Many AEC software firms talk openness, but as the industry shifts from file-based systems to data lake environments, none inspire as much confidence as Bentley Systems in ensuring that customers will retain full control of their data now and well into the future

Bentley Systems wasn’t wasting time at its recent YII conference, hammering home its ‘open’ approach to data. The message from Bentley’s execs was clear: the company is putting its weight behind openness— the sub text being that some of its competitors are not.

The emphasis was hard to miss. In the first two keynote presentations alone, led by new CEO Nicolas Cumins and CTO Julien Moutte, the word ‘open’ was used a staggering 60 times.

While AI also got a strong showing with 47 mentions, it was obvious that Bentley was speaking to customers, and not trying to impress investors. The message? Openness isn’t just a token word; it’s a cornerstone of Bentley’s strategy. “Your data is your data always,” said Cumins.

Moutte outlined the three pillars of Bentley’s open approach: open standards where everybody that was granted access to the data can read and understand it; open source, where every developer can leverage that data; and open APIs, where users are free to take their data out whenever they want, instead of just being able to query it.

Cumins also touched on the complexity of infrastructure projects, which involve multiple organisations, teams, and disciplines “This complexity makes it impossible for you to rely on any single system or single vendor. Instead, you need an ecosystem that enables flexibility, integration and interoperability across different tools and platforms,” he said.

He also addressed a common concern among customers: “Don’t get locked in,” he said. “Make sure you retain control of your data.”

As AEC firms navigate the transition from files to a data-lake world, this message should resonate more than ever. With proprietary files (DWG / DGN / RVT) at least drawings and models could be accessed via Open Design Alliance (ODA) libraries. With proprietary databases, access is granted only via APIs, which are under the control of the vendor.

“We are not creating another silo,” said Cumins.

Looking ahead, Bentley is focused not just on the present, but on the long-term future. Infrastructure is built to last. “Our users must assure that this data, their data, remains accessible for decades to come, and we believe this is only possible with a truly open approach,” said Moutte.

At the heart of Bentley’s open strategy is the iTwin platform, a suite of APIs and services designed to help AECO firms develop digital twin applications for designing, building, and operating infrastructure assets. iTwin integrates data from various sources—specs, drawings, CAD and BIM models, reality captures, sensor data, inspection records, and more.

The platform is built on a schema specifically designed for infrastructure. While the majority of this schema is open-source, one component — the Parasolid geometry modelling kernel —is proprietary, as it is owned by Siemens.

As Cumins explained, “The schema goes beyond basic data exchange, ensuring that data isn’t just accessible, but its meaning can also be understood, whether you’re dealing with materials or structures or subsurface data.”

He emphasised that this schema helps engineers, constructors, and organisations maximise the value of their data. “We’re not keeping it to ourselves. We actively encourage others in the industry to adopt the schema. This is about moving the entire infrastructure sector forward together.”

Artificial Intelligence (AI)

Cumins described AI as a “paradigm shift” for the infrastructure sector, highlighting the massive scale of data generated during the design, construction, and operational phases. “It makes infrastructure a prime area where AI can have the greatest impact,” he said.

Bentley’s investment in AI dates back several years. In 2018, the company acquired machine learning and IoT developer AIworx, which former CTO Keith Bentley described as an “acqui-hire,” meaning it was made primarily for the talent. Since then, that talent has driven several successful AI use cases, primarily in asset operations. These include automatic object classification in reality meshes and using computer vision, IoT sensors, and machine learning for predictive maintenance—detecting issues before they lead to failures.

Many of these technologies now fall under Bentley Asset Analytics, a new product line that uses AI to provide insights into the condition of infrastructure assets. “This approach is especially important for critical infrastructure like bridges and dams, where monitoring and maintenance are key to ensuring long-term safety and performance,” said Mike Campbell, Chief Product Officer, Bentley Systems.

The portfolio includes Blyncsy, which utilises crowd-sourced dashcam footage and machine learning models to automate roadway maintenance and asset inventory. “AI can help identify roadside assets and assess their conditions, everything from a broken stop sign to a faulty streetlight to a fresh pothole,” explained Mike Schellhase, VP of asset analytics at Bentley. “These insights feed directly into the infrastructure digital twin, the iTwin, and are presented in iTwin Experience to show the latest conditions and context.”

Another product, OpenTower iQ, uses drone imagery, data, and AI to manage telecom towers throughout their lifecycle, handling everything from data acquisition and visualisation to structural analysis, site design, and maintenance.

Bentley plans to expand these solutions to cover a broader range of asset types, offering owner-operators increasingly advanced AI-powered tools.

Now, the company is pushing AI further into the design phase, using generative AI to automate repetitive tasks.

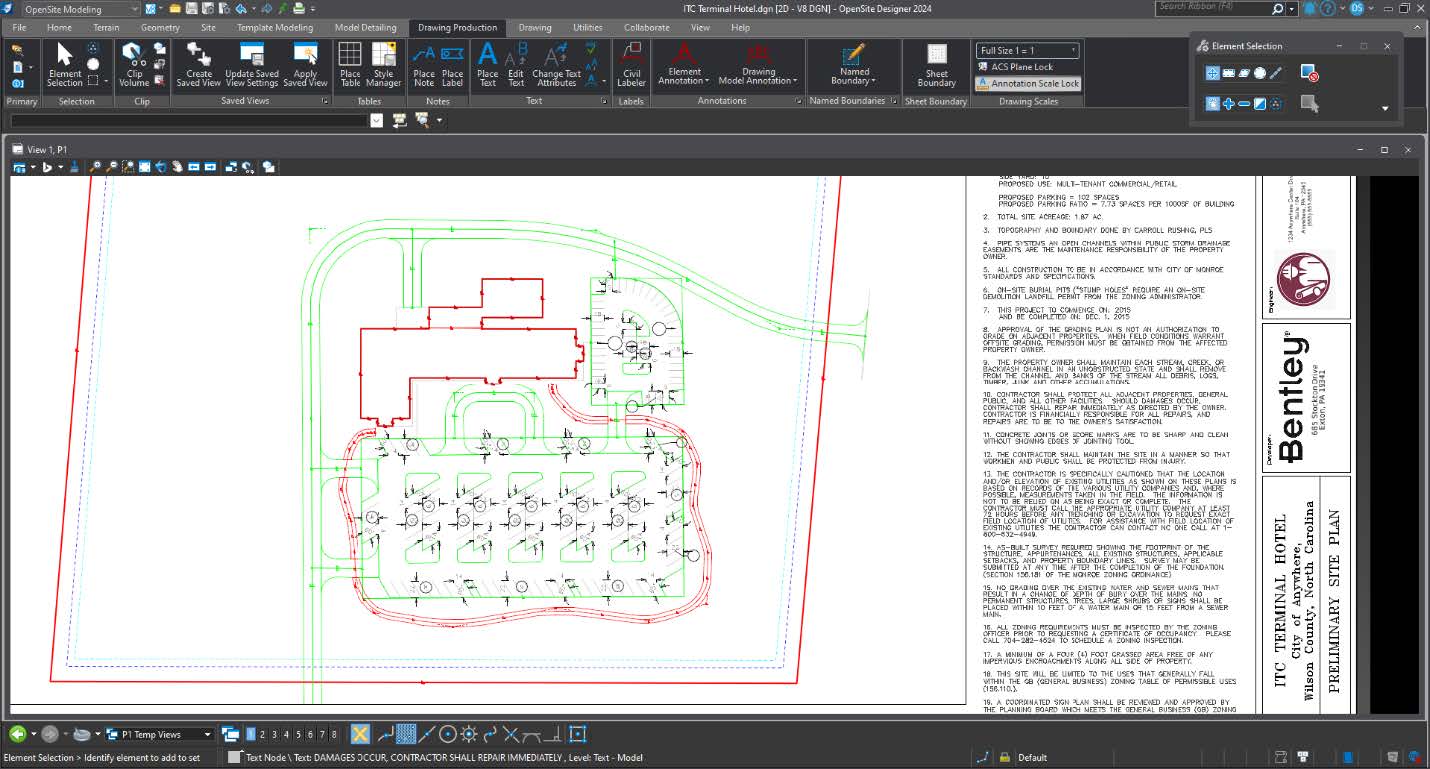

The first of a new generation of AI-powered design tools is OpenSite+, which is used for civil site design (including roadways, parking lots, and buildings).

The software features a co-pilot experience that taps into knowledge stored in documentation, specifications, and 3D site models through natural language interactions. “We can ask questions like, ‘Can I build a hotel in this area?’ or ‘Do I have enough parking to meet my requirements?’” said Francois Valois, VP of civil infrastructure at Bentley.

“At this stage [in the design process], we don’t know if our layout is optimal, so we build a neural network that evaluates thousands of alternatives to find the best one, optimising costs while meeting engineering requirements,” Valois explained. The software also offers AI-powered earthwork optimisation, which Bentley has enhanced by wrapping its current engine in a neural network to make the process significantly faster.

Another key feature is automated drawing production, a hot topic in AEC as it can save so much time and money (read this AEC Magazine article). According to Bentley, drawing production can account for up to 50% of a site design project’s time, and Bentley’s AI-powered tools automate annotation, labelling, and sheeting, optimising the placement of labels and dimensions, and according to organisational standards.

Currently, drawing production isn’t built directly into OpenSite+, but rather, it’s routed through OpenSite Designer, an existing power-platform based product based on MicroStation. However, as Campbell explained by going down this route, the technology can then be made available in other power platform-based applications. Watch this space.

This process will take time, as the large language model (which Campbell playfully wants to call a “large drawing model”) has so far only been trained on tens of thousands of site plans and only from North America. “We’ve got to do that for the UK, for Australia, for all of the other places, because the standards are all different,” Campbell said. “Roadway plans have a different look and feel, right? So, we’ve got to build a model for that.”

As to where the training data has come from, Campbell explained that most of it is sourced from a licensed open-source library, though some customers have granted Bentley explicit permission to use their data. “We’re not just going and taking plans from random [customer] accounts,” he said, adding that Bentley keeps track of the provenance of every data set used. If a company decides to withdraw its data, Bentley will retrain the model accordingly.

In the future, customers will be able to train the AI model on their own data. “Say you’ve got 6,000 site plans—you can put them into your own local, retrained version of the model, and that will be yours and yours alone.”

As for the future of AI at Bentley, Campbell hinted at broader applications. “Instead of using AI to generate a site, could we use AI to generate other designs, a bridge design, for example, optimise a road for – not just the obvious ones like curvature and safety, but things like carbon impact and cost and time.”

“Civil engineers can imagine a certain section of the design space. AI can imagine a much broader design space,” Campbell added. “The good news is that in engineering, we’re governed by rules of physics and standards and safety factors and all those kinds of things, so that limits it, but still, it’s bigger than what a typical engineer can think about.”

Desktop deployment

Beyond AI, one of the most significant aspects of OpenSite+ is that it’s a completely new type of application. It’s iTwin-native, so it writes directly to an iModel without needing to go through intermediary formats like DGN. Unlike many modern applications, it’s also a desktop application, rather than running in a browser.

“We’re not yet convinced that all of these engineering workloads are going to be able to work on the cloud,” explained Campbell. “We also want to be able to take advantage of local compute. And we’ve also got our eye on these new AI processors that are coming out – NPUs – and we want to be able to take advantage of that.”

OpenSite+ works both online and offline, syncing changes (deltas) when connectivity is restored. Bentley is taking the same desktop/iTwin-native approach with its new visualisation tool, Advanced Visualization, which is built on Unreal Engine (more on this later).

Campbell acknowledges that more tools are in the pipeline, either going through validation or still in the research phase, and they will all follow this same framework.

With many new AEC software tools from startups running in the browser, we asked Campbell if this would influence Bentley’s acquisition strategy. “Not necessarily, but it would be a consideration,” he said. “We certainly look at architecture [of the software].”

He also admitted that technical integration has become a key focus for Bentley, which is one reason why acquisitions have slowed over the last couple of years. The priority now is ensuring that products work seamlessly together. “The idea of convergence and integration, ensuring that data flows smoothly across applications and the lifecycle, and informs the infrastructure digital twin—that’s the goal,” Campbell emphasised.

Back into BIM?

Bentley once held a strong position in architecture, especially in the early 2000s with MicroStation and GenerativeComponents, a pioneering computational design tool that preceded Grasshopper.

However, in recent years, the company has shifted its focus away from this market. Given the growing interest in next-generation BIM tools, the question arises: does Bentley have aspirations to get back into BIM?

“Our focus right now is absolutely on horizontal infrastructure, and there’s plenty there to keep us busy,” said Campbell.

“But I’m reluctant to say never, especially in light of the sentiment of the broader AEC ecosystem. In particular, I’m thinking about open letters, I’m thinking about the AEC spec [AEC Future Software Specification]. I’m thinking about what their vision is for the tools they’ll use in the future. And I’m thinking about the tools that we’re building. And when I read that spec and I look at our strategy, it’s not dissimilar. It’s not a slam dunk, but we’re in the ballpark.

“The data lake, the elements of openness, design in context and at scale. That’s in the AEC spec.”

Geospatial – giving assets context

Last month, out of the blue, Bentley Systems acquired Cesium, developer of an industry cherished 3D geospatial platform – Cesium ion – with an ecosystem of open standards, including Cesium.JS and 3D Tile technology. (To learn more about the acquisition read this AEC Magazine article).

“With the acquisition of Cesium, we are now able to provide a 3D geospatial view of infrastructure,” said Cumins. “We are effectively changing the vantage point of an infrastructure digital twin, from the engineering model of the infrastructure asset to the planet Earth, upon which we geolocate the engineering model and all the necessary data from the surrounding built and natural environments.”

However, as Cumins explained, perhaps the most significant aspect of the acquisition is that Cesium as a company, perfectly aligns with Bentley’s vision of open standards and interoperability.

“The combination of Cesium plus iTwin enables developers to seamlessly align 3D geospatial data with engineering, subsurface, IoT, reality, and enterprise data to create digital twins with astonishing user experiences that scale from vast infrastructure networks to the millimetre-accurate details of individual assets—viewed from land, sky, and sea, from outer space to deep below the Earth’s surface to support engineering workflows.”

Cesium’s 3D Tile technology makes light work of huge geospatial datasets by streaming only what the user needs for any given view.

It uses a concept called hierarchical level of detail (HLOD), where you basically have a tree of tiles – the root being the least detailed version, the branches adding more detail, and the leaves having the highest resolution.

3D Tiles can handle a whole smorgasbord of 3D geospatial data including point clouds, reality models (derived from photogrammetry), and 3D buildings. Through its recent AECO Tech Preview Program it can also handle BIM models (IFC and Autodesk Revit), complete with metadata which can be used for querying, filtering, styling, and analytics.

The long-term plan is to unite the iTwin and Cesium Ion platforms, but as Patrick Cozzi, CEO of Cesium and now chief platform officer at Bentley, explained nothing will be done without input from the community. The potential is limitless, he said. “We can add voxels for biometric visualisation, for subsurface, we can add Gaussian splats for higher visual quality for point clouds; we can do temporal tiles to help show the change in construction sites over time.”

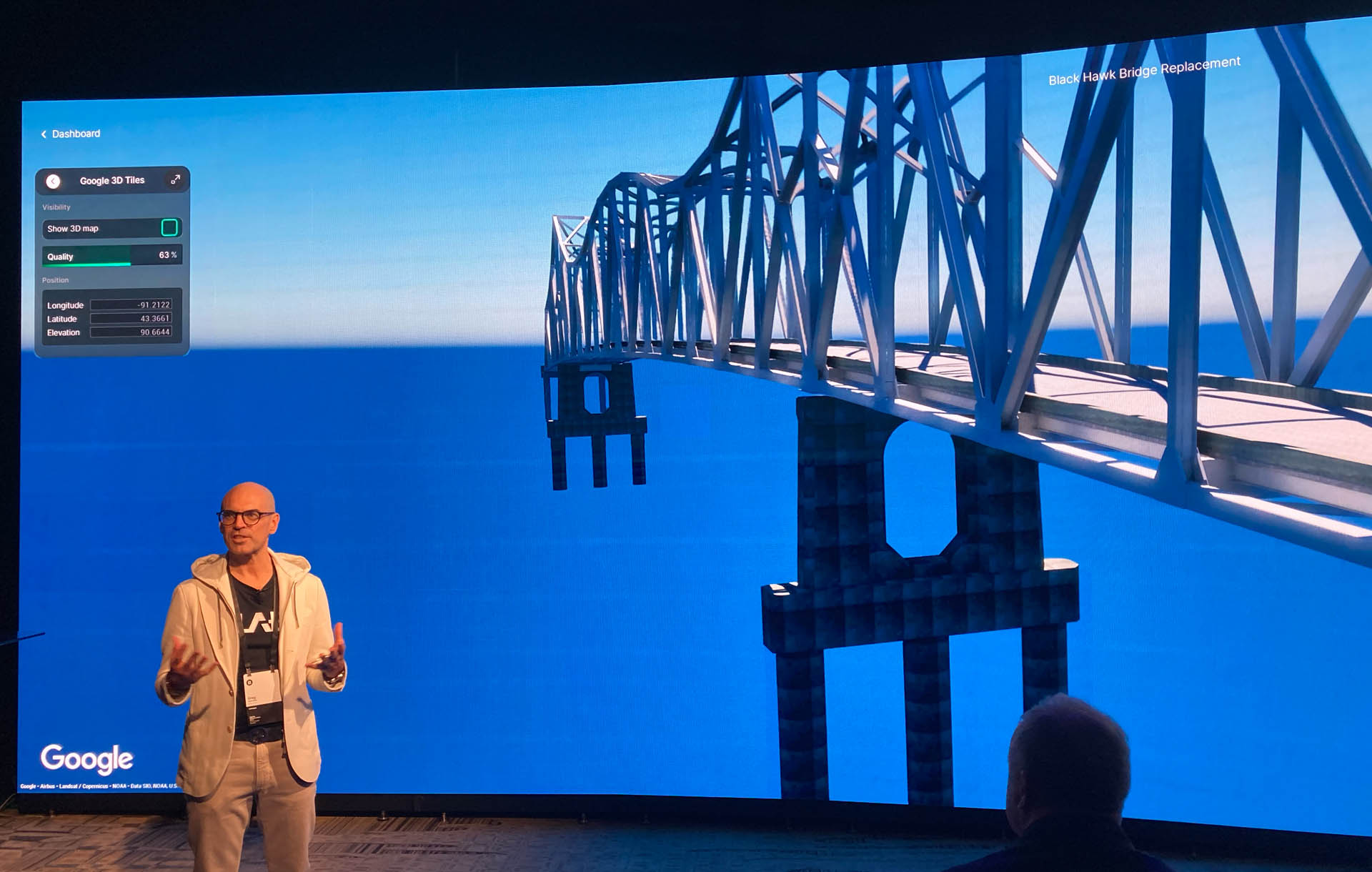

Building on this geospatial focus, Bentley announced a new strategic partnership with Google which will integrate Google’s comprehensive repository of 3D geospatial data with Cesium and Bentley’s iTwin platform.

“Consider a large urban development project where multiple infrastructure systems are used – roads, bridges, energy and water networks – that must be coordinated across various stakeholders,” said Cumins. “By integrating Google’s vast 3D geospatial data with Bentley Cesium technology and iTwin platform stakeholders can visualise their assets, both existing and plan in full real-world context.”

Advanced Visualization

Cesium 3D Tiles and Google 3D Tiles play a key role in Advanced Visualization, a new product from Bentley powered by Unreal Engine, designed to overcome the challenges of creating immersive, interactive, and photorealistic infrastructure experiences.

This software integrates seamlessly with iTwin for live access to up-to-date project data, enabling users to navigate massive models in real time using Cesium 3D Tiles.

As Greg Demchak, VP, emerging technologies group at Bentley explained, users can enrich their scenes with additional context and content: “Context in the form of Google 3D tiles, and content in the form of easy to place trees, cars, scale, figures and equipment.”

Advanced Visualization functions either as an out-of-the-box solution or as a flexible platform for building custom applications and is currently in Early Access.

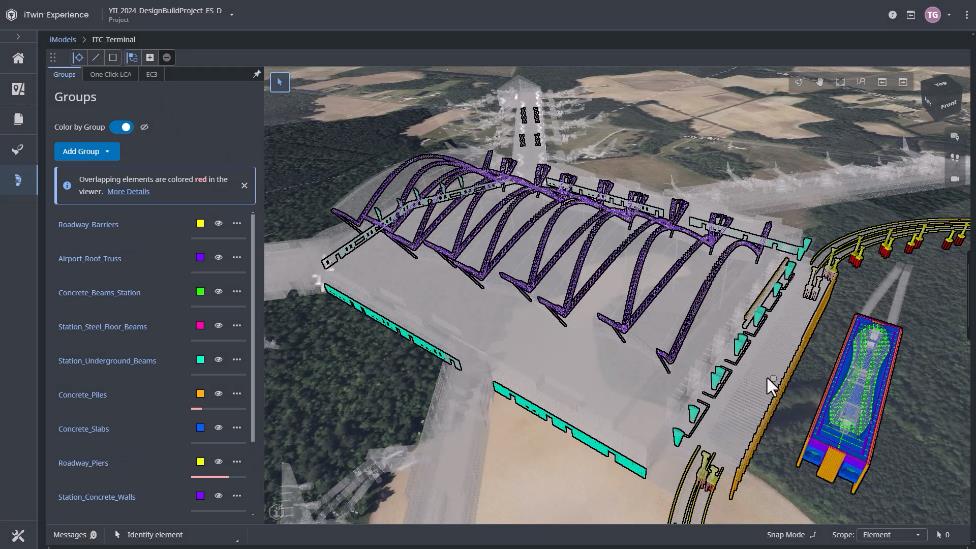

Up front carbon analysis

One of the key challenges in achieving sustainability on infrastructure projects is the time-consuming nature of carbon reporting, which is typically handled by specialists.

Kelvin Saldanha, associate director at WSP, elaborated: “Once you’re ready to measure carbon, it needs to go through a rigorous quantity take-off process, including design compilation and data cleansing, before that data can be used in third-party software.”

This process can cause significant delays. As Saldanha noted, “A lot of times that delay means that the design team doesn’t know what the carbon score is until the design is very mature, and you kind of miss the opportunity to reduce your carbon score.”

He emphasised that the best opportunity to make a meaningful impact on carbon reduction is in the early stages of a project’s design cycle.

WSP has been testing new carbon analysis capabilities in iTwin Experience through Bentley’s Early Access Program, which Saldanha said gives the design team much-needed transparency in the earlier phases of a project. “Continuous calculations during the design process allow for accurate carbon reports to be generated much earlier in the project lifecycle,” he added.

What truly sets Carbon Analysis apart, according to Saldanha, is the software’s visualisation capabilities. “Instead of sifting through spreadsheets and tables, designers can now exchange data directly with EC3, view heat maps, and interact with them to quickly identify where they’ve got carbon intensive features on their project, and then they can target those.”

Bentley’s new Carbon Analysis capabilities are available to iTwin Experience users at no additional cost, though a separate licence is required for carbon assessment calculators like EC3 or OneClickLCA.

Conclusion

While many AEC software companies talk openness, few demonstrate the same level of commitment as Bentley – though open standards, open source and open APIs.

At YII, Bentley’s executives made this abundantly clear with deliberate, impactful messaging: “Don’t get locked in,” “Your data is your data,” and “We’re not creating another silo.”,

This was a strong signal to customers that the keys to their data must remain in their hands, a crucial point as the AEC industry transitions from file-based systems to data lake environments.

Of course, Bentley’s approach isn’t purely altruistic; as a company with shareholders now, it stands to benefit from the industry moving towards storing data in its model wrapper.

And while third parties can choose to use the open specification to create an iModel / iTwin independently, Bentley has a suite of mature data management, authoring and analysis tools and services ready to go.

But with this open approach it’s clear that Bentley is playing the long game—a smart strategy considering the long lifecycle of infrastructure assets.

Cumins pointed out that the software and platform used to manage these assets will evolve considerably over time. “So, by ensuring that our systems remain open, we allow organisations to adopt new technologies and innovations while still being able to access and build on their historical data,” he said.

Of course, it’s possible that future platforms may not even be developed by Bentley, but the key takeaway for customers investing in the Bentley iTwin ecosystem is this: they will always have the freedom to choose.