A look at the project, the challenges, the lessons learnt and the implications on future projects. By Bob Garrett, Excitech.

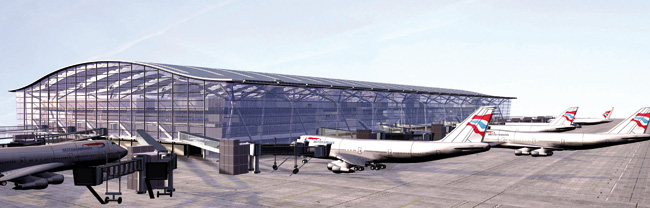

The design and construction of a new airport terminal presents a unique challenge unlike any other building. In the case of Heathrow Terminal 5 it had to fulfil numerous functions including retail facilities, rail terminal, multi-storey car park, river diversions, production line (handling baggage) and office suite as well as the obvious passenger handling facilities. Furthermore, its construction, design and mere existence attracted other additional complexities from a high profile public planning enquiry to the need for security unlike any other public building, project or area.

With such complexity and unique challenges one might have expected most organisations, when planning such a development, to consider only traditional, tried and tested approaches. BAA, however, considered that there might be much to gain in adopting new methodologies in design and construction as well as in project and contract management; and perhaps most unusually it, as client and owner, chose to manage the project from design to construction and to carry the associated risks.

In this article we look at the overall design project from its inception through to completion; how it met its goals, the lessons learnt and the implications already affecting other projects.

A brief history

Astonishingly the T5 project goes back around twenty years to the late 1980s with a first design milestone in 1989 when the then Richard Rogers Partnership won the design competition. In 1993 planning applications were submitted and from 1995 to 1999 a public enquiry examined the need and every aspect of the design before producing a report. This resulted in government approval in 2001, though subsequent challenges and more local approval processes lasted until 2003.

Earlier projects demonstrated to BAA the importance of a more collaborative design process and this was reinforced in 1995 when the investigation into a tunnel collapse at Heathrow Central was hampered by the lack of a central design data source. In 1996 Excitech commenced a project to investigate how geographical information and building design data could be brought more closely together. Through various iterations of AutoCAD-based technologies, Excitech, together with BAA, BA, TPS, Mott McDonald, Laing OÝRourke and Arup, assembled systems that demonstrated not just that it was possible but the benefits it would bring and some of the issues which would need to be managed. In 1997 these techniques were applied to over four gigabytes of data from BAA and other companies involved in construction at Heathrow. This vast quantity of data was manipulated and merged from the various formats, co-ordinates systems and units to form a single model environment (SME) conforming to BS1192 part 5. This SME was not a single file, but it ensured any item was only represented once and was related to the whole through that single model environment.

Technical details

´500 CAD users inducted

´25 CAD Coordinators

´12 supported CAD sites

´15 CAD applications in use

´24 large format printerst

´300 CAD helpdesk calls per month

´1,000 gigabytes of design data

Following this Proof Of Concept, Excitech was appointed as CAD consultant to the project and, together with the other suppliers to BAA, commenced setting out CAD standards including the processes and procedures that would ensure their implementation and success through the design process and beyond.

In 2002 construction work began on a ýprogramme¯ entitled T5; but this was further broken down into some 18 major projects, each of which were still of significant size. That same year the main design tool was migrated to AutoCAD Architecture (at the time called Autodesk Architectural Desktop), which made the management of 3D data and objects more efficient. This was alongside other software including MX, CAD-Duct, 3D+, Xsteel and other applications including NavisWorks.

In 2003 further work went into a design specification as to how design data ± in the form of objects ± could be used within BAA maintenance systems for subsequent management of the assets within the building (and the rest of the infrastructure). This resulted in enhancements to the design object data and the establishment of links and processes for databases external to the design data. The same year erection of the innovative roof commenced even while the detailed internal design was still evolving. 2008 finally saw the opening of Terminal 5, with some initial operational problems in managing the logistics of baggage handling, but on time and on budget.

Design project goals

The overriding objective behind the design and construction of T5 was to ensure it was delivered on-time and on-budget; but people count too, so safety and ýteam-working¯ were also paramount. However, the project looked beyond just design and construction. As both ýdeveloper¯ and ýclient¯, BAA recognised the importance of ensuring that the ýT5 Asset¯ should be efficient (economical, ecological and effective) throughout its life.

To deliver these goals BAA set out various initiatives including, but not limited to, the following. BAA established a different way of working with its suppliers and subcontractors for T5 with a Framework Agreement aimed at facilitating more collaborative working between all the companies involved. It did not want time (and money) wasted on disagreements between its suppliers or BAA itself, and to do this it accepted much of the risk upon itself.

As part of accepting that risk, and indeed to reduce the risk, BAA sought to manage the design and construction much more closely and to introduce the latest techniques in design data management as well as off-site manufacturing for construction.

From a design perspective a number of aspirations were set with the intention of supporting BAAÝs goals. Core to these aspirations was the ýSingle Model Environment¯ (SME), which was subsequently adapted to the ýCommon Data Environment¯ (CDE) to recognise an even broader purpose. The SME/CDE brought many benefits.

´ It made core project information available to all who needed it so increasing understanding and team working

´ It maximised use and reuse of design and project data; so reducing redrawing and the risk of errors

´ It provided a design environment for all design disciplines; so data was consistent

´ It maximised use and reuse of design and project data; so reducing redrawing and the risk of errors

´ It formed a single source of information so increasing quality and consistency Working in conjunction with the SME was the concept of object-based design where designers do not place basic lines, arcs and circles but real-world objects like beams, doors, floors etc. This, in turn, carried additional benefits to the designers, to the project, to the contractors and to BAA.

´ It made CAD work more interesting and increased productivity in the design stage

´ It provided an object modelling capability for all design disciplines; so data was consistent

´ It stored not just graphical information for drawings but property sets and intelligence for each object

BAA have an initiative in place named AMA (Acquire and Maintain Assets), which has the goal of ensuring that all assets are acquired and maintained in the most efficient manner. This initiative influences all projects to ensure the right procedures and systems are in place for the entire lifecycle of these assets. A smooth information flow from concept through to completion and into maintenance was thus key for T5 and part of this related to the transfer of design data to their maintenance system Maximo through AIM.

{mospagebreak}

Asset integration

A particular goal of BAAÝs AMA initiative was and remains the efficient addition of asset information from a buildingÝs (or other assetÝs) completion into the BAA building maintenance system, Maximo.

With T5 design data being held in an object-based model it was clear that there could be major efficiencies gained if this data could be transferred through some automatic process rather than gathered from drawings and surveys as would normally be the case. From early in the project it was envisaged that this should be an intention and in 2001 a proof of concept project was undertaken by Excitech to examine how this could be achieved. This considered carefully how the relevant asset data could be created and held within the graphical data models for later retrieval and validation prior to being exported via a common data environment into Maximo for the ongoing operation and maintenance of T5. The benefits in time and cost saving were substantial and clear, as was the recognition that the data quality would be much better. Hence the development and implementation in 2002 of a software tool and process so that the design data included the necessary information ready for transfer and update during the completion period.

CAD management

ExcitechÝs appointment as CAD Consultants to BAA for the T5 programme has been key to many aspects of the projects at both strategic and tactical levels. Setting out a new methodology for CAD within a project can be a significant task; but ensuring it works, is supported and delivers the expected benefits is the real measure for success.

ExcitechÝs team, which grew to a maximum of nine full-time staff, were working with over 25 separate design teams. Absolutely essential to successful collaboration and the smooth running of the design aspects were the needs to educate and promote the requirements of BAA and the programme to each and every individual within all these teams. Handling the cultural issues, which always go with the implementation of new processes, techniques and methods was also both vital and sensitive.

As with any project there are risks where design teams overlap so coordination as to responsibilities was critical. Discussions were centred on what a group was doing (what are the deliverables to be), how they are undertaking this (the processes) and why (who should be doing this). Emphasis was placed on creating an environment of a single programme team no matter who employs them, what their design discipline, where they are based or which project they are working on.

ExcitechÝs team also supported design data quality, collaboration and productivity by being active in each of the following areas

´ Object and design content

´ CAD standards and compliance

´ CAD skills assessment

´ Training

´ Model management

´ Storage management

´ Application design and development

´ CAD desktop implementation

´ Technical support As with other projects intensive training programmes attempting to teach everyone everything were not used. Instead the technique has been to

´ Identify what expertise is needed for each team and individual

´ Introduce object technology without the end user being aware of the technicalities and extra data within the objects

´ Establish an efficient process for production of the particular deliverables

´ Provide central expertise to kick-start and encourage teams

´ ýCAD roadshows¯ to improve awareness

´ Regular ýtips and tricks¯ guides

´ Workshops

´ Regular CAD Coordinator Meetings

The legacy

The evidence for the success of the T5 Programme is clear; it has achieved its major design and construction goals on time and on budget. As a gateway between the UK and the world, though, it is more than just an airport terminal. T5 has been one of the worldÝs largest construction programmes that has adopted innovative design technologies ± and it made that choice a decade ago. That the basic concept and its implementation were able to be sustained and developed over this long period through changes in the design technology systems and changes in design requirements is testament to the excellence of the decisions, processes and people involved.

However, the real legacy may not be the Terminal 5 programme as represented at Heathrow. The real legacy may be how the programme has shown and continues to show the way for other construction projects ¾ not just for BAA but for the whole construction industry. As Peter Rebbeck, the former Technology Solutions Manager at BAA says: ýAt the outset we were really pushing the technology to its limits but as we have rolled out T5, software solutions capable of supporting these 3D design methodologies have increasingly come on line.¯ But does this design technology bring benefits? Dr Chris Millard, Head of Engineering for the T5 Programme and Head of Technology for BAA Capital Projects is certain when he states that: ýIf we had not used such an approach we would not have built the terminal as quickly and efficiently as we did.¯

His enthusiasm is shared by others who have worked on the project including Mervyn Richards, who was CAD Technology Manager at BAA framework partner Laing OÝRourke. With BAAÝs agreement he used T5 project documentation to work within the UK government sponsored AVANTI project, which was investigating ways to improve collaboration within the construction industry. AVANTI then implemented similar processes in other projects to analyse and quantify their success. ýThe conclusion was that the approach does work, it has great advantages and has enabled everyone in the supply chain to save money,¯ says Richards, ýand the benefits extend far beyond the project end deliverable.¯

Project facts

´T5 on its own is equivalent in size to the complete London Gatwick site

´T5A ¾ 396m x 176m by 40m high

´T5B ¾ 442m x 52m by 19.5 high

´260 hectares

´30 million passengers p.a.

´60 aircraft stands

´ Control tower 87m

´18km Baggage system

´1.3km, 8.1m diameter airside road tunnel

´4.1km, 2.9m diameter storm water outfall tunnel

´6km of twin rivers diversion

´4,000 space multi-storey car park

´70% of the construction is below the surface

The principles of the AVANTI approach have now been enshrined in the BS1192:2007 data management standard ± the code of practice for collaborative production of architectural, engineering and construction information.

It worked for T5 and has been seen to work elsewhere, so what is holding back this design technologyÝs more widespread adoption? Perhaps the best answer comes from BAA, to quote Chris Millard: ýThe problem in implementing this model is, to a large extent, now a people problem. The difficulty is teaching people to use the software and educating clients about the savings that can be made. The secret is to get a nucleus of workers working in this way as this will encourage adoption amongst other project staff.¯

Conclusion

With the T5 Programme, BAA has demonstrated a visionary approach to achieving its goals through innovation. Through the design technology, processes and expertise provided, Excitech is proud to have delivered practical support to BAA in its goals for T5 by delivering ground-breaking but effective solutions, ensuring design productivity, implementing and supporting the processes and ultimately by providing a solid return on the investment BAA has made in this project for now and for the future.

The fact that such technologies for design are becoming more and more widely adopted is excellent news for all in the industry and the publication of BS1192:2007 adds a formal ýstamp of approval¯.

This article originally appeared in the Design Productivity Journal (DPJ).