SafetiBase model helps to visualise risks and improve construction collaboration

AstraZeneca is a global pharmaceutical company with a major presence in the UK. Employing 6,500 people across five UK sites, the company focuses on R&D for cancer research, cardiovascular and metabolic diseases, respiratory, inflammation and autoimmune diseases as well as conditions affecting the central nervous system.

The company’s largest UK manufacturing plant and its European centre for packing is based in Macclesfield, Cheshire where over 4,000 people are employed. The Macclesfield Campus manufactures, packs and distributes medicines to 130 global markets.

AstraZeneca has an ongoing programme of investment in its sites to ensure that its facilities provide the most safe and efficient environment for ongoing research, development and manufacture.

Expanding facilities

At the Macclesfield site, construction lead David Ayres is responsible for the effective delivery of construction for 60-100 projects each year. All are specialist construction projects, with facilities requiring sterile and clean environments and climate control.

Moreover, due to the critical nature of the medicines and the conditions that they need to be manufactured and stored in, it is essential that any project works do not affect drug output and other business as usual activities for the company.

As part of its ongoing developments and improvements, the company needed to add an extension to an archive and quality assurance building, where samples of medicines are kept in a secure and environmentally controlled area and regular testing is carried out to ensure ongoing safety and compliance.

Safety at heart

Work started on the design for the extension in January 2021. Health and safety is integral to all construction projects and AstraZeneca has a thorough safety risk management process in place.

A detailed risk register is drawn up and kept continually updated throughout the project. Typical risk elements include working with live services; excavation; asbestos; confined space; working at height; etc.

Discovering Safety

As part of its commitment to Health and Safety and continuous improvement, and as a sponsoring member of the Construction Clients’ Leadership Group, AstraZeneca became involved in the Discovering Safety programme in late 2019.

The programme is run by Lloyd’s Register Foundation and supported by the Health and Safety Executive, which aims to improve safety by using data more efficiently. One element of the programme is to create a detailed risk and risk treatment library; to compile a comprehensive database of risks and treatments for construction projects with a view to improving construction risk management and safety throughout the industry.

AstraZeneca is running Discovering Safety in tandem with its established protocols to determine what additional benefits the new processes can offer. To test the new processes and software, the team imported the usual risks and hazards into the SafetiBase platform and looked at them in more detail. They then worked through them together to check they hadn’t left anything out.

“When carrying out our construction risk analysis there were some issues that we found much earlier with the help of SafetiBase. We would have picked them up later, but this would have cost us time and money,” explains project manager Philip Shaw.

“To date we have identified 40 risks on this project which would not be obvious to the people doing the work. Working on the Discovering Safety programme has been a great opportunity to re-examine the way we approach construction risk management and mitigation.”

“SafetiBase has not only provided value from a health and safety perspective. We have also been able to accelerate the programme which has saved time. As a result, we have put in place a quality process that demonstrates good value for money.”

Risk assessments with SafetiBase

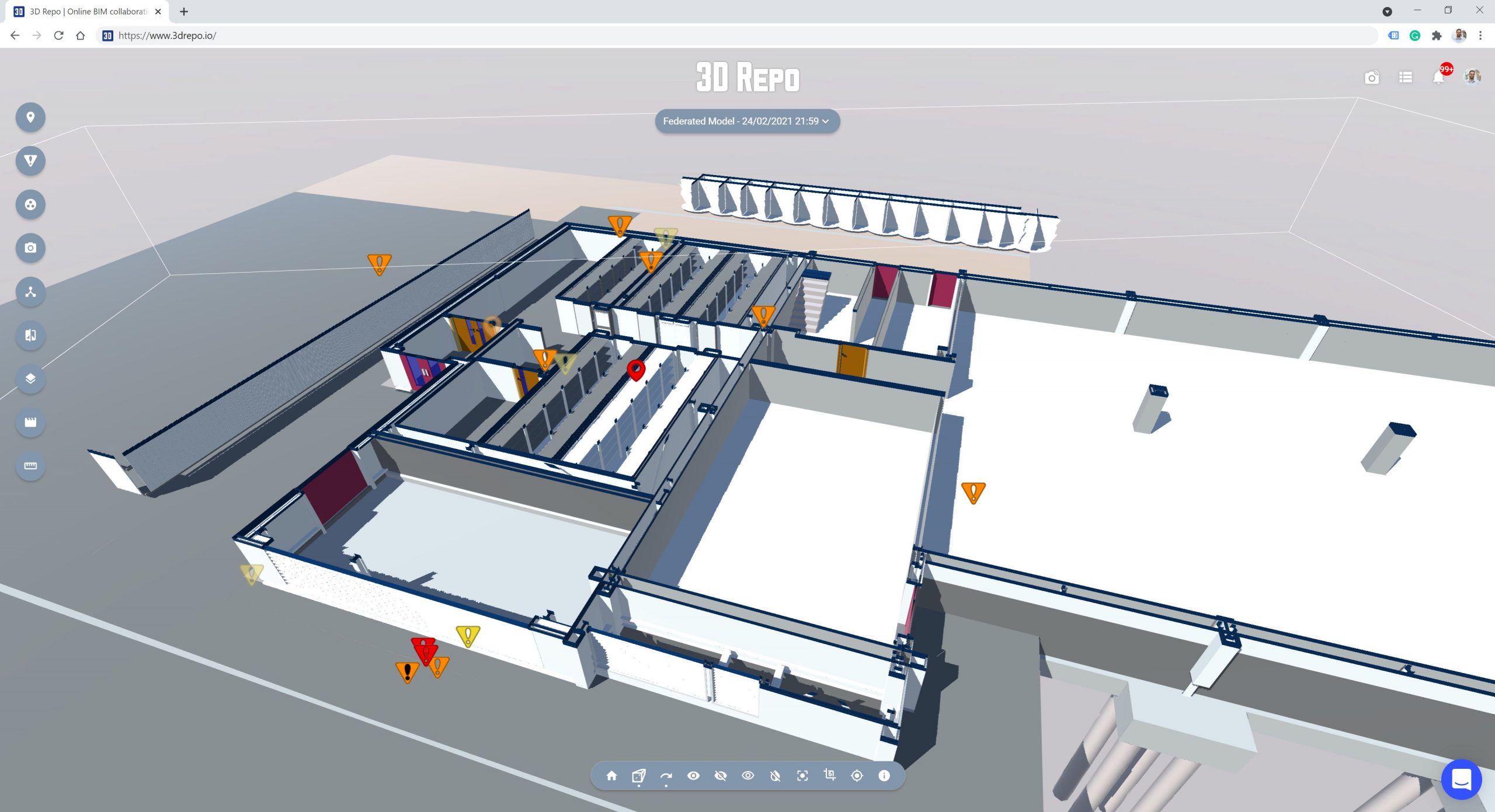

As the use of SafetiBase included developing a 3D model of the building, a number of changes to the building’s design were made early on.

“With SafetiBase, we have a much fuller view of the finished design. In particular, people who are not accustomed to reading 2D drawings have found the 3D model very useful,” says Ayres.

“For example, with the help of the 3D model, our client immediately spotted that the storage racking was too high. It was only by looking at the designs in 3D that our client was able to see this so early on.”

The extension involves creating five separate chambers that will store the samples which will be maintained at different temperatures. In the original plans, the plant for climate control was designed to be located at roof level. However, with the help of the 3D model, the team saw that this was going to cause a number of potential risks around working at height.

“It encouraged us to question whether we needed to put the plant on the roof,” says Shaw. “The answer was no and instead we installed it on the ground floor. Without SafetiBase, we would have found out much later on in the process which would have cost time and money. Our duty is to find the best way, and the safest way to do something.”

Communication and collaboration

With the help of SafetiBase, AstraZeneca was able to bring project stakeholders into the process earlier, which was very beneficial. This helped them understand the risks they may not have seen otherwise and also helped them to understand the process and where any potential delays can come from.

“The ability to share information more easily and in a visual way with project stakeholders is another advantage of using SafetiBase. We’ve been able to let the companies bidding for the tender know that there is a 3D model available as a way of representing risks,” says Shaw.

“Another example is in our communications with the client team and the team that will look after the facility once it’s complete. They have been very impressed with the ability to walk through the project and make changes to the design early on.”

Because SafetiBase is stored in the cloud, all those working on the project can access it at the same time. With more people working remotely, using SafetiBase as part of project meetings and sharing it via Teams or Zoom eased collaboration with the wider team.

New processes for the future

“The whole project team is very happy with SafetiBase. As the project goes on, we expect to see even more benefits of using the system. We work with restricted access for bringing materials onto site and the chambers are shipped in modules to provide flexibility. With SafetiBase and the 3D model we will be able to look more closely at how they are brought in and potentially make some efficiency changes to our processes.

“We plan to use SafetiBase on another project shortly. Now that we have the register in place within SafetiBase, we won’t need to start from scratch for the next project – we can update our existing risk register.

“It takes some time to set everything up using SafetiBase and to bring everybody on board. However, it is worth the initial time and effort spent. We have found you need to start as early as possible in the project, in order to get the full benefits of the Discovering Safety approach,” concludes Shaw.