Greg Corke caught up with Newtecnic’s Andrew Watts to learn how the firm uses technology to optimise the design, manufacture and construction of complex facades on iconic projects

Andrew Watts is not your typical building engineer and architect. The CEO of façade-led multidisciplinary engineering firm Newtecnic is more likely to draw inspiration from Concorde or the Bentley Blower than from a Le Corbusier building. He is fascinated by components that perform multiple functions and by how they fit together, both functionally and aesthetically.

“I’m still inspired by the world of Lotus from the 1960s, where they didn’t just put an engine into the back of a Formula One car. The engine was the structure,” he says. “The wheels were fixed directly to the engine. But it needed to have a double function in a way that adds to the visual quality of the assembly.”

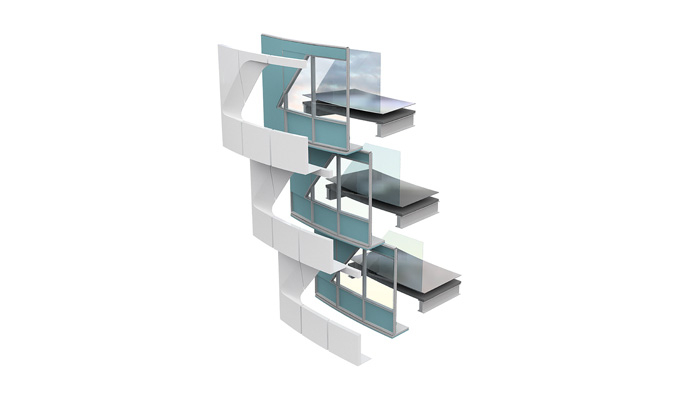

Such influences can be seen in many of the high-profile projects undertaken by the global firm, which has offices in London, Cambridge, Los Angeles and Riyadh. Watts has helped develop an advanced system whereby components can be put together in different ways, a bit like Lego. “We try to create more components that can do more jobs,” he explains. “We might have, for example, a set of components for a bracket and that covers everything, rather than reducing it to one with vast numbers of bits added to it.

“Each component for a façade could be formed by ten standard sub-components that can then be put in different combinations and permutations.”

This kind of standardisation is a great way to cuts costs, but Watts is keen to point out that the same custom components are not used across multiple projects.

“We don’t go as far as it being a product – because every project is different. Every building is different,” he explains. “It’s very tempting to want to shortcut a process – but shortcutting a process for us, as engineers, means that we can miss something that actually allows us to reduce cost.”

Technology and imagination

Newtecnic is very technology-led and is always looking at new materials and processes to deliver the highly complex buildings conceived by the firms it works with, including Zaha Hadid Architects, Gensler and Aedas.

“By using technology, it is possible to reduce risk while creating more imaginatively conceived buildings at lower cost that use less energy, are more durable, look better and are interesting to inhabit,” says Watts. “They also take less time to make and on completion appear effortless.”

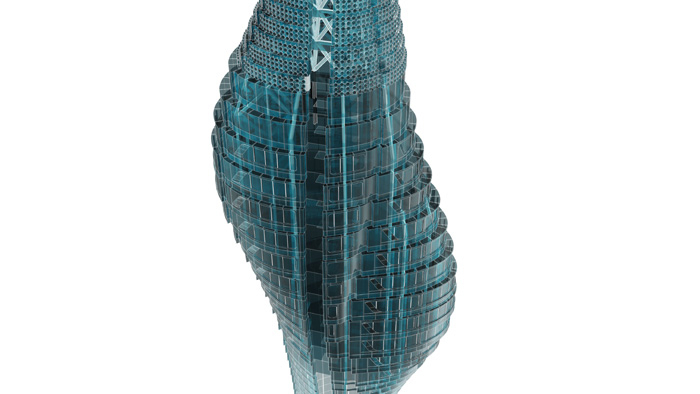

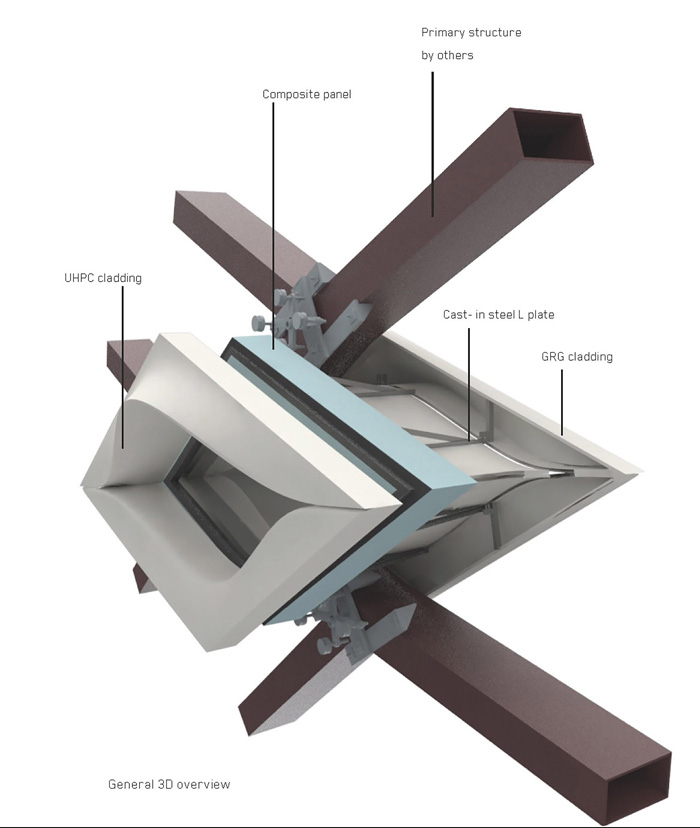

The firm specialises in iconic buildings and advanced building envelope systems. The futuristic KCTV Tower in Istanbul, for example, features an innovative facade that allows inhabitable spaces to be attached to the whole of the tower’s core. Likewise, the design of the envelope system on the KAFD Metro Station in Riyadh was driven by the need to minimise installation time through prefabrication while achieving a highly durable facade assembly.

“If you’ve got a regular box, there’s no point coming to Newtecnic – there’s nothing we can really add to that,” explains Watts. “But if you’re setting yourself out with a complex geometry problem that requires structural engineering, that requires façade engineering, that requires being able to squeeze in environmental performance into a shrink-wrapped box – then we’re the guys for that.”

Close collaborations

Newtecnic works very closely with both contractors and architects. With a contractor, the firm might work to interpret a design that is already well-defined. With an architectural firm, it typically gets involved much earlier on in the process, even at competition stage. Here, Newtecnic might be presented with an architect’s spatial and aesthetic vision and asked to give it an authenticity by defining what it’s made out of, how it will be made, and who will make it.

Ideas are developed with the structure at their heart, in recognition that it has to stand up and be cost-effective, but Newtecnic also works very closely with the architect to develop the aesthetic. “We want to show off the engineering design as reinforcing the architectural design, not something which is somehow drawing out limitations in the architectural design.

“At all stages, we need input from the architect to see how does this fit into the bigger picture of the building – particularly as we are always encouraged to move any decorative elements which are not essential. We try not to cover anything up, but of course, in revealing everything, it’s got to look good.”

The design process often starts by evaluating the performance of a building design in the context of its surroundings. An architect’s 3D CAD model might be brought into Rhino, for example, and combined with third-party survey data to carry out virtual wind tunnel testing in Computational Fluid Dynamics (CFD) software tool Comsol.

Virtual wind tunnel testing can also help drive the design. By combining preliminary airflow results with computational algorithms, completely new designs for the building or its facade can be automatically generated. This could be to reduce material quantities or to maximise airflow to help reduce energy consumption in the building. This is particularly relevant for projects in hot climates, of which Newtecnic works on many.

The surrounding site can be modelled precisely using photogrammetry or more loosely by tracing the outline of a photo. Buildings are generally simplified, concentrating first on form, followed by surface texture, to see how that impacts things like turbulence.

At this early stage, Newtecnic places a big emphasis on future-proofing the building, by exploring exactly how it might perform in its ever-changing environment. “We want to understand what is happening now, what might happen in the future and therefore how much can we realistically reduce the quantity of material. We’re thinking always 25 years, 50 years into the future.”

“Surrounding buildings are always a bit of leap of faith, as you don’t know which ones are going to get knocked down or which ones are about to be built,” says Watts.

The design is assessed from different wind directions, generating pressures for the structure and façade. Wind speeds used for ultimate limit state design are applied to see how the building responds when it is theoretically pushed to its limit. Newtecnic also places a big emphasis on typical wind conditions and how they might affect the serviceability aspects of the design.

“We want to know how it behaves on a day-to-day basis,” explains Watts. “Is it comfortable, is the structure moving in a way that makes you feel a bit queasy? Is the door always slamming, or are you fighting to open the front door?

“You don’t want to end up having to have sliding doors put in [retrospectively] to solve a problem that could have been addressed in a completely different way in the beginning.

“It’s also user comfort. You don’t really want to have a restaurant or a big terrace ten metres up in the air when it’s going to be windswept.”

Virtual wind tunnel testing is always proven out with physical wind tunnel testing, to get an accurate a picture as possible. This is done in conjunction with the University of Cambridge, where Newtecnic has strong ties with the Engineering Department.

“You do get unexpected effects in areas where the [CFD] mesh is not really dense enough or the CFD software is not picking up local behaviours,” explains Watts. “Subtleties, secondary effects, emergent effects – those are picked up by the physical tests. So what we thought was working really well, we may find we now have to smooth out a whole area.”

Once the physical wind tunnel results have been assessed, the geometry model and structural model can be refined and the CFD study set to run again.

Newtecnic hasn’t gone so far as to feed back physical test results into the CFD engine to better align the virtual and physical worlds in order to improve the accuracy of future simulations. “We would need bigger computers for that,” admits Watts. “We already have Aston Martin’s set downstairs. We would need to get more into Airbus-level to do that.”

Curves, planes and connections

Simulation is also used extensively in the development of the complex structural systems with curves, sweeping planes and composite connections that are typical of most Newtecnic projects.

“You analyse it [the building] globally, you analyse everything, you analyse every connection,” says Watts. “You build the whole building virtually in the computer. You make sure that the parallel world inside the computer tells you that it’s going to work. We do endless investigation and we think that is a way to provide greater certainty at reasonable cost.

“We need to know the forces acting or being acted upon at any given point – usually a point of intersection of the structure or façade.”

For structures, Newtecnic uses the simulation tool SOFiSTiK, as it offers the flexibility of being able to analyse complex forms, as Watts explains. “It’s a Finite Element Analysis software that takes into account curvature, whereas other softwares are pretty much limited to rectilinear frames.”

Another reason for its popularity is that it responds very well to change. “It’s very good at being able to demonstrate structural behaviour,” Watts says, adding that with other software, when removing small components in large-scale structures, you don’t know if it has destroyed the structural integrity, stability and stiffness of the structure as it’s creating local stresses or deformations.

“If you build these models in SOFiSTiK, you can understand the behaviour by removing pieces and seeing what effect it has. It tells you what you need to do if you want to keep making changes.”

For connection design, Newtecnic uses Comsol, which is popular with the team because it is customisable and extremely good at dealing with complex small-scale assemblies. “How things are connected, how two things next to each other will separate as they are pushed and pulled – those can be very closely analysed in Comsol, which other software doesn’t allow us to do,” explains Watts.

This could be when a piece of steel joins a reinforced concrete rebar assembly, for example, and problems such as leaks in the facade or micro-cracking in the concrete can occur.

Newtecnic also uses fatigue analysis to help ensure its buildings continue to perform well into the future. The technique is widely used in the aerospace and automotive industries but less so in building design. “We want to know how the long-term movements are going to affect the structural integrity of specific small-scale components, which are generally in the façades and exposed to the effects of the weather,” he says.

Let’s get physical

When connections are made from many separate components, it can be very hard to predict performance with simulation alone, admits Watts. As a result, Newtecnic works with the University of Cambridge to test, verify and rubber-stamp the performance of these parts.

Mock-ups are often made by third-party contractors, on spec before tender, in order to demonstrate their ability to deliver the final components, which are often complex to manufacture.

“We get components made – it might be a piece of a panel and a connection bracket. We might get those from a couple of manufacturers,” says Watts. “We then put them together and apply loads in a very specific way that allows the assembly to be tested and evaluated through codes.

“It means we can go to a competitive tender, not just with a BIM model, but a BIM model where things are costed and where the specific assemblies that have not been done before, which have been innovated, have been tested and we have some kind of sign off from the [University of Cambridge] engineering department.”

Newtecnic also relies heavily on engineering- grade 3D printing. In its headquarters in Shoreditch, London, it has an Objet 3D printer that it uses to make functional prototypes out of polymers. This not only helps it get a much better understanding of components in the development phase but also allows it to effectively simulate the process of construction.

“We print a combination of 1:1 connections and scale assemblies that shows how pieces would go together,” says Watts. “We can show how things would go together if a crane was in place and why you’d need to assemble things in a certain sequence to allow them to be self-stabilising, for instance, rather than requiring lots of additional props.”

3D printed models are shared directly with contractors, not only for better communication, but also to keep costs down.

“We do it, so a contractor says, ‘OK, you guys have got this worked out. You’re not setting a problem and asking us to resolve it. You’re providing us with a resolved design’.

“And that allows us to say, in return, ‘We want the tender price to come back pretty much the same price as a standard building. We don’t want you multiplying by two or three because it’s iconic or it’s bijou or it’s a one off. We want you to take it on and construct it, following a basic set of instructions.’”

Software for problem-solving

Newtecnic uses a huge range of modelling software throughout its development process. The choice depends not only on the capabilities of the software itself and its applicability to different workflows, but also on its ability to share data effectively with third parties.

“We like to be able to do quick sketching and quick build-up of a model in Rhino,” explains Watts. “That can be ultimately the form that is agreed with the designers, but it has to keep on changing.

“Then, as we start to quantify everything and work out how it fits together, we either continue working with Rhino or we move to Revit – we’re big fans of Revit. Or we use Catia, because then we can talk to [CNC] machines. It depends on whether we’re talking to a machine or talking to a committee.”

The company also uses generative design as a problem-solving tool to help deliver logical solutions to visual criteria, often as a means to realise an architectural vision. Common tools include Grasshopper, Dynamo and Matlab. Newtecnic is also taking tentative steps into Python and R to go beyond visual scripting.

“Generative designs are often the starting point for human designers to adapt these shapes and to be inspired to develop new types of façade and detailing,” he says.

Watts stresses that with all software, it’s not just the model or data that is important. It’s also the process. “For any output, we need to be able to know how we got there and therefore how we can start again,” he says. “We used to find this a little intimidating in the early days when we were used to creating something and somebody saying ‘Wow, that’s great, but could you make it a little smaller or a bit this or a bit that’.”

“As time has gone on, every part of the process is interrogated as being a part of the design and therefore we‘ve needed to adjust to becoming much more accountable for not just the output but the process.

“We’ve had this major shift from having an unregulated creative process, where one was always proud of the output, to one where we’re more sceptical of the output, but more proud of the process.”

In order to formalise this process, Newtecnic has taken a leaf out of another industry, that of software development. “We’ve developed agile management in the firm, scrum, as if we’re designing software, in order to provide a work method that is different from the traditional architectural and building engineering methods of being output-focused.”

“[With traditional methods] if you want something changed, you mark it up and make changes, but when you want to start all over again, you need to be able to know how to do that without it being a disaster.”

Change is a recurring theme at Newtecnic and making changes and being required to make changes is a huge driver for the firm.

“All the governments, developers, contractors, architects that we work with, expect us to respond to change, because they themselves are responding to some change in the brief.”

Watts recalls a recent project where there was a problem with installation on site, where something was made bigger than it should have been. “The fabricator changed a few things and there were unexpected consequences, but we were able to come up with a solution on site,” he explains, adding that it involved a complex weld.

Photographs of this ‘proof of concept’ were then sent to the Cambridge office as a series of photographs and subsequently added to the Comsol model for analysis and verification.

“We are able to solve difficult structural problems, a changing of a connection within half a day. No other tool we have can do that with the degree of accuracy that we need.

“It means we are able to respond to how the world is, rather than how we would like it to be.”

Visualisation and optimisation

With a constant need to balance functional and aesthetic requirements, assess ideas and communicate its designs internally and to third parties, Newtecnic places a big emphasis on visualisation. This includes entire buildings, detailed systems and components.

“Everyone is a viz specialist at Newtecnic,” explains Watts, adding that the company uses a heavily customised version of 3ds max that has been ‘scripted to death’ combined with the V-Ray render engine.

3ds max is a complex product and not the type of tool one would expect your average building engineer to be able to use. So, to keep its team up to date on new technologies Newtecnic places a huge emphasis on training.

“Every fortnight we have a training day for new skills – not just engineering skills but skills that allow you to contribute to the visual artbook,” says Watts.

With its holistic approach to façade engineering, Newtecnic has optimised many different parts of the process from concept design to fabrication and construction. But the company is not finished yet in its drive to cut costs and accelerate project delivery.

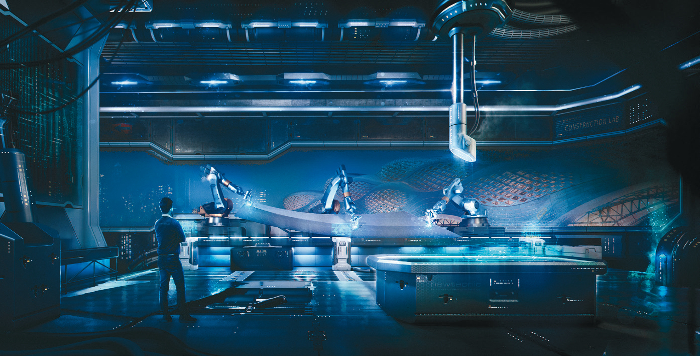

The next big step, says Watts, is to further optimise fabrication by drilling down as far as factory design. This would be ‘design for manufacture’ in action, a practice championed by the manufacturing industry where the ease and cost with which components are made has a major influence on the design itself.

“It’s a way of reducing cost through a process rather than through the product,” he says.

Currently, when contractors make initial mock-ups for Newtecnic, they are often built from a process that is not optimised. “It’s put together like in a giant model shop,” says Watts. “So, technically, a contractor will know that they can do it, but they don’t know if it’s the right process for them, and that’s a real limitation.”

He adds that when it comes to manufacture, some contractors may even end up sub-contracting jobs to a company that is better set up for a specific process but this can introduce further delays.

Newtecnic is currently developing links with the Institute of Manufacturing at Cambridge University to help optimise its process. The aim is for Newtecnic to have in-house manufacturing specialists that would be actively involved in the design process, working alongside engineers to advise how components could be made with similar functional characteristics but quicker and cheaper. These specialists would also work closely with regional factories to help optimise their manufacturing process in advance.

In this way, Newtecnic will continue to bring some of the rigour and exactitude of the mechanical engineering and manufacturing disciplines to the world of construction – an industry synonymous in some minds with inefficiency. It could be just the kind of approach to help drive things forwards, and upwards.

If you enjoyed this article, subscribe to AEC Magazine for FREE