A Revit family component is a functional element that must communicate the design intent, occupy a realistic space within the building. Paul Woddy looks at how to get the best out of Building Information Modelling software.

Users and project managers involved with Building Information Modelling (BIM) software need to find comfortable middle ground between the desire to take full advantage of the benefits afforded by detailed, data-rich 3D models of components, and the need to produce contractually adequate deliverables.

Understanding what is required or available from BIM is often overlooked in the panic to produce accurate building models, with libraries of components that are badly specified and subsequently neglect key objectives and advantages.

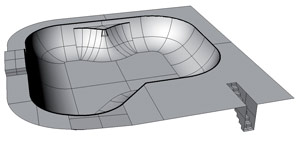

A Revit family component is, for the most part, not created to be hung on the wall of the Victoria and Albert Museum. It is a functional element that must communicate the design intent, occupy a realistic space within the building and provide enough meta-data to drive the specification, cost analysis, procurement and construction/installation processes.

What is often misunderstood is that this requirement can often be delivered by a simple three-dimensional cube; certainly at an early, concept stage of the project.

Hardware demands of using BIM are an important factor for consideration in larger projects, but many of the associated issues can be avoided by managing the model creation with scale in mind. If a design for a 500,000 metre square hospital starts with an anatomically accurate door with 3D hinges and a bespoke, artistic handle, then I can safely predict failure of the model.

In Mechanical, Electrical, Plumbing (MEP) particularly, a propensity to provide accurate models of pumps and fan units, complete with grilles, switches and mesh covers will lead to the conclusion that Revit can only handle the smallest of buildings before the refresh rate of the average PC is counted in days, not seconds. And yet, this approach is almost systemic in some practices.

Taking charge

On numerous occasions, I have advised that a component QA role is assigned to a team adopting Revit and the response has been to identify an individual within the practice on the basis of

their previous background in product design or similar field. My emphatic advice in each case has been to keep that individual as far away from the process as is possible and at all costs, do not put them in charge.

It is recommended that building models progress through each stage with the appropriate level of detail and specification. If developed properly, the models produced in the early design stages of a project can be more readily progressed through to production without time-consuming and costly redevelopment or unnecessarily complicated splitting of the model into workable pieces.

In practice, this translates into a template that provides only conceptual examples of each element type. Default walls should be designated as internal or external, possibly with a couple of thickness variations for each, but we should not be using a cavity wall with 50mm insulation and a blockwork core unless a conscious decision has been made to do so.

My recommended template offers concept walls as described, and then a Concept Roof, Concept Floor, Concept Door, Concept Window, etc. All the materials are set to Concept White or Concept Glass (which is a copy of Concept White with added transparency). Default components such as the door and window are the simplest that they can possible be while still being identifiable.

The entire model should be constructed using this principle and kept free of unnecessary detail and extraneous information at the early stages, in which case, the scale of project that can be modelled is considerable. It becomes a collection of placeholders in the correct locations at a nominal size, to aid the development of the general design layout. They are correctly categorised and inter-related where relevant.

As the design progresses towards production, detail can be added by replacement of the components with more detailed examples, specific to a manufacturer or at least to an informed design decision. This can be done by individual element or across the entire project, eventually supplanting all remaining concept components. This should be done while keeping one eye on the workability of the project model, but as this usually coincides with the need for multiple team members to access the model simultaneously, it can be broken down as required into discrete work packages or zoned according to the project BIM strategy.

At each stage the model should be checked for compliance to the specified standards and for any issues that may prove detrimental to the overall performance. It is recommended that a copy of the main model be stored as a record of the work at the completion of each stage or milestone. This also allows the model to be cleared (purged) of any component definitions from earlier stages that have been replaced with more detailed equivalents.

This may all sound obvious, but a successful modelling approach is down to mind-set, and the principles lend themselves to the most elemental and simplistic objects. Treat every component as if you have to array a thousand of them and still be able to spin the model around.

Graded element

Making a distinction between the 2D and 3D requirement of the element can also be important to this process, as is the use of 3D linework (Model Lines) to simplify or replace geometry.

In this example, the plan view of the chair is identical across the grades, allowing for accurate placement and space allocation. The Grade 1 component is sufficiently modelled to indicate a chair and is generic in terms of manufacturer information and technical data. The same 3D representation could be used for almost all chairs.

The Grade 2 chair contains all relevant metasdata and technical information, and is sufficiently modelled to identify the type of chair and the materials. I would strongly argue that in most cases, this grade of component should be sufficient, as it delivers on every level except the detailed, realistic 3D picture.

The Grade 3 component is a special case. If scheduled or interrogated by annotation, it appears to be identical to the Grade 2 version, and only differs in 3D representation. It is to be used only when a 3D view at a sufficient scale deems the detail necessary due to the object proximity to the camera.

As mentioned, in MEP this principle can be especially relevant, where a Grade 2 Air Handling Unit is based on the correct overall dimensions and contains all the required connection and technical data without the need for vents, buttons, fans or removable panels. As this unit is almost always hidden behind a ceiling or inside a plant room, I do not see much point in developing the modelled geometry beyond this stage. If it should be taken to a Grade 3 element, then 3D model lines will suffice to provide extra information to distinguish the actual manufactured component.

This varies slightly from the AIA advice in the US, which advocates five grades (LOD 100 to LOD 500) for much the same reasons as described here, with a preference to keep the geometry simple.

We diverge only when it comes to the subject of meta-data, which is seen as an optional extra instead of being central to BIM philosophy.

Conclusion

Some of you may be wondering if the product design student is not the best member of my team specifying the building component library, who is?

My answer: The document manager.

For me, BIM is all about controlling information. It is the data attached to the model that will ultimately see this technology make a real difference to the construction industry; not the drawing production, the 3D modelling or even the co-ordination aspects.

All of these are vital but not revolutionary in the long run. Data is the key, and someone capable of collating, managing and realising the importance of data is the best person for the job of creating or at least specifying the components.