A market leader in the manufacturing space, with brands including Solidworks and Catia, Dassault Systèmes is developing a new generation of AEC tools, which aim to cross the chasm between digital design and digital manufacture. We talked to Jonathan Asher, the DS executive in charge of the company’s AEC business development

Dassault Systèmes’ flagship brand Catia was originally released in 1977, back when the company was a manufacturer of aircraft called Avions Marcel Dassault. Its name derives from the French abbreviation ‘CATI’, which stands for ‘conception assistée tridimensionnelle interactive’ (or in English, interactive three-dimensional aided design). The software was spun off into its own division in 1981, where it became Catia and went on to provide multi-platform software for MCAD, CAE and PLM (product lifecycle management), initially targeting the aerospace and automotive industries.

While Dassault Systèmes (DS) focused on its work as a software development house, sales and service was supported by IBM via a long-standing partnership, which turbocharged the company’s global reach. From 2014 onwards, the company added 3DExperience to its brand as the integrated platform that brings together all of the company’s software solutions.

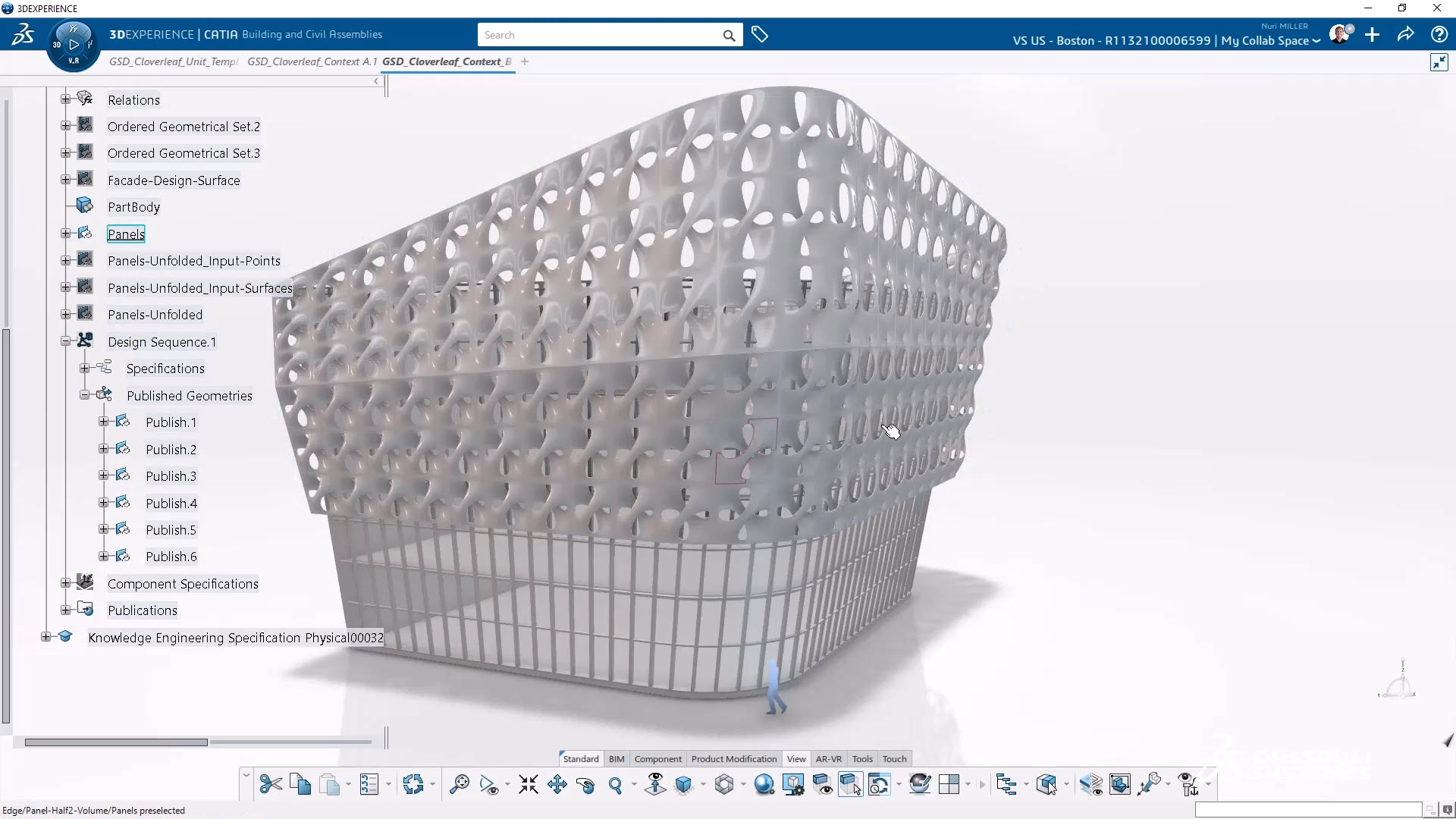

Historically in AEC, DS has had a casual relationship with AEC, with some leading architects using Catia on large engineering projects. For example, ZHA, SHoP and Frank Gehry are all well known users of the software.

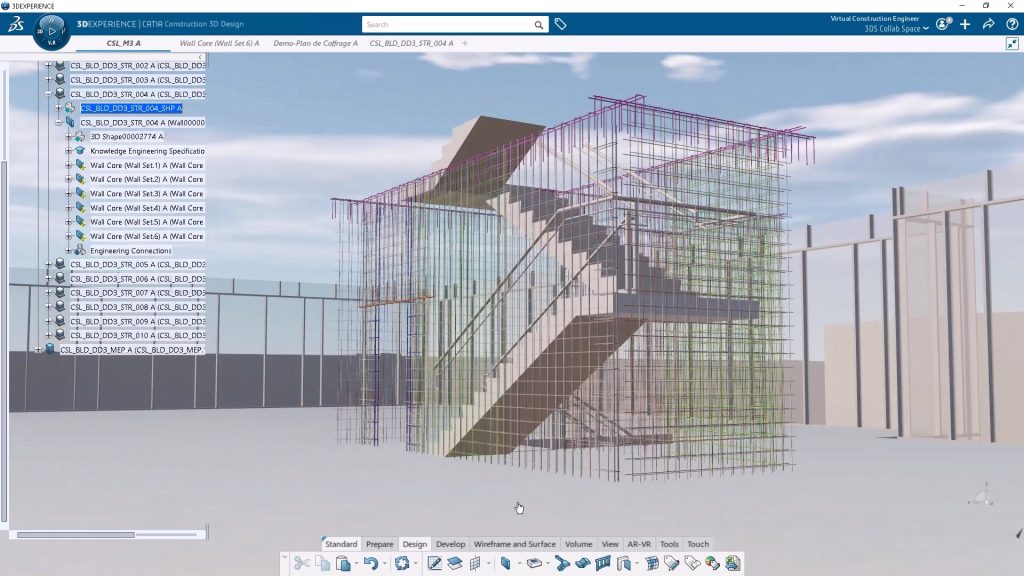

In this way, a tool that enables aerospace and automotive firms to design and fabricate complex surfaced products has also proved exceptionally useful on complex buildings. Recently, during the years of the Covid-19 pandemic, DS and Bouygues Construction collaborated on designing a Catia-based system to automate and optimise construction bidding and fabrication from 3D design inputs, generating fabrication drawings and estimating costs.

At AEC Magazine’s NXT BLD conference in London on 25 June, Antoine Morizot of Bouygues will speak specifically about this development.

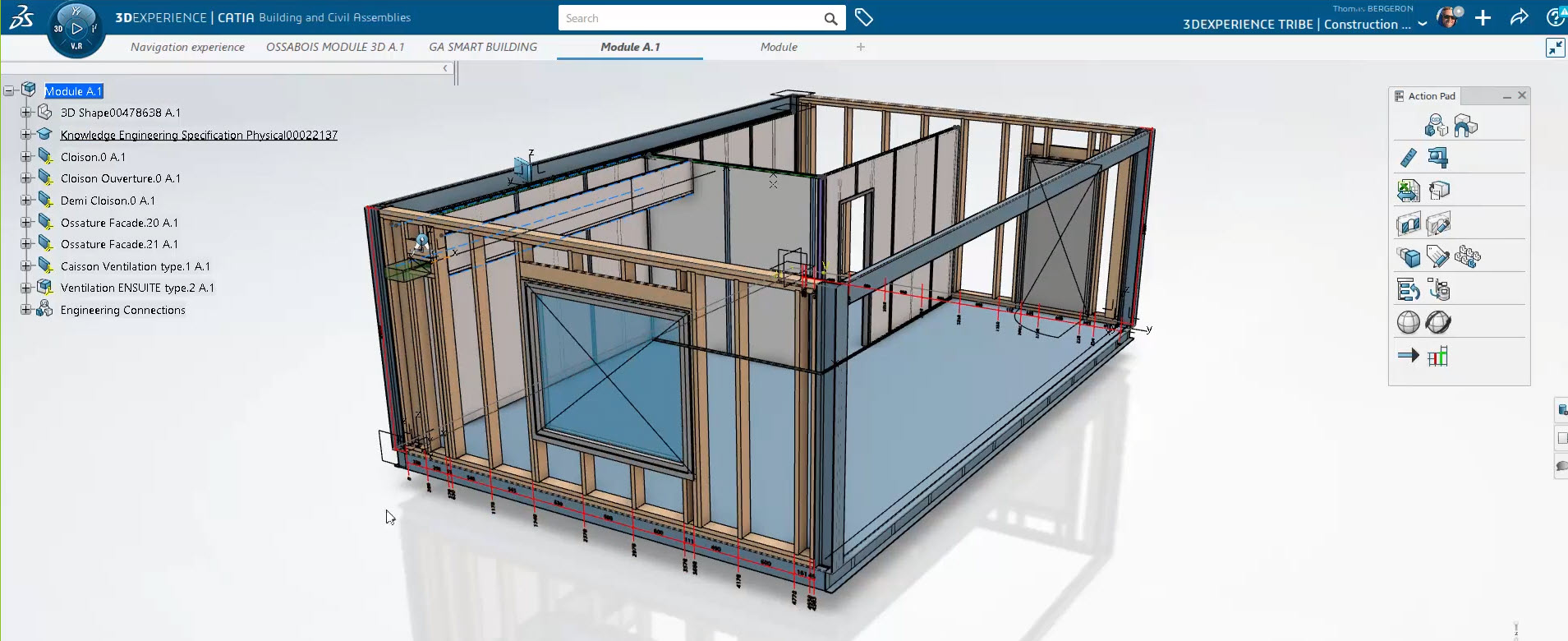

DS has been interested in exploring the mainstream AEC market since 2012, but has yet to pull all of its software together to directly take on the traditional BIM players. As AEC and manufacturing converge around digital fabrication, the benefits of a Catia-based platform start to make more sense in the industry.

We spoke with Jonathan Asher, architect, software developer and now head of the business development of DS’s AEC business.

AEC Magazine: How did you get into Dassault Systémes and Catia?

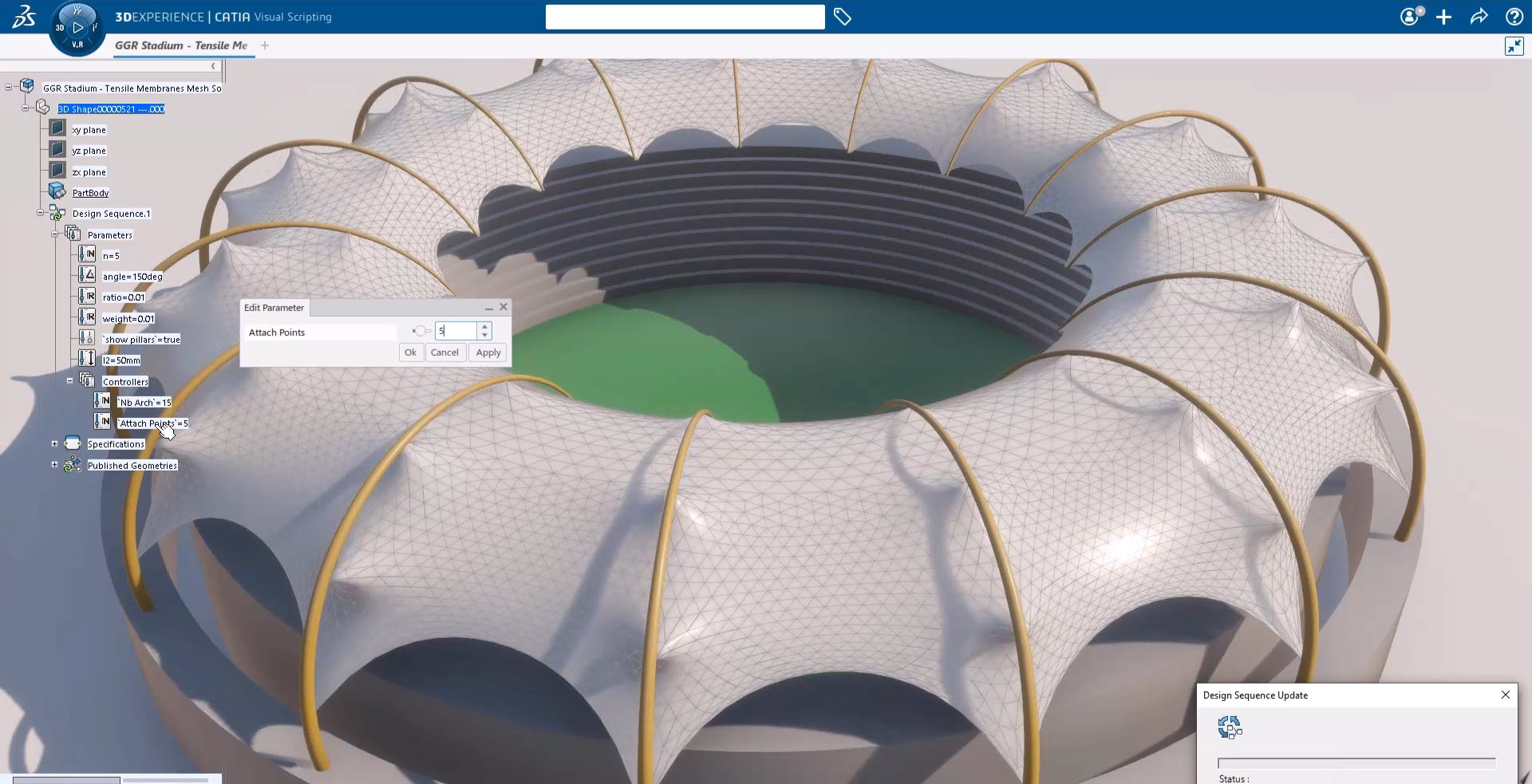

Jonathan Asher: I’m an architect by training and spent many years in the industry as an architect. I started using Catia V5 when I was at Coop Himmelb(l)au (Austria) in 2009 as a part of its first real BIM team. There I used Catia as an architect and I fell in love. Up until that point, I had been using Generative Components and other applications in the ‘smartgeometry’ ecosystem. I took the generative and parametric approach to modelling from Generative Components into Catia and it blew my mind, the things the team and I were able to model in such a short amount of time. I realise Catia is best known as an engineering software, but I use it for design, and at this point, I couldn’t imagine using any other software for design. What is more, the applications in the software now compared to what we were using in V5 are pretty incredible.

AEC Magazine: You were in AEC software development but then you changed your role?

Jonathan Asher: I joined Dassault Systèmes to lead our Catia software development efforts for AEC. After more than seven years in R&D, I switched roles last year, moving into a sales position. I’m not a ‘salesman’, but I oversee our global sales strategy for Catia in the AEC industries, as well as go-to-market strategy, market awareness and user adoption worldwide.

I’m happy to do this, because I’m convinced that we have the best software for these industries. I’ve been around long enough to have seen the competition, to have used the competition, and there really is no competition. When you look at it, Catia is like a Ferrari and our competitors are offering Toyotas. No disrespect to a flagship Catia customer, but you can’t drive a Ferrari as you would a Toyota, and if you try, you will never see what the car can really do. This can be the case for people who have tried Catia and may have struggled with it, because they’re probably driving it the wrong way. Catia is different from most other AEC software and that is not a bad thing.

AEC Magazine: Some architects are experimenting with MCAD applications to replace products like Revit so they can ‘talk the same language’ as their fabricators and model assemblies. Picking midrange tools from their product bundles seems logical, but aren’t there limitations to mid-range tools?

Jonathan Asher: Absolutely. There’s a scalability wall or ceiling that you hit in mid-range desktop modellers, where you simply can’t go any further. Moreover, with file-based modelling applications, file size is a major issue that impacts collaboration and performance. On the other hand, Catia scales with the size and detail of the project; even in huge complex assemblies, you can visualise the nuts and bolts. In addition, the Catia V6 architecture is no longer file-based; we are integrated into the 3DExperience platform, which hosts a database on the cloud, making collaboration and performance much better.

AEC Magazine: Dassault Systemès has not only been developing for architects but also for construction. What can you tell us about that?

Jonathan Asher: Four years ago, we signed a partnership with Bouygues Construction and, since then, we have dedicated a number of resources specifically to construction. With Bouygues, we are focused heavily on integrating construction processes into our tools, to streamline the creation of generative 3D construction models (that we call Brycks), link these to design models coming from their architects/engineers, and drive their site and logistics systems. We call this approach ‘productisation’ and it’s gone very well. The team at Bouygues Construction has been super involved and we continue to ramp up our engagement every year.

AEC Magazine: There are many workflow enhancements in development in the industry. Automated drawings will make a big impact on AEC, removing a lot of manual work. We know Catia for modelling – but what about drawings?

Jonathan Asher: Every conversation with every architecture office inevitably gets to the topic of drawings. They recognise Catia’s modelling capabilities, but in the end, they all need to produce drawings, drawings, and more drawings!

Most architects spend too much time in 2D working on individual views, jumping from view to view, trying to coordinate geometry in their head and representing that in their drawings. This process is obviously time-consuming and error-prone. For automotive, aerospace and other traditional Catia customers, they use the 3D master approach to document the model; in this way, the drawings are extracted from annotated and dimensioned sliced views of the 3D model. If there is ever a doubt about what you see in the drawing, you open the 3D Catia model, navigate to the annotated view and check the 3D. Of course, the drawings are only as good as the 3D model, but the geometry is always coordinated between views.

At this point, drafting is a short-term problem. It won’t be automated tomorrow, but we’re looking at somewhere in the one to three year timeframe, certainly by the end of this decade.

[Editor’s note: Graebert’s autodrawings will find its way first into DraftSight, DS’s DWG drafting tool (www.draftsight.com)]

Find many more articles like this in AEC Magazine

👉 Subscribe FREE here 👈

AEC Magazine: AI and automation seem to be hot topics in the software we are seeing developed. How do you believe they will impact the industry?

Jonathan Asher: In the next five to ten years, AI will first impact engineering, where things are more rule-based and data-driven. Eventually, most building design will be automated, as will the manufacturing. However, design is subjective. Yes, computers will design – but in the end, will people ever let go completely?

Right now, the design-to-manufacturing component can already be automated to a large extent, and this is what our customers in the AEC space are doing. They take a design model as an input and automate everything downstream through to manufacturing. This is already happening. The promise of AI is that it will get even easier, faster and more performative, with less user input and decision-making. Today, it’s limited by dataset training models and hardware constraints, but in the future, AI will be better, faster and more experienced than any human.

A clue as to what the future might look like is already available in Catia – not yet for AEC, but it will come. We call this our ModSim approach, where we model and simulate at the same time. The simulation informs the design in an iterative loop to find the optimal design solution.

AEC Magazine: There have not as yet been any big announcements of applications from DS for architects, but are these coming?

Jonathan Asher: Dassault Systemès’ strategic path for AEC has been years in the making. We have so many things going on, so many incredible applications that already exist, we haven’t made any big announcements – but that’s not to say we don’t already have an incredible solution. That said, we have some really exciting things in the works. Automated drawing generation is one example, but there’s a lot more to come. Because we are on the 3DExperience platform, and our data model supports granularity, we can deliver solutions that offer scalability, control of complexity and ease of collaboration. There just aren’t any other technologies like ours, many of these competitive tools are still monolithic point solutions.

London Catia buildings user day

With NXT BLD and NXT DEV running consecutively on 25 and 26 June, Dassault Systèmes is taking our lead and carrying on the innovation theme by putting together a Catia Buildings User Day on 27 June at its Hammersmith offices in London. If you would like to attend to learn more about Catia for AEC and meet Jonathan Asher and his team, you can sign up here.