For the design of its latest waterfront hotel in Boston, Marriot International turned to Building Information Modelling (BIM) to help the steel fabrication, building services and architectural design teams solve potential interferences before and during the construction phase.

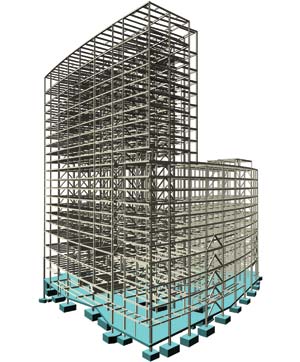

One of Marriott InternationalÝs main goals in the development of its new 22-storey Renaissance Boston Waterfront was to complete the project with as few changes and schedule delays as possible. Featuring 471 guest rooms, including 21 suites, the Boston, Massachusetts, hotel offers more than 20,700 square feet of meeting space, including a 10,700-square-foot ballroom, a junior ballroom, a restaurant and restaurant lounge, room service, and banquet facilities. The hotel also provides a fitness centre with a pool and treatment rooms, an outdoor terrace and a business centre.

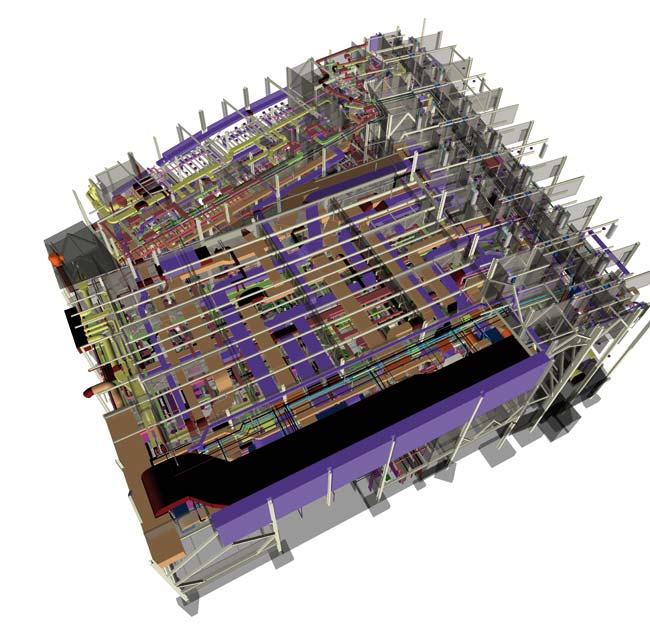

Marriott recognised that interferences between design elements during the construction phase are a major cause of cost overruns and scheduling conflicts in large commercial projects. In addition, because floor-to-floor heights were reduced during the design of this particular hotel, Marriott was concerned about the coordination of the mechanical, electrical and plumbing systems in the available ceiling spaces on each floor.

Marriott turned to 3D building information modelling (BIM) soon after the paper-based bidding documents were complete. Realising the limitations inherent in the 2D delivery system and the potential of avoiding costly change orders and associated schedule delays with 3D technology, Marriott tasked GHAFARI Associates, L.L.C. to introduce BIM as a value-added tool for the already assembled design and construction teams. By implementing BIM during design and throughout construction, steel fabrication has been streamlined and interferences between mechanical, electrical, and plumbing (MEP) systems have been minimised.

Tailored workflow

GHAFARI – an organisation of architects, engineers, consultants, and staffing specialists serving the manufacturing, government, and commercial sectors – acted as the 3D BIM integrator for the Renaissance Boston Waterfront project. The firm has considerable experience applying 3D-enabled lean design and construction for automotive facilities and was able to translate those skills to the hospitality industry.

GHAFARIÝs first task was to model the building entirely and accurately as quickly as possible in order to identify potential coordination problems that might affect early-bid packages such as structural steel. At the same time, the team adjusted its delivery workflow model – which was initially developed as an integrated automotive fast-track design-build delivery system – to MarriottÝs particular need for a design-bid-build delivery system. A difference in the design-bid-build delivery system is that the 3D BIM effort needed to focus on identifying critical design issues without over-coordinating the facility subsystems to a level that might limit the choices for selected subcontractors.

{mospagebreak}

To meet the projectÝs specific needs, GHAFARI divided its 3D BIM effort into two phases. In the first phase, the facilityÝs 22 storeys were fully modelled using Bentley TriForma-based architectural, structural, and MEP solutions. Automatic interference detection was used to detect design collisions, which were reviewed and grouped into two categories: those requiring design modifications and those that could eventually be resolved during MEP coordination with the subcontractors. The detected interferences were reviewed with the owner and the design teams.

" The structural steel changes were the most notable because the design team could increase the available space for MEP systems to avoid potential conflicts between bracing and architectural components "

The teams began to review the design documents based on those reports. ýAs a result, revisions to the structural steel and to ceiling heights were issued before steel was fabricated,¯ said Samir Emdanat, manager of advanced technologies for GHAFARI. ýIn addition, a redesign for parts of the piping and HVAC systems was necessary on many floors.¯

During the second phase, GHAFARI worked with the selected subcontractors to advance the original BIM effort to installation-level documentation. Subcontractors were encouraged to work in 3D and to deliver their data for coordination using 3D systems whenever possible. Detailed 3D models from the steel fabricator and the sheet-metal contractors were successfully obtained. In order to complete the coordination process, GHAFARIÝs BIM team augmented the subcontractorsÝ efforts when 3D data could not be obtained.

Integrating information

Since the intent was to transition this BIM effort into the construction phases, it was important to select systems that supported open industry standards. Choice of Bentley Structural, for example, allowed the team to use industry-standard file formats and integrate the steel fabricatorÝs 3D model files, when they became available, into the overall BIM. ýThe ability to import the fabricatorÝs steel information and to integrate it into the mainstream coordination models reduces the chances for data re-entry mistakes and saves hundreds of hours of rework that would have been required if the models were to be updated using conventional 2D document methods,¯ Emdanat noted.

In addition, BentleyÝs support for the DWG format allowed the team to interface with the 3D models supplied by the sheet-metal fabricator as well as other file types provided by the subcontractors and the design. ýEarly results from the project demonstrate that a number of potential construction changes were detected and resolved early in the process, thus avoiding a more-than-likely increase in the construction schedule and budget,¯ said Emdanat.

The structural steel changes were the most notable because the design team could increase the available space for MEP systems to avoid potential conflicts between bracing and architectural components. In addition, as the effort continues and additional detail is provided to update the 3D BIM during construction, the team is producing highly coordinated 3D-based installation-level documents that will significantly reduce the chances for field changes and associated schedule delays.