Morson Projects uses upfront computational fluid dynamics to help ensure safe airflow in the Granary Wharf car park in Leeds, writes Bob Cramblitt.

Car parks — or parking garages as they are called in the US — are usually judged by their parking capacity and the efficiency at which an even flow of traffic can be maintained. But, there is another flow that is critical to car park design — the flow of air throughout the structure, both in normal circumstances and in the event of a fire.

For 25 years Manchester’s Morson Projects has been providing multi-disciplined engineering, design and project management services to international clients from a wide range of industries, from automotive to nuclear design to utilities. A key sector of the company’s business is Heating, Ventilation and Air-conditioning (HVAC) analysis for process, commercial and residential buildings.

Computational fluid dynamics (CFD) specialist Chris Roach recently adopted CFdesign, upfront CFD software from Blue Ridge Numerics. CFdesign helped Mr Roach decrease his modelling time from a day to a few hours and cut down analysis time by two-thirds while giving him more detailed results than the traditional CFD software he was using.

Surprising ventilation complexity

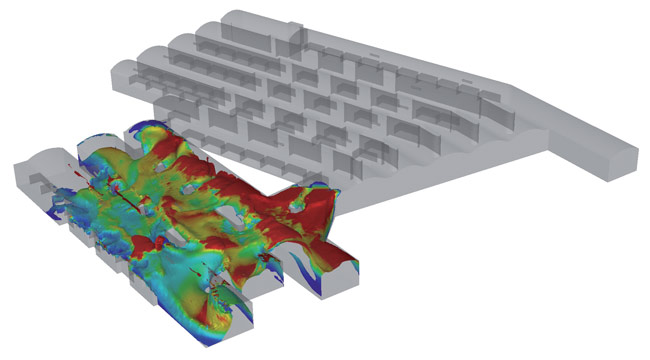

Morson Projects recently performed a CFD analysis of a proposed car park for Granary Wharf, a shopping and tourist area situated below Victorian-era railway arches in Leeds. At Granary Wharf, shoppers can buy anything from international beers to exotic art from Indonesia. The eclecticism of its retailers, combined with its impressive architecture, ensures a steady flow of consumers who need good parking, access and egress.

Although it encompasses only a single floor with 90 spaces and three exits/entrances, ventilation requirements for the car park are complex. A large fan positioned at the top right of the car park extracts stale air. Sixteen jet fans are strategically positioned to draw fresh air in, circulate it around the car park, and force stale air towards the extract fan.

Normal and fiery conditions analysis

Morson was asked to produce an analysis of the car park to show that the mechanical ventilation system would work as designed, adhering to the British safety standard. That meant providing a minimum of six air changes per hour with fans running at half speed and 10 air changes per hour with fans running at full speed.

The client also asked Morson to do what is known as an eight-megawatt fire analysis — the equivalent of the energy given off by two cars on fire. This analysis is designed to show that the ventilation system will clear smoke adequately enough within 60 seconds to allow people to escape the car park safely. Two months later, the client came back to Morson and asked to see the effects of smoke after 180 seconds.

The importance of CAD integration

Just over a year earlier, the client’s requests and project timeframe would have been daunting. At that time, Chris Roach was using traditional CFD software that was not integrated into Morson’s Catia V5 software. Every model had to be reproduced within the modelling program of the traditional CFD software.

CAD models could not be imported into the traditional software without an additional license, which Roach says was an added cost on top of already expensive software. Using the traditional CFD software, modelling for a car park, for example, was done in blocks by adding cuboids and prisms to create the shape of the building. The software could not deal with curves or complex shapes required for an accurate CAD model and CFD meshing program.

In contrast, CFdesign is fully integrated with Catia V5 and other popular CAD/CAM packages. The tight integration ensures that associations between geometry are maintained as the model moves between design and simulation iterations. It enables mechanical engineers to conduct fluid flow and heat transfer simulation early in the product development process, where it can save the most time and money.

“CFdesign’s integration with Catia V5 makes it possible for me to model with software I am very competent in using,” says Mr Roach. “It also enables the more than 50 other people at Morson Projects who use Catia to work on models while I run analyses on CFdesign for a few different projects at the same time.”

Better results, faster

In addition to reducing modelling time from a day to about an hour, Mr Roach has seen a dramatic decrease in the time it takes to reach an analysis solution using CFdesign.

“CFdesign has shortened the solution time of analyses by almost two-thirds,” he says, “even when the meshing system is a lot more complex and delivers more accurate results.”

A CFdesign feature that has been critical for Morson Projects is something called Local Mean Age of air (LMA), which Blue Ridge Numerics added by Mr Roach’s request a few weeks after he purchased the software. “LMA is the period of time a quantity of air is circulated around the same area or building,” says Roach. “When you select ‘residence time’ within CFdesign, it automatically shows results on a plot or isosurface. This is one of the most important features we use for CFD analysis.”

Getting the model right

Mr Roach began the car park project by taking 2D AutoCAD drawings, converting them to DXF files and importing them into Catia V5 to create a 3D model. Gilberto Fernandez, a Blue Ridge technical support employee in the UK, helped Mr Roach develop a model that retained essential elements, but was not too large for CFD meshing. “He talked me through the modifications needed to increase the accuracy of my analysis while decreasing the solution time,” says Mr Roach. “He also looked at my model over the Internet to search for any problems or discrepancies.”

Something old, something new

The Catia model was then meshed directly in CFdesign to prepare for the airflow analysis of the car park under normal circumstances. Different layout arrangements of the jet fans were tested to optimise airflow and extraction rates in the car park to prevent carbon monoxide build-up.

The simulations showed that the car park was being supplied with sufficient fresh air from the outside to relieve the small areas of low air speed. General circulation of the air was found to be good with no dead spots. Modelling and analysis took about a week.

The fire simulation required something new for Mr Roach. He had to set up a transient analysis with time steps that saved results at certain points to show smoke movement without any mechanical ventilation from the impulse fans.

These results — first for 60-second intervals and later for 180-second intervals — were then used for the full eight-megawatt analysis showing what would happen when the impulse fans were turned on to remove the smoke.

Positions of the fans and the fires were changed to optimise smoke removal and to improve areas where the LMA was too high. Additional complexity was added when blocks used to represent cars were introduced to see how air and smoke movement would change with the car park at 80 percent capacity. Because the car park has a high roof, the presence of cars did not have a significant effect on smoke movement.

The final ventilation configuration showed good air circulation, with only small areas of recirculation and no dead spots.

The 60-second and 180-second smoke analyses took about two weeks to complete, since the model had already been created for the original analysis. CFdesign’s ability to output features, plots and animations showing transient conditions added a richness to the company’s reports.

“Even when the project was changed in midstream, it was easy to modify small details within CFdesign, save the original analysis as a new one, then re-run to get the latest results.”

The unseen safety net

Few, if any, visitors using the Granary Wharf car park will realise the technological know-how helping to ensure their safety in both normal and extraordinary circumstances.

Bob Cramblitt is principal of Cramblitt & Company in Cary, North Carolina. He writes about technologies that dramatically impact the way products are designed, engineered and manufactured.