Through a simple-to-use wizard style interface, CADS is looking to offer steel fabricators a way to design and cost their own Portal Frame structures, ready for tender in a matter of minutes, says Greg Corke.

Product: Smart Portal 3D

Supplier: CADS

Price: ú2,500

Portal frame building construction is big business in the UK, forming the backbone for countless supermarkets, retail parks, and warehouses nationwide. But for many steel fabricators calculating an accurate estimate of a job for tender can be a task fraught with problems. An accurate quote requires an accurate design, one that is not only extremely cost effective, but also structurally sound. The problem is that in such a competitive marketplace tendering must be done with minimal overheads. Hiring a consulting engineer is one option, as is employing an engineer in-house, but with a new Portal Frame Design package, structural software specialist CADS is looking to provide steel fabricators with a way of designing and costing their own Portal Frame structures for tender, in as little time as possible.

Smart thinking

Smart Portal is a 2D/3D elastic/plastic portal frame design suite. It enables steel fabricators and structural engineers to rustle up a simple 3D Portal Frame Building Design in a matter of minutes via a wizard-style interface. Then, applying a combination of loads for analysis, design estimates can be created quickly. These can then be refined to optimise the design, and an accurate estimate sent off to tender. So there’s the whistle stop tour, how does it work in practice?

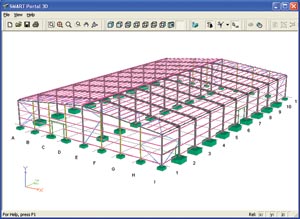

3D geometry and loads: Creating a portal frame building in Smart Portal is simply a case of stepping through a wizard, rather than modelling individual structural elements. Starting with a template for a particular type of frame and roof shape, users define variables such as number of spans, length of span, number of frames, length of building, roof angle, support type etc, and a 3D model is developed on the fly.

The next step is to add all loads including dead, imposed, wind and snow. For example, dead loads can be selected from a library, which includes roof cladding, suspended ceilings, and services. Smart Portal includes a range of standard material types, though users can add their own manufacturer-specific values to the library or on the fly if required.

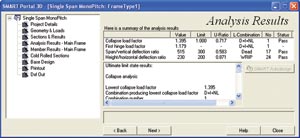

Design and analysis: Once all the geometry and loads have been defined, users simply click the Smart Autodesign button, and the software goes off and estimates member sizes for columns, rafters, posts, cross bracing, rails etc based on BS 5950 (N.B. CADS is already working to integrate European EC codes). The system then carries out elastic/plastic analyses of all ultimate and serviceability load combinations to ensure that BS code and user design criteria are satisfied economically and automatically re-selects sections where necessary to achieve this.

The whole process only takes a matter of minutes on a moderately specified PC, so users can quickly assess different design scenarios to see which is the most cost effective. Cost is currently defined only in terms of steel weight, but CADS is looking into ways of implementing actual material prices, where users can define costs for more accurate BOMs.

Output: Smart Portal provides a fully customisable report facility, where users can print out exactly what they require including sketch layouts, supports, loadings, primary and secondary member details etc. In addition, users can output reports to Microsoft Word or PDF format, and Smart Portal is also capable of creating DXF files for use in all the major CAD packages.

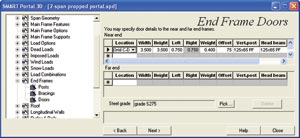

For example, users can use the ‘wizard’ for the bulk of the design, and then swap out to advanced mode to gain more control over the design process or to carry out more specialist design operations. Users may want to design frames with non-uniform spacing, or features such as door frames (where users can design vertical posts and header beams), canopies, cantilevers and parapet posts. Users can also gain more control over loading conditions, to simulate specialist design scenarios, like fire collapse for example.

Smart Portal Jobs can also be loaded into CADS’ AutoCAD-based steel fabrication solution, AdvanceSteel, for the automatic production of general arrangement drawings and fabrication details. Not forgetting the competition, CADS is also looking to introduce links to AceCad’s StruCad and Tekla’s Xsteel.

The past few years have seen Poole-based CADS take a fresh look at the steel fabrication sector – first with Advance Steel (formerly HyperSteel) and now with its in-house developed Smart Portal software. While Smart Portal has the required depth of functionality to offer structural engineers a comprehensive Portal Frame design solution, it’s in the steel fabrication sector that its use becomes more interesting.

Here, through its Wizard-style interface, steel fabricators are able to quickly generate accurate estimates for Portal Frame projects – not only for calculating the weight of steel required, but also ensuring the project will be structurally correct. After all, there’s no point in being able to pull off accurate material lists for tender if the structure wouldn’t stand up when built, or be able to withstand six foot of snow when it’s located in Dubai.

With estimates in Smart Portal currently based on steel weight alone, it’s good to hear that CADS is working on ways of implementing actual material costs. Furthermore, with links to steel fabrication software applications such as Advance Steel, Smart Portal also has the potential to become a front end Portal Frame design solution for steel fabricators.