Building Information Modelling (BIM) is no longer just for buildings, it is becoming more widely used for infrastructure as well. 3D bridge modelling has therefore become more popular, with modelling techniques particularly suited to bridges whose geometry is governed by the bridge axis or alignment. However, bridges come in many types and shapes, and are built with different methods. Some of these bridges could require a different approach to modelling, as their geometry is only indirectly governed by the axis – such as precast girder bridges.

Precast concrete bridges offer a range of benefits, so it is easy to see why, since the late 50s, they are so common, especially for highway bridges. Precasting eliminates many onsite in-situ work processes and with this reduces construction time, costs and improves the quality of the products.

It also enables construction companies to work on more projects simultaneously and there are minimal dependencies on weather conditions. In addition, the use of precast components enables transport authorities to capitalize on the economy and high quality of prefabricated girders while minimizing the environmental impact and disruption to the local area during construction.

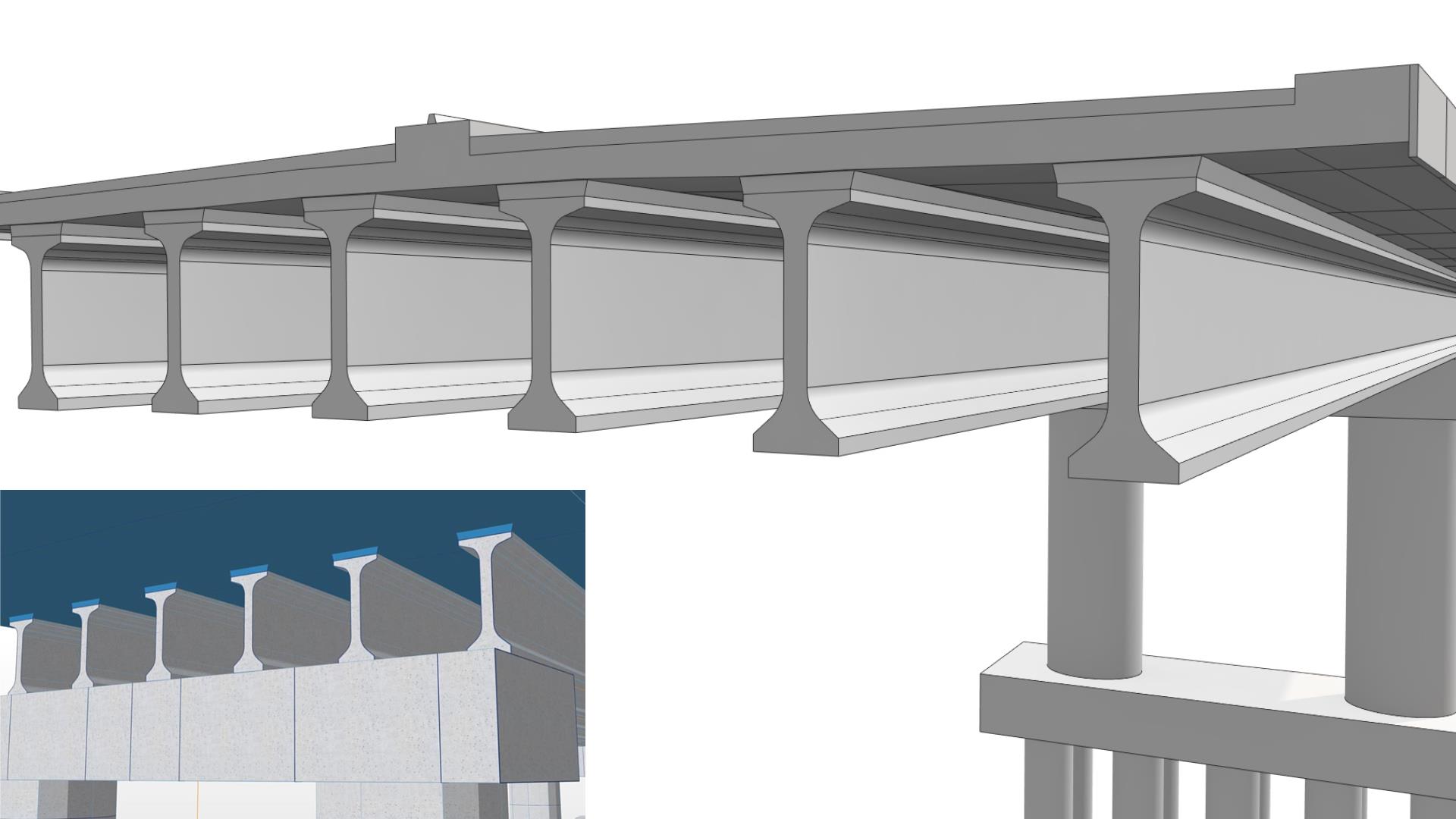

While there are different types of precast girder bridges, they all have one thing in common – their component geometry. Girders are straight, which is why their geometry is not directly impacted by the road or bridge axis. This is also the case with respect to their final position on the bridge, which is dictated by the geometry of the supporting substructure. For these reasons, a different approach is required when modelling precast girder bridges.

Allplan Bridge – a complete, integrated BIM solution for bridges – has been recently updated to address this need. The latest version includes new features that provide an updated modelling workflow so precast girder bridges can be created with ease. With just one bridge model, an entire BIM-supported bridge design process can be carried out from within this parametric design solution.

New Modelling Approach

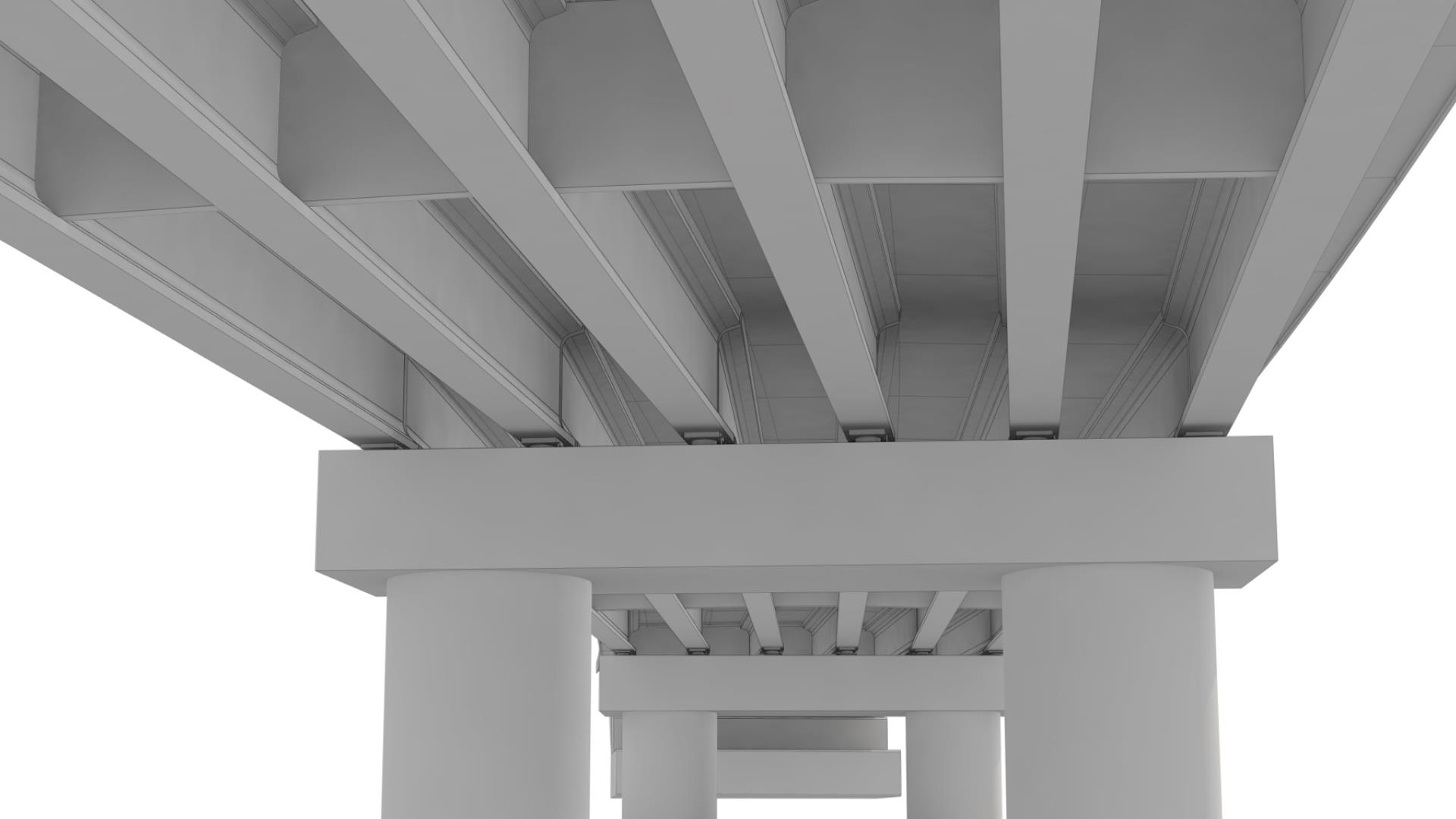

For precast girder bridges, a similar modelling approach to the conventional process is used at first. A bridge axes needs to be created or imported, and the cross-sectional geometry either designed or taken from a template. Then, the substructure – with or without foundations – can be generated, and the precast girders positioned on top.

For easy yet precise modelling of precast girders, a new element called Link Girder has been introduced into Allplan Bridge. This is a parametric, linear, 3D element between two 3D points. These two reference points define the virtual and local axis which is used for the calculation of geometry. Once this is set, it can be used for modelling tendons, defining the construction sequence, and even detailing, rebar modelling, and drawing production. Because it is parametric, it can be adjusted quickly and easily if there are any changes.

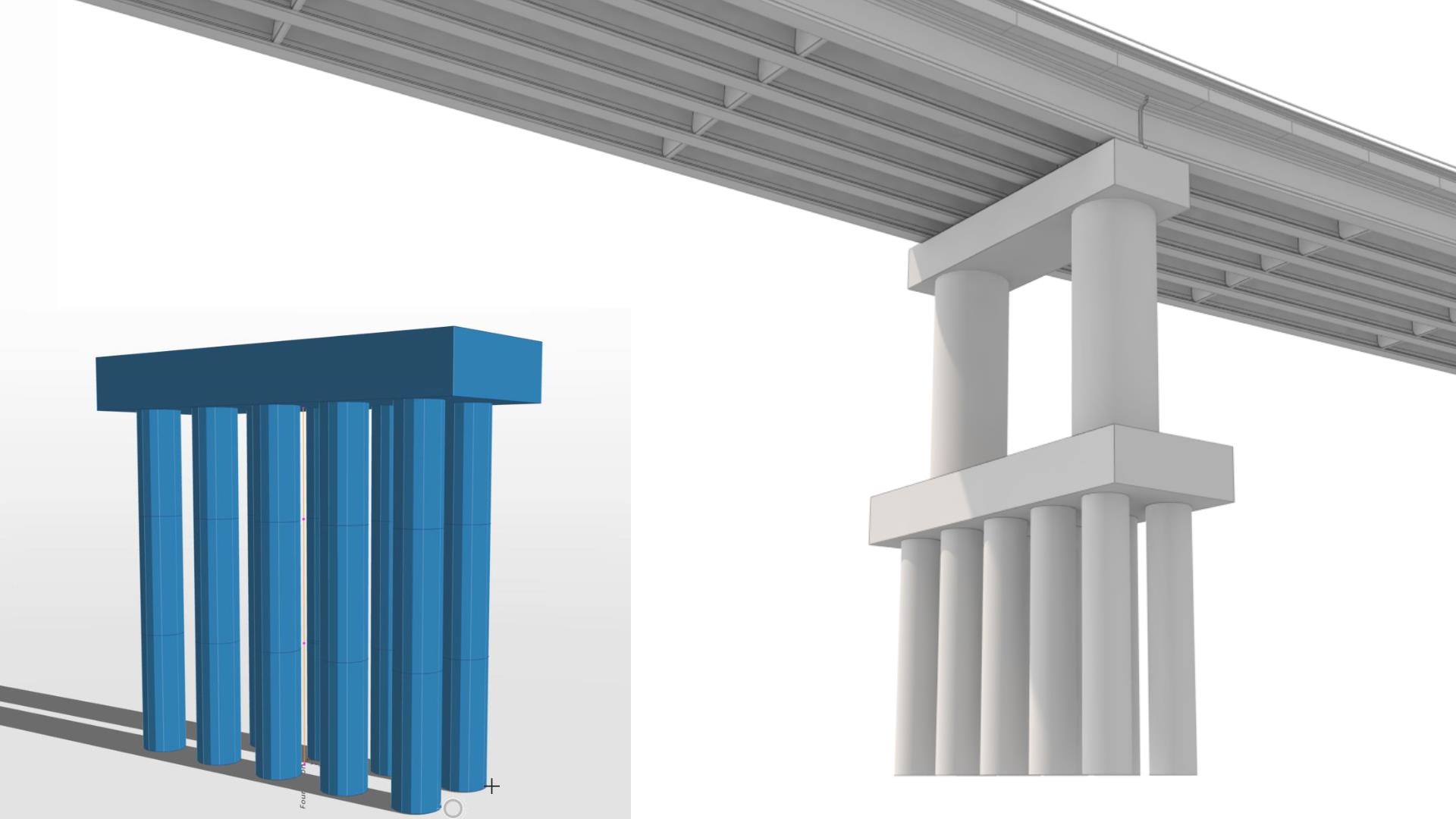

Precast girder bridges often reuse girder shapes and lengths. To address this efficiently, Allplan Bridge includes a new feature called modular modelling. With this tool, as many templates as necessary can be generated, either for link girder elements or pier elements. Once a template is generated, it can be used in the 3D model as many times as necessary simply by dragging and dropping it in. This way, all the girders can be generated rapidly, saving considerable time.

Of course, the girder length can be another hurdle. Either the girder section can vary along the length, the exact length of the girder may vary, or the substructure may be skewed, making it difficult to model the geometry precisely. Here, Allplan Bridge makes this easy to overcome by allowing the template length to be specified as the girder length or by using a virtual length until the girder is positioned on the substructure. Which solution to use depends on the bridge geometry and which is more convenient.

Where the girder section varies, there are now new station types – fixed stations – which enable the position where the girder section changes to be fixed. However, the final girder length can still be adjusted, and the fixed stations will remain in their specified positions. This significantly shortens the time required for modelling these types of girders.

Closing the Gap

The next step in the modelling process is to create a bridge deck by extruding a cross-section along the bridge axis. At this point, two bridge elements will have been generated – leaving a gap between the girders and plate. Filling this requires a haunch, but the 3D geometry for this is influenced by many constraints. The geometry of the deck slab and girder arrangement affect the haunch geometry, and the thickness may vary along the bridge axis. The construction process and vertical deflections of the girders also influence the haunch shape.

Allplan Bridge solves this problem by using 3D Boolean operations to create the haunch quickly and easily. All the parameters which govern the geometry are already defined. Therefore, the haunch just needs to be pre-defined in such a way that it intersects the deck plate and can be merged with it. To do this, a cross-section of the haunch is created, and then Allplan Bridge automatically calculates and generates the 3D form based on the other bridge parameters.

With the main bridge elements modelled, other details – such as diaphragms, bearings, pavements, barriers, and others – can be easily created. They can be either modelled from scratch, inserted from a library, or created using customized intelligent objects.

Rebar Modelling

If a template can be created for a girder, it would also make sense to prepare a template for the girder reinforcement. Naturally, this option is available in Allplan.

A reinforcement template for a girder – or other bridge element – can be easily created using a PythonPart. It can then be used multiple times in the same project or across projects, saving the engineers time. The template is parametric – just like the girder model – making the placement of reinforcement easier. Additionally, the reinforcement’s parameters can be linked with the girder model’s parameters. Therefore, adjusting the girder model will also change the reinforcement, creating an efficient and automated process.

Defining rebar shapes, placing the bars, and introducing changes after placement has traditionally made working with reinforcement challenging. However, the use of parametric reinforcement objects overcomes this issue. As a result, changing the rebar model is as easy as modifying a few parameters and watching the model update automatically.

Accelerating Design Processes

These new features result in an improved modelling approach specifically tailored for prefabricated girder bridges. The straightforward procedure accelerates the design process while enabling a precise model to be generated with ease. As prefabricated girder bridges are one of the most common bridge types used globally, the time – and therefore cost – savings can be significant.

Additionally, with the integration and synchronization offered by Allplan’s cloud-based BIM platform, Bimplus, the BIM process can be completely supported, from initial import of data for axis definition. With this new modelling approach for precast girder bridges together with enhanced tools for optimized BIM workflows, Allplan Bridge lets engineers focus on what they do best: designing and building safe and attractive bridges.

Finally, with Allplan’s competence in precast fabrication, through Allplan Precast solutions, including detailing and manufacturing work preparation, a complete design to build approach, including manufacture, can be supported.

To learn more about modelling precast girder bridges, watch here: Precast Girder Bridge Workflow (allplan.com)