Siemens continues to flesh out AEC features for its flagship NX modelling tool. Building on its foundation in product design and manufacturing, the company is now identifying key use cases in infrastructure and fabrication.

Software vendors more typically associated with the world of product design and manufacturing are increasingly eyeing upthe AEC sector — and with good reason. Experiments in factory fabrication of building components mean that the gap between architecture and manufacturing is shrinking all the time. However, the AEC software tools most commonly in use today simply can’t match their manufacturing counterparts when it comes to raw modelling capabilities and rich fabrication features.

Take, for example, Dassault Systèmes and Siemens, developers of Catia and NX, respectively. Their products are considered the Ferrari and Lamborghini of the CAD design world, so it’s no surprise that these companies have been keenly watching the AEC industry grapple with problems that they solved years ago for clients in complex manufacturing sectors such as aerospace and automotive.

Dassault Systèmes, in particular, first signalled its intent to get involved in AEC over a decade ago. Today, it offers 2D drafting tools (Draftsight), some BIM capabilities (in Catia Building Designer), along with solutions for building fabrication and generative design.

Siemens, by contrast, is a relative latecomer, but has had a division for some years now that works alongside Bentley Systems in addressing factory design. And, over the last two years, the company has established a small team that focuses specifically on augmenting its core modelling product Siemens NX with AEC features. These features are primarily intended for companies that are already NX customers and would prefer to do all their modelling in that package. At the same time, this team is also working on building BIM concepts and features into NX that, over time, could make it a real contender as an infrastructure platform.

This is not to say that Siemens is on a journey to create a Revit rival. So far, its development team in this area remains small. But I do get the definite feeling that the company is sounding out the market – and if sufficient demand is identified, or a promising technology emerges from its R&D work, Siemens certainly has the deep pockets to develop or acquire any technology it might need to take on more of a ‘market challenger’ role.

Testing the market

Behind the scenes at Siemens, developers have been analysing AEC workflows, software, licensing and lifecycles. The company recognises that the software tools that architects use today are poorly suited for construction, having primarily been designed for documentation and drawings. Not only that, but it views the high number of tools that are needed to support a typical AEC project as being rather wasteful.

By direct comparison, complex products such as cars and aeroplanes are primarily designed and then fabricated using one CAD system (with the exception, perhaps, of aspects of their conceptual phases). In short, the mess of design data and tools that tends to pile up in AEC at the general contractor and supplier level would never be tolerated in many manufacturing sectors.

At the same time, Siemens NX is already used in the manufacturing world to do many things which are replicated in the AEC space. NX is a highly flexible solid modelling tool, capable of handling very large data sets, both in terms of complexity and detail. It offers capabilities in areas such as CNC, piping, welding, steel structures, P&ID, human ergonomics, VR and fly-throughs, as well as complex analytics.

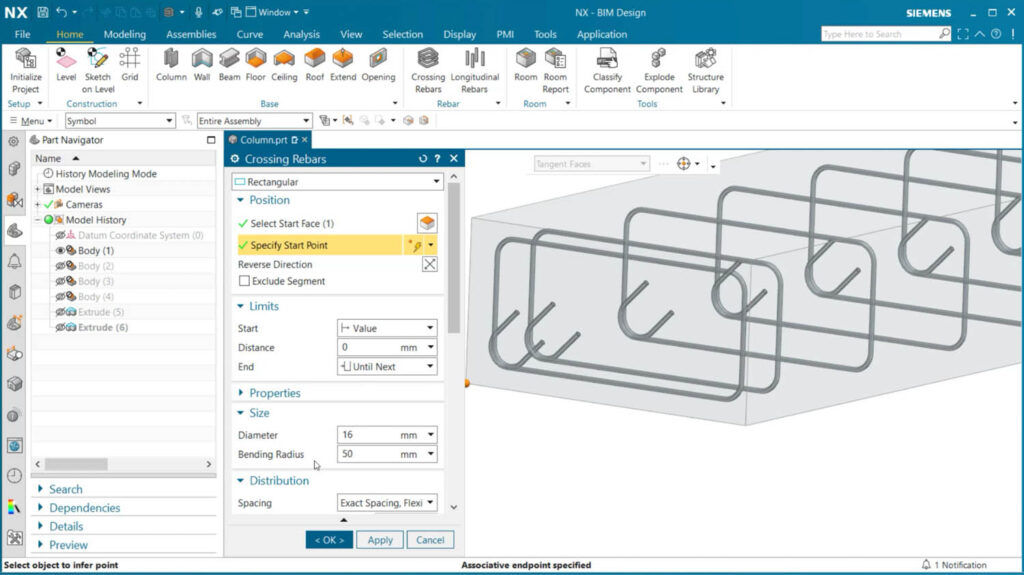

By adding a BIM module to NX, Siemens is just extending this already wide-ranging product even further, tailoring the file system to understand and support BIM schemas and component logic, terrain maps, AEC drawing standards, and in its December 2023 release, reinforced concrete design.

AEC Magazine recently got the chance to talk with the team behind these enhancements and get their take on the AEC market. As mentioned, one of their key takeaways has been the sheer number of tools required in this market to get work done, not to mention the copious data flows between applications that can come with significant interoperability issues. As a result, this is something they are looking to address.

NX Render is a case in point. Siemens has carried out extensive testing to see how well the materials and ray tracing rendering quality can be used to deliver 3ds Max-quality images. NX ships with over 1,000 materials, and the team has been looking to expand this total to support the various AEC focus areas it is looking to address. NX Immersive Explorer takes this further and can be used to deliver VR experiences that share the same materials library.

Perhaps the most intriguing aspect of this release is the evident potential for JT in data flows. It really is an excellent wrapper for complex geometry and large files, although it could arguably be better tailored for BIM use

Siemens already has on its customer roll call many companies that design and fabricate infrastructure, such as concrete bridges, for example. They typically use NX to design such structures, but when it comes to the rebar detailing, they’re forced Siemens continues to flesh out AEC features for its flagship NX modelling tool. Building on its foundation in product design and manufacturing, the company is now identifying key use cases in infrastructure and fabrication, writes Martyn Day Siemens NX AEC to export work out to Tekla, and then export out of Tekla to feed the manufacturing process. With this in mind, Siemens has built an associative design feature, which is highly configurable to support zones, different spacing options, alignment, angles and hook options. Siemens sees great potential for this functionality when applied to modular construction.

NX is already certified for IFC 2×3 import and export, a process that required a lot of testing and involved a steep learning curve when it came to supporting IFC capabilities, but which taught the team a great deal.

Find this article plus many more in the January / February 2024 Edition of AEC Magazine

👉 Subscribe FREE here 👈

JT’s time to shine

Elsewhere in the sprawling Siemens empire is a real estate arm, which goes by the unsurprising name of Siemens Real Estate, or SRE. This part of the business is responsible for running and maintaining the company’s own buildings and factories and has historically been a Revit user, despite calls from the shop floor to move to NX. An attempt to migrate between the two systems got messy, so a Revit-to-JT translator was built.

For those who don’t know, JT is a super powerful engineering equivalent of the PDF file format and an ISO standard. While PDF remains document-centric (notwithstanding its failed shift in the direction of 3D capabilities), JT is all about 3D models. More importantly, it enables NX designs to be stored in an open, lightweight file that supports multiple resolutions. For example, it can hold little more than facet data, or it can be far richer, holding associations to original CAD information, assemblies, metadata and PMI. In other words, it can be rich enough to provide production facilities with everything they need to start manufacturing.

Basically, this means that a design in Revit can be saved as a JT file, and then saved as an NX part file, and subsequently edited in NX. It was this thinking that led the development team at Siemens to settle on JT as an ‘NX glue’ in multi-CAD BIM workflows. For example, Siemens’ own PLM solution Teamcenter uses JT as the 3D visualisation format when handling data from Catia, Solidworks or Inventor in high-end engineering organisations, so the concept is certainly industry tried-and-tested. (For more on this see here).

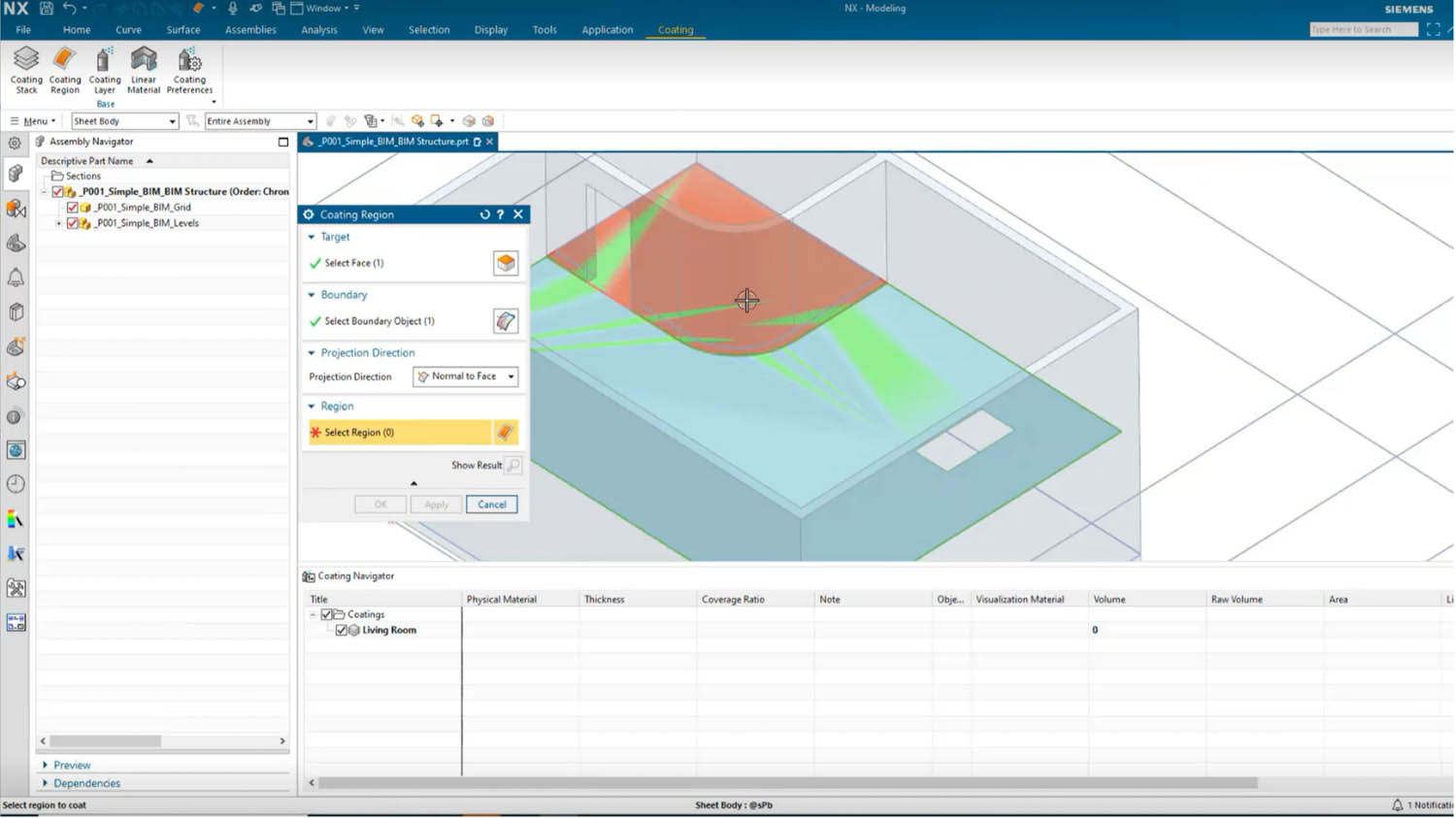

Another target for the team was rather an unusual one. Its members wanted to demonstrate the ability to apply coatings to BIM geometry to estimate material quantities when it came to the paint, carpet, varnish or epoxy applied to areas of a model. Storing information on thickness, volume, area and so on enables room-byroom costings for materials, made easily available in a spreadsheet and a boon for quality assurance.

When it comes to the cloud, meanwhile, Siemens is the last of the major MCAD developers to embrace this platform. However, NX X is the new cloudbased version of Siemens’ flagship app, making it easier for newcomers to deploy NX via an off-premise cloud subscription (although it can also be run behind a firm’s own firewall, if required). Siemens is currently working on a whole new suite of apps that will be connected to this cloud platform.

Concrete progress

Obviously, the major AEC-relevant addition in the December 2023 release of Siemens NX is the work on rebar and the focus on precast elements for construction. These efforts will put Siemens in a good position, if it continues to covet a place at the modular, offsite fabrication table. The fact that it already handles steel, piping and electrical is another major point in its favour.

But perhaps the most intriguing aspect of this release is the evident potential for JT in data flows. It really is an excellent wrapper for complex geometry and large files, although it could arguably be better tailored for BIM use. While the AEC world is excited about USD right now, JT was designed back in 2007 for sharing accurate complex solids and NURBSbased engineering data and docs at various levels of detail.

As discussed, JT can support assembly/ part/instance, facets, lighting, textures, precise topology, B-rep, PMI, 3D annotations and properties. In many ways, it’s a mature engineering equivalent of USD. What’s more, it’s open. All this makes it extremely likely that Siemens could do something very interesting with JT in AEC and fabrication.

Main image: Siemens NX now has a focus on rebar and precast elements for construction