectWise Scenario Services is a cloud service for early stage design optimisation — or as Bentley likes to call it, ‘optioneering’. The idea is designers can use the power of the cloud to test out hundreds of designs, instead of the usual two or three, in the quest for an optimal solution.

The cost benefits can be huge, as Santanu Das, senior vice-president, design and modelling, explained. He told AEC Magazine that one customer who has been trialling the technology managed to save $450,000-$500,000 in material costs on a 14-storey residential building project. Using RAM Concept and Scenario Services it took just four hours to get feedback on 1,200 different designs that featured various combinations of post tension and rebar. The optimisation also allowed the designer to extend the building to 15 storeys, which was of huge benefit to the client.

Savings can also be made in labour costs, said Mr Das, citing an example of an offshore structure where a design with smaller welds makes it much easier (and therefore cheaper) for workers to prepare in situ.

To date, Scenario Services has only been rolled out to a limited number of Bentley customers. This soft launch is partly because Bentley has been negotiating pricing with Microsoft for use of its Azure cloud platform, which has proved tricky due to unpredictable demands of analysis.

The big launch will come in the first quarter 2015 when the service will be accessible from most of Bentley’s simulation products, including SACS, Moses, STAAD, AutoPIPE, RAM and RM Bridge.

There is still work to do on automation. With the exception of STAAD, which has a pretty unique input mechanism in that it allows users to set up different scenarios, each and every design option from the other analysis tools will need to be created individually. This will change over time though and long-term it is likely that Generative Components technology will be made available in the cloud so hundreds of design options can be automatically produced based on input ranges.

At present, the only way to automatically generate such a variety of design options is on the desktop through Generative Components or AECOsim Building Designer, prior to uploading to the cloud. However, as these applications are primarily focused on design, users will need to add additional attribute information to fully prepare the model for structural analysis.

In the first quarter 2015 Bentley will also launch beta releases of Scenario Services for Autodesk Revit and Rhino, where data from these third-party products will be able to be fed into Bentley’s cloud-based analysis engines. Mr Das said support for SketchUp was proving more problematic due to its data structure and the way it stores geometry, which does not really have a hierarchy.

The holy grail for ProjectWise Scenario Services is to optimise using multiple engines. For example, to move a building by a few degrees and see what impact it has on site, energy and structural. This capability should be available in the first half 2015, but Bentley needs to fine-tune the way the different options are presented. In 2013 the focus was on pareto charts, but according to Mr Das, Bentley has now realised these are not necessarily the clearest way to convey this information to non-experts.

As the service matures other engines will be added, including heating and cooling and airflow. Bentley has also developed an API and is working with partners on acoustics, fire and smoke propagation and others.

The other obvious technology to be integrated into Scenario Services is SITEOPS, the software that Bentley acquired in its purchase of Blueridge Analytics in late September 2014. The software works on the same ‘optioneering’ principle of Scenario Services insofar as it uses the power of the cloud to enable designers to explore different engineering alternatives and their costs.

With SITEOPS you can trace out a building footprint onto a proposed site (or import an AECOsim Building Designer i-model), orient it and it will give real time design and cost feedback on parking, grading and drainage. Saved site designs can be ‘drag and dropped’ to another site for comparison. SITEOPS is used by retail and restaurant chains such as Target, Walmart and McDonalds.

While the long-term plan is to bring the SITEOPS engine into Scenario Services, this would be done slowly. The software would run on both the SITEOPS and the ProjectWise Scenario Services cloud frameworks for some time, Mr Das said.

The SITEOPS technology will also be integrated into OpenRoads, the umbrella technology that forms the backbone to Bentley’s civil design tools — InRoads, Geopak and MX — which sounds like a very exciting proposition.

To learn more about Scenario Services, check out our in-depth article from earlier in the year

ProjectWise Essentials

Launched just before YII 14, Bentley ProjectWise Essentials is a pretty exciting product for those that have wanted to have the industrial-strength collaboration application but were put off by the scope or price.

ProjectWise Essentials is a cloud-based design integration service that is leased by the quarter for smaller firms (up to 40 seats) with lower budgets. As it is based in the cloud, access is immediate and users get to choose from a number of best practice templates, following standards, to streamline workflows and connect team members.

ProjectWise Essentials is CAD and BIM agnostic and works just as well with Revit files, as it does with AutoCAD, Civil3D and MicroStation. The system provides version control, change management, document relationship creation, search and fast distribution.

It comes with free Bentley CONNECTIONS Passport access to the Bentley range of mobile solutions including Bentley Map Mobile, Field Supervisor, InspectTech Collector Mobile, Navigator Mobile, ProjectWise Explorer Mobile, and the Bentley LEARN App. Mobile access is secure and data can be made available to those onsite, either on or offline.

Armed with the virtually unlimited power of the cloud, Mr Karp envisages two big growth areas for analysis moving forward. The first is to use analysis much earlier on in the design process, where it could give real time structural performance feedback when modelling in a product like AECOsim.

The second is in operations and maintenance. Here, sensors placed on the as-built asset can be used to feed back data into the analytical model for health monitoring and to assess on-going performance.

This is already being done in bridge maintenance, where vibration data can be collected periodically to find out where strength might be degrading. However, in industries such as plant it could also be used to monitor structural strength and fluid flow, which may have been impacted by corrosion, all in real time.

For a technology that has traditionally been used in design validation workflows on a handful of proposals it is a compelling vision for analysis in the future.

With a huge number of acquisitions over the past decade or so Bentley has established itself as a powerhouse in structural design and analysis. But with close to twenty products in its portfolio it continues to have a major challenge of how to best handle data interoperability and future software development.

Its Structural Synchronizer software has done a great job of matching Bentley model data with third party applications, but the longer-term goal is to get more of its products working together.

Consolidation is an essential part of this process but that does not mean Bentley is about to merge its products into a single design or analysis tool. Instead, its aim is to harness its technology better and to make a consistent experience for its users.

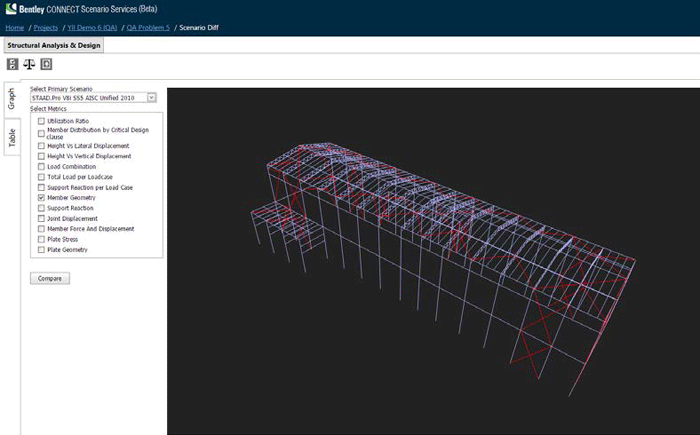

At the heart of this transition is the ‘structural modelling component’, which creates functional modelling tools that can be shared between Bentley’s structural products. This not only gives users a consistent way to model structural components, but a consistent data schema between tools that is a massive benefit for interoperability.

Raoul Karp VP, structural and BIM products, explains that by going down to the data level you will be able to ensure that a beam created in OpenPlant, AECOsim or Bulk Material Handling is the exact same beam and, users will not lose data as they move back and forth. This could have big benefits for workflow: a detailer, for example, could open an AECOsim model directly inside ProStructures and start work immediately.

Bentley has also done some technology sharing between its concrete tools and has migrated some 2D labelling and symbol tools from Bentley Rebar, which is big in bridges, into the advanced 3D modelling features of ProConcrete. By next year Mr Karp hopes he can talk about how ProConcrete is not just a general purpose detailer but a special purpose tool for bridges as well.

Consistency of results is also a big priority. Any design code that has been introduced in the last two or three years has been shared, explained Mr Karp. For example, Bentley has just brought out the Canadian codes and the results will be the same across all of its products. Moving forward, this will extend to a common analysis engine so analytical results will also be consistent in all products.

The new engine will be able to adapt to different workflows including the higher non-linear demands of an offshore product like SACS and the different loading requirements of Bentley’s bridge design and analysis tools.

Of course, in line with its overall CONNECT strategy, the cloud is playing an increasingly important role in Bentley’s structural plans. Analysis will continue to be carried out locally, but the cloud will allow solve times for very large models to be significantly reduced. More importantly, it will allow engineers to test out many different options in the quest for a more optimal design.

Bentley calls this ‘optioneering’ and the enabling technology is a cloud service called Bentley ProjectWise Scenario Services, which can be used in conjunction with Generative Components to automatically generate hundreds of different options. Genetic algorithms are then applied to pick the best ones.

Armed with the virtually unlimited power of the cloud, Mr Karp envisages two big growth areas for analysis moving forward. The first is to use analysis much earlier on in the design process, where it could give real time structural performance feedback when modelling in a product like AECOsim.

The second is in operations and maintenance. Here, sensors placed on the as-built asset can be used to feed back data into the analytical model for health monitoring and to assess on-going performance.

This is already being done in bridge maintenance, where vibration data can be collected periodically to find out where strength might be degrading. However, in industries such as plant it could also be used to monitor structural strength and fluid flow, which may have been impacted by corrosion, all in real time.

For a technology that has traditionally been used in design validation workflows on a handful of proposals it is a compelling vision for analysis in the future.

MicroStation under the bonnet

With any significant upgrades comes the opportunity to change the user interface — which will probably be the biggest challenge for experienced users, as there has been quite a radical reworking of how MicroStation looks, feels and responds to element selection.

The first thing you will see is that all sessions are started by selecting a project, either existing or new. Model management and keeping related documents together is now built in from the get go.

Once loaded, the new ribbon toolbar is clean with multiple tabs for different tool palette selection. The menu is context sensitive and so will change depending on what items are selected.

Under the hood, MicroStation has become fully 64-bit throughout which will allow users to work with much bigger models and should offer better performance.

Parametric content is also big in this release.Bentley has included the capability to download cloud-provisioned content with catalogues of ‘functional components’ which include managed specifications, for reference throughout comprehensive project delivery and handover. These go way beyond 2D cells/blocks and have the potential to rapidly improve design productivity with users producing highly intelligent downloadable content that can be widely distributed through a managed system.

Codename Graphite

Not content with showing off the next generation of MicroStation, Bentley presented products that were developed on a new platform, codenamed ‘Graphite’.

Keith Bentley, CTO, told AEC magazine that Graphite is an environment with which Bentley Systems can create new products and easily compile code for multiple operating systems.

Once upon a time, Bentley supported 14 operating systems, but quickly dropped to just Microsoft Windows, and the company has been deeply tied into Microsoft’s .Net and programming tools ever since. However, the industry is changing and Keith Bentley stated that Apple and Google had won the mobile space, meaning the company had to consider that, once more, it needed to develop for different target platforms.

In its first incarnation, Graphite was used to create the new Bentley Navigator CONNECT application. The platform has a new SQLite-based file format that enables file streaming and is more suited to distributed server-based access. The SQLite format makes design information more granular and provides relational links, enabling multiple data schemas (e.g. COBie) to be included. It also provides powerful and fast search/filter capabilities.

For now it is being used to create a file viewing and annotation application, not unlike the very first version of MicroStation written in 1985. This will probably expand to replace DGN in the future as the transaction conduit of project information.

We asked if we would see a version of MicroStation for the Apple OSX and Keith Bentley replied “No, it wouldn’t look or feel like MicroStation if we did a port to OSX but we won’t rule out other future products coming out for the Mac.”

Reading between the lines, Bentley has a new development platform, a new ‘format’ and has done a lot of work to prepare the way for a multi-operating system future for both desktop and mobile. For cloud, Bentley is completely committed and optimised for Microsoft’s Azure infrastructure. Keith Bentley is confident that distributed computing — powerful servers with local workstations — is still the way to go.

This compares with competitors, such as Autodesk, who are looking to deliver ‘virtualised’ access to their software via remote hosted applications through pixel streaming technologies provided by the likes of OTOY, Citrix and Mainframe2.

Bentley is currently experimenting with a technology from Numescent, which allows fast download/distribution of Windows-based applications that run in an application ‘player’, but the actual application is streamed and still uses the CPU and graphics of the local machine.

Bentley Research

The Bentley Research presentations at YII are becoming a highlight for those that love seeing the cutting edge of development. This year we had presentations on augmented reality, on-site positioning, laser scanning, converting photos to 3D models, real-world object recognition, rapid bridge structural analysis and thoughts on construction efficiency, as to how it was different from typical manufacturing.

The key problem is in accuracy of locating and tracking the viewer both outside and inside buildings. Bentley has been experimenting with a wide variety of technologies to improve this, from Bluetooth tracking triangulation via iBeacons and signal strength, to registering external views with Google Streetview.

Experiments with projecting Augmented Reality images on construction sites quickly established that blocking the visibility of workers could have an impact on safety for those near by, particularly if driving an excavator. Bentley is working on a way to project transparent ‘painted’ 3D model data instead, ensuring clarity of view.

In another experiment, laser-scanned point model data collected on a motorway was combined with Google Streetview images to identify objects in the scene. Optical Character Recognition (OCR) was also used to add on street signs for inclusion in the models.

Conclusion

Bentley used YII to unleash Azure applications being developed for the next release, showing that its development strategy is defining products many years in advance.

For this release it is all about the ‘commonness’ of its converging technology stack and extending mobile by creating and integrating apps seamlessly into its established server-based solution.

Bentley has been teasing us with its cloud-based analysis plans for a few years now and next year this will become reality. Optioneering is being built into the company’s products and Bentley has harnessed the power of the cloud to offer subscribers easy access to its ‘solvers’ with near unlimited power.

The promise that next year we will see complete building analysis with multiple simulation and analysis solvers running simultaneously via the cloud will mean every design should be proven to work and the best solution possible. This is incredibly exciting.

With ProjectWise Essentials, cloud delivery, term licensing and the possibility to download design applications via Numescent technology, the barriers to entry will become much lower for new customers with smaller projects.

With the CONNECT Edition Bentley has laid the ground for engineering data and applications to be much more dynamic and pervasive.

If you enjoyed this article, subscribe to AEC Magazine for FREE